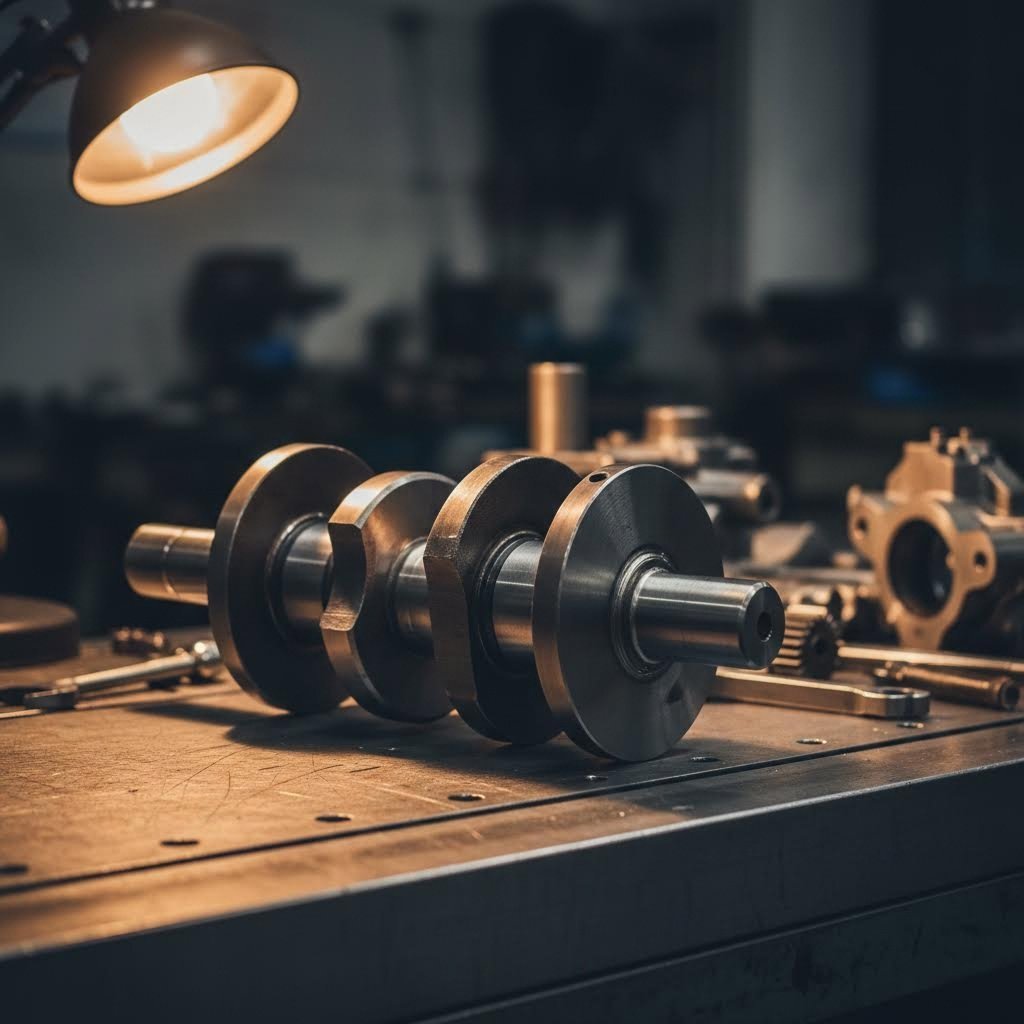

Forged Steel Vs Cast Iron Crankshafts: Which One Survives Your Build?

Understanding the Crankshaft Material Showdown

You're staring at a rotating assembly catalog, and one question keeps nagging: which crankshaft material will actually survive your build? Whether you're piecing together a mild 383 stroker for weekend cruising or engineering a high-horsepower monster, this decision shapes everything from engine longevity to your wallet's health.

Here's the thing most comparisons get wrong—they pit forged vs cast crankshaft options as a simple two-way battle. Reality demands a more nuanced approach. You're actually choosing among three distinct materials: cast iron, cast steel, and forged steel. Each brings unique strengths to the table, and understanding these differences separates informed builders from those left scratching their heads at unexpected failures.

Why Your Crankshaft Choice Defines Engine Longevity

Think of your crankshaft as the backbone of your engine's rotating assembly. According to industry data from Hot Rod, cast iron cranks typically deliver tensile strength around 70,000 to 80,000 psi, while cast steel pushes approximately 105,000 psi. Jump to a premium 4340 forged crankshaft, and you're looking at roughly 145,000 psi of tensile strength.

But raw numbers only tell part of the story. The real difference? How these materials behave under stress. A cast crankshaft's grain structure resembles beach sand—individual particles loosely connected. A forged crank, however, features compressed, interwoven grain flow where molecules are forced to "hold hands" with neighboring molecules, creating dramatically superior fatigue resistance.

The Material Decision That Separates Street Builds from Race Engines

Here's where confusion runs rampant: many builders lump cast iron and cast steel together as if they're interchangeable. They're not. Nodular iron offers around 95,000 psi tensile strength—a meaningful step up from basic cast iron. Cast steel climbs higher still. This distinction matters when you're evaluating whether your stock rebuild truly needs an expensive upgrade.

Throughout this guide, you'll find application-specific recommendations covering everything from budget street rebuilds to full-tilt race engines. We've weighted durability, cost, and real-world performance to deliver ranked guidance you can actually use.

One crucial caveat before diving deeper: not all forged crankshafts are created equal. Manufacturing processes, heat treatment methods, and steel alloy grades vary significantly between manufacturers. A budget forging from an unknown source may actually underperform a quality cast steel crank from a reputable supplier. Quality control and certified manufacturing processes separate premium components from those that merely carry the "forged" label.

Our Crankshaft Evaluation Criteria Explained

So how do you actually compare crankshaft materials in a meaningful way? Sounds complex, right? We've developed a transparent evaluation framework that goes beyond surface-level specifications to examine what truly matters when your engine is spinning at redline under load.

The two underlying factors in crank strength are material composition and manufacturing process. When you align tensile strength, price, and horsepower capacity, a clear hierarchy emerges. But here's what most comparisons miss—you need to weigh these factors against your specific application, not just chase the highest numbers.

Performance Metrics That Matter for Rotating Assemblies

We evaluated crank casting options across six critical criteria. Each factor carries different weight depending on whether you're building a daily driver or a dedicated drag car:

- Tensile Strength: The maximum stress a material can withstand before stretching or deforming. According to Counterman, this ranges from 65,000 psi for basic cast iron up to 145,000+ psi for premium forged steel alloys.

- Fatigue Resistance: How well the crankshaft handles repeated stress cycles without developing cracks. This is where grain structure becomes critical—the difference between a crankshaft casting that lasts 100,000 miles versus one that fails at 50,000.

- Weight Considerations: Lighter rotating assemblies reduce parasitic losses and improve throttle response. However, weight reduction must never compromise structural integrity.

- Machinability: How easily the material can be finished, balanced, and prepared. Cast iron offers excellent machinability at low cost, while some high-grade forged steels require specialized equipment.

- Cost-Effectiveness: The balance between initial investment and long-term reliability. A crankcase casting that fails prematurely costs far more than the upfront savings.

- Application Suitability: Matching material properties to actual engine demands—compression ratio, RPM range, power adders, and driving habits.

How We Weighted Durability, Cost, and Application Fit

Here's what separates useful guidance from generic advice: understanding why horsepower and torque thresholds matter for material selection. The crankshaft doesn't just transfer power—it absorbs tremendous forces. Visualize what happens during every combustion event: explosive pressure drives the piston downward, twisting the crank through the connecting rod while adjacent cylinders compress their charges. Add high RPM and the momentum of pistons holding on for dear life, and you're painting a picture of immense stress.

According to technical experts at Summit Racing, cast iron crankshafts reliably handle 300 to 400 horsepower with occasional weekend track usage. Push toward 450-500 horsepower—especially when driven hard regularly—and you're entering territory where upgraded materials become essential. Forged steel cranks can reliably manage 600 to 1,000+ horsepower depending on steel grade and manufacturing quality.

The metallurgical difference comes down to microstructure. A casting produces a sand-like grain pattern where individual particles sit loosely connected. Forging compresses and aligns the grain structure, creating uniform flow that follows the component's contours. Think of it like the difference between a handful of gravel and interlocking bricks—one crumbles under stress while the other distributes loads efficiently.

This grain structure directly determines fatigue life. Modern surface treatments like induction hardening, shot peening, and nitriding can enhance durability, similar to how wet sanding refines a surface finish during paint preparation—each process addresses specific performance requirements. These treatments create hardened surface layers while maintaining tough cores, but they work with the base material's inherent properties rather than replacing them.

With these evaluation criteria established, let's examine how each crankshaft material performs in real-world applications, starting with cast iron—the baseline OEM option that still has its place in the right builds.

Cast Iron Crankshafts for Budget Rebuilds

When you're rebuilding a stock small-block or refreshing a daily driver on a tight budget, cast iron crankshafts deserve serious consideration. They've powered millions of factory engines reliably for decades—and they can still get the job done when your build stays within their comfort zone.

Cast iron cranks represent the baseline OEM option that came standard in countless 350/400 combinations rolling off assembly lines. Understanding when this material works—and when it doesn't—saves you from both overspending on unnecessary upgrades and underspending on components that can't handle your power goals.

Cast Iron Cranks in Stock Rebuilds and Daily Drivers

Imagine you're freshening up a numbers-matching restoration or building a budget cruiser. The original cast iron crank sitting in your block might be perfectly adequate. According to technical data from Ohio Crankshaft, nodular iron crankshafts perform satisfactorily in small-block engines producing up to 400-450 horsepower and big-blocks making 500-600 horsepower.

For stock rebuilds maintaining factory compression ratios and naturally aspirated configurations, cast iron handles the workload without complaint. These cranks excel in applications where:

- Power output stays under 400 horsepower for small-blocks

- RPM limits remain at or below factory redline specifications

- No power adders like turbochargers, superchargers, or nitrous are planned

- Budget constraints make the $200-$300 price difference significant

- Originality matters for restoration projects

The SBC crankshaft identification process for cast iron versus other materials starts with visual inspection. Cast iron cranks typically display a rougher surface texture near the counterweights compared to steel variants. You'll also notice casting seams and a duller gray appearance when cleaned. Casting numbers stamped on the crank's front flange or first counterweight help confirm material type—cross-reference these with factory specifications to verify what you're working with.

When Factory Equipment Gets the Job Done

Here's the practical reality: cast iron vs forged comparisons often overlook that most street-driven engines never approach the stress levels where material differences become critical. Your grandmother's grocery-getter and your weekend cruiser don't need race-spec components.

Cast iron cranks offer genuine advantages in specific scenarios:

Pros

- Excellent machinability: Machine shops easily grind journals and perform standard maintenance procedures

- Lower cost: Significant savings over cast steel and forged options—money that can fund other improvements

- Proven reliability: Decades of service in factory applications demonstrate adequate durability for intended power levels

- Availability: Readily sourced through salvage yards for restoration projects requiring factory-correct components

- Damping characteristics: The material's inherent properties help absorb some harmonic vibrations

Cons

- Lower tensile strength: Approximately 70,000-80,000 psi compared to 105,000+ psi for cast steel options

- Brittleness under extreme stress: Cast iron cast steel comparisons reveal iron's tendency to crack rather than bend when overloaded

- Reduced fatigue life: The sand-like grain structure accumulates stress damage faster than steel alternatives

- Weight penalty: Cast iron typically runs heavier than equivalent steel cranks, affecting rotating assembly balance

- Limited upgrade potential: Once you've reached the material's power ceiling, replacement becomes mandatory rather than optional

The weight consideration matters more than many builders realize. Cast iron's density creates heavier counterweights that must work harder during high-RPM operation. This additional rotating mass affects throttle response and places greater stress on main bearings during aggressive driving. For engines that rarely see sustained high-RPM use, this trade-off proves acceptable. For performance-oriented builds, it becomes a limiting factor.

One critical warning about cast iron forge processes versus true forged steel: some budget crankshafts advertised as "performance" options are simply cast iron with surface treatments. These cosmetic enhancements don't address the underlying material limitations. Always verify material composition through reputable suppliers before assuming an upgrade provides meaningful strength improvements.

When budget allows even modest flexibility, cast steel crankshafts offer a compelling middle ground that addresses many of cast iron's shortcomings while remaining accessible for street performance builds.

Cast Steel Crankshafts for Street Performance Builds

Ready to step up from cast iron without breaking the bank on a full forged rotating assembly? Cast steel crankshafts occupy that sweet spot where improved strength meets reasonable cost—and this is precisely where most street performance builds belong.

Here's the distinction competitors consistently miss: cast steel is not just slightly better cast iron. According to Smeding Performance, cast steel crankshafts deliver tensile ratings between 65,000 and 100,000 psi depending on the alloy used—with quality aftermarket options pushing toward that upper range. Compare this to basic cast iron's 70,000-80,000 psi ceiling, and the gap becomes meaningful when power levels climb.

Cast Steel Cranks Bridge the Gap for Street Performance

When you start 383 stroker builds or similar street performance projects, cast steel emerges as the logical choice. The 383 stroker market relies heavily on cast steel crankshafts for good reason—they handle the increased stroke length and accompanying stress levels while keeping complete 383 stroker kit prices accessible for weekend warriors.

So what makes forged vs cast steel comparisons favor forged for race applications but cast steel for hot street builds? The answer lies in grain structure and ductility. Cast steel offers improved grain characteristics over cast iron, providing better stress distribution and increased flexibility before failure. When overloaded, cast steel tends to bend rather than crack suddenly—giving you warning signs rather than catastrophic destruction.

Ideal applications for cast steel crankshafts include:

- Hot street builds producing 400-500 horsepower

- Moderate power adders like small superchargers or mild nitrous kits (75-100 shot range)

- Engines seeing occasional track duty with primarily street use

- Stroker combinations where increased displacement stays naturally aspirated

- Budget-conscious performance upgrades that still demand reliability

The Sweet Spot Between Economy and Strength

Manufacturers like Scat crankshaft, Eagle, and K1 Technologies all offer cast steel options specifically targeting the street performance segment. These aftermarket cranks undergo quality control processes that factory castings never see—better alloy selection, improved heat treatment, and precision machining that reduces stress risers.

The Skip White Performance catalog and similar suppliers stock numerous cast steel 383 stroker options because demand remains consistently strong. Builders recognize that spending $400-$600 on a quality cast steel crank makes more sense than gambling with a worn factory piece or overspending on forged steel their application doesn't require.

Pros

- Significantly improved tensile strength: Up to 100,000 psi versus cast iron's 70,000-80,000 psi ceiling

- Better ductility: Bends under extreme stress rather than cracking suddenly

- Improved grain structure: More uniform than cast iron, though lacking forged steel's directional flow

- Cost-effective performance: Typically 40-60% less expensive than comparable forged options

- Wide aftermarket availability: Numerous stroke lengths and journal configurations from reputable manufacturers

- Handles moderate power adders: Suitable for mild forced induction and small nitrous applications

Cons

- Still lacks directional grain flow: Cannot match forged steel's fatigue resistance under sustained high stress

- Power ceiling exists: Not recommended beyond 500-550 horsepower in most applications

- RPM limitations: Extended high-RPM operation accelerates fatigue compared to forged alternatives

- Quality varies significantly: Budget cast steel cranks may underperform premium cast iron options

- Not suitable for serious racing: Drag racing, circle track, and sustained competition use demand forged components

Understanding how cast steel handles stress differently than cast iron helps explain its popularity. When combustion forces twist the crankshaft, cast iron's rigid molecular structure resists—until it can't. Then it fractures. Cast steel's improved ductility allows microscopic flexing that dissipates stress more effectively. This doesn't mean cast steel cranks are infinitely durable, but they provide a meaningful safety margin over iron for the additional investment.

The limitation that ultimately separates cast steel from forged steel comes down to grain structure. Even quality cast steel lacks the directional grain flow that forging creates. Those compressed, aligned molecules in a forged crank follow the component's contours, distributing stress along natural pathways. Cast steel's grain remains more randomized—adequate for street performance, but insufficient when horsepower climbs beyond 550 or sustained high-RPM operation becomes routine.

For builders pushing beyond these thresholds or planning serious competition use, precision forged steel crankshafts deliver the fatigue resistance and ultimate strength that demanding applications require.

Precision Forged Steel Crankshafts for Maximum Durability

When your build demands absolute reliability under extreme stress, precision forged steel crankshafts represent the definitive solution. Whether you're assembling a chevy small-block 427 build destined for the drag strip or upgrading an 8.1 Vortec for heavy towing applications, understanding why forged steel dominates high-performance rotating assemblies helps you make informed decisions that protect your investment.

The forging of crankshaft components fundamentally transforms the steel's internal architecture. According to technical analysis from OBFE, forging involves shaping heated steel billets under immense compressive forces—a process that creates directional grain flow following the component's contours. Imagine kneading dough until the structure becomes uniform and resilient; similarly, forging refines the metal's grain structure, aligning it with the stresses the crankshaft will experience during operation.

Forged Steel Cranks Deliver Unmatched Fatigue Resistance

Here's what separates a forged crank from cast alternatives at the molecular level: directional grain flow. When you examine a cast crankshaft's internal structure, you'll find randomly oriented grain patterns resembling loosely packed sand. A forged crankshaft's grain structure, however, flows continuously along the component's geometry—like reinforced fibers running through composite material.

This aligned grain flow creates several critical advantages:

- Superior fatigue resistance: Cracks typically initiate at grain boundaries or internal defects. Forging minimizes these weak points by creating a continuous, refined grain structure that resists crack initiation and propagation through millions of stress cycles.

- Increased density: The high-pressure forging process compacts the material, eliminating porosity and segregation that create stress risers in cast components. This denser structure withstands thermal cycling and high-pressure combustion events without degradation.

- Directional strength: The aligned grain flow provides maximum strength precisely where the crankshaft experiences peak loads—at the journals and crankpins where bending and torsional stresses concentrate.

- Work hardening benefits: The plastic deformation during forging increases dislocation density within the metal's crystal structure, creating inherent hardness and strength that casting cannot replicate.

According to industry specifications, premium 4340 forged steel crankshafts deliver tensile strength exceeding 145,000 psi—nearly double what basic cast iron provides. But tensile strength alone doesn't tell the complete story. The SBC forged crankshaft advantage becomes most apparent under repeated stress cycles, where that aligned grain structure prevents the microscopic crack propagation that eventually destroys lesser materials.

Why Serious Builds Demand Forged Rotating Assemblies

Think about what happens inside a high-performance engine: explosive combustion events drive pistons downward with tremendous force, twisting the crankshaft while adjacent cylinders simultaneously compress their charges. Add forced induction, nitrous, or sustained high-RPM operation, and stress levels multiply dramatically.

Forged crankshafts prove essential in these demanding applications:

- High-horsepower naturally aspirated builds: Engines producing 550+ horsepower generate sufficient combustion pressures and rotating mass to exceed cast material limitations

- Forced induction applications: Turbochargers and superchargers increase cylinder pressure beyond what cast cranks reliably handle

- Nitrous oxide systems: Even moderate nitrous shots (150+ horsepower) create instantaneous stress spikes that demand forged components

- Drag racing and competition use: Repeated high-stress launches and sustained high-RPM operation accelerate fatigue in cast materials

- Marine and industrial applications: Extended operation under load requires fatigue resistance that only forged construction provides

The forged crankset you select must match your application's specific demands. Not all forged cranks are created equal—manufacturing quality varies significantly between suppliers. According to automotive industry analysis, compliance with standards like IATF 16949 certification ensures consistent quality control across production runs. Manufacturers meeting these stringent requirements, such as Shaoyi (Ningbo) Metal Technology, deliver the precision hot forging and rigorous inspection protocols that separate premium components from budget alternatives carrying the "forged" label without the quality to back it up.

Pros

- Dramatically superior fatigue resistance: Continuous grain flow prevents crack initiation even through millions of stress cycles

- Highest tensile strength available: 4340 steel forgings exceed 145,000 psi, supporting 1,000+ horsepower applications

- Reduced weight potential: Superior strength-to-weight ratio allows material removal for lighter rotating assemblies without sacrificing durability

- Handles extreme power adders: Large turbos, aggressive supercharger setups, and substantial nitrous systems present no structural concerns

- Extended service life: Premium forged cranks outlast cast alternatives by significant margins under equivalent stress levels

- Better response to surface treatments: Nitriding, shot peening, and induction hardening enhance already-superior base material properties

- Peace of mind: Eliminates crankshaft as a failure point in expensive, high-output engine combinations

Cons

- Higher initial cost: Quality forged crankshafts typically cost 2-3 times more than cast steel equivalents

- Requires precise balancing: Tighter tolerances demand professional balancing equipment and expertise

- Quality varies by manufacturer: Budget forgings may not deliver expected performance—sourcing matters significantly

- Machining complexity: Harder materials require specialized equipment and increase machining costs

- Overkill for mild applications: Stock rebuilds and budget street builds don't benefit from premium forged construction

The manufacturing process matters as much as the material specification. Precision hot forging at controlled temperatures ensures optimal grain refinement, while post-forging heat treatments like quenching and tempering further enhance hardness and toughness. Quality control inspections verify dimensional accuracy, surface integrity, and material properties meet exacting standards. When these processes align—certified manufacturing, proper alloy selection, and rigorous quality assurance—the resulting forged crank delivers reliability that justifies its premium price point.

For builders and manufacturers sourcing forged crankshafts, partnering with an IATF 16949-certified precision forging supplier ensures consistent quality across production runs. This certification standard, recognized throughout the automotive industry, mandates rigorous process controls and documentation that separate professional-grade components from commodity parts. The difference becomes apparent when your engine survives season after season of hard use without rotating assembly concerns.

With forged steel established as the premium benchmark for demanding applications, the question becomes: which aftermarket forged crankshaft brands deliver the best combination of quality, availability, and value for your specific build?

Top Aftermarket Forged Crankshaft Brands Compared

You've decided your build demands forged steel—now comes the next question: which manufacturer delivers the quality your engine deserves? The aftermarket forged crankshaft landscape includes established names like Scat cranks, Eagle Specialty Products, and K1 crankshaft lines, each offering distinct advantages depending on your application and budget.

But here's what most buyers overlook: selecting a quality forged crank represents only half the equation. Matching that crankshaft to compatible rods, pistons, and harmonic balancers determines whether your rotating assembly works as an integrated system or fights itself at every revolution.

Aftermarket Forged Cranks from Scat, Eagle, and K1

According to Engine Builder Magazine, manufacturers like Scat, Callies, and Eagle have gone all-in on the stroker and performance crankshaft market, offering extensive ready-to-assemble rotating assembly options. Each brand brings specific strengths to the table:

Scat Crankshafts pioneered the performance rotating assembly market and maintains one of the industry's deepest inventories. Their website claims over 1,200 stroker combinations available off-the-shelf, including the popular Scat 350 crankshaft options for small-block Chevy applications. What sets Scat apart? According to industry reports, the company treats each rotating assembly as an individual order rather than production-line work—meaning balance quality matches what premium engine shops deliver. Scat offers cast, forged, and billet options across their lineup, allowing builders to match component quality to budget and horsepower goals.

Eagle Specialty Products brings over 1,900 rotating assembly combinations covering everything from domestic V8s to import applications including Subaru, Toyota, and Mitsubishi platforms. Their Pro Street kits feature forged 4140 steel crankshafts paired with FSI 4340 steel I-beam connecting rods. Eagle's documentation provides detailed compatibility guidance, helping builders understand which combinations work for specific displacement and compression targets.

K1 Technologies has partnered with Wiseco to develop rotating assembly components engineered around each other from initial design. According to manufacturer information, this collaborative approach means assemblies balance more easily and require less finish work before installation. K1 offers both forged and billet steel options—either choice delivers a rock-solid bottom end matched with Wiseco's USA-manufactured forged pistons.

Callies occupies the premium tier, offering V8 crankshafts ranging from approximately $2,000 to $6,500 depending on specifications. Their center-counterweighted designs have gained popularity for boosted applications, keeping the crankshaft from flexing under heavy loads. When building an SBC 400 forged crankshaft combination or tackling a 454 forged crankshaft project, Callies delivers components engineered for the most demanding applications.

Matching Forged Cranks to Your Rotating Assembly

Imagine ordering a premium forged crankshaft only to discover your connecting rods won't clear the cam or your pistons pop out above the deck surface. These compatibility nightmares happen when builders focus solely on the crankshaft without considering the complete rotating assembly package.

Here's the critical matching sequence that prevents costly mistakes:

- Stroke vs. Rod Length vs. Piston Compression Height: These three dimensions must work together within your block's deck height. Increasing stroke requires either shorter pistons or shorter connecting rods to prevent interference. According to industry guidance, using stock-length rods often necessitates shorter pistons—while shorter rods allow stock-height pistons that won't protrude above the block deck.

- Cylinder Head Compatibility: Piston dome or dish configuration must match your cylinder head chamber volume and valve relief requirements. Most stroker kit manufacturers list compatible heads with their assemblies for this reason.

- Block Clearancing Requirements: Longer strokes may require grinding the bottom of cylinder bores, relieving main cap areas, or clearancing the camshaft. Know your clearancing needs before ordering components.

- Balancing Configuration: According to Summit Racing's technical department, Chevy 305 and 350 engines typically run internally balanced configurations, while Chevy 400 and 454 engines often require external balancing with weighted harmonic dampers and flywheels.

- Harmonic Damper Selection: Your damper must match the crankshaft's balance specification and snout dimensions. Internally balanced cranks use neutral-balance dampers; externally balanced setups require specific counterweighted dampers.

For 383 stroker kit applications—one of the most popular small-block Chevy combinations—the typical recipe pairs a 3.75" stroke crankshaft with a 0.030" overbored 350 block. Both cast steel and forged options exist at various price points, with forged versions recommended when power goals exceed 500 horsepower or power adders enter the equation.

When building a 454 forged crankshaft combination for big-block applications, the larger main and rod journal sizes provide inherent strength advantages. According to technical sources, big-block crankshafts feature thicker cross-sections between main and rod journals, allowing higher horsepower thresholds before requiring billet construction.

Key Considerations When Selecting Aftermarket Forged Cranks

- Steel alloy grade matters: 4340 steel offers superior strength over 4140 or 5140 alloys—pay attention to material specifications rather than assuming all forgings are equivalent.

- Manufacturing process quality: Non-twist forging methods create less internal stress than twist-forged alternatives. Reputable manufacturers use more complex dies to forge all crank throws simultaneously.

- Heat treatment and finishing: Look for induction-hardened journals, shot-peened surfaces, and radiused journal fillets that indicate professional-grade production standards.

- Verify actual forging vs. marketing claims: Some budget "forged" crankshafts are actually cast components with surface treatments. Purchase from established manufacturers with documented quality control processes.

- Complete kit vs. individual components: Pre-matched rotating assemblies from manufacturers like Scat and Callies eliminate compatibility guesswork and often include professional balancing.

- Supplier expertise: According to industry experts, the most important step is asking detailed questions about application, budget, and expectations before finalizing component selection.

The quality variation among forged crankshafts cannot be overstated. A budget forging from an unknown supplier may actually deliver worse performance than a premium cast steel option from an established manufacturer. According to Scat's Tom Lieb, the company uses its expertise from thousands of rotating assemblies to match parts appropriately—ensuring customers receive components compatible with their wallets and performance expectations.

With so many options available, how do you systematically compare materials and identify the right choice for your specific application? A comprehensive head-to-head breakdown helps cut through the confusion.

Complete Crankshaft Material Comparison Table

You've seen the individual breakdowns—now let's put cast iron, cast steel, and forged steel crankshafts side by side where the differences become impossible to ignore. This comprehensive comparison addresses the gap most resources leave unfilled: application-specific guidance that matches material properties to real-world demands across street driving, drag racing, circle track, marine, and diesel applications.

When evaluating cast steel vs forged steel options, or deciding whether cast iron still makes sense for your build, the details matter. The table below synthesizes technical specifications from engineering research and industry sources to provide the clearest picture possible.

Material Properties Head-to-Head Breakdown

Think of this comparison as your decision matrix. Each material excels in specific areas while showing limitations in others. The forged cast distinction becomes most apparent under demanding conditions, but even nodular iron vs cast iron differences matter when you're optimizing for budget applications.

| Property | Forged Steel (4340) | Cast Steel | Cast Iron (Nodular) |

|---|---|---|---|

| Tensile Strength | 145,000+ psi | 65,000–100,000 psi | 70,000–95,000 psi |

| Fatigue Resistance | Excellent – directional grain flow prevents crack propagation | Good – improved over iron but lacks aligned grain structure | Fair – random grain pattern allows stress accumulation |

| Typical Weight | Lightest option – superior strength-to-weight allows material removal | Moderate – heavier than forged, lighter than iron | Heaviest – density creates larger counterweights |

| Machinability | Challenging – harder material requires specialized equipment | Good – standard machining procedures apply | Excellent – easy grinding and low tooling costs |

| Cost Range | $800–$2,500+ (premium options exceed $3,000) | $400–$700 | $200–$400 (often salvage/reground) |

| Horsepower Ceiling | 1,000+ HP (alloy dependent) | 450–550 HP | 350–450 HP (small-block); 500–600 HP (big-block) |

| Ideal Applications | Racing, forced induction, nitrous, sustained high-RPM | Hot street builds, mild power adders, weekend track use | Stock rebuilds, daily drivers, restorations |

| Failure Mode | Gradual fatigue (rare) – typically survives beyond engine's lifespan | Bending under extreme load – provides warning signs | Sudden brittle fracture – often catastrophic with little warning |

According to engineering analysis, the forging process creates a phenomenon called directional grain flow where the metal's internal structure aligns along the crankshaft's contours. This uninterrupted grain flow enhances strength, toughness, and fatigue resistance precisely where forces concentrate. Cast versus forged irons and steels simply cannot replicate this molecular alignment through any casting process.

Cost vs Performance Value Analysis

Here's where the decision crystallizes for most builders: what's the actual value proposition for each material? Spending $2,000 on a forged crank for a 300-horsepower grocery-getter wastes money. But gambling with a $300 cast iron piece in a 600-horsepower turbo build invites catastrophic failure.

Application-Specific Recommendations:

Street Driving (Daily/Weekend Cruiser)

- Power under 400 HP: Cast iron remains perfectly adequate—save your budget for other upgrades

- Power 400–500 HP: Cast steel offers meaningful improvement at reasonable cost

- Power 500+ HP: Forged steel becomes the only sensible choice for reliability

Drag Racing

- Bracket racing (mild): Cast steel handles occasional passes with power under 500 HP

- Serious competition: Forged steel mandatory—repeated high-stress launches destroy cast materials

- Pro-level builds: Premium forged or billet construction for engines exceeding 800 HP

Circle Track Racing

- Entry-level classes: Quality cast steel survives most Saturday night racing with proper maintenance

- Competitive programs: Forged steel provides the fatigue resistance sustained high-RPM operation demands

- Professional touring: Premium forged cranks justify their cost through extended service intervals

Marine Applications

- Recreational use: Cast steel handles typical marine duty cycles adequately

- Performance boats: Forged steel essential—marine engines often run under load for extended periods, accelerating fatigue in lesser materials

- Offshore/commercial: Premium forged construction prevents failures far from shore

Diesel Applications

- Stock replacement: Factory cast iron or cast steel typically sufficient for stock power levels

- Modified performance diesels: Modern high-pressure common rail systems create extreme combustion forces—forged steel recommended for any significant power increase

- Competition diesel pulling: Premium forged or billet mandatory for the instantaneous loads competition diesels experience

Understanding Failure Modes and Warning Signs

Each material fails differently, and recognizing warning signs can prevent catastrophic engine destruction. According to failure analysis research, fatigue failure represents the dominant mechanism in crankshaft destruction—and the material's response to repeated stress cycles determines how quickly and dramatically failure occurs.

Cast Iron Failure Characteristics:

- Brittle fracture with minimal warning—cracks propagate rapidly once initiated

- Failure often occurs at journal fillets where stress concentrates

- Microscopic porosity and inclusions from casting create stress risers

- Warning signs: Unusual vibrations, bearing wear patterns, or metallic debris in oil may precede failure—but often there's no advance notice

Cast Steel Failure Characteristics:

- More ductile than iron—tends to bend before breaking

- Visible deformation may occur before complete fracture

- Better grain structure reduces crack initiation compared to iron

- Warning signs: Progressive bearing clearance changes, oil pressure fluctuations, or harmonic damper wobble indicate developing problems

Forged Steel Failure Characteristics:

- Extremely rare in properly matched applications

- When failure occurs, it typically results from manufacturing defects, improper heat treatment, or operation far beyond design limits

- Directional grain flow resists crack propagation even when damage initiates

- Warning signs: Similar to cast steel but with much greater margin before catastrophic failure

"The isotropic nature of cast iron's microstructure means there isn't the same directional resistance to crack propagation. Cracks that initiate in cast components require less energy to grow compared to forged alternatives where they must cross aligned grain boundaries."

Understanding these failure characteristics helps you make informed decisions about material selection. A cast iron crankshaft in a stock rebuild presents acceptable risk—the same component in a high-boost application becomes a liability waiting to destroy your engine and potentially injure bystanders.

The forged steel vs cast steel comparison ultimately comes down to application demands. Cast steel occupies legitimate territory for street performance builds staying under 550 horsepower without sustained high-RPM operation. Push beyond those limits, and forged steel's superior fatigue resistance becomes essential rather than optional.

With these material properties and application guidelines established, the next question becomes practical: when does your current crankshaft require upgrading, and how do you identify what material you're working with?

When to Upgrade from Cast to Forged Crankshafts

You've reviewed the material comparisons and application guidelines—but here's the practical question keeping you up at night: does your current build actually need a forged upgrade, or would that money serve you better elsewhere? This decision flowchart cuts through the confusion with specific thresholds and identification techniques that remove guesswork from your upgrade path.

According to KingTec Racing's technical analysis, waiting until your crankshaft fails means you're already too late. A crank failure typically destroys the entire engine—connecting rods punch through blocks, bearing material contaminates every oil passage, and rebuild costs can exceed $5,000 before you've even addressed the original problem. Proactive upgrading based on application demands protects your investment.

Power Thresholds That Demand a Forged Upgrade

Think about what happens when you add boost, nitrous, or displacement to your engine. Every modification that increases cylinder pressure or rotating mass multiplies the forces your crankshaft must endure. Your stock cast crank—often cast iron or low-grade steel—was engineered for factory power levels, not the explosive torque spikes of a boosted setup.

Here's when upgrading becomes essential rather than optional:

- Forced induction installations: Whether you're bolting on a turbocharger or supercharger, cylinder pressures increase dramatically. According to industry experts, even moderate boost levels (8-12 psi) push many engines beyond cast crankshaft comfort zones. Symptoms like engine knock under boost, uneven crank balance, or torsional flex at high RPM indicate your factory crank is struggling.

- High-RPM operation beyond 7,500 RPM: Track builds, drift cars, and road racing engines spinning regularly above factory redlines experience massive cyclical stress. Cast cranks suffer metal fatigue under these conditions, developing cracks that lead to sudden failure. If you're building a 283 crankshaft combination for vintage racing or a modern high-revving screamer, forged construction provides the fatigue resistance sustained operation demands.

- Stroker conversions: Increasing stroke length multiplies torque output while simultaneously increasing lateral forces on the crankshaft. A 302 crank swapped into a stroker application experiences entirely different stress patterns than its original design intended. The increased crank throw creates greater leverage that cast materials weren't engineered to handle.

- Nitrous oxide systems: Even moderate nitrous shots (150+ horsepower) create instantaneous stress spikes that exceed normal combustion loads. According to technical sources, nitrous-equipped engines demand forged bottom ends because the explosive nature of nitrous-assisted combustion concentrates forces far beyond what cast construction reliably handles.

- Previous bottom-end failure: If you've already cracked a crankshaft, spun a bearing, or found metal shavings in your oil pan, your OEM crank has already proven insufficient. Replacing it with another stock unit simply resets the failure countdown.

Decision Flowchart for Your Build

Sounds complex? This step-by-step decision sequence simplifies the upgrade question. Work through each point in order—your answers determine whether forged steel becomes mandatory or optional for your specific application:

- Identify your current crankshaft material. Before deciding on upgrades, confirm what you're working with. SBC crankshaft casting numbers stamped on the first counterweight or front flange reveal material type and original application. Cross-reference these SBC crank casting numbers with factory specifications to verify whether you're starting with cast iron, nodular iron, or cast steel.

- Determine your realistic horsepower target. Be honest here—not your dream number, but what your combination will actually produce. Stock rebuilds staying under 400 horsepower rarely justify forged construction costs. Builds targeting 450-550 horsepower enter the gray zone where cast steel becomes minimum acceptable specification. Above 550 horsepower, forged steel transitions from "nice to have" to "essential insurance."

- Evaluate power adder plans. Planning turbo, supercharger, or nitrous? Add these projected gains to your baseline horsepower estimate. Even a mild 75-100 shot nitrous kit pushes many engines past cast material thresholds. Forced induction applications should assume forged bottom-end requirements regardless of baseline power.

- Assess RPM operating range. Engines that rarely exceed 6,000 RPM place significantly less fatigue stress on crankshafts than those regularly spinning to 7,500+ RPM. High-revving applications accelerate material fatigue in cast components, making forged construction increasingly important as your operational RPM ceiling rises.

- Consider usage pattern. Weekend cruisers experience fundamentally different stress patterns than dedicated track cars or drag racers. Sustained racing use—repeated high-stress launches, extended high-RPM operation, or competitive endurance events—demands fatigue resistance that only forged construction provides reliably.

- Calculate failure cost versus upgrade cost. A quality forged crankshaft costs $800-$2,500 depending on application and manufacturer. Complete engine failure from crankshaft destruction typically exceeds $5,000 in parts and labor—not including downtime, towing, and potential collateral damage. This risk calculation often tips the scales toward proactive upgrading.

Identifying Your Current SBC Crank Material

Before spending money on upgrades, verify what's currently spinning inside your block. SBC crank identification relies on casting numbers combined with visual inspection techniques that reveal material composition.

For small-block Chevy applications, locate the casting number stamped on the crankshaft's first counterweight or front flange. Common SBC crank casting numbers include:

- 3932442: Found in many 350 applications—typically nodular iron, two-piece rear main seal

- 14088526: One-piece rear main seal design used in later 350 engines

- 10243552: Common in 1996-2002 Vortec applications

Visual inspection provides additional confirmation. Cast iron cranks display rougher surface texture near counterweights, visible casting seams, and a duller gray appearance when cleaned. Steel cranks—whether cast or forged—show smoother surfaces and different coloration. Forged cranks typically display evidence of the forging process: parting lines that follow the crank's contours rather than straight casting seams, plus denser, more refined surface characteristics.

The magnetic particle inspection technique (Magnafluxing) reveals subsurface cracks and material defects that visual inspection misses. Any crankshaft destined for high-performance use should undergo this testing regardless of apparent condition—internal defects from previous stress cycles can cause sudden failure even when surfaces appear pristine.

With your current crankshaft material identified and upgrade decision made, the final step involves matching your selection to specific build goals and budget constraints.

Final Crankshaft Recommendations by Application

You've absorbed the metallurgical details, studied the comparison tables, and worked through the decision flowchart. Now it's time for definitive answers: which crankshaft material belongs in your engine? Whether you're freshening a small block Chevy for weekend cruising or building a chevy big block destined for serious competition, this final synthesis translates everything we've covered into actionable guidance you can apply immediately.

The forged crank vs cast debate ultimately comes down to matching material capabilities to application demands. Overspending wastes budget that could fund other improvements. Underspending invites catastrophic failure that destroys far more than just the crankshaft. Here's how to get it right the first time.

Your Crankshaft Selection Based on Build Goals

Think of these ranked recommendations as your definitive guide. Each tier addresses specific power levels, usage patterns, and budget considerations—ensuring you invest appropriately without gambling your engine's survival on inadequate components.

-

Budget Street Rebuilds (Under 400 HP): Cast Iron Acceptable

Rebuilding a numbers-matching restoration or freshening a daily driver that stays naturally aspirated under factory power levels? Your stock cast iron crankshaft—or a quality replacement—handles this duty reliably. According to Engine Labs' technical experts, cast-iron crankshafts work fine in the majority of street applications, especially restorations. The money saved here funds quality bearings, rings, and proper machining that matter more for longevity in mild builds. Just ensure your cast crank passes Magnaflux inspection before reuse—internal cracks from previous service can cause sudden failure regardless of power level.

-

Hot Street and Mild Performance (400-550 HP): Cast Steel Optimal

Building a 400 SBC crankshaft kit combination for weekend fun? Assembling a mild stroker with occasional track duty? Cast steel crankshafts from reputable manufacturers like Scat crank or Eagle deliver the strength improvement your build demands without breaking the budget. This sweet spot covers most street performance applications—engines with mild power adders, weekend autocross duty, or spirited driving that stays under 6,500 RPM. According to Engine Builder Magazine, a 383 Chevy small block making 400 horsepower doesn't need a $1,000 forged crank when a quality $300-$600 cast steel unit handles everything the application demands.

-

Serious Performance and Racing (550+ HP): Forged Steel Mandatory

Planning forced induction, substantial nitrous, or dedicated racing use? Forged steel becomes non-negotiable. The fatigue resistance, superior tensile strength, and directional grain flow that forging creates provide the reliability margin serious builds demand. According to Hot Rod's technical analysis, quality 4340 forged crankshafts reliably handle 1,500+ horsepower applications—well beyond what any cast alternative safely supports. The additional investment protects against catastrophic failure that destroys engines and potentially injures bystanders.

Final Verdict for Street, Strip, and Everything Between

Here's what separates successful builds from expensive lessons: understanding that crankshaft material selection works alongside manufacturing quality to determine long-term reliability. A premium forged crank from a reputable manufacturer paired with proper break in oil procedures and quality bearings delivers decades of service. A budget casting from an unknown supplier fails regardless of the steel grade stamped on the box.

For builders and manufacturers sourcing forged crankshafts in volume, partnering with an IATF 16949-certified precision forging supplier ensures consistent quality across production runs. This automotive industry certification—recognized globally for rigorous process controls—separates professional-grade components from commodity parts. Suppliers like Shaoyi (Ningbo) Metal Technology deliver precision hot forging backed by in-house engineering and documented quality control, whether you need rapid prototyping or high-volume production for rotating assembly components.

The bottom line? Match material to application, verify manufacturing quality, and invest appropriately. Cast iron serves budget rebuilds adequately. Cast steel handles street performance reliably. Forged steel protects serious investments definitively. Every dollar spent on the right crankshaft for your build pays dividends in reliability, longevity, and peace of mind—whether you're cruising the boulevard or chasing records at the strip.

"What a crank looks like when it's produced is all a balancing act between weight, strength, improving performance, intended application, cost, availability of supporting parts and production feasibility." — Alan Davis, Eagle Specialty Products

Your crankshaft choice defines engine longevity. Armed with this knowledge, you're equipped to make the decision that keeps your rotating assembly spinning reliably for years to come.

Frequently Asked Questions About Crankshaft Materials

1. What is the best material for a crankshaft?

SAE-4340 alloy forged steel represents the premium choice for high-performance crankshafts, delivering tensile strength exceeding 145,000 psi with superior fatigue resistance. This material excels in racing, forced induction, and high-horsepower applications due to its directional grain flow that prevents crack propagation. However, cast steel adequately serves street performance builds under 550 horsepower, while cast iron remains suitable for stock rebuilds under 400 horsepower. The best material depends on your specific power goals, usage pattern, and budget constraints.

2. What are the benefits of a forged crankshaft?

Forged crankshafts offer unparalleled strength, durability, and fatigue resistance through their unique directional grain flow structure. The forging process compresses and aligns the steel's molecular structure along the component's contours, creating continuous grain flow that distributes stress efficiently. This provides tensile strength nearly double that of cast alternatives, handles power levels exceeding 1,000 horsepower, and survives millions of stress cycles without crack initiation. IATF 16949-certified manufacturers like Shaoyi ensure consistent quality through precision hot forging and rigorous quality control processes.

3. What is the difference between a forged crankshaft and a cast crankshaft?

The fundamental difference lies in grain structure and manufacturing process. Cast crankshafts are formed by pouring molten metal into molds, creating random grain patterns resembling loosely packed sand. Forged crankshafts are shaped under immense compressive forces, creating aligned directional grain flow that follows the component's contours. This structural difference translates to significant performance gaps: forged cranks deliver 145,000+ psi tensile strength versus 70,000-100,000 psi for cast options, along with dramatically superior fatigue resistance for demanding applications.

4. How can I tell if my crankshaft is cast or forged?

Identify your crankshaft material through visual inspection and casting number verification. Cast iron cranks display rougher surface texture near counterweights, visible straight casting seams, and a duller gray appearance. Forged cranks show parting lines that follow the crank's contours rather than straight seams, plus denser, more refined surfaces. For small-block Chevy applications, locate casting numbers stamped on the first counterweight or front flange, then cross-reference with factory specifications. Magnaflux testing reveals internal defects invisible to visual inspection.

5. At what horsepower level should I upgrade to a forged crankshaft?

Power thresholds for upgrading vary by application: cast iron handles up to 400 horsepower for small-blocks and 500-600 horsepower for big-blocks in street applications. Cast steel serves builds producing 400-550 horsepower reliably. Above 550 horsepower, forged steel becomes essential for reliability. Additionally, any forced induction, substantial nitrous systems (150+ HP shots), sustained operation above 7,500 RPM, or dedicated racing use demands forged construction regardless of baseline power levels due to the instantaneous stress spikes these applications create.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —