Forged Vs Cast Knuckle Strength: Which One Survives Your Build?

Why Forged vs Cast Knuckle Strength Matters for Your Build

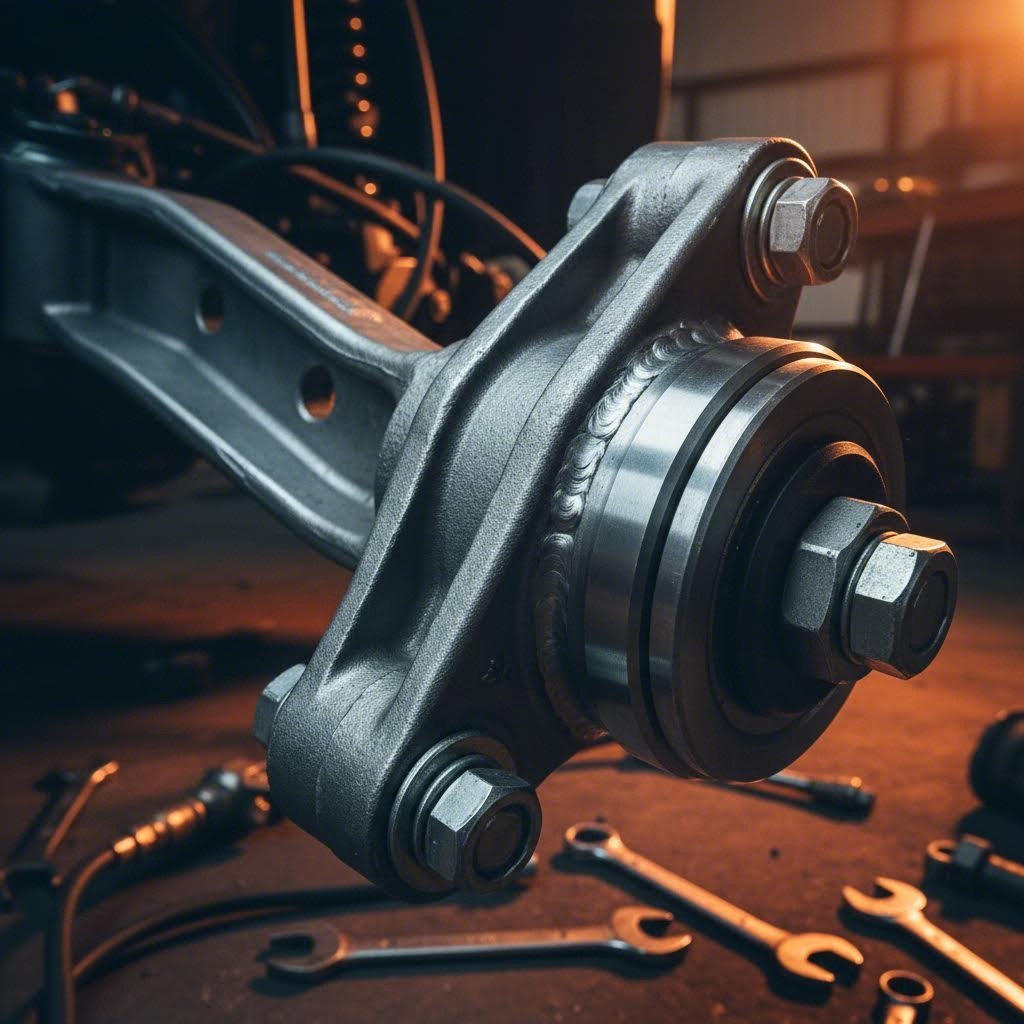

When you're building a rig that needs to handle serious weight, aggressive terrain, or high-speed performance, the steering knuckle isn't just another component—it's a critical safety link between your wheels and your vehicle. Get this wrong, and the consequences can be catastrophic. The debate between forged vs cast knuckle strength isn't just technical jargon for engineers; it's a decision that directly impacts whether your build survives the trail, the track, or the highway.

Why Knuckle Strength Determines Vehicle Safety

Consider what happens when a steering knuckle fails. The NHTSA recently opened an investigation into 91,856 Range Rover Sports (2014-2017 models) due to aluminum front steering knuckles fracturing at the upper control arm connection point. According to the investigation, this failure can cause "detachment of the upper suspension arm" and "compromise the vehicle's controllability." That's the clinical way of saying you could lose steering control entirely.

Your knuckles connect the wheel assembly, brakes, and suspension to the vehicle itself. When comparing forging vs casting methods, understanding how each manufacturing process affects this critical junction becomes essential for any serious builder.

The Hidden Risks of Choosing the Wrong Knuckle Type

The difference between casting vs forging goes far beyond price tags. Cast knuckles—while more affordable—can harbor internal porosity and random grain structures that create unpredictable weak points. Forged steel components, by contrast, develop aligned grain patterns that resist fatigue and provide more predictable failure modes.

Off-road enthusiasts on forums like Pirate4x4 regularly debate these trade-offs. One builder considering severe-duty applications noted that while some aftermarket cast knuckles are "made of 8620 CROMO," they're "still cast"—and that distinction matters when you're running a rig at 14,000 pounds GVW with another 10,000 pounds in tow. The offroad design community understands that components face forces far beyond what street vehicles experience.

What Off-Road Builders and Engineers Need to Know

If you've spent time researching knuckle options, you've likely encountered fragmented information scattered across manufacturer spec sheets, forum debates, and technical papers. Builders discuss everything from Dana 60 knuckles to Superduty components, often without clear guidance on which manufacturing method—forged vs cast—actually delivers the strength their application demands.

This article consolidates that scattered information into a definitive resource. Whether you're upgrading your suspension system, replacing a leaf spring shackle, or building a custom rear-steer axle rated for serious weight, understanding how manufacturing methods affect knuckle strength will help you make the right investment decision. We'll examine the technical differences, compare real-world performance data, and provide application-specific recommendations so you can choose with confidence.

How We Evaluated Knuckle Strength and Performance

How do you objectively compare forged vs cast knuckle strength when manufacturers throw around terms like "high-strength steel" and "premium quality" without quantifiable data? You need a systematic framework—one grounded in metallurgical science and validated by real-world testing. That's exactly what we developed for this evaluation.

Understanding the difference between casting and forging at a molecular level helps explain why identical-looking components can perform so differently under stress. What is forging? It's a process where solid metal billets are shaped under extreme compressive forces, realigning the internal grain structure to follow the component's contours. What is casting? It involves pouring molten metal into molds, allowing it to solidify with a random, equiaxed grain pattern. These fundamentally different manufacturing philosophies create components with distinct mechanical properties—even when the same base alloy is used.

Strength Testing Standards We Evaluated

Our evaluation draws from industry-standard testing protocols used by OEMs and independent laboratories. According to research published by the Forging Industry Educational Research Foundation and American Iron and Steel Institute, monotonic tensile tests, strain-controlled fatigue tests, and Charpy V-notch impact tests provide the foundation for comparing cast vs forged components.

Key testing standards we considered include:

- ASTM E8 – Standard test methods for tension testing of metallic materials, measuring ultimate tensile strength and yield strength

- ASTM E606 – Standard practice for strain-controlled fatigue testing, critical for determining cyclic load performance

- ASTM E23 – Charpy V-notch impact testing, measuring a material's ability to absorb sudden shock without fracturing

- IATF 16949 – Automotive quality management certification required for safety-critical components, ensuring consistent manufacturing processes

For manufacturers producing safety-critical suspension components, IATF 16949 certification isn't optional—it's the baseline standard that ensures rigorous quality control from raw material selection through final inspection. When evaluating stainless steel forging processes or forging stainless steel applications, these certifications become even more critical due to the specialized heat treatment requirements involved.

The Five Critical Performance Metrics

When comparing forging strength against cast alternatives, we weighted five key performance metrics that directly impact real-world reliability:

- Tensile Strength: The maximum stress a material can withstand before breaking. Research from the University of Toledo comparing forged steel and ductile cast iron crankshafts found that forged steel demonstrated higher tensile strength than cast alternatives. The forged steel specimens showed yield strength of 625 MPa compared to 412 MPa for ductile cast iron—a 52% advantage.

- Fatigue Resistance: How many stress cycles a component can endure before failure. The same research found that at 106 cycles, forged steel's fatigue strength was 359 MPa versus 263 MPa for cast iron—a 36% improvement. In practical terms, forged components demonstrated approximately 30 times longer life in the long-life region when plotting stress amplitude versus reversals to failure.

- Yield Strength: The stress level at which permanent deformation begins. Higher yield strength means better resistance to permanent bending under load.

- Grain Structure Integrity: Forged components develop continuous grain flow aligned with stress patterns, while cast parts have random grain orientation with potential internal porosity. This structural difference explains much of the performance gap.

- Failure Mode Predictability: Forged steel typically shows more gradual, predictable failure patterns. Cast components can fail more suddenly due to internal defects acting as crack initiation sites.

How We Weighted Safety vs Cost Factors

Any honest evaluation must acknowledge that cast components cost less—sometimes significantly less. The question isn't whether forging delivers better performance; the research clearly shows it does. The question is whether that performance advantage justifies the cost premium for your specific application.

We weighted our evaluation criteria using this framework:

- Safety-Critical Applications (highest weight): For builds exceeding factory specifications—heavy towing, aggressive off-road use, high-performance applications—we prioritized fatigue resistance and impact toughness over initial cost. The Charpy impact testing data showed forged steel absorbed 62.7 joules at room temperature versus only 4.9 joules for cast iron, demonstrating dramatically superior impact toughness.

- Moderate-Duty Applications (balanced weight): For street vehicles with occasional spirited driving or light off-road use, we considered whether high-quality cast components with proper heat treatment could deliver acceptable performance at lower cost.

- Light-Duty Applications (cost-conscious weight): For vehicles operating well within factory parameters, we evaluated whether premium forged components represent over-engineering.

One critical consideration: percent reduction in area—a measure of ductility—was 58% for forged steel versus only 6% for cast iron in the referenced research. This means forged components can deform substantially before fracturing, often providing warning signs before catastrophic failure. Cast components may fracture more suddenly, with less margin for error.

With this evaluation framework established, let's examine how specific knuckle types—from hot forged steel to ductile iron castings—perform against these metrics.

Hot Forged Steel Knuckles Top Choice for Maximum Strength

When your build demands the absolute best in strength and reliability, hot forged steel knuckles stand alone at the top of the performance hierarchy. The metal forging process creates components with mechanical properties that simply cannot be replicated through casting—and the data proves it. Whether you're running a Dana 60 front axle at extreme articulation angles or pushing a heavy-duty rig through punishing rock crawls, understanding why drop forging produces superior knuckles will help you invest wisely.

Grain Flow Advantages in Forged Knuckles

Imagine the difference between a bundle of aligned ropes versus a tangled mess of the same material. That's essentially what happens at the microstructural level when comparing forged metal to cast alternatives. During hot die forging, metal is heated to its recrystallization temperature—typically above 1,700°F for steel—and then shaped under immense compressive forces. This process doesn't just change the component's shape; it fundamentally transforms its internal structure.

According to Carbo Forge's technical documentation, this grain flow pattern "assures superior strength, even at critical stress points." The aligned grain structure follows the contours of the knuckle, creating directional strength precisely where stress concentrations occur—at the kingpin bore, spindle attachment, and steering arm mounting points.

Why does this matter for your build? Consider the forces acting on a steering knuckle during aggressive off-road use:

- Torsional shear stress as hydraulic steering tries to twist the knuckle about the kingpin axis

- Impact loading when wheels hit obstacles at speed

- Cyclic fatigue from thousands of steering inputs and suspension cycles

In each scenario, the continuous grain flow of forged alloy steel distributes stress more evenly throughout the component. Cast knuckles, with their random grain orientation, concentrate stress at grain boundaries—creating crack initiation sites that can lead to sudden, catastrophic failure.

Tensile and Fatigue Performance Data

The performance gap between hot forged and cast components isn't theoretical—it's quantifiable. According to research on hot die forging solutions, the process produces parts with "superior strength-to-weight ratios" and "better fatigue resistance," which is "vital for components subjected to repeated stress cycles."

Let's examine the specific numbers. Forged steel forgings demonstrate tensile values that can exceed 200,000 PSI according to Carbo Forge's specifications. But raw tensile strength only tells part of the story. Consider these comparative metrics from the University of Toledo's research on forged versus cast components:

| Performance Metric | Forged Steel | Cast Alternatives | Advantage |

|---|---|---|---|

| Yield Strength | 625 MPa | 412 MPa (ductile iron) | 52% higher |

| Fatigue Strength (106 cycles) | 359 MPa | 263 MPa | 36% higher |

| Impact Toughness (Charpy) | 62.7 joules | 4.9 joules | 12.8× higher |

| Reduction in Area (ductility) | 58% | 6% | 9.7× higher |

That impact toughness number deserves special attention. Forged steel absorbing nearly 13 times more impact energy before fracturing means the difference between a knuckle that survives a hard hit and one that shatters. For severe-duty applications—think full hydraulic steering pushing 40-inch tires through technical terrain—this margin of safety isn't luxury engineering. It's essential.

The fatigue life advantage compounds over time. Research indicates forged components can demonstrate approximately 30 times longer life in the long-life fatigue region. Your knuckles absorb stress with every steering input, every bump, every rock strike. Over thousands of trail miles, that 30× fatigue advantage represents the difference between components that stay intact and components that develop fatigue cracks.

Best Applications for Hot Forged Knuckles

Hot forged steel knuckles excel in applications where failure isn't an option. The Crane HSC 60 knuckles—cast from nickel-chromium-molybdenum alloy steel (ASTM A487, equivalent to SAE 8630)—illustrate what premium forged alloy steel construction delivers:

- Tensile strength of 105,000-130,000 PSI

- Yield strength of 85,000 PSI

- Brinell hardness of 235

- 17% elongation (ductility indicator)

Comparing these numbers to standard plate steel (1030) at 50,000 PSI yield strength reveals a 70% improvement—and that's before considering the additional benefits of the nickel-chromium-molybdenum alloying elements that increase strength, toughness, and corrosion resistance.

When are hot forged knuckles the right choice? Consider these applications:

- Full hydraulic steering systems: The high forces generated by hydraulic assist create stress concentrations that cast components may not survive

- Extreme articulation builds: Aggressive suspension travel increases loads on steering components at full droop and compression

- Heavy towing applications: Combined vehicle and trailer weights exceeding factory specifications demand stronger components

- Competition and racing: Repeated high-stress cycles accelerate fatigue on inferior components

Pros

- Superior tensile and yield strength—up to 70% stronger than standard steel

- Continuous grain flow aligned with stress patterns for maximum fatigue resistance

- Predictable failure modes with gradual deformation before fracture

- Excellent impact toughness—12× better than cast iron in Charpy testing

- Near absence of internal defects, porosity, or inclusions

- Consistent heat treatment response for reliable performance

Cons

- Higher cost than cast alternatives—premium materials and processes add expense

- Longer lead times for custom or low-volume applications

- Limited availability from specialized manufacturers

- May require matching premium components (bearings, steering arms) for full benefit

For builders requiring forged stainless steel or specialized stainless steel forgings for corrosion-prone environments, the same principles apply—though material selection becomes more complex. The question "can you forge stainless steel" has a definitive answer: yes, though it requires precise temperature control and specialized expertise.

When sourcing safety-critical forged knuckles, manufacturer certification matters as much as material specifications. IATF 16949 certified manufacturers like Shaoyi (Ningbo) Metal Technology deliver the quality control essential for safety-critical components, with rapid prototyping capabilities that accelerate development—sometimes in as little as 10 days. Their in-house engineering and rigorous quality control ensure that every forged component meets exact specifications, from suspension arms to drive shafts.

Understanding how cold forging differs from hot forging—and when each process excels—provides additional options for builders seeking the right balance of strength, precision, and cost.

Cold Forged Knuckles Precision Meets Performance

What if you could achieve near-forged strength with tighter tolerances and smoother surfaces—all while reducing production costs? Cold forged knuckles offer exactly that combination, making them a compelling alternative for specific applications. While hot forging dominates the conversation around maximum strength, understanding when cold forging metal delivers superior results can save you money without sacrificing reliability.

The forge vs foundry distinction becomes even clearer when examining cold forging. Unlike casting—where molten metal fills a mold and solidifies with random grain patterns—cold forging shapes solid metal billets at room temperature under extreme pressure. This process maintains grain integrity similar to hot forging while adding unique benefits that make it ideal for certain knuckle applications.

Cold Forging Process and Strength Characteristics

Cold forging, also known as cold forming, operates at or near room temperature—typically below the metal's recrystallization threshold. According to industry research, steel remains below 400°C during cold forging, while aluminum stays between 100-200°C. Under pressures ranging from 500-2000 MPa, the metal undergoes plastic flow, producing components with remarkable dimensional accuracy.

What happens to the metal during this process? Unlike hot forging where heat makes material malleable, cold forging relies on work hardening—a phenomenon where plastic deformation at low temperatures actually increases material strength. The grain structure compresses and elongates, creating enhanced mechanical properties without the energy costs of heating.

The key characteristics of cold forged components include:

- Strain hardening benefits: Material strength increases through the deformation process itself

- Superior dimensional accuracy: Tolerances of IT6-IT9 are achievable, often eliminating secondary machining

- Excellent surface finish: Surface roughness of Ra 0.4-3.2 μm straight from the forge

- Material utilization up to 95%: Minimal waste compared to machining operations

- Energy consumption only 1/5 to 1/10 of hot forging: Lower operational costs per component

According to Total Materia's comprehensive analysis, cold forging produces components with "superior mechanical properties compared to cast or machined components due to enhanced grain flow structures." The process delivers what standard forged components offer—continuous grain flow—while adding the precision benefits that hot forging cannot match.

When Cold Forged Beats Hot Forged

Sounds surprising? There are legitimate scenarios where cold forging outperforms its hot counterpart. The decision comes down to application requirements, material selection, and production economics.

Cold forging excels when you need:

- Tight tolerances without secondary machining: Cold forged components achieve dimensional accuracy that hot forging simply cannot match without additional processing

- High-volume production efficiency: The automotive industry relies on cold forging for over 60% of forged components, according to industry data

- Superior surface quality: Parts come off the press with smooth finishes, eliminating polishing or grinding operations

- Lower per-unit costs: Energy savings and reduced finishing requirements translate to better economics at scale

For knuckle applications specifically, cold forging makes sense when the geometry isn't excessively complex and when precision matters more than extreme strength. Consider forge steel tools and similar precision components—they often use cold forging because the process delivers consistent, repeatable results with minimal variation between parts.

The comparison data from Laube Technology illustrates the trade-off clearly: cold forging produces "high precision and tight tolerances" with "superior surface finish," while hot forging enables "intricate designs and larger parts." For smaller, precision-critical knuckle components—think steering arm attachment points or bearing housings—cold forging delivers commercial forged products with exceptional consistency.

Ideal Use Cases and Limitations

Where do cold forged knuckles make the most sense? The answer depends on your build's demands and the specific component geometry.

Ideal applications include:

- Factory-replacement knuckles for street vehicles operating within design parameters

- Precision bearing housings where dimensional accuracy prevents premature wear

- High-volume aftermarket components where cost-per-unit matters

- Applications using aluminum, brass, or low-carbon steel—metals that perform well at room temperature

Limitations to consider:

Cold forging requires significantly higher press forces than hot forging because the material isn't softened by heat. This means more robust tooling, increased die wear, and constraints on achievable geometries. Complex shapes with deep cavities, sharp corners, or dramatic cross-section changes often exceed cold forging's capabilities.

Material selection also narrows considerably. While hot forging accommodates nearly any metal—including titanium and stainless steel—cold forging works best with ductile metals. Cast iron, for example, cannot be cold forged due to its brittleness. The question of whether you can forge certain materials at room temperature has practical limits that affect knuckle design options.

Pros

- Excellent dimensional accuracy—tolerances of IT6-IT9 achievable without secondary operations

- Superior surface finish—Ra 0.4-3.2 μm directly from the forming process

- Work hardening benefits—material strength increases during deformation

- Lower energy consumption—1/5 to 1/10 of hot forging costs

- Material utilization up to 95%—minimal waste and efficient production

- Consistent part-to-part repeatability—ideal for high-volume applications

Cons

- Limited to simpler geometries—complex shapes require hot forging or multi-stage processes

- Material restrictions—brittle metals like cast iron cannot be cold forged

- Higher tooling costs—increased die wear from room-temperature deformation

- Reduced ductility in finished parts—work hardening decreases remaining formability

- Size limitations—typically suited for components under 50 pounds

For builders evaluating cold forged knuckles, the decision framework is straightforward: if your application demands extreme strength for severe-duty use, hot forging remains the superior choice. But if precision, surface quality, and production economics matter—and your geometry stays within cold forging's capabilities—this process delivers excellent value without sacrificing the fundamental grain structure advantages that separate all forged components from cast alternatives.

Understanding where cold forging fits in the manufacturing spectrum helps clarify when cast steel knuckles might serve as an acceptable budget option—and when their inherent limitations become deal-breakers.

Cast Steel Knuckles Budget Option with Trade-offs

Let's be honest—not every build requires top-tier forged components. If you're running a trail rig at stock weight with occasional weekend adventures, does it really make sense to spend premium dollars on forged knuckles? Cast steel offers a legitimate middle ground, delivering acceptable strength at significantly lower cost. But understanding exactly where that "acceptable" line falls—and what risks you're accepting—separates smart budget decisions from dangerous compromises.

The steel casting process fundamentally differs from forging, and those differences create inherent limitations. When evaluating cast metal components for safety-critical applications, you need to understand both what casting can deliver and where it falls short. Forum discussions on platforms like Pirate4x4 regularly feature builders debating whether cast knuckles handle their specific applications—and the answers aren't always straightforward.

Cast Steel Knuckle Manufacturing Process

How does casting create a knuckle? Molten steel—heated above 2,700°F—pours into a pre-formed mold cavity and solidifies as it cools. The geometry possibilities are nearly unlimited since liquid metal flows into any shape the mold allows. This flexibility explains why casting dominates applications requiring complex, intricate designs that would be prohibitively expensive to forge or machine.

The problem lies in what happens during solidification. Unlike forging, where compressive forces align grain structures along stress paths, casting produces random grain orientation. According to research published by the Investment Casting Institute, "the size and structure of the grains in a polycrystalline metal strongly influence the mechanical properties of the material." The relationship follows the Hall-Petch equation, which confirms that fine-grained materials demonstrate higher yield strength than coarse-grained versions of the same alloy.

Cast knuckles face several manufacturing challenges:

- Random grain orientation: Grains form without directional preference, creating inconsistent mechanical properties throughout the component

- Solidification shrinkage: As metal cools, it contracts—creating potential voids if shrinkage isn't properly fed during casting

- Freezing range concerns: Alloys with wide temperature ranges between solidus and liquidus are "more difficult to cast fully sound," according to the research

- Variable grain size: Large sections typically develop larger grains due to slower cooling rates, while thin sections cool faster and produce finer structures

The casting process also introduces porosity risks that simply don't exist in forged components. The referenced research shows that "significant porosity in the gage section can often lead to failing or non-repeatable test results." For knuckles—where consistent strength matters every time you steer—this variability becomes a legitimate concern.

What about cast stainless steel applications? The same principles apply, though stainless steel casting introduces additional complexity around heat treatment and corrosion resistance. The casting process works, but the inherent grain structure limitations remain regardless of alloy selection.

Strength Limitations and Acceptable Applications

When does a cast steel knuckle make sense for your build? The answer depends on understanding exactly how casting affects mechanical performance—and matching those capabilities to your actual demands.

The research data tells a clear story. Comparing identical alloy compositions, cast components showed significantly different mechanical testing results than their forged counterparts. In stress rupture testing documented by the Investment Casting Institute, carrot-shaped cast test bars "experienced multiple failures to pass requirements"—with "only 2 samples passing the minimum elongation requirement and no samples passing the minimum rupture life requirement." The hourglass-shaped bars with finer grain structure passed all requirements consistently.

This variability stems from grain structure, not material deficiency. As the researchers noted, "the mechanical properties of the carrot shaped test bars will be highly dependent on the limited number of coarse grains found in the gage section and on the orientation of the coarse grains."

For knuckle applications, this translates to:

- Acceptable for stock-weight vehicles: Factory-spec rigs operating within design parameters rarely approach component strength limits

- Acceptable for mild trail use: Occasional off-road adventures at moderate speeds don't generate the repeated stress cycles that expose fatigue limitations

- Questionable for heavy builds: Rigs exceeding 14,000 GVW with significant towing push cast components toward their limits

- Risky for full hydraulic steering: The high forces generated by hydraulic assist create stress concentrations that cast components may not survive long-term

Discussions on Pirate4x4 reflect this practical reality. When one builder asked about inner C's on a D44—questioning whether they were forge cast or true castings for welding purposes—the community response was straightforward: "Weld to them, they will be fine." For moderate applications, cast components do work. The critical question is understanding your application's actual demands.

Quality Indicators for Cast Knuckles

If you're considering cast steel knuckles for budget reasons, how do you separate acceptable quality from dangerous compromises? According to industry quality assessment guidelines, several inspection points help identify well-manufactured castings.

Visual inspection criteria:

- Surface finish: "Good quality steering knuckle surface should be smooth, no obvious defects, sand holes, pores, cracks and other defects"

- Color uniformity: "If there is a color difference, it may be caused by uneven material or improper heat treatment"

- Dimensional consistency: Proper clearances at kingpin bores—typically no more than 0.20mm for truck applications

For internal defect detection, non-destructive testing methods provide additional assurance. X-ray and ultrasonic testing "can detect whether there are cracks, inclusions and other defects in the steering knuckle without destroying it." Premium stainless steel casting operations routinely include such testing—though budget castings often skip these steps.

The manufacturing process itself matters significantly. As quality guidelines note, "the forging process can make the internal structure of the metal more dense and improve the strength; Good heat treatment technology can make the steering knuckle obtain suitable hardness and toughness." When evaluating cast alternatives, understanding whether proper heat treatment occurred helps predict real-world performance.

Brand reputation and quality certification provide additional indicators. ISO quality management system certification "is a recognition of product quality and production management level." For safety-critical components, choosing certified manufacturers reduces—though doesn't eliminate—the inherent risks of cast construction.

Pros

- Lower cost—significantly cheaper than forged alternatives for budget-conscious builds

- Complex geometry capability—liquid metal flows into intricate shapes impossible to forge

- Faster production—casting enables quicker turnaround for replacement parts

- Wide material selection—nearly any alloy can be cast, including specialized compositions

- Adequate strength for moderate applications—stock-weight vehicles rarely approach cast component limits

Cons

- Random grain structure—mechanical properties vary depending on grain orientation at stress points

- Potential porosity—internal voids can create unpredictable weak points

- Lower fatigue resistance—cyclic loading exposes grain boundary weaknesses over time

- Variable quality—manufacturing consistency varies significantly between suppliers

- Less predictable failure modes—sudden fracture more likely than gradual deformation

- Limited impact toughness—Charpy testing shows dramatically lower energy absorption than forged steel

The bottom line on cast steel knuckles? They work for many applications—but understanding exactly where your build falls on the demand spectrum determines whether "acceptable" translates to "safe" or "risky." For builders pushing beyond factory parameters, the cost savings often don't justify the performance compromise. For those running moderate builds within reasonable limits, properly manufactured cast knuckles can deliver years of reliable service.

Between cast steel and forged steel sits another option worth evaluating: ductile iron castings. Understanding where SG iron fits in the strength hierarchy—and how it applies to popular axle platforms like the Dana 60—provides additional choices for budget-conscious builders seeking better-than-basic performance.

Ductile Iron Cast Knuckles Mid-Range Durability Option

What if you need better performance than standard cast iron but can't justify forged steel pricing? Ductile iron—also known as nodular cast iron or SG iron—occupies this middle ground, offering mechanical properties that bridge the gap between brittle gray iron and premium forged steel. For builders running popular platforms like the Dana 60 front axle, understanding where ductile iron fits in the strength hierarchy helps make smarter purchasing decisions.

The distinction between sg iron vs cast iron comes down to microstructure. Traditional gray cast iron contains graphite in flake form—these flakes act as stress concentrators that make the material prone to cracking under tension or impact. Ductile iron transforms this weakness into a strength advantage through a simple but effective metallurgical change.

Ductile Iron Properties for Knuckle Applications

How does ductile iron achieve its improved mechanical properties? According to metallurgical research, the addition of magnesium (0.03-0.05%) during production transforms graphite from flakes into spheres or nodules. This nodular shape allows the metal to "bend rather than break," providing ductility and toughness not seen in traditional cast iron.

The microstructure directly controls strength, elongation, and resistance to cracking. Nodular graphite disperses stress more evenly than flakes, creating a material that can absorb energy before fracturing. This improved impact resistance makes ductile iron suitable for dynamic and load-bearing applications where gray cast iron would fail.

Key mechanical properties of ductile iron for knuckle applications include:

- Higher tensile strength: The nodular graphite structure significantly improves tensile performance compared to gray iron

- Improved elongation: Material can stretch 10-20% before fracturing—versus near-zero elongation for gray iron

- Better impact resistance: Nodular structure absorbs sudden shock without catastrophic fracture

- Enhanced fatigue resistance: Components survive repeated loading cycles better than traditional castings

- Good machinability: Easier to machine than steel while maintaining acceptable strength

The comparison between forged iron vs cast iron reveals significant performance gaps. While ductile iron outperforms gray cast iron dramatically, it still falls short of forged steel's mechanical capabilities. As industry analysis notes, ductile iron offers "remarkable toughness" that allows it to "bend and deform under pressure without cracking"—but forged components still demonstrate superior fatigue life and impact toughness in direct comparisons.

Understanding this hierarchy matters when evaluating aftermarket knuckles. A quality ductile iron casting represents a meaningful upgrade over stock gray iron components, but it doesn't match what premium forged alternatives deliver. The question becomes whether that performance gap matters for your specific application.

Dana 60 and Popular Axle Compatibility

Forum discussions on platforms like Pirate4x4 frequently focus on Dana 60 knuckle options—and for good reason. The Dana 60 remains one of the most popular heavy-duty front axle platforms for serious off-road builds, and knuckle selection directly impacts the axle's ultimate capability.

Stock Dana 60 knuckles—depending on vintage and application—use various cast iron formulations. When builders push these axles beyond factory parameters with larger tires, hydraulic steering, and aggressive articulation, the original components face stress levels they weren't designed to handle. This is where the cast iron forge versus nodular distinction becomes practically relevant.

According to technical documentation from BillaVista's detailed analysis, premium aftermarket knuckles like the Crane HSC 60 are "cast from nickel-chromium-molybdenum alloy steel"—not cast iron. The distinction matters: "DO NOT confuse the term 'cast' here—it is not short for 'cast iron' as it is so frequently used." Those premium cast steel knuckles deliver yield strength of 85,000 PSI—compared to standard mild steel at 50,000 PSI, representing a 70% improvement.

Where do ductile iron knuckles fit for Dana 60 applications? Consider your build's actual demands:

- Stock-weight trail rigs: Quality ductile iron provides adequate strength for moderate use

- Mild upgrades (33-35" tires, manual steering): Ductile iron handles increased loads within reasonable limits

- Heavy builds (37"+ tires, hydraulic steering): The stress concentrations from full hydraulic steering push ductile iron toward its limits

- Extreme applications (40"+ tires, rock crawling, competition): Forged alloy steel becomes the sensible choice

For tandem axle setups or heavy towing applications, the calculus shifts further toward premium materials. The cumulative stress from combined vehicle weight, trailer loads, and repeated impacts accelerates fatigue on any component—and ductile iron's fatigue limitations become more pronounced under sustained heavy use.

When Ductile Iron Makes Sense

Imagine you're building a weekend trail rig that sees occasional off-road adventures but spends most of its time on pavement. Does premium forged steel make economic sense? Probably not. Ductile iron offers a practical compromise—better than stock gray iron at a fraction of forged steel pricing.

The cost-benefit analysis favors ductile iron when:

- Your build operates at or near stock weight and tire size

- Off-road use remains occasional rather than constant

- Manual or power-assisted (not full hydraulic) steering limits peak loads

- Budget constraints prevent premium component investment across the entire build

- Replacement availability and cost matter for trail repairs

The concept of forging cast iron itself doesn't apply—cast iron's brittleness prevents cold or hot forging. But understanding that ductile iron represents an improved casting formulation helps clarify where it fits in the manufacturing hierarchy. You're getting better cast material, not a different manufacturing process.

Quality control becomes especially important with ductile iron components. As metallurgical research confirms, the magnesium treatment that creates nodular graphite must be precisely controlled. Insufficient magnesium produces inferior nodularization; excessive magnesium creates other problems. Variable quality from offshore suppliers often stems from inconsistent process control during this critical step.

Pros

- Better ductility than gray iron—bends rather than shatters under stress

- Cost-effective—significantly cheaper than forged steel alternatives

- Good machinability—easier to machine bearing surfaces and mounting points

- Improved impact resistance—nodular structure absorbs sudden loads

- Wide availability—common material for aftermarket and replacement components

- Adequate strength for moderate applications—suitable for stock-weight builds

Cons

- Still inferior to forged—grain structure limitations persist despite improvements

- Variable quality—manufacturing consistency depends heavily on supplier process control

- Limited fatigue life—repeated stress cycles expose nodular iron's weaknesses over time

- Temperature sensitivity—mechanical properties degrade at elevated temperatures

- Less predictable failure than forged steel—though better than gray iron

- Not suitable for extreme applications—full hydraulic steering and competition use exceed safe limits

Ductile iron knuckles represent a legitimate mid-tier option for builders who need better-than-stock performance without premium pricing. The key is matching material capabilities to actual application demands—and being honest about where your build falls on that spectrum. For weight-sensitive applications where neither cast iron nor heavy forged steel fits the requirements, forged aluminum presents an entirely different set of trade-offs worth examining.

Forged Aluminum Knuckles Lightweight Performance Choice

What happens when you need steering knuckle strength but can't afford the weight penalty of steel? Forged aluminum parts answer this question for racing teams, performance builders, and weight-conscious enthusiasts who understand that every pound matters. The trade-off between cast aluminum vs forged aluminum becomes especially critical in suspension components—where unsprung weight directly affects handling, acceleration, and braking performance.

When comparing forged metals for knuckle applications, aluminum occupies a unique position. It won't match steel's absolute strength numbers, but the strength-to-weight calculation tells a different story. For applications where reducing rotational and unsprung mass takes priority, forged aluminum knuckles deliver performance advantages that heavier forged materials simply cannot.

Forged Aluminum Strength-to-Weight Analysis

The numbers reveal why forged aluminum parts dominate weight-sensitive applications. According to PTSMAKE's comprehensive aluminum forging guide, the forging process "applies immense pressure" that "refines the metal's grain structure" and "eliminates tiny internal defects found in other methods." This creates forged materials with exceptional strength-to-weight ratios unavailable through casting.

Consider the density difference: aluminum weighs approximately 2.70 g/cm³ compared to steel's 7.85 g/cm³—roughly one-third the weight. A forged aluminum knuckle can weigh 60-65% less than its steel counterpart while still providing adequate strength for many demanding applications.

The 6061 T6 alloy—commonly used in forged aluminum suspension components—demonstrates this balance effectively:

- Tensile strength: 290-310 MPa (compared to 625 MPa for forged steel)

- Yield strength: Approximately 250 MPa

- Density: 2.70 g/cm³

- Specific strength: Higher than steel when calculated per unit weight

For racing and performance applications, this weight reduction translates directly to improved vehicle dynamics. Reducing unsprung weight—the mass not supported by the suspension—improves tire contact with the road surface, accelerates suspension response, and reduces the energy required for acceleration and braking.

Can you forge stainless steel for similar weight-sensitive applications? Yes, though stainless steel forgings don't offer the same weight advantages. When absolute corrosion resistance matters more than weight savings, stainless remains an option—but aluminum's combination of light weight and adequate strength makes it the preferred choice for performance-focused builds.

Heat Treatment and Final Properties

The T6 temper designation isn't just marketing—it represents a precise heat treatment process that transforms aluminum's mechanical properties. According to technical documentation on 6061 T6 aluminum, this process combines solution heat treatment with artificial aging to achieve peak strength.

The heat treatment sequence for 6061 aluminum knuckles follows specific parameters:

- Solution treatment: Heating to 515-535°C dissolves alloying elements (magnesium and silicon) into the aluminum matrix

- Quenching: Rapid water cooling locks dissolved elements in place, creating a supersaturated solid solution

- Artificial aging: Controlled heating at 160-180°C precipitates fine Mg₂Si particles that dramatically increase strength

This process produces "consistent mechanical properties—yield ~ 250 MPa, UTS ~ 300 MPa, hardness ~ 90 HB—across various section thicknesses." The forging process itself contributes additional benefits: research indicates forged 6061 exhibits "fatigue life (5-10% improvement) and impact toughness compared to extruded or cast 6061 T6" due to refined, equiaxed grain structure.

However, aluminum's heat sensitivity creates important limitations. Above approximately 150°C, 6061-T6 begins losing its peak-aged hardness and strength. For continuous service above 200°C, yield strength can drop 30-50%. This temperature sensitivity matters for knuckles positioned near brakes—heat soak during aggressive driving can temporarily reduce component strength.

Racing and Performance Applications

Where do forged aluminum knuckles excel? Racing series from Formula cars to time attack builds leverage aluminum's weight advantages for competitive edge. The specific applications that benefit most include:

- Road racing: Reduced unsprung weight improves corner entry, mid-corner grip, and exit acceleration

- Autocross: Quick directional changes benefit from lighter suspension components

- Time attack: Every gram matters when chasing lap records

- Lightweight street builds: Track-day cars prioritizing handling over absolute durability

The trade-off becomes clear in application selection. Forged aluminum knuckles suit vehicles where performance driving occurs within controlled parameters—smooth racing surfaces, predictable loads, and regular inspection intervals. They're less suitable for off-road abuse, heavy towing, or applications where impacts and overloading occur regularly.

Higher-strength aluminum alloys like the 7xxx series offer even better strength-to-weight ratios. According to PTSMAKE's research, these alloys "achieve the highest strengths available in forged aluminum" through precipitation hardening. However, 7xxx series aluminum costs more, requires more precise heat treatment, and offers reduced corrosion resistance—requiring protective coatings for long-term durability.

Pros

- Significant weight reduction—60-65% lighter than equivalent steel components

- Good corrosion resistance—Mg-Si matrix provides inherent oxidation protection

- Adequate strength for many applications—T6 temper delivers 290-310 MPa tensile strength

- Improved vehicle dynamics—reduced unsprung weight enhances handling and response

- Excellent machinability—achieves tight tolerances and fine surface finishes

- Superior strength-to-weight ratio—outperforms steel when calculated per unit mass

Cons

- Lower absolute strength than steel—approximately half the tensile strength of forged steel

- Heat sensitivity—mechanical properties degrade above 150°C, problematic near brakes

- Higher material cost—premium aluminum alloys and precise heat treatment add expense

- Not suitable for extreme abuse—off-road impacts and overloading exceed safe limits

- Requires regular inspection—fatigue monitoring more critical than with steel components

- Limited to appropriate applications—heavy towing and severe duty exceed design parameters

Forged aluminum knuckles represent the right choice for the right application—weight-sensitive builds where performance advantages outweigh absolute strength requirements. Understanding where your build falls on the weight-versus-strength spectrum determines whether aluminum delivers a competitive advantage or creates an unacceptable compromise. With all five knuckle types now evaluated, comparing their complete performance profiles side-by-side clarifies which option truly survives your specific build demands.

Complete Knuckle Strength Comparison and Analysis

You've seen the individual breakdowns—now let's put everything side by side. When comparing forged vs cast steel for steering knuckles, the performance gaps become strikingly clear once you examine all five options against identical criteria. This comprehensive comparison eliminates guesswork and gives you the data needed to match component capability to your build's actual demands.

Think of this section as your decision matrix. Whether you're evaluating cast steel vs forged steel for a weekend trail rig or analyzing forged steel vs cast steel for a competition rock crawler, these comparisons cut through marketing claims and forum opinions to reveal what the engineering actually delivers.

Side-by-Side Strength Comparison Table

The following table consolidates mechanical performance data from the reference materials and research we've examined throughout this article. Note that actual values depend on specific alloy selection, heat treatment, and manufacturing quality—but these relative comparisons hold true across typical production components.

| Material Type | Relative Tensile Strength | Fatigue Resistance Rating | Cost Factor | Best Applications | Failure Mode |

|---|---|---|---|---|---|

| Hot Forged Steel | Excellent (625 MPa yield) | Superior (+37% vs cast) | High ($$$) | Full hydraulic steering, competition, heavy towing | Gradual deformation with warning signs |

| Cold Forged Steel | Very Good (work-hardened) | Very Good | Medium-High ($$) | Precision applications, high-volume OEM replacement | Gradual deformation, predictable |

| Forged Aluminum | Moderate (290-310 MPa) | Good (5-10% better than cast aluminum) | High ($$$) | Racing, weight-sensitive performance builds | Gradual with proper monitoring |

| Cast Steel | Good (412 MPa yield typical) | Moderate | Low-Medium ($-$$) | Stock-weight vehicles, mild trail use | Potential sudden fracture at defects |

| Ductile Iron | Moderate-Good | Moderate | Low ($) | Budget builds, stock replacements | Better than gray iron, still unpredictable |

The difference between forged and cast becomes especially apparent in fatigue resistance. According to research comparing manufacturing methods, forged components demonstrate approximately 37% higher fatigue strength in representative comparisons. For steering knuckles absorbing thousands of stress cycles per trail run, this advantage compounds over the component's service life.

Similar principles apply across automotive components. The cast crankshaft vs forged debate follows identical logic—forged crankshafts dominate high-performance and heavy-duty applications because the grain flow alignment provides superior fatigue resistance under cyclic loading. The same reasoning explains why cast vs forged pistons discussions always favor forging for high-output engines. The wrought vs cast distinction fundamentally comes down to grain structure integrity.

Cost vs Performance Analysis

Here's where the decision gets interesting. Premium forged knuckles might cost 3-4 times more than cast alternatives—but does that premium always make sense? The answer depends entirely on your application's actual stress profile.

Consider the economics from industry cost analysis:

- Initial tooling cost: Forging requires higher upfront investment, but tooling lasts longer

- Defect rate: Cast components show higher rejection rates, increasing effective per-unit cost

- Lifecycle cost: Forged parts typically deliver lower total cost of ownership due to longer service life and fewer replacements

- Machining requirements: Forgings often need minimal secondary operations compared to castings

The cost-benefit calculation shifts based on volume and criticality. For safety-critical components in demanding applications, the forging premium represents insurance against catastrophic failure. For budget builds operating well within factory parameters, quality castings deliver acceptable performance at significant savings.

The same framework applies to cast vs forged wheels—another common comparison in the automotive world. Forged wheels command premium pricing because the manufacturing process delivers superior strength-to-weight ratios and impact resistance. Budget-conscious builders accept cast wheel limitations for street use, while serious track and off-road enthusiasts invest in forged alternatives.

Application-Specific Recommendations

Matching knuckle type to application eliminates both over-engineering waste and dangerous under-specification. Use this framework to guide your selection:

Choose Hot Forged Steel When:

- Running full hydraulic steering systems generating high force loads

- Building competition vehicles with repeated high-stress cycles

- Exceeding 14,000 GVW with significant towing capacity

- Installing 40"+ tires creating substantial leverage on steering components

- Operating in conditions where component failure creates safety emergencies

Choose Cold Forged Steel When:

- Precision tolerances matter for bearing fitment and alignment

- Producing high-volume replacements where consistency is critical

- Geometry remains relatively simple without complex internal features

- Surface finish requirements exceed what hot forging delivers

Choose Forged Aluminum When:

- Weight reduction takes priority over absolute strength

- Racing applications demand minimized unsprung mass

- Operating within controlled parameters (smooth surfaces, predictable loads)

- Regular inspection intervals ensure fatigue monitoring

Choose Cast Steel When:

- Operating at or near stock weight and tire size

- Budget constraints prevent premium component investment

- Replacement availability and trail-repair cost matter

- Off-road use remains occasional rather than constant

Choose Ductile Iron When:

- Upgrading from stock gray iron on a budget

- Running moderate builds with manual or power-assisted steering

- Machinability and cost matter more than maximum strength

- Application stress levels fall well below material limits

Understanding Failure Mode Differences

Perhaps the most critical distinction between forged and cast components isn't peak strength—it's how they fail when overloaded. This knowledge can save your build and potentially your safety.

- Forged steel failure mode: Gradual plastic deformation before fracture. The aligned grain structure and high ductility (58% reduction in area in testing) means forged components bend, stretch, and show visible warning signs before catastrophic failure. You might notice steering looseness, unusual play, or visible deformation—giving you time to address the problem.

- Cast steel failure mode: More sudden fracture potential. Random grain orientation and internal porosity create stress concentration points where cracks can initiate and propagate rapidly. While quality castings can provide service life, failure when it occurs tends toward sudden fracture rather than gradual deformation.

- Ductile iron failure mode: Improved over gray iron but still less predictable than forged steel. The nodular graphite structure allows some deformation, but fatigue cracks at grain boundaries can still lead to relatively sudden failure.

- Forged aluminum failure mode: Gradual with proper monitoring, but heat sensitivity adds complexity. Thermal cycling near brakes can temporarily reduce strength, and fatigue crack propagation requires regular inspection to catch developing issues.

Warning signs to monitor across all knuckle types:

- Unusual steering play or looseness developing over time

- Visible cracks, especially at stress concentration points like kingpin bores

- Deformation or bending of steering arms or mounting surfaces

- Abnormal wear patterns on bearings or bushings indicating component movement

- Grinding or clicking sounds during steering input

- Uneven tire wear suggesting alignment changes from component deformation

The 12.8× impact toughness advantage of forged steel over cast iron—62.7 joules versus 4.9 joules in Charpy testing—represents the difference between a knuckle that survives a hard hit and one that shatters.

Understanding these failure characteristics transforms component selection from guesswork into engineering. The question isn't just "which is stronger?"—it's "which failure mode can I accept for my application?" For builds where sudden failure creates dangerous situations, forged components' predictable, gradual failure modes provide critical safety margins that cast alternatives simply cannot match.

With this complete comparison framework established, translating the data into actionable recommendations for specific build types becomes straightforward—whether you're prioritizing off-road durability, street performance, or budget optimization.

Final Recommendations for Choosing Your Knuckle Type

You've seen the data, examined the failure modes, and compared the manufacturing processes. Now it's time to translate all that information into actionable decisions. Whether you're building a rock-crawling beast, a weekend canyon carver, or a budget-friendly trail rig, matching your knuckle selection to your actual application demands ensures you're neither over-spending nor under-engineering.

The forged versus cast decision ultimately comes down to one question: what happens if your knuckle fails? For some builds, that scenario means a tow home. For others, it means a potentially dangerous loss of vehicle control. Understanding where your build falls on that spectrum drives the right investment decision.

Best Choice for Off-Road and Heavy-Duty Builds

When you're running serious weight, aggressive tires, and full hydraulic steering, component failure isn't just inconvenient—it's potentially catastrophic. The casting and forging comparison becomes crystal clear at these stress levels: forged steel delivers the safety margins that heavy-duty applications demand.

Consider what defines a heavy-duty build:

- GVW exceeding 10,000 pounds with towing capacity

- Tire sizes of 37 inches or larger creating substantial steering leverage

- Full hydraulic steering generating forces that stock components never anticipated

- Extreme articulation angles loading knuckles at their mechanical limits

- Competition use with repeated high-stress cycles

For these applications, the difference between forged and cast irons—or more specifically, between forged steel and any cast alternative—becomes a safety issue rather than a preference. The 52% yield strength advantage and 12.8× impact toughness superiority of forged steel provides margins that demanding applications require.

The forging and casting processes create fundamentally different grain structures, and those differences matter most when components face loads approaching their limits. Forged steel's gradual failure mode—visible deformation before fracture—provides warning signs that cast components may never display before sudden failure.

Street Performance Recommendations

Street performance builds occupy interesting middle ground. You want better-than-stock capability without the expense of competition-grade components. The right choice depends on how aggressively you drive and what modifications you've made.

- Aggressive track use with modified suspension: Hot forged steel knuckles provide peace of mind when pushing hard through corners and over curbs. The fatigue resistance advantage pays dividends over repeated track sessions.

- Spirited street driving with mild modifications: Cold forged or quality cast steel knuckles typically handle these demands adequately. The key is honest assessment of your actual driving style.

- Weight-sensitive performance builds: Forged aluminum knuckles excel when reducing unsprung mass takes priority. Racing applications, time attack builds, and serious autocross competitors benefit from the improved dynamics.

- Daily drivers with occasional enthusiasm: Quality cast steel or ductile iron replacements often provide appropriate performance at budget-friendly pricing.

The cast versus forged irons debate shifts toward forged options as modification levels increase. Lowered suspensions, upgraded brakes, and stickier tires all increase loads on steering components. Each modification that improves performance also adds stress to your knuckles.

Making the Right Investment Decision

Smart builders match component quality to actual demands—neither over-engineering nor cutting dangerous corners. Use this decision framework to guide your final selection:

Invest in forged when:

- Component failure creates safety emergencies (highway speeds, remote locations)

- Modifications exceed factory design parameters by significant margins

- The build represents a long-term investment you'll use for years

- Replacement difficulty or cost makes component longevity valuable

- Competition or professional use demands maximum reliability

Accept cast alternatives when:

- Operating within or near factory specifications

- Budget constraints require prioritizing other critical components

- Application stress levels fall well below material limits

- Easy replacement access reduces the consequence of failure

- The vehicle serves as a project with planned future upgrades

The forged vs cast crankshaft decision in engine building follows similar logic—and experienced builders apply the same framework to steering knuckles. Premium forged components make sense when the application demands it and when failure consequences are severe.

For builders requiring forged knuckles and suspension components with verified quality, partnering with an IATF 16949 certified manufacturer ensures rigorous production standards from raw material through final inspection. Shaoyi (Ningbo) Metal Technology delivers precision hot forging solutions backed by this certification, with rapid prototyping capabilities and efficient global shipping from their Ningbo Port location—making quality-controlled forged components accessible regardless of your build's location.

Whatever your application demands, the decision now rests on solid engineering rather than guesswork. Match your knuckle selection to your actual stress profile, invest appropriately in safety-critical components, and build with confidence knowing your choices are grounded in metallurgical reality rather than forum speculation.

Frequently Asked Questions About Forged vs Cast Knuckle Strength

1. Is forged stronger than cast?

Yes, forged components demonstrate significantly superior strength. Research shows forged parts have approximately 26% higher tensile strength and 37% higher fatigue strength compared to cast alternatives. In practical terms, forged steel knuckles exhibit yield strength of 625 MPa versus 412 MPa for ductile cast iron—a 52% advantage. The forging process aligns grain structure along stress paths, eliminating internal porosity and creating components that can withstand up to 12.8 times more impact energy before fracturing. IATF 16949 certified manufacturers like Shaoyi ensure these strength advantages are consistently achieved through rigorous quality control.

2. What are the disadvantages of forged steel?

Forged steel knuckles come with trade-offs despite their superior strength. Higher initial cost—often 3-4 times more than cast alternatives—represents the primary disadvantage. Longer lead times for custom or low-volume applications can delay projects. The forging process limits geometric complexity compared to casting, and matching premium knuckles with equivalent bearings and steering arms may be necessary to realize full benefits. However, when factoring in longer service life and reduced replacement frequency, the total cost of ownership often favors forged components for demanding applications.

3. Does forging increase strength?

Absolutely. Forging fundamentally transforms metal's internal structure through heat and extreme compressive forces. This process refines grain patterns, creating continuous grain flow aligned with the component's contours. The result is dramatically improved tensile strength, ductility, and fatigue resistance. Testing shows forged components demonstrate approximately 30 times longer fatigue life in the long-life region compared to cast alternatives. The aligned grain structure distributes stress evenly throughout the knuckle, particularly at critical points like kingpin bores and steering arm mounts where failures typically originate.

4. Why is forging preferred over casting for safety-critical components?

Forging excels for safety-critical applications due to predictable failure modes and superior fatigue resistance. Cast components contain random grain orientation and potential porosity that can cause sudden, catastrophic fracture without warning. Forged knuckles demonstrate gradual deformation before failure—bending and showing visible warning signs that allow inspection and replacement before complete failure occurs. For steering knuckles connecting wheels to vehicles, this predictability can mean the difference between a safe tow home and a dangerous loss of vehicle control. The NHTSA's investigation into Range Rover steering knuckle fractures highlights why manufacturing method matters for these components.

5. When should I choose cast knuckles over forged?

Cast knuckles make economic sense for specific applications: stock-weight vehicles operating within factory parameters, occasional weekend trail use, builds with manual or power-assisted steering (not full hydraulic), and budget-conscious projects where replacement availability matters. Quality cast steel knuckles can deliver years of reliable service when stress levels remain well below material limits. The key is honest assessment of your build's actual demands—if you're running moderate modifications and staying within reasonable weight limits, properly manufactured cast components offer acceptable performance at significant cost savings compared to premium forged alternatives.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —