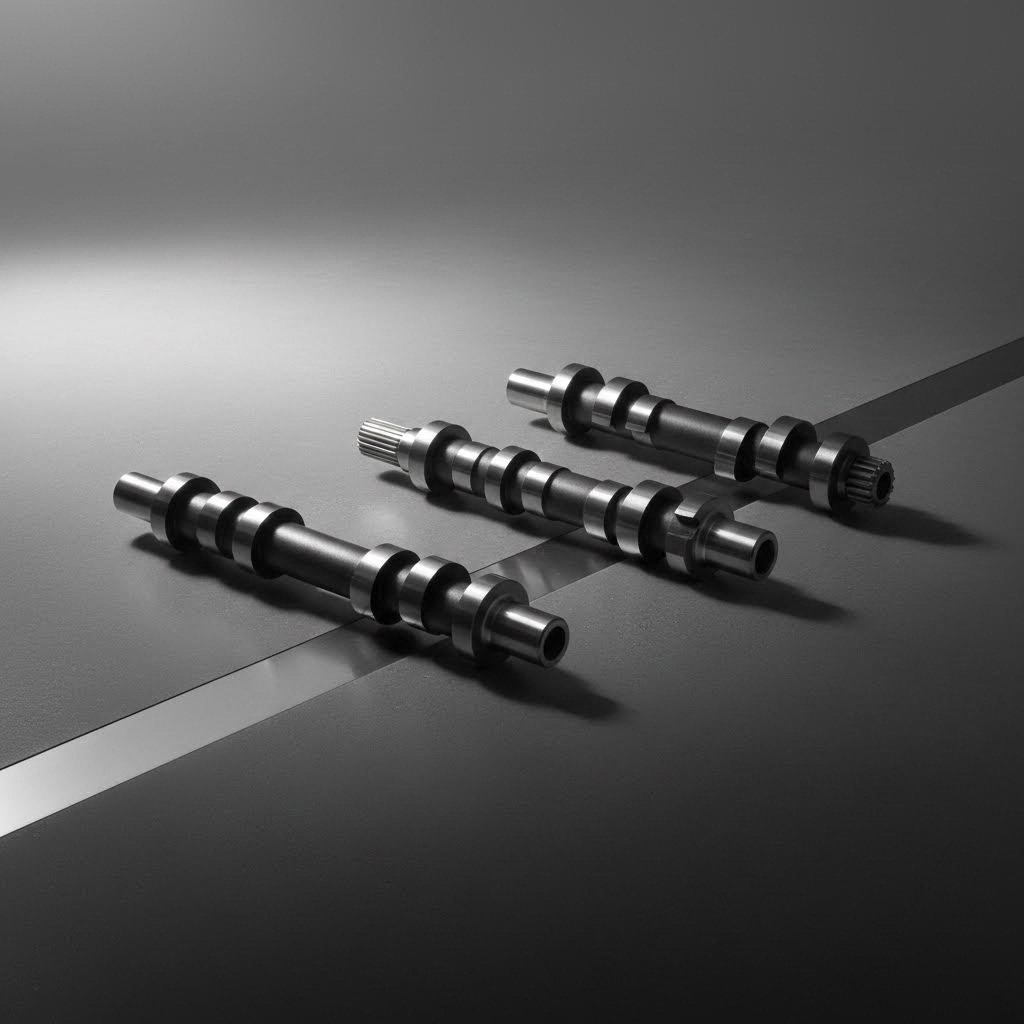

Forged Vs Cast Camshaft Durability: Which Survives 100K Miles?

Why Your Camshaft Choice Determines Engine Longevity

When you're building an engine meant to last 100,000 miles or more, every component matters. But here's the thing: most enthusiasts obsess over crankshafts while completely overlooking the camshaft sitting right above it. That's a costly oversight. Your camshaft controls the precise timing of every valve in your engine, and when it fails prematurely, you're looking at catastrophic valve damage, bent pushrods, and a rebuild that could have been avoided.

The difference between forged vs cast camshafts isn't just marketing speak. It's the difference between a camshaft that handles aggressive valve springs for decades and one that wears out before your warranty expires. Understanding the cast vs forged debate for camshafts requires looking at what actually happens inside these components at a molecular level.

Why Camshaft Manufacturing Method Matters for Engine Life

Camshafts endure constant stress every time your engine runs. The lobes push against lifters thousands of times per minute, and that interface experiences tremendous wear. According to industry experts at DCR Inc, the manufacturing process directly impacts a camshaft's grain structure, which determines how well it resists wear, fatigue, and eventual failure.

The forged versus cast question comes down to how metal atoms arrange themselves during production. Casting pours molten metal into molds, creating a random grain structure. Forging uses compressive forces on heated metal, aligning the grain structure along the camshaft's contours. This alignment dramatically affects durability under high-stress conditions.

Beyond Crankshafts: The Overlooked Camshaft Durability Question

Search for "forged vs cast" online, and you'll find endless articles about crankshafts and connecting rods. Camshafts? They're practically ignored. Yet camshafts fail more often than most enthusiasts realize, especially when upgraded valve springs increase lobe pressures beyond what a stock camshaft can handle.

This article fills that gap by focusing specifically on camshaft durability across three primary manufacturing methods: cast iron, forged steel, and billet. Each method creates distinct metallurgical properties that determine real-world longevity.

What This Durability Ranking Reveals

Throughout this guide, we'll rank each manufacturing method based on factors that actually matter for long-term reliability. The difference between forged and cast camshafts becomes clear when you evaluate these specific criteria:

- Grain structure integrity - How metal atoms align and resist crack propagation under stress

- Heat treatment response - The depth and effectiveness of hardening processes on cam lobes

- Lobe wear resistance - How well the camshaft surface withstands constant lifter contact

- Application suitability - Matching the right manufacturing method to your specific build goals

Whether you're building a daily driver expected to cruise past 150,000 miles or a weekend warrior that sees occasional track duty, the manufacturing method you choose will determine whether your camshaft survives the journey. Let's break down exactly what separates these manufacturing methods and which one deserves a place in your engine.

How We Evaluated Camshaft Durability Across Manufacturing Methods

How do you objectively compare forged vs cast steel camshafts when both manufacturers claim superior durability? You need a consistent evaluation framework that focuses on the metallurgical properties actually responsible for long-term survival. Rather than relying on marketing claims, we analyzed each manufacturing method against five specific criteria that determine whether a camshaft reaches 100,000 miles or fails prematurely.

Understanding these criteria helps you match the right manufacturing method to your specific application. A weekend drag racer and a daily-driven commuter have vastly different demands, and the cast vs forged steel debate looks completely different depending on which seat you're sitting in.

Durability Criteria That Actually Matter

Not all durability factors carry equal weight. For high-performance applications where camshafts face extreme stress, certain characteristics become critical while others fade into the background. Here's how we ranked the evaluation criteria for performance-oriented builds:

- Metallurgical grain structure integrity - The arrangement of metal grains determines how cracks initiate and propagate. According to research published in Materials Research Express, grain size and structure directly influence fatigue crack initiation, with finer, aligned grains offering superior resistance under cyclic loading.

- Fatigue resistance under high-RPM conditions - Camshafts spinning at 7,000+ RPM experience millions of stress cycles annually. The forged steel vs cast steel comparison becomes stark here, as forged components typically demonstrate 20-40% better fatigue life.

- Resistance to cam lobe wear patterns - Lobe surfaces must maintain precise geometry despite constant lifter contact. Industry data from Crane Cams indicates that finished camshafts should maintain hardness above 50Rc on lobe surfaces to resist wear.

- Heat treatment effectiveness - How deeply hardening penetrates the cam lobe surface determines long-term wear resistance. Forged steel typically accepts heat treatment more uniformly than cast alternatives.

- Regrind potential - The ability to machine a worn camshaft back to specification depends on hardness depth. Shallow hardening limits how many times a camshaft can be salvaged.

How Application Type Changes the Equation

Imagine comparing tire compounds without considering whether you're driving on pavement or gravel. The same logic applies to camshaft selection. Each application type weights our durability criteria differently, fundamentally changing which manufacturing method makes sense.

Daily drivers prioritize cost-effectiveness and adequate durability at moderate stress levels. With valve spring seat pressures typically ranging from 85 to 105 pounds, stock-style cast camshafts often perform adequately for 150,000+ miles. Fatigue resistance matters less when RPM rarely exceeds 5,000.

Street performance builds shift the balance. Upgraded valve springs pushing 105 to 130 pounds of seat pressure demand better metallurgical properties. Here, the forged vs cast debate starts favoring forged steel for its superior grain structure and heat treatment response.

Drag racing applications compress extreme stress into short bursts. High-RPM launches and aggressive cam profiles with elevated valve spring pressures require maximum fatigue resistance. Billet or forged camshafts become essential rather than optional.

Endurance racing presents the ultimate durability test. Hours of sustained high-RPM operation with aggressive valve springs demand the best grain structure and deepest heat treatment penetration available. Forged steel camshafts dominate this category.

Diesel applications introduce different stress patterns. High torque loads at lower RPM ranges emphasize lobe wear resistance over fatigue cycling. Cast steel often provides adequate durability here, though heavy-duty applications benefit from forged alternatives.

Grain Structure and Lobe Wear Analysis Explained

Why does grain structure matter so much? Picture two camshafts under a microscope. The cast version shows randomly oriented metal grains with potential voids and inclusions from the cooling process. The forged version displays grains aligned along the camshaft's contours, following the shape of each lobe.

When stress concentrates at a cam lobe, cracks seek the path of least resistance. In cast materials, that path often follows grain boundaries or internal defects. Forged steel's aligned grain structure forces cracks to travel against the grain flow, requiring significantly more energy to propagate. This is why forged steel vs cast steel comparisons consistently show forged components lasting longer under identical stress conditions.

Lobe wear analysis focuses on the contact zone between camshaft and lifter. This interface experiences tremendous sliding friction combined with Hertzian contact stress. Surface hardness must remain consistent across the entire lobe profile, and the hardened layer must extend deep enough to survive normal wear without exposing softer core material.

With these evaluation criteria established, we can now examine each manufacturing method individually and rank their real-world durability across different applications.

Forged Steel Camshafts Lead in Fatigue Resistance and Regrind Potential

When you need a camshaft that survives punishing conditions mile after mile, forged steel consistently rises to the top. The forging process fundamentally transforms how metal behaves under stress, creating a component engineered at the molecular level to resist the exact forces camshafts face during operation. Understanding why forged camshafts outperform their cast counterparts requires examining what happens during manufacturing and how those differences translate to real-world durability.

Unlike casting, which pours molten metal into a mold and allows it to cool with random grain orientation, forging uses tremendous compressive force on heated steel. This process doesn't just shape the metal. It reorganizes its internal structure in ways that dramatically improve performance under cyclic loading conditions.

Grain Flow Advantage in Forged Camshafts

Imagine the difference between a bundle of sticks arranged randomly versus aligned in the same direction. That's essentially what separates cast from forged grain structures. During the forging of crankshaft and camshaft components, compressive forces align metal grains along the contours of the part. This creates what metallurgists call "continuous grain flow" - a pattern where the internal structure follows the camshaft's shape rather than fighting against it.

According to research from JSY Machinery, forging aligns the metal's grain structure along the contours of the part, creating a continuous flow that enhances mechanical properties. Unlike casting or machining, which can leave random or disrupted grain patterns, forged components have a uniform microstructure that actively resists crack propagation.

Why does this matter for your engine? Fatigue failure in camshafts typically begins with microscopic cracks at stress concentration points - usually at the cam lobes where valve spring pressure creates the highest loads. In a forged crankshaft or camshaft, cracks attempting to propagate must travel against aligned grain boundaries. This requires significantly more energy than following random grain paths in cast materials, which translates directly to longer service life.

The forged vs cast crankshaft debate often dominates enthusiast forums, but the same metallurgical principles apply equally to camshafts. Racing teams discovered decades ago that forged components survive conditions that destroy cast alternatives, and modern manufacturing has only widened that performance gap.

Heat Treatment Response and Hardness Depth

Sounds complex? Here's what you need to know: heat treatment creates the hardened surface layer that resists wear on cam lobes. The effectiveness of this process varies dramatically between manufacturing methods, and forged steel responds exceptionally well.

According to technical documentation from Performance Wholesale, pushrods can apply 2,000 to 6,000 pounds of load between cam lobes and roller wheels in performance applications, reaching as high as 10,000 pounds in Pro Stock engines. These extreme forces demand exceptional surface hardness combined with a hardened layer deep enough to survive long-term wear.

Forged steel camshafts typically use SAE 8620, SAE 5160, or SAE 5150 steel alloys. During heat treatment processes like carburizing or induction hardening, the aligned grain structure of forged material allows more uniform penetration of the hardening effect. The result is:

- Deeper hardness penetration - Hardened layers extend further into the lobe surface, providing more material before softer core is exposed

- More consistent hardness across lobes - Uniform grain structure means predictable heat treatment results

- Better ductility in non-hardened areas - The core maintains flexibility while surfaces resist wear

The cast vs forged crankshaft comparison reveals similar patterns. Forged materials accept heat treatment more uniformly because the aligned grain structure creates consistent pathways for carbon diffusion during carburizing or electromagnetic energy during induction hardening.

Why Racing Applications Demand Forged

When failure means losing a race - or worse, destroying an engine worth tens of thousands of dollars - racing teams choose forged camshafts almost exclusively. The combination of superior fatigue resistance, excellent heat treatment response, and enhanced regrind potential makes forged steel the only sensible choice for serious competition.

High-RPM naturally aspirated builds push camshafts to their limits. Engines routinely spinning to 8,000 or 9,000 RPM subject camshafts to millions of stress cycles during a single racing season. The aligned grain structure of forged steel resists the fatigue that would crack cast alternatives long before the season ends.

Forced induction applications add another layer of stress. Turbo and supercharged engines often run aggressive cam profiles with higher valve spring pressures to maintain valve control at elevated boost levels. Forged camshafts handle these extreme loads without the premature wear that plagues cast components.

Endurance racing represents the ultimate test. Hours of continuous high-RPM operation with no opportunity for inspection or adjustment demands absolute reliability. Teams running 24-hour events trust forged camshafts because the metallurgical advantages compound over extended operation.

Pros

- Superior fatigue life - Aligned grain structure resists crack initiation and propagation under cyclic loading

- Excellent regrind potential - Deeper hardness penetration allows multiple regrinds before replacement

- Handles aggressive valve springs - Withstands pressures that destroy cast camshafts prematurely

- Consistent quality - Forging eliminates porosity and internal voids common in castings

Cons

- Higher cost - Forging requires more specialized equipment and processing than casting

- Longer lead times - Custom forged camshafts often require extended production schedules

- Overkill for stock applications - Daily drivers with factory valve springs rarely stress camshafts enough to justify the premium

The bottom line? Forged steel camshafts represent the durability benchmark against which other manufacturing methods are measured. While they command premium pricing, the metallurgical advantages translate directly to extended service life in applications where camshafts face real stress. For builds targeting 100,000+ miles with performance valve springs, forged steel delivers the reliability that lets you stop worrying about your camshaft and focus on enjoying the drive.

But forged steel isn't the only premium option available. For applications demanding even greater consistency and quality assurance, precision hot-forged camshafts with certified manufacturing processes offer another level of durability confidence.

Precision Hot Forging Delivers Certified Durability Standards

What separates a forged camshaft that performs adequately from one that delivers exceptional, repeatable durability across thousands of units? The answer lies in manufacturing precision and quality control systems that ensure every component meets identical metallurgical standards. Precision hot forging combined with rigorous certification processes represents the evolution of traditional forging into a manufacturing discipline where consistency becomes as important as raw material strength.

When you're sourcing camshafts for performance applications, understanding the difference between standard forging and precision hot forging helps you identify suppliers capable of delivering the metallurgical consistency your engine demands. This distinction matters especially for high-volume applications where every camshaft must perform identically to the last.

Precision Hot Forging for Consistent Cam Lobe Integrity

Standard forging creates excellent grain structure, but precision hot forging takes this foundation and adds manufacturing controls that eliminate variability. During precision hot forging, steel billets are heated to precisely controlled temperatures - typically between 1,700°F and 2,200°F depending on the alloy - before being formed in dies engineered to exacting tolerances.

According to industry research from Creator Components, forged camshafts exhibit surfaces devoid of imperfections like pores, with uniform material density contributing to impeccable wear resistance. This flawlessness stems from the controlled deformation process that eliminates the internal voids and random grain patterns common in crankshaft casting and other cast forging processes.

The near-net-shape capability of precision hot forging deserves special attention. Near-net-shape forging produces components that closely match final dimensions before machining, reducing the amount of material that must be removed during finishing operations. Why does this matter for camshaft durability? Every machining operation introduces potential stress risers - microscopic surface irregularities where cracks can initiate under cyclic loading.

As documented by Queen City Forging, forging assures optimum strength at critical stress points with minimum material, and forged parts are fully dense with no voids that can initiate component failure. Near-net-shape forging minimizes post-forge machining on cam lobes, preserving the aligned grain structure exactly where you need it most - at the high-stress contact surfaces.

Quality Certification and Durability Assurance

How do you verify that a supplier's precision hot forging actually delivers consistent metallurgical properties? Quality management certifications provide objective verification that manufacturing processes meet international standards for automotive components.

IATF 16949 certification represents the gold standard for automotive component manufacturing. This certification, which evolved from earlier TS16949 standards, requires suppliers to demonstrate process control, defect prevention, and continuous improvement across their entire manufacturing operation. According to documentation from Carbo Forge, IATF16949 certification reflects a comprehensive understanding of process and quality control, implemented through zero-defect policies that ensure customers receive the highest quality forgings possible.

For camshaft applications, IATF 16949 certification means:

- Statistical process control - Critical dimensions and material properties are monitored continuously, not just spot-checked

- Traceability - Every camshaft can be traced back to specific raw material lots and processing parameters

- Documented procedures - Forging temperatures, pressures, and timing follow validated specifications

- Continuous improvement - Manufacturing processes evolve based on performance data and customer feedback

When forging crankshafts and camshafts for performance applications, certified manufacturing processes eliminate the variability that can turn one exceptional component into a batch of inconsistent products. This matters especially when you're building engines expected to survive 100,000+ miles under demanding conditions.

Custom Profiles Without Compromising Strength

Imagine needing a specific cam profile optimized for your application but worrying that customization might compromise durability. Precision hot forging with in-house engineering capabilities solves this dilemma by enabling custom cam profiles while maintaining the metallurgical advantages that make forged camshafts superior.

Rapid prototyping capabilities allow manufacturers to develop and validate new cam profiles quickly. For suppliers like Shaoyi (Ningbo) Metal Technology, rapid prototyping in as little as 10 days combined with IATF 16949 certification means custom camshaft profiles can move from concept to validated production without sacrificing quality assurance. Their precision hot forging solutions deliver the metallurgical consistency critical for camshaft durability while accommodating application-specific requirements.

In-house engineering becomes particularly valuable when optimizing camshafts for specific durability requirements. Engineers can analyze lobe geometry, valve spring pressures, and operating conditions to recommend alloy selections and heat treatment specifications that maximize service life for your particular application. This level of customization, backed by certified manufacturing processes, represents the premium tier of camshaft production.

Pros

- Certified quality control - IATF 16949 and ISO 9001 certifications verify consistent manufacturing processes

- Rapid prototyping for custom profiles - Application-specific cam profiles without extended development timelines

- Consistent metallurgical properties - Every unit matches the same specifications, eliminating batch variability

- Near-net-shape advantages - Reduced machining preserves optimal grain structure at cam lobes

Cons

- Requires specification expertise - Getting the most from precision forging demands clear communication of application requirements

- Best suited for volume applications - Per-unit economics improve with larger production runs

- Premium pricing - Certification overhead and engineering support add cost compared to standard forging

Precision hot forging with certified quality control bridges the gap between standard forged camshafts and the ultimate consistency of billet manufacturing. For applications demanding both the metallurgical advantages of forging and the assurance of verified manufacturing processes, certified precision hot forging delivers durability you can document and trust.

But what about applications where even forged grain structure introduces potential weak points? For the most extreme builds, billet camshafts offer another approach to eliminating durability concerns entirely.

Billet Camshafts Offer Ultimate Consistency for Extreme Builds

When forged steel's aligned grain structure still isn't enough, and you're building an engine where failure simply cannot happen, billet camshafts represent the pinnacle of camshaft manufacturing. These components take a completely different approach to achieving durability - rather than optimizing grain flow through forging, billet manufacturing starts with premium bar stock and machines away everything that isn't a perfect camshaft. The result? Complete material consistency from core to surface with zero internal defects.

Professional drag racing teams discovered decades ago that billet camshafts survive conditions that destroy even the best forged alternatives. Today, if you peek under the valve covers of a Pro Mod or Top Fuel engine, you'll find billet camshafts handling valve spring pressures that would shatter ordinary components within seconds.

Billet Machining Eliminates Structural Weak Points

What exactly is a billet camshaft? According to technical documentation from Cylinder Head MFG, a billet camshaft is made by turning a lump of steel, deriving its name from its initial form before production: a forged slug instead of a cast form. The steel is usually blank without any profile, and everything must be cut, including the lobe separations and journals.

Think about what this means for material consistency. Cast camshafts can harbor internal porosity - tiny voids created when molten metal cools unevenly. Forged camshafts eliminate porosity but introduce flow lines where grain structure bends around lobe profiles. Billet camshafts? They start from homogeneous bar stock with uniform grain structure extending throughout the entire cross-section.

The machined forging approach used for billet production means:

- No casting porosity - Solid bar stock eliminates any possibility of internal voids that could initiate cracks

- No forging flow lines - Uniform grain orientation throughout the component regardless of lobe geometry

- Complete material verification - Bar stock metallurgy can be tested and certified before machining begins

- Precise material selection - Exotic alloys unavailable in cast or forged form can be specified for extreme applications

Billet camshaft manufacturers typically use hardened alloy steels and tool steel cores. As noted by industry experts, common materials include 5150 and 5160 steels, with options extending to 8620, 8660, and 9310 for specific applications. These materials produce sturdy blanks that resist wear and shock under the most demanding conditions.

When Uniform Grain Structure Justifies the Premium

You'll notice that billet camshafts command significantly higher prices than forged alternatives. A typical cast camshaft might cost $150, while a comparable billet version runs $300 or more. So when does this premium make sense?

The answer comes down to valve spring pressure and RPM. According to Cylinder Head MFG, billet cams are tougher and represent aftermarket parts ideal for highly demanding applications like racing or pulling. In these engines, spring pressures are high, requiring sturdier cams that won't deflect or fail under extreme loads.

Consider what happens in a high-boost turbocharged application. Valve springs might generate 400+ pounds of open pressure to maintain valve control at elevated boost levels. At 8,000 RPM, cam lobes experience this loading thousands of times per minute. Any material inconsistency - a casting void, a forging flow line oriented in an unfavorable direction - becomes a potential failure point.

Interestingly, the question of what is stronger billet or forged aluminum arises frequently in automotive discussions. While that debate typically centers on wheels and suspension components, the underlying metallurgical principles apply to camshafts as well. Billet offers uniform properties throughout, while forging provides optimized grain flow at the cost of some directional variation. For camshafts operating under extreme cyclical stress, billet's uniformity often wins.

The forged vs cast aluminum comparison in wheel manufacturing offers an interesting parallel. Just as enthusiasts debate the difference between cast and forged wheels weight and strength characteristics, camshaft selection requires balancing material properties against application demands. Premium applications justify premium manufacturing methods.

The Pro Mod and Top Fuel Standard

Want proof that billet camshafts represent the ultimate in durability? Look at professional drag racing. According to reporting from Engine Builder Magazine, top-tier Pro Mod engines feature 65-millimeter tool steel camshafts as standard equipment. These engines produce 3,200 to 3,300 horsepower in NHRA-legal trim, with the same basic components capable of supporting 5,000 horsepower with larger turbochargers.

Carl Stevens Jr.'s championship-winning Pro Mod engine, which set records at the Drag Illustrated World Series of Pro Mod running 5.856 seconds at 245.26 mph, relied on billet camshafts to handle valve spring pressures and RPM levels that would destroy lesser components instantly. When $100,000 purses and professional reputations are on the line, teams choose billet.

The production process for billet camshafts requires sophisticated CNC machining equipment. Every lobe profile, journal diameter, and surface finish must be cut with precision - there's no mold or die doing the shaping work. This manufacturing intensity explains both the premium pricing and the extended lead times associated with billet production.

Pros

- Ultimate material consistency - Homogeneous grain structure from core to surface eliminates weak points

- No internal defects - Solid bar stock verified before machining cannot contain hidden porosity or inclusions

- Ideal for extreme valve spring pressures - Handles loads that would deform or crack other manufacturing methods

- Superior regrind potential - Thicker, uniform material allows extensive regrinding for profile changes or wear correction

- Exotic material options - Tool steels and specialty alloys unavailable in cast or forged form can be specified

Cons

- Highest cost - Extensive machining time and material waste drive prices 2-3x higher than forged alternatives

- Significant material waste - Much of the original bar stock becomes chips rather than camshaft

- Extended lead times - Custom billet camshafts often require weeks of production time

- Overkill for most applications - Street performance builds rarely generate enough stress to justify billet's premium

For professional drag racing, unlimited class competition, and extreme forced induction applications generating 1,000+ horsepower, billet camshafts provide durability insurance that no other manufacturing method can match. The uniform material properties eliminate variables that could cause failure at the worst possible moment.

But what about the vast majority of engine builders who don't need billet's extreme capabilities? Cast iron camshafts continue serving millions of engines reliably, and understanding when cast components provide adequate durability helps you avoid overspending on manufacturing methods your application doesn't require.

Cast Iron Camshafts Remain Viable for Stock Applications

After exploring premium forged and billet options, you might wonder why anyone would choose cast iron camshafts. Here's the reality: millions of engines run cast camshafts reliably for 200,000+ miles without issues. The casted vs forged debate isn't about one method being universally superior - it's about matching manufacturing methods to actual application demands. For stock and mild street builds, cast iron delivers adequate durability at a fraction of the cost.

Understanding how cast camshafts achieve their durability helps you recognize when they're appropriate for your build and when you should upgrade. The chilled iron casting process creates surprisingly effective wear surfaces, though with limitations that matter for performance applications.

Chilled Iron Casting and Lobe Hardness

How does a casting process create the hard surfaces necessary to resist constant lifter contact? The answer lies in controlled cooling rates during solidification. According to research published in the Journal of Materials & Design, chilled cast iron camshafts use metal chills placed strategically in molds to induce rapid cooling at cam lobe surfaces.

When molten iron contacts these chills, it cools rapidly enough to form a ledeburitic phase - a hard, wear-resistant microstructure containing iron carbides. The study documented that on rapid cooling areas, ledeburitic phase and high hardness values develop, while slower cooling surfaces show rosette-like graphite in pearlitic matrix with lower hardness. This differential cooling creates exactly what camshafts need: hard lobe surfaces with softer, machinable cores.

The science gets more interesting when you examine the microstructure. Researchers found dendrite arm spacing (DAS) of 2-15 micrometers on chilled surfaces, indicating extremely fine grain structure in the hardened layer. Finer DAS correlates with better wear resistance because smaller grains create more grain boundaries that impede crack propagation.

However, this hardening effect only penetrates to a limited depth. Unlike forged camshafts where heat treatment can achieve hardness depths exceeding 0.200 inches, cast iron chilling typically produces hardened layers of 0.100 inches or less. This shallow hardness depth creates significant limitations for performance applications and regrinding potential.

Why OEMs Still Choose Cast for Stock Engines

If forged vs cast irons comparison consistently favors forged for durability, why do virtually all OEM engines use cast camshafts? The answer combines economics with engineering reality.

Factory engines operate within carefully defined parameters. Valve spring seat pressures typically range from 85-105 pounds - well within cast iron's comfort zone. Maximum RPM stays below 6,500 in most applications, limiting fatigue cycling. And importantly, engineers design cam profiles specifically to work within cast iron's capabilities.

Cast iron offers manufacturers several advantages for mass production:

- Lowest production cost - Casting requires less energy and simpler tooling than forging

- Near-net-shape capability - Cast camshafts need minimal machining compared to billet alternatives

- Excellent machinability - Graphite in the iron matrix provides natural lubrication during grinding

- Adequate durability for stock specifications - Factory valve springs don't stress cast camshafts beyond their limits

The cast crankshaft vs forged debate in OEM engines follows similar logic. Factory stress levels rarely approach material limits, making premium manufacturing methods unnecessary for warranty-period survival. Engineers know exactly how much stress their designs generate and specify materials accordingly.

For stock replacement applications, matching the original manufacturing method makes perfect sense. A cast iron camshaft in a stock 350 Chevy or 302 Ford will easily exceed 150,000 miles with proper maintenance. The component wasn't overbuilt originally, but it wasn't underbuilt either.

Regrind Limitations You Should Know

Here's where cast iron's shallow hardness depth becomes a critical limitation. According to industry experts at Moore Good Ink, raw unground camshafts have case-hardened rims penetrating 0.200 to 0.250 inches, but finish-ground surfaces must maintain minimum hardness depth of 0.100 inches. If less, the lobe will be impaired and likely fail.

What does this mean for regrinding worn camshafts? Each regrind removes material from the lobe surface. With only 0.100-0.150 inches of hardened material to work with, cast iron camshafts offer limited regrind potential. One careful regrind might be possible; two almost certainly exposes soft material beneath the hardened case.

The situation worsens when modifying lobe timing. As the reference material explains, each degree of advance or retard consumes approximately 0.027 inches of lobe metal. Requesting four degrees of advance on a regrind consumes over 0.100 inches of material - potentially taking the profile completely through the hardened layer.

Signs of hardness failure include:

- Excessive valve lash developing after initial break-in

- Visible tracks from roller lifters on lobe surfaces

- Caved-in or deformed lobe profiles

- Rapid wear patterns appearing within the first few thousand miles

For budget restorations and stock rebuilds, these limitations rarely matter. Original cam profiles don't need modification, and most rebuilds don't involve regrinding anyway. But if you're planning a mild performance upgrade with a reground camshaft, understanding cast iron's hardness depth limitations helps set realistic expectations.

Pros

- Lowest cost - Cast iron camshafts cost 50-70% less than forged alternatives

- Adequate for stock valve springs - Factory pressure levels don't stress cast iron beyond its limits

- Readily available - Stock replacement camshafts for virtually any engine are easy to source

- Proven durability - Millions of engines demonstrate cast iron's reliability in stock applications

- Excellent machinability - Graphite content makes precision grinding easier

Cons

- Limited regrind potential - Shallow hardness depth restricts how much material can be removed

- Shallow hardness depth - Typically 0.100-0.150 inches versus 0.200+ for forged

- Not suitable for performance valve springs - Pressures above 110-120 pounds accelerate wear dramatically

- Random grain structure - Potential weak points under high cyclic stress

- Limited modification flexibility - Timing changes consume hardened material quickly

Cast iron camshafts serve their intended purpose exceptionally well. For stock replacement, mild street builds, and budget restorations where factory valve springs remain in place, cast iron provides reliable service without unnecessary expense. The problems arise when enthusiasts push cast camshafts beyond their design parameters with upgraded valve springs or aggressive regrinding requests.

But what if your build falls somewhere between stock cast iron and premium forged steel? Cast steel camshafts occupy an interesting middle ground that balances improved durability against the cost premium of forging.

Cast Steel Camshafts Balance Cost and Improved Durability

What if you need more durability than cast iron provides but can't justify the premium for forged steel? Cast steel camshafts occupy precisely this middle ground, offering meaningful improvements over cast iron while keeping costs manageable. For many street performance builds, cast steel represents the sweet spot where the forge vs casting debate finds a practical compromise.

The cast vs forge decision becomes less binary when you understand what cast steel brings to the table. Unlike cast iron with its high carbon content creating brittleness, cast steel contains only 0.1-0.5% carbon - similar to forged steel alloys. According to material science documentation from Lusida Rubber, this lower carbon content in cast steel results in higher strength and toughness, making it less brittle and more resistant to deformation than cast iron.

Cast Steel Bridges the Durability Gap

Think of cast steel as cast iron's stronger, more resilient cousin. The casting process remains similar - molten metal poured into molds - but the material itself behaves differently under stress. Cast steel's microstructure is more homogeneous than cast iron, contributing to improved strength and flexibility that matters when cam lobes face elevated valve spring pressures.

Here's what makes cast steel a meaningful upgrade from cast iron:

- Higher tensile strength - Cast steel handles dynamic loads better than brittle cast iron

- Improved impact resistance - Less likely to crack under sudden stress spikes during aggressive valve events

- Better ductility - Can deform slightly under extreme loads without catastrophic failure

- Enhanced fatigue resistance - Survives more stress cycles before crack initiation compared to cast iron

Many aftermarket camshaft manufacturers recognize these advantages. Looking at performance camshaft offerings from Crower, you'll notice their mechanical roller camshafts for street and mild racing applications feature cast steel cores. Products like their Torque Beast and Power Beast lines specify cast steel construction, designed for applications ranging from 2,500 to 7,000 RPM with appropriate valve spring pressures.

The forged crank vs cast comparison often dominates enthusiast discussions, but the same material science principles apply to camshafts. Cast steel won't match forged steel's aligned grain structure, but it significantly outperforms cast iron in applications demanding moderate performance upgrades.

Heat Treatment Response Compared to Forged

Sounds like cast steel might be the perfect solution? Not so fast. While cast steel accepts heat treatment better than cast iron, it still can't match forged steel's response. Understanding this limitation helps you set realistic expectations for cast steel camshaft longevity.

During heat treatment processes like carburizing or induction hardening, the metallurgical structure of the base material determines how deeply and uniformly hardness penetrates. Forged steel's aligned grain structure creates consistent pathways for carbon diffusion during carburizing, producing predictable hardness depths across every lobe.

Cast steel presents more variables:

- Random grain orientation - Heat treatment penetration varies based on local grain structure

- Potential microporosity - Tiny voids from the casting process can affect hardness uniformity

- Less predictable results - Hardness depths may vary slightly between lobes on the same camshaft

Despite these limitations, cast steel still achieves meaningful hardness depths - typically 0.150-0.180 inches compared to cast iron's 0.100-0.150 inches. This improved hardness depth translates to better regrind potential and longer service life under moderate stress conditions.

The cast vs forged steel comparison reveals that while cast steel won't survive the extreme conditions that forged steel handles effortlessly, it provides a substantial margin above cast iron's capabilities. For applications generating 110-140 pounds of valve spring seat pressure, cast steel often provides adequate durability without forged pricing.

The Performance Street Sweet Spot

Where does cast steel truly shine? Street performance builds represent the ideal application - aggressive enough to stress cast iron beyond its limits, but not extreme enough to require forged steel's premium properties.

Consider a typical street performance scenario: a mild small block Chevy with upgraded heads, intake, and a performance camshaft. Valve springs generating 115-125 pounds of seat pressure support the cam profile while controlling valvetrain at 6,500 RPM. Cast iron struggles at these pressures over extended mileage. Forged steel survives easily but adds $200-300 to the build cost. Cast steel handles the application reliably while keeping the budget reasonable.

Cast steel camshafts excel in these specific use cases:

- Street performance builds - Mild to moderate cam profiles with upgraded but not extreme valve springs

- Moderate boost applications - Turbocharged or supercharged engines running 6-10 PSI with appropriate cam timing

- Weekend track cars - Occasional high-RPM use with adequate cooling and maintenance between events

- Budget racing classes - Where rules or budgets prohibit premium components

Pros

- Better than cast iron strength - Higher tensile strength and improved fatigue resistance

- More affordable than forged - Typically 30-50% less expensive than equivalent forged camshafts

- Decent heat treatment response - Achieves adequate hardness depth for moderate performance applications

- Improved regrind potential - Deeper hardness than cast iron allows more flexibility for profile modifications

- Widely available - Most aftermarket performance camshafts in this category use cast steel cores

Cons

- Casting porosity risks - Potential for internal voids that can initiate fatigue cracks

- Grain structure not optimized - Random orientation doesn't resist crack propagation like forged alternatives

- Limited extreme application suitability - Not recommended for valve spring pressures exceeding 150 pounds

- Variable quality - Manufacturing consistency varies between suppliers

Cast steel camshafts represent practical engineering - matching material capabilities to actual application demands without overspending on unnecessary premium properties. For the enthusiast building a street performance engine expected to survive 100,000+ miles with moderate valve spring upgrades, cast steel delivers reliable durability at a reasonable price point.

With all manufacturing methods now examined individually, how do they compare side by side across the durability factors that actually matter? A comprehensive comparison table reveals exactly where each method excels and where it falls short.

Complete Durability Comparison Across All Manufacturing Methods

You've seen the individual strengths and weaknesses of each camshaft manufacturing method. Now it's time to put them side by side and see exactly how they stack up. Whether you're rebuilding a daily driver or assembling a dedicated race engine, this comprehensive comparison helps you match the right manufacturing method to your specific durability requirements without overspending or underbuilding.

The difference between cast and forged components becomes crystal clear when you examine multiple durability factors simultaneously. A camshaft that excels in one category might fall short in another, and understanding these trade-offs helps you make informed decisions rather than relying on marketing claims or forum opinions.

Durability Factor Breakdown by Manufacturing Method

How does each manufacturing method perform across the criteria that actually determine whether your camshaft survives 100,000 miles? This table summarizes what we've covered throughout this guide, giving you a quick reference for comparing options:

| Manufacturing Method | Grain Structure Quality | Lobe Wear Resistance | Heat Treatment Depth | Regrind Potential | Best Application | Relative Cost |

|---|---|---|---|---|---|---|

| Precision Hot Forged | Excellent - Aligned grain with certified consistency | Excellent - IATF 16949 quality verified | 0.200"+ with uniform penetration | Excellent - Multiple regrinds possible | High-performance, OEM racing programs | $$$$ |

| Standard Forged Steel | Very Good - Aligned grain flow | Very Good - Handles aggressive springs | 0.180"-0.220" typical | Very Good - 2-3 regrinds typical | Endurance racing, high-RPM builds | $$$ |

| Billet | Excellent - Uniform throughout | Excellent - Tool steel options available | Full depth - Solid material | Excellent - Maximum material available | Pro Mod, Top Fuel, extreme boost | $$$$$ |

| Cast Steel | Moderate - Random orientation | Good - Better than cast iron | 0.150"-0.180" typical | Moderate - 1-2 regrinds possible | Street performance, moderate boost | $$ |

| Cast Iron | Fair - Random with potential voids | Fair - Adequate for stock springs only | 0.100"-0.150" from chilling | Limited - One careful regrind maximum | Stock replacement, budget builds | $ |

Notice how the cast forge process used in cast steel provides meaningful improvements over cast iron while remaining more affordable than forged alternatives. This middle-ground option serves many street performance applications adequately, demonstrating that the best choice isn't always the most expensive one.

Application Matching Guide

Knowing the technical specifications is one thing - knowing which method wins for your specific build is another. Here's a practical breakdown of which manufacturing method delivers the best value for each common application type:

- Daily Driver (Stock Valve Springs) - Winner: Cast Iron. Factory valve spring pressures of 85-105 pounds don't stress camshafts significantly. Cast iron provides adequate durability for 150,000+ miles at the lowest cost. Spending more on forged or billet for a stock commuter wastes money that could go toward other upgrades.

- Street Performance (110-140 lb Springs) - Winner: Cast Steel or Standard Forged. Upgraded valve springs push cast iron beyond its comfort zone. Cast steel handles moderate upgrades affordably, while forged steel provides extra insurance for builds approaching the upper pressure limits or targeting higher mileage.

- Drag Racing (High RPM, Aggressive Profiles) - Winner: Billet or Precision Hot Forged. Quarter-mile passes concentrate extreme stress into short bursts. The forging strength of precision hot forged camshafts handles most drag racing applications, while billet becomes essential for Pro Mod and similar unlimited classes where valve spring pressures exceed 300 pounds open.

- Endurance Racing (Sustained High RPM) - Winner: Precision Hot Forged or Standard Forged. Hours of continuous operation at elevated RPM demand exceptional fatigue resistance. Certified precision hot forging provides documented quality assurance that teams can rely on, while standard forged steel serves budget-conscious endurance builds effectively.

- Diesel Applications (High Torque, Lower RPM) - Winner: Cast Steel or Standard Forged. Diesel engines generate different stress patterns than gasoline engines - higher torque loads at lower RPM ranges. Cast steel provides adequate durability for stock and mildly modified diesels, while forged becomes appropriate for competition pulling or severe-duty applications.

Cost vs Longevity Analysis

When you calculate the true cost of camshaft ownership, initial purchase price tells only part of the story. A $150 cast iron camshaft that fails at 50,000 miles costs more than a $350 forged steel camshaft that survives 200,000 miles when you factor in replacement labor, potential engine damage, and vehicle downtime.

Consider these long-term cost factors when evaluating manufacturing methods:

- Replacement frequency - Forged and billet camshafts typically survive 2-4x longer than cast alternatives under equivalent stress conditions

- Regrind economics - Deeper hardness in forged and billet camshafts allows multiple regrinds at $100-200 each, extending service life significantly

- Failure consequences - A failed camshaft can destroy lifters, pushrods, rocker arms, and potentially valves and pistons - damage often exceeding $2,000 to repair

- Downtime costs - Race teams and performance enthusiasts lose more from missed events than the price difference between manufacturing methods

The forged vs cast camshaft durability equation becomes clearer when you spread costs across expected service life. For a street performance build targeting 100,000 miles with 125-pound valve springs, a forged steel camshaft at $350 costs roughly $0.0035 per mile. A cast steel alternative at $200 that requires replacement at 60,000 miles costs $0.0033 per mile initially - but add replacement costs and labor, and the forged option proves more economical long-term.

The most expensive camshaft is the one that fails before its time. Match your manufacturing method to your application's actual stress levels, and the durability question answers itself.

With this comprehensive comparison in hand, you're equipped to make informed decisions about which manufacturing method serves your specific build goals. But knowing what to buy is only half the equation - understanding how to source quality components and match them to your exact application completes the picture.

Final Recommendations for Every Engine Application

You've seen the data, compared the manufacturing methods, and understand the metallurgical differences that separate durable camshafts from premature failures. Now comes the practical question: which camshaft belongs in your engine? The answer depends on matching your build goals, budget constraints, and long-term expectations to the right manufacturing method - and sourcing from suppliers who can deliver consistent quality.

Whether you're dropping a camshaft into a 302 crank-powered street machine, building a high-revving D16 crankshaft Honda, or assembling a torque-monster around a 393 crankshaft stroker, these recommendations help you avoid both overspending and underbuilding.

Match Your Build Goals to the Right Manufacturing Method

After analyzing grain structure, heat treatment response, lobe wear resistance, and real-world performance data, here's how to prioritize camshaft manufacturing methods based on your specific application:

- Extreme Racing (Pro Mod, Top Fuel, Unlimited Classes) - Choose billet or precision hot forged camshafts exclusively. Valve spring pressures exceeding 300 pounds open demand ultimate material consistency. The cost premium disappears when measured against potential engine damage from a failed camshaft. Tool steel billet options provide maximum insurance for engines producing 1,500+ horsepower.

- Street Performance and Weekend Track (130-180 lb Springs) - Standard forged steel delivers the ideal balance of durability and value. Aligned grain structure handles aggressive cam profiles and elevated spring pressures without the billet premium. For builds targeting 100,000+ miles with performance modifications, forged steel provides peace of mind that cast alternatives cannot match.

- Mild Street Builds (110-130 lb Springs) - Cast steel serves these applications well at reasonable cost. The improved strength over cast iron handles moderate valve spring upgrades without the forged pricing. Perfect for budget-conscious enthusiasts who want reliability without overspending on manufacturing methods their application won't stress.

- Stock Replacement (85-105 lb Springs) - Cast iron remains the practical choice. Factory valve spring pressures don't challenge cast iron's capabilities, and millions of engines prove its reliability in stock applications. Save your upgrade budget for components that will actually see increased stress.

Diesel Engine Camshaft Considerations

Diesel engines present unique demands that shift the camshaft manufacturing equation. Unlike gasoline engines that generate peak stress through high RPM operation, diesel powerplants concentrate their demands differently - understanding these differences helps you select appropriately.

According to industry documentation from GlobalSpec, large diesel engines often rotate more slowly but deal with much greater forces and loads than typical automotive camshafts. These camshafts must be built more carefully to ensure that they will be able to perform in critical applications.

Key considerations for diesel camshaft selection include:

- Torque loading emphasis - Diesel camshafts face higher static loads from fuel injection timing demands, favoring materials with excellent fatigue resistance under sustained stress rather than high-cycle conditions

- Lower RPM stress patterns - Peak RPM in most diesel applications stays below 4,500, reducing fatigue cycling compared to gasoline engines revving to 7,000+

- Injection timing precision - Mechanical diesel injection systems require precise cam lobe geometry that must remain stable across extended service intervals

- Extended service expectations - Commercial diesel applications often target 500,000+ mile service life, making initial material quality investments more cost-effective

For stock diesel applications, cast steel typically provides adequate durability. Performance diesel builds - especially competition pulling trucks and severe-duty applications - benefit from forged steel's superior fatigue resistance and consistent heat treatment response. The investment pays dividends over extended service life.

Installation and Break-In Considerations by Manufacturing Method

Your camshaft's manufacturing method affects more than just durability - it influences proper installation and break-in procedures that determine whether your new component reaches its full service potential.

Forged and Billet Camshafts:

- Surface finishes may require specific break-in lubricants - verify manufacturer recommendations

- Heat treatment uniformity typically allows standard break-in RPM protocols

- Deeper hardness provides more forgiveness for minor installation variations

- Higher investment justifies professional installation verification

Cast Iron and Cast Steel Camshafts:

- Assembly lubricant application becomes critical due to shallower hardness depth

- Initial break-in RPM protocols must be followed precisely to establish proper wear patterns

- Flat tappet applications require especially careful break-in with ZDDP-fortified oils

- Avoid aggressive spring pressures until lobe surfaces have properly seated against lifters

Regardless of manufacturing method, proper break-in establishes the wear pattern that determines long-term durability. Skipping or rushing break-in procedures can undo the metallurgical advantages of even the finest forged camshaft.

Supplier Quality Indicators That Matter

Knowing which manufacturing method to choose means nothing if your supplier delivers inconsistent quality. How do you evaluate whether a camshaft manufacturer can actually deliver the metallurgical properties their marketing claims?

Look for these quality indicators when sourcing camshafts:

- IATF 16949 Certification - This globally recognized automotive quality standard indicates suppliers who maintain rigorous process control, defect prevention, and continuous improvement protocols. According to Smithers, IATF 16949 requirements include comprehensive quality management systems, planning and risk analysis, process management, and continuous monitoring that ensure consistent manufacturing results.

- Material traceability - Quality suppliers can trace any camshaft back to specific raw material lots and processing parameters. This documentation proves manufacturing consistency and enables root cause analysis if issues arise.

- Heat treatment documentation - Hardness depth verification and process certification demonstrate that critical lobe surfaces meet specifications. Request hardness test results for critical applications.

- In-house engineering capability - Suppliers with engineering resources can optimize cam profiles for your specific application rather than offering one-size-fits-all solutions.

For critical engine components like camshafts, certified manufacturing processes provide the quality assurance that determines whether your investment survives 100,000 miles or fails prematurely. The metallurgical consistency that separates reliable camshafts from ticking time bombs starts with supplier selection.

For performance and racing applications requiring precision hot forging with documented quality assurance, IATF 16949 certified suppliers like Shaoyi (Ningbo) Metal Technology deliver the metallurgical consistency that determines camshaft longevity. Their location near Ningbo Port enables fast global delivery, while rapid prototyping capabilities - often in as little as 10 days - allow custom cam profiles without extended development timelines. When your build demands both premium forging quality and verified manufacturing processes, certified suppliers provide the confidence that your camshaft investment will pay dividends mile after mile.

The forged vs cast camshaft durability question ultimately answers itself once you match manufacturing method to application demands. Stock engines run cast iron reliably for decades. Street performance builds thrive with cast steel or forged options. Racing applications demand forged or billet construction. Choose appropriately, source from certified suppliers, and your camshaft becomes one component you'll never need to worry about again.

Frequently Asked Questions About Camshaft Durability

1. What are the disadvantages of a forged engine camshaft?

Forged camshafts cost 2-3x more than cast alternatives due to specialized equipment and intensive energy requirements. Lead times extend longer for custom orders, and the premium metallurgical properties represent overkill for stock applications with factory valve springs under 105 pounds. For daily drivers that rarely exceed 5,000 RPM, the investment in forged steel provides minimal benefit over properly manufactured cast components.

2. Why is forging preferred over casting for performance camshafts?

Forging creates aligned grain structure that follows the camshaft's contours, providing 26% higher tensile strength and 37% better fatigue life than cast equivalents. This alignment forces cracks to travel against grain boundaries, requiring significantly more energy to propagate. Forged camshafts also accept heat treatment more uniformly, achieving deeper hardness penetration of 0.200+ inches compared to cast iron's 0.100-0.150 inches, enabling multiple regrinds and extended service life under aggressive valve spring pressures.

3. How long do cast iron camshafts last compared to forged?

Cast iron camshafts reliably exceed 150,000-200,000 miles in stock applications with factory valve springs generating 85-105 pounds of seat pressure. However, under performance conditions with upgraded springs exceeding 120 pounds, cast iron degrades significantly faster. Forged steel camshafts typically survive 2-4x longer under identical stress conditions due to superior fatigue resistance and deeper hardness penetration that maintains lobe geometry throughout extended service.

4. When should I choose a billet camshaft over forged?

Billet camshafts become essential when valve spring pressures exceed 300 pounds open, such as in Pro Mod, Top Fuel, and extreme forced induction applications producing 1,000+ horsepower. The homogeneous grain structure from solid bar stock eliminates all internal defects and flow lines that could initiate failure. Tool steel billet options handle conditions that would destroy even premium forged alternatives, though the 2-3x cost premium makes billet excessive for typical street performance builds.

5. Can cast steel camshafts handle performance valve springs?

Cast steel camshafts adequately handle moderate performance upgrades with valve spring seat pressures of 110-140 pounds. They offer higher tensile strength and better fatigue resistance than cast iron while remaining 30-50% less expensive than forged alternatives. For street performance builds, weekend track cars, and moderate boost applications running 6-10 PSI, cast steel provides reliable durability. However, pressures exceeding 150 pounds or sustained high-RPM racing conditions warrant upgrading to forged steel.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —