Why Forged Carbon Fiber Vs Forged Aluminum Matters for Your Business

The Ultimate Showdown Between Two Premium Performance Materials

You're standing at a crossroads that separates good performance from exceptional performance. Whether you're upgrading your sportbike, building a high-performance vehicle, or sourcing components for aerospace applications, the choice between forged carbon fiber and forged aluminum can define your project's success. But here's what most comparisons miss: these two materials share the word "forged," yet they're created through completely different manufacturing philosophies.

Why the Forged vs Forged Debate Matters

When you compare carbon fiber vs aluminum in their forged forms, you're not just comparing two materials. You're evaluating two distinct engineering approaches that deliver premium performance through fundamentally different paths. Most online comparisons lump all carbon fiber together or treat aluminum as a single category. That's a mistake that could cost you thousands of dollars and compromise your results.

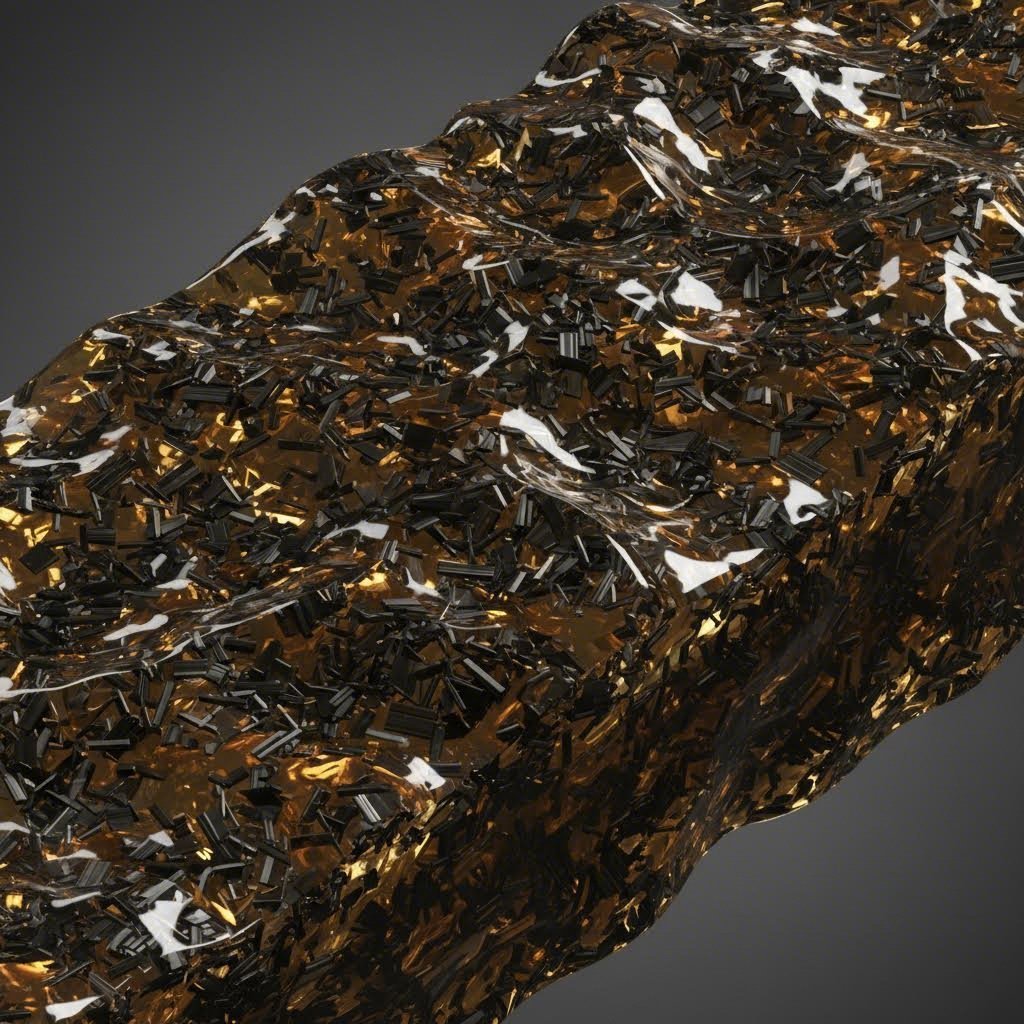

Forged carbon fiber involves compression molding where chopped carbon fiber strands are mixed with resin and compressed under high heat and pressure. This creates that distinctive marbled appearance you've probably seen on high-end carbon fiber plates and components. According to Easy Composites, the compression process helps squeeze out air and excess resin, resulting in solid, high-performance parts with strength in all directions.

Forged aluminum, on the other hand, uses die forging to compress solid metal billets under extreme pressure. This process aligns the grain structure, making it far stronger than cast aluminum alternatives.

Understanding Two Different Forging Philosophies

Think of it this way: forged carbon creates strength through composite chemistry, while forged aluminum achieves it through metallurgical transformation. Neither approach is universally "better." Each excels in specific scenarios based on your priorities.

Throughout this comparison, we'll evaluate these premium materials across the factors that actually matter for real-world applications:

- Strength-to-weight ratio: Where every gram counts

- Cost considerations: Initial investment versus long-term value

- Repairability: What happens when things go wrong

- Thermal properties: Heat management in demanding conditions

- Application suitability: Matching material to purpose

By the end, you'll understand exactly when forged carbon vs carbon fiber alternatives make sense, why aluminum vs carbon fiber isn't a simple winner-take-all decision, and how to match these materials to your specific application needs.

How We Evaluated These Premium Materials

Sounds complex? Comparing forged carbon fiber vs forged aluminum fairly requires more than picking a favorite and running with it. You need a structured framework that accounts for how each material actually performs under real-world conditions. That's exactly what we've developed here.

Before diving into specifications, let's acknowledge something important: these materials serve different masters. Understanding carbon fiber cost alongside carbon fiber density gives you only part of the picture. You also need to consider how strong is carbon fiber in your specific application and whether its unique carbon fiber structure delivers advantages you can actually use.

Our Comparison Framework

We've built our evaluation around six core criteria that matter most when selecting between these premium materials. Unlike comparisons that focus solely on one metric, this framework captures the complete performance picture:

- Mechanical properties: Tensile strength, elastic modulus, and fatigue resistance under cyclic loading

- Weight-to-strength ratios: Specific strength calculations that account for density differences

- Thermal performance: Heat conductivity, dissipation capabilities, and temperature tolerance

- Manufacturing complexity: Production requirements, tooling needs, and scalability factors

- Cost analysis: Raw material expenses, processing costs, and total cost of ownership

- Real-world application suitability: How each material performs in actual use cases

This approach differs from typical comparisons you'll find online. Many articles treat carbon fiber versus fiberglass as interchangeable with aluminum comparisons. They're not. Each material category has distinct properties that require separate evaluation standards.

Key Performance Metrics Explained

Let's break down what these metrics actually mean for your decision-making process.

Specific strength represents the strength-to-weight ratio of a material. According to research from Grand Valley State University's School of Engineering, specific strength equals tensile or yield strength divided by the material's density. A material with high specific strength delivers excellent performance without adding unnecessary weight. This metric proves especially valuable when comparing materials with vastly different densities.

Specific modulus indicates stiffness relative to weight. The same research demonstrates that metals generally exhibit higher specific modulus values than polymers, meaning they're less prone to deformation under equal stress. This directly impacts how components behave under load.

When evaluating forging processes, remember these fundamental differences:

- Carbon fiber forging: Compression molding combines chopped carbon strands with resin under heat and pressure. This creates isotropic properties with strength distributed equally in all directions.

- Aluminum forging: Die forging compresses solid metal billets under extreme pressure, aligning grain structure for enhanced directional strength compared to cast alternatives.

The distinction matters because carbon fiber versus fiberglass comparisons often ignore these processing differences entirely. Forged materials behave differently than their non-forged counterparts, and that difference shows up in every performance metric we'll examine.

With this framework established, we can now examine each material in detail, starting with a deep dive into forged carbon fiber's unique characteristics and capabilities.

Forged Carbon Fiber Deep Dive and Performance Analysis

Imagine holding a component that's up to 70% lighter than its steel equivalent while delivering comparable strength. That's the promise of carbon fiber forged through compression molding. But understanding exactly how this material achieves such remarkable properties requires looking beneath that distinctive marbled surface.

Forged carbon fiber, also known as forged composite, represents a fundamentally different approach to carbon fiber materials. Unlike traditional woven carbon fiber that relies on carefully stacked layers of continuous fiber fabric, this variant takes a more unconventional path to performance.

The Compression Molding Advantage

The manufacturing process begins with carbon filament chopped into short segments, typically ranging from 5 to 50 millimeters in length. According to RC Wing, these chopped strands are thoroughly mixed with a resin system, usually epoxy, along with a catalyst to form what's called a bulk molding compound.

Here's where the magic happens. This pre-mixed material gets placed into a pre-heated metal mold and subjected to extreme compression. We're talking pressures up to 1,000 psi combined with carefully controlled temperatures. Under these conditions, the material flows to fill every contour of the mold cavity while the resin cures and locks the fibers permanently in place.

The result? That characteristic swirled, marbled pattern that makes every forged carbon component genuinely one-of-a-kind. But this isn't just about aesthetics. The random fiber orientation creates something far more valuable: isotropic strength.

Traditional woven carbon fiber excels along its fiber direction but shows weakness perpendicular to it. Forged carbon fiber eliminates this limitation entirely. The short fibers distribute uniformly in all directions, granting consistent strength and stiffness regardless of which way forces are applied. This makes it ideal for complex carbon fiber shapes where multi-directional stresses are common.

Strength Profile and Limitations

When evaluating carbon fiber materials for your application, understanding both capabilities and constraints proves essential for making smart decisions.

Pros of Forged Carbon Fiber

- Exceptional strength-to-weight ratio: Comparable to titanium in many applications while being approximately 40% lighter

- Isotropic properties: Equal strength in all directions eliminates concerns about delamination under multi-directional stress

- Complex geometry capability: Compression molding handles intricate designs with curves, undercuts, and detailed features that woven carbon struggles to achieve

- Production efficiency: Faster cycle times compared to labor-intensive traditional layup processes, making it more suitable for higher-volume manufacturing

- Superior impact and wear resistance: The random fiber distribution provides more reliable performance in complex stress environments

- Unique aesthetic appeal: The carbon fiber black marbled patterns create premium visual differentiation

Cons of Forged Carbon Fiber

- Higher carbon fiber price point: While more affordable than woven carbon fiber for mass production, it remains 2-3 times more expensive than aluminum alternatives

- Limited repairability: Damaged components typically require complete replacement rather than simple repairs. Unlike metals that can be welded or patched, forged carbon demands specialized techniques

- UV sensitivity: Exposure to ultraviolet light degrades the resin matrix over time, causing discoloration and potential material weakening. Outdoor applications require UV-resistant coatings

- Surface scratch vulnerability: Without protective coatings, the material can scratch more easily than some metals and ceramics

- Temperature limitations: Standard resin systems have lower temperature tolerance compared to metals, restricting use in extreme heat applications

Best Applications for Forged Carbon

Where does forged carbon fiber truly shine? In applications where weight savings deliver measurable performance advantages and premium pricing finds acceptance.

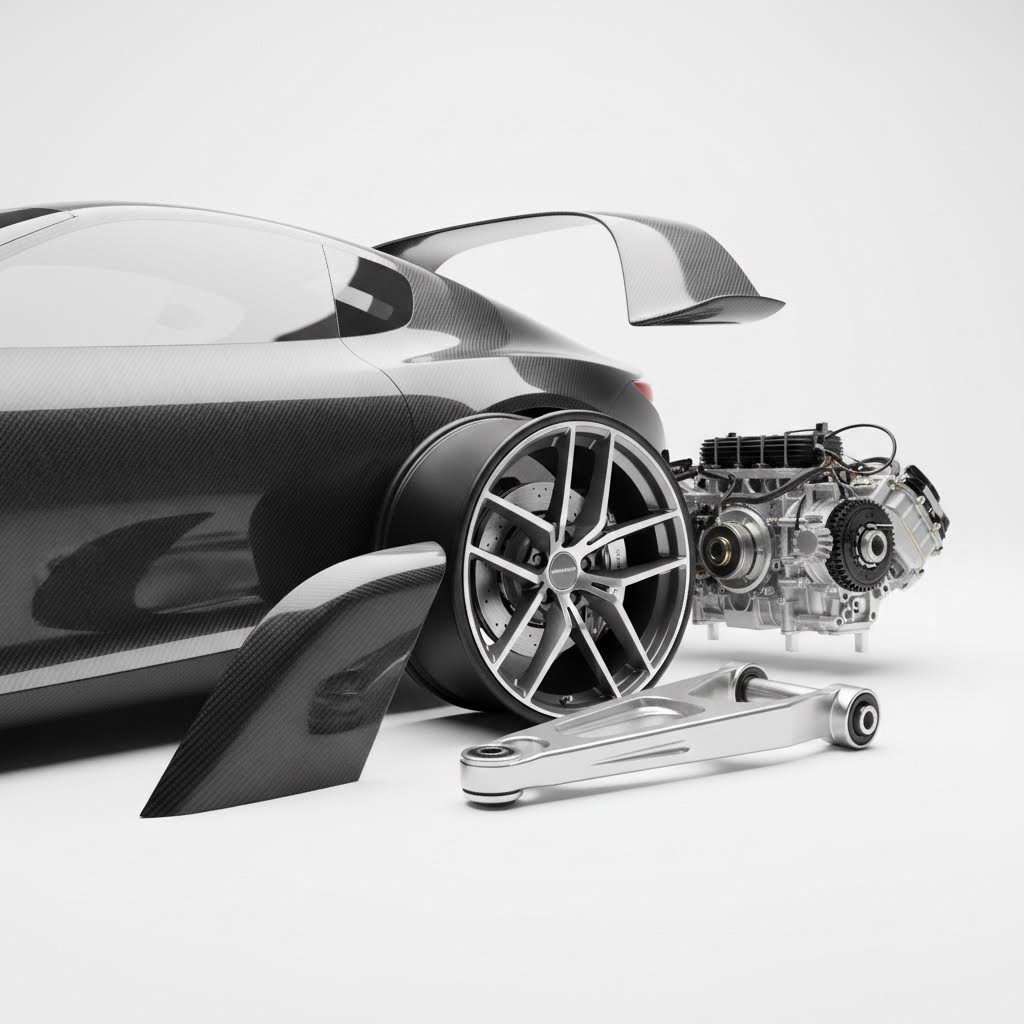

Automotive industry applications represent one of the largest markets. Performance and supercars leverage forged carbon for body panels like hoods and doors, interior components including dashboard panels and paddle shifters, and structural elements like seat frames. According to YICHOU, as manufacturing costs decrease, even mass-produced vehicles are adopting forged carbon for engine internals like rocker arms and connecting rods to reduce reciprocating mass and improve throttle response.

Aerospace and marine sectors utilize forged carbon for drone fuselages, propellers, aircraft interior panels, and control mechanisms. Marine applications include steering wheels, instrument panels, and speedboat components where lightweight properties combine with saltwater corrosion resistance.

Consumer electronics and luxury goods showcase forged carbon's premium appeal. Carbon fiber phone cases deliver both protection and exclusivity. High-end watch cases, laptop shells, and designer eyewear frames leverage the material's lightweight durability and unique visual patterns. Carbon fiber helmets in motorsports and cycling benefit from the material's impact absorption characteristics.

Sports equipment manufacturers have embraced forged carbon for hockey sticks, bicycle frames, tennis rackets, golf club heads, and fishing rods. The material provides superior impact absorption and power transfer compared to traditional alternatives.

The common thread across these applications? Each represents a scenario where customers willingly pay premium carbon fiber prices because the weight savings, aesthetic appeal, or performance advantages justify the investment.

Now that you understand forged carbon fiber's capabilities and ideal use cases, let's examine how forged aluminum stacks up in the same evaluation framework.

Forged Aluminum Capabilities and Real-World Performance

When you need components that withstand punishing conditions day after day, forged aluminum delivers a combination of strength, reliability, and practicality that's hard to match. While forged carbon fiber captures headlines with its exotic appearance, forged aluminum quietly powers critical applications across automotive, aerospace, and industrial sectors. Understanding why requires examining the metallurgical transformation that makes this material exceptional.

The question of alloy vs aluminum often comes up in material discussions, but here's the reality: forged aluminum alloys represent the gold standard for applications demanding consistent performance under stress. Unlike cast alternatives that can harbor hidden weaknesses, the forging process creates a fundamentally superior material structure.

Die Forging Process Explained

The transformation from raw aluminum billet to high-performance component happens through controlled violence. Die forging subjects solid aluminum billets to extreme compressive forces, often exceeding several thousand tons of pressure. This isn't gentle shaping. It's a fundamental restructuring of the metal's internal architecture.

According to Southwest Aluminum, the forging process refines the grain structure of aluminum, aligning the metal grains along the lines of force. This alignment creates a much stronger and more uniform material compared to casting. The process works like kneading bread dough. Each compression stroke reorganizes the internal structure into something more cohesive and powerful.

Here's how the process typically unfolds:

- Billet preparation: Aluminum alloy billets are heated to optimal forging temperatures, typically between 350-500°C depending on the specific alloy

- Die placement: The heated billet enters precision-machined dies designed for the specific component geometry

- Compression: Hydraulic or mechanical presses apply massive force, flowing the metal into every contour of the die cavity

- Heat treatment: Solution treatment and artificial aging optimize the final mechanical properties

- Finishing: Machining, surface treatment, and quality inspection complete the process

The result? Components with predictable, reliable strength characteristics that engineers can confidently specify for critical applications.

Mechanical Advantages of Grain Alignment

Why does grain alignment matter so much? Imagine the difference between a bundle of sticks tied randomly versus carefully arranged in parallel. The aligned bundle resists bending forces far more effectively. That's essentially what happens at the microscopic level inside forged aluminum.

When comparing carbon fiber vs steel or aluminum alternatives, understanding failure modes becomes critical. Forged aluminum offers predictable behavior under stress. The aligned grain structure creates consistent mechanical properties throughout the component, eliminating weak points where failures typically originate.

Research from Southwest Aluminum demonstrates that clients who switch from cast to forged aluminum often report fewer part failures and improved product longevity. An automotive sector client switching to forged aluminum suspension components saw dramatic reductions in warranty claims related to part breakage.

The mechanical advantages extend across multiple performance dimensions:

| Property | Forged Aluminum | Cast Aluminum |

|---|---|---|

| Grain Structure | Refined and aligned, continuous flow | Random, potentially porous |

| Tensile Strength | 20-30% higher | Baseline |

| Fatigue Resistance | Superior cyclic load tolerance | Prone to fatigue cracking |

| Ductility | Higher deformation before failure | More brittle behavior |

| Internal Defects | Virtually eliminated | Common voids and inclusions |

This structural integrity proves especially valuable for carbon fiber beams and carbon fiber structural beams alternatives where consistent load-bearing performance is non-negotiable.

Where Forged Aluminum Excels

Understanding where forged aluminum outperforms alternatives helps you match material to application. Several key advantages drive material selection decisions across industries.

Pros of Forged Aluminum

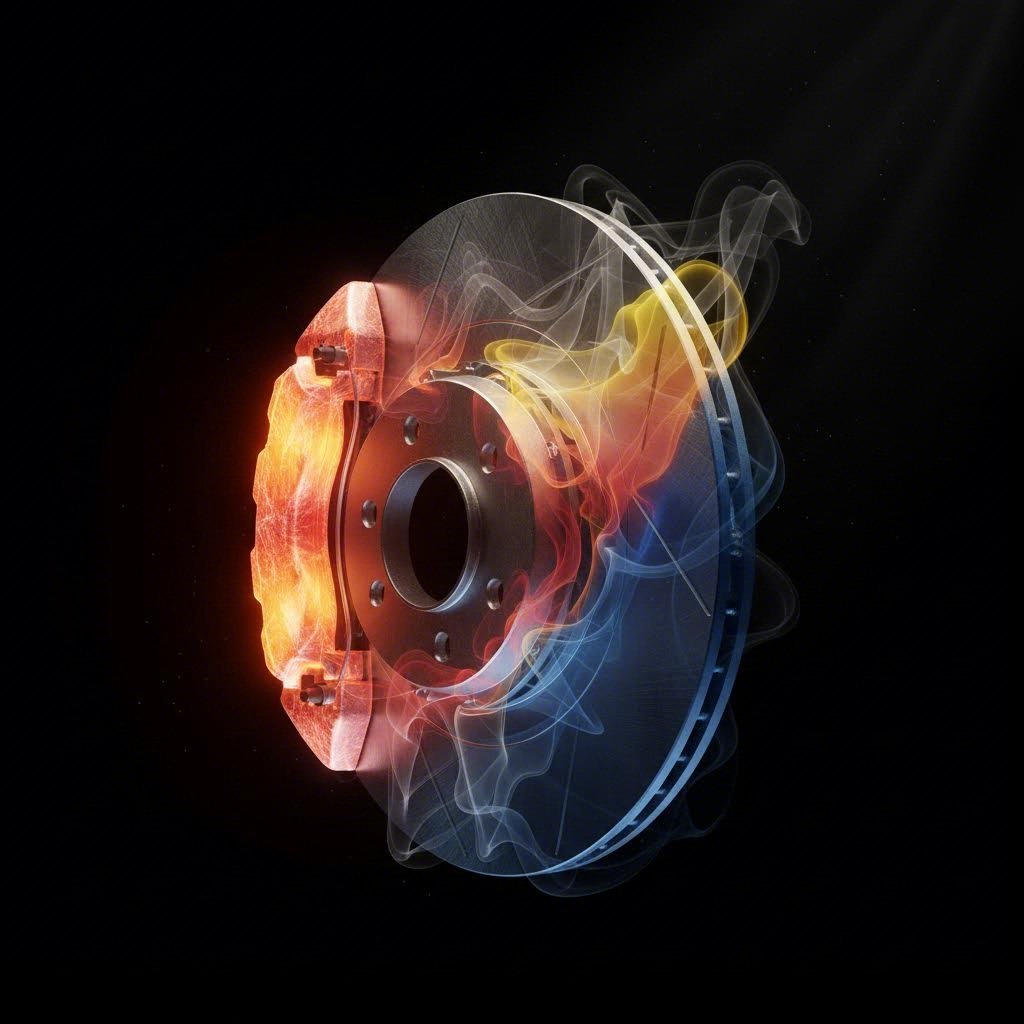

- Exceptional thermal conductivity: According to Metal Forging, the thermal conductivity of aluminum alloy is 3-4 times that of steel. This makes it ideal for brake components, engine parts, and any application where heat dissipation impacts performance and safety

- Outstanding repairability: Unlike composite materials, forged aluminum can be welded, machined, and refinished. Damaged components often require simple repairs rather than complete replacement

- Proven durability: Decades of real-world data confirm performance in demanding applications from forged wheels motorcycle enthusiasts trust to aerospace structural components

- Accessible pricing: Established manufacturing infrastructure and mature supply chains keep costs reasonable compared to exotic alternatives

- Excellent machinability: Secondary operations like drilling, threading, and surface finishing proceed without specialized equipment or techniques

- Corrosion resistance: Aluminum's natural oxide layer provides inherent protection, with additional treatments available for extreme environments

Cons of Forged Aluminum

- Higher weight than carbon fiber: When answering is carbon fiber stronger than aluminum on a weight-adjusted basis, carbon fiber typically wins. Aluminum's density of approximately 2.7 g/cm³ exceeds forged carbon fiber

- Initial tooling investment: Precision dies require significant upfront costs, though this amortizes across production volumes

- Multiple heating cycles: Complex components may require several heating stages, extending production timelines and increasing energy costs

- Design geometry limitations: Die forging handles robust shapes better than intricate, thin-walled designs

The thermal conductivity advantage deserves special attention. When components like brake calipers, suspension arms, or drive shafts operate under stress, they generate heat. Aluminum's superior heat dissipation prevents thermal buildup that could compromise performance or accelerate wear. This explains why a carbon fibre propshaft might offer weight savings, but forged aluminum driveshaft components remain standard in many high-performance applications where heat management proves critical.

For automotive manufacturers and suppliers, ensuring consistent quality across production volumes becomes paramount. This is where precision hot forging from IATF 16949 certified manufacturers makes a measurable difference. Organizations like Shaoyi (Ningbo) Metal Technology combine rigorous quality control with manufacturing flexibility, delivering components like suspension arms and drive shafts that meet exact specifications. Their capability spanning rapid prototyping in as little as 10 days to high-volume mass production addresses the full spectrum of automotive supply chain needs.

The established manufacturing infrastructure surrounding forged aluminum creates another practical advantage. Supply chains are mature, secondary suppliers are abundant, and engineering expertise is widely available. When you specify forged aluminum, you're tapping into decades of accumulated knowledge and proven processes.

With both materials now thoroughly examined, the natural question arises: how do they compare head-to-head on specific mechanical properties? Let's put these premium materials side by side.

Mechanical Properties Face-Off

Now that you understand what makes each material tick, let's get to the numbers. When evaluating forged carbon fiber vs forged aluminum for your specific application, raw data tells a clearer story than marketing claims. But here's the catch: comparing these materials isn't as straightforward as looking at a single specification sheet. Their fundamentally different structures mean they excel in different ways.

So, is carbon fiber strong enough for your application? That depends entirely on which type of strength matters most. Let's break down the key mechanical properties that drive real-world performance decisions.

| Property | Forged Carbon Fiber | Forged Aluminum (6082 T6) | Advantage |

|---|---|---|---|

| Density (g/cm³) | ~1.5 - 1.6 | ~2.7 | Carbon Fiber (40-45% lighter) |

| Tensile Strength (MPa) | 200 - 400 | 290 - 340 | Comparable (application dependent) |

| Specific Strength (kN·m/kg) | 130 - 260 | 105 - 125 | Carbon Fiber |

| Elastic Modulus (GPa) | 30 - 50 | ~70 | Aluminum (stiffer) |

| Fatigue Resistance | Good (random fiber distribution) | Excellent (aligned grain structure) | Aluminum |

| Impact Resistance | Moderate (brittle failure possible) | Excellent (ductile deformation) | Aluminum |

The density of carbon fiber compared to aluminum reveals the most dramatic difference. According to testing documented by Easy Composites, forged carbon fiber components can achieve weight reductions of 40-50% compared to equivalent aluminum parts while maintaining comparable mechanical performance. That carbon weight advantage compounds quickly when you're building performance vehicles or aerospace components where every gram matters.

Strength-to-Weight Ratio Breakdown

Here's where things get interesting. Raw tensile strength numbers can mislead you if you ignore density. A material that's twice as strong but three times heavier actually delivers worse performance in weight-sensitive applications.

Specific strength, calculated by dividing tensile strength by density, provides the clearer picture. Using this metric, forged carbon fiber typically outperforms forged aluminum by 25-100% depending on the specific formulations being compared. This explains why high-end automotive manufacturers specify carbon fiber for body panels and interior components where weight carbon reduction directly translates to better acceleration, braking, and fuel efficiency.

However, the comparison shifts when you consider stiffness. Forged aluminum's higher elastic modulus means it resists deformation more effectively under load. For structural applications where dimensional stability matters more than absolute weight savings, aluminum often proves the smarter choice.

Testing from Easy Composites demonstrated that forged carbon fiber components performed comparably to cast aluminum in real-world lever pull tests, with both materials showing similar ultimate failure loads. The critical difference? The carbon fiber component achieved this performance at significantly lower weight.

Fatigue and Durability Comparison

When components experience repeated stress cycles, like suspension parts absorbing thousands of road impacts or wheels rotating millions of times, fatigue resistance determines longevity. This is where forged aluminum's grain structure alignment delivers substantial advantages.

The forging process creates continuous grain flow that follows the component's contours. According to research from GVICHN, this aligned structure can absorb impact energy without catastrophic failure, often allowing for repair in cases of minor damage. The failure mode is predictable: aluminum deforms gradually before breaking, giving warning signs that trained eyes can catch during inspections.

Forged carbon fiber behaves differently under cyclic loading. The randomly oriented short fibers create isotropic properties, meaning strength distributes equally in all directions. This eliminates the directional weakness found in woven carbon fiber. However, composite materials can develop internal damage that's invisible to surface inspection. Micro-cracks may propagate through the resin matrix without obvious external signs until sudden failure occurs.

This distinction matters enormously for safety-critical applications. Consider motorcycle wheels: forged aluminum remains the dominant choice despite carbon fiber options existing. The aluminum wheel that contacts a pothole deforms predictably, maintaining structural integrity while showing visible damage. A carbon fiber wheel experiencing the same impact might appear undamaged yet harbor internal fractures that compromise future performance.

For applications involving carbon fiber nylon composites or hybrid materials, the fatigue characteristics become even more complex. Each material combination introduces unique failure mechanisms that require specialized testing and validation.

The bottom line: forged carbon fiber wins the weight carbon battle decisively, but forged aluminum provides superior predictability in failure modes and longer service life under cyclic loading conditions.

Understanding these mechanical trade-offs sets the stage for an equally important consideration: how each material handles heat. Thermal performance often determines which material survives in demanding applications, and that's exactly what we'll examine next.

Thermal Performance and Heat Dissipation Analysis

Picture yourself descending a mountain pass at 70 km/h, applying brakes repeatedly into hairpin turns. Where does all that kinetic energy go? Straight into heat, and how your components handle that thermal load can mean the difference between confident stopping power and dangerous brake fade. This is where the forged carbon fiber vs forged aluminum debate takes a critical turn that many comparisons overlook entirely.

Thermal properties might not grab headlines like strength-to-weight ratios, but they determine whether your components survive demanding conditions or fail when you need them most. Let's examine how these two materials manage heat in real-world applications.

Heat Management in High-Performance Applications

When components operate under stress, they generate heat. Brake calipers converting motion into stopping power, wheels absorbing road friction, suspension parts flexing thousands of times per mile. Each application creates thermal challenges that the material must handle.

According to testing documented by Superteam Wheels, continuous or heavy braking can raise rim temperatures to over 200°C (392°F). Poor heat management at these temperatures leads to serious consequences:

- Brake fade: Progressively weaker braking as heat builds up

- Material degradation: Resin softening in carbon composites or structural weakening

- Component failure: Warping, cracking, or even tire blowouts from overheated inner tubes

- Safety compromises: Unpredictable performance when you need reliability most

The way each material responds to these thermal demands shapes where it belongs in your application.

Thermal Conductivity Comparison

The numbers tell a stark story. Forged aluminum conducts heat approximately 15-30 times more effectively than forged carbon fiber. This isn't a subtle difference. It fundamentally changes how each material performs in heat-critical applications.

| Thermal Property | Forged Aluminum | Forged Carbon Fiber | Practical Impact |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 130 - 200 | 5 - 10 | Aluminum dissipates heat 15-30x faster |

| Heat Absorption Rate | Fast heating, fast cooling | Slow heating, slow cooling | Aluminum recovers between braking events |

| Temperature Tolerance | Stable to 300°C+ | Resin-limited (150-200°C typical) | Aluminum handles extreme heat better |

| Thermal Expansion | Higher (23.1-23.6 µm/m·°C) | Lower (0.1-0.5 µm/m·°C) | Carbon maintains dimensions under heat |

According to data from Rinasclta Bike, carbon fiber composites have thermal conductivity of just 5 to 10 W/m·K, compared to aluminum's 130 to 205 W/m·K. This makes aluminum far more effective at conducting heat away from critical contact points.

But here's the nuance: carbon fiber's lower thermal expansion means it maintains dimensional stability better under temperature swings. Components that must hold precise tolerances across varying conditions can benefit from this characteristic. It's not that carbon fiber has universally worse thermal properties. Rather, it excels at different thermal challenges than aluminum.

Real-World Implications for Component Selection

Understanding these thermal differences guides smarter material choices across specific applications.

Wheel selection illustrates the trade-offs clearly. When comparing carbon rims vs aluminum rims, the thermal question becomes critical for rim brake users. Aluminum rims heat up quickly but also cool down rapidly between braking events, maintaining consistent stopping power on long descents. A carbon fiber rim builds heat more slowly but retains it longer, creating cumulative thermal stress that can soften resins and compromise braking performance. This explains why many riders choosing carbon vs aluminum wheels for mountainous terrain still prefer aluminum when running rim brakes.

The cycling industry's experience with carbon fibre in bikes provides valuable lessons. Modern high-TG (glass transition temperature) resins and specialized brake pads have improved carbon rim performance significantly, but aluminum remains the gold standard for heat management on technical descents.

Brake components demand excellent heat dissipation. Calipers, rotors, and associated hardware must shed thermal energy rapidly to maintain performance through repeated braking cycles. Forged aluminum's thermal conductivity makes it the natural choice here. The material absorbs braking heat and disperses it quickly, preventing the thermal accumulation that causes fade.

Suspension components face different thermal challenges. While they don't generate as much heat as braking systems, they must maintain consistent properties across temperature variations. Forged aluminum's ability to dissipate heat from flexing and road impacts helps maintain predictable damping characteristics throughout demanding use.

The thermal verdict: forged aluminum wins decisively for heat-critical applications like brakes and high-stress cycling wheels, while forged carbon fiber's thermal stability suits applications where dimensional consistency matters more than heat dissipation.

Thermal performance represents just one piece of the ownership puzzle. The next critical consideration: what happens when something goes wrong? Cost and repairability often determine long-term value far more than initial performance specifications.

Cost Analysis and Repairability Considerations

You've seen the performance numbers. You understand the thermal trade-offs. But here's the question that often determines real-world material decisions: what does ownership actually cost? When comparing forged carbon fiber vs forged aluminum, initial purchase price tells only part of the story. The complete picture includes maintenance requirements, repair scenarios, and long-term value retention.

Think about it this way. That stunning carbon fiber decal-wrapped component might look incredible on day one, but what happens when it meets a stray rock on a mountain road? Understanding total cost of ownership helps you invest wisely rather than just impressively.

Initial Investment vs Long-Term Value

Let's address the elephant in the room: how much does carbon fiber cost compared to forged aluminum? The gap is substantial and worth understanding before committing your budget.

According to data from Carbon Fiber Gear, the raw material cost difference runs approximately 5 to 10 times higher for carbon fiber:

- Aluminum: Around $1.50 to $2.00 per pound

- Carbon fiber: $10 to $20 or more per pound

But raw material costs only begin the calculation. How expensive is carbon fiber when you factor in manufacturing complexity? The cost of carbon fiber components escalates further because production requires specialized equipment, precise environmental controls, and skilled technicians. Each step adds expense that transfers to the final price tag.

For complete wheel sets, GVICHN reports that carbon fiber options typically range from $5,000 to $15,000 or more depending on size and design complexity. Comparable forged aluminum sets run $1,500 to $4,000 for most applications. That's a 3-5x price premium for carbon fiber.

| Cost Factor | Forged Carbon Fiber | Forged Aluminum |

|---|---|---|

| Raw Material (per lb) | $10 - $20+ | $1.50 - $2.00 |

| Wheel Set (typical) | $5,000 - $15,000+ | $1,500 - $4,000 |

| Manufacturing Complexity | High (specialized equipment) | Moderate (established processes) |

| Production Volume Scalability | Limited economies of scale | Strong volume discounts |

| Repair Costs | Often requires replacement | Usually repairable |

So when does the premium make financial sense? The value proposition tilts toward carbon fiber when weight savings deliver measurable returns. Professional racing teams calculate lap time improvements per gram saved. Aerospace engineers quantify fuel savings over aircraft lifespans. In these contexts, the higher upfront cost generates returns that justify the investment.

For most automotive enthusiasts and everyday performance applications, forged aluminum delivers the sweet spot. You get significant performance improvements over cast alternatives without the extreme cost associated with exotic materials. A cosmetic carbon fiber overlay might give you the look, but forged aluminum delivers the structural substance at accessible pricing.

Repair and Maintenance Realities

Imagine this scenario: you're enjoying a spirited drive when debris impacts your wheel. With forged aluminum, you likely face a repair bill. With forged carbon fiber, you're probably shopping for a replacement. This repairability gap fundamentally changes the ownership equation.

Forged aluminum benefits from decades of repair infrastructure development. Skilled technicians worldwide can address common damage scenarios using proven techniques:

Forged Aluminum Repair Options

- Welding: Cracks and breaks can be welded by qualified specialists, restoring structural integrity

- Machining: Minor deformations can be corrected through precision machining operations

- Refinishing: Cosmetic damage addresses easily through sanding, filling, and recoating

- Straightening: Bent components can often be straightened using specialized equipment

- Surface treatment: Anodizing, powder coating, or painting restores appearance and protection

The story changes dramatically with forged carbon fiber. According to GVICHN, carbon fiber wheel repair options are extremely limited compared to aluminum wheels, and most damage requires complete wheel replacement rather than repair.

Forged Carbon Fiber Repair Options

- Minor cosmetic repairs: Surface scratches to clear coat layers might be addressable

- Complete replacement: Any structural damage typically requires full component replacement

- Specialized assessment: Non-destructive testing may be needed to evaluate internal damage

- Limited service network: Fewer facilities capable of carbon fiber evaluation and repair

Why such a dramatic difference? The composite nature of forged carbon fiber creates repair challenges that metals don't share. When aluminum deforms, the material remains continuous. Its crystalline structure can be manipulated back toward original specifications. Carbon fiber composites consist of fibers bonded within a resin matrix. Damage disrupts this bond in ways that simple repairs cannot address. Internal delamination or fiber breakage may be invisible from the surface yet compromise structural integrity.

This repairability advantage extends aluminum's practical lifespan significantly. A forged aluminum wheel that encounters curb damage can often return to service after professional repair. The same impact on carbon fiber might create internal fractures that render the component unsafe regardless of external appearance.

Manufacturing Volume and Supply Chain Advantages

Here's a factor that rarely gets discussed: how much does aluminum weigh on your purchasing decision when supply chain reliability matters? Forged aluminum benefits from established automotive supply chains that carbon fiber simply cannot match.

The aluminum forging industry has decades of infrastructure development behind it. Multiple suppliers compete for business, driving innovation and keeping prices competitive. When you need replacement parts or additional components, availability rarely presents problems. Lead times remain predictable, and quality standards are well-established across the industry.

Carbon fiber production remains more specialized. Fewer manufacturers means less competition and higher prices. Supply disruptions impact availability more severely. Quality can vary more significantly between producers, requiring careful supplier qualification.

For businesses sourcing components at volume, this supply chain maturity translates to practical advantages: more predictable costs, reliable delivery schedules, and established quality benchmarks. The performance gains from carbon fiber must justify not only the higher component cost but also the increased supply chain complexity.

The cost reality: forged carbon fiber commands premium pricing that makes sense for weight-critical professional applications, while forged aluminum delivers excellent performance with superior repairability and supply chain reliability for most real-world uses.

With cost and repairability factors now clear, you're ready for the practical payoff: specific recommendations for matching material to application. Let's examine exactly when each material delivers the best value for common use cases.

Application-Specific Material Selection Guide

You've absorbed the technical specifications, understood the cost implications, and grasped the thermal trade-offs. Now comes the practical question: which material belongs in your specific application? The answer isn't universal. It depends on what you're building, how it will be used, and which performance characteristics matter most for your goals.

Let's cut through the complexity with clear, application-specific recommendations. Whether you're sourcing automotive components, specifying aerospace parts, or selecting consumer products, this guide matches material to purpose based on real-world performance requirements.

Automotive Component Selection Guide

The automotive industry presents the clearest use case distinctions between forged carbon fiber vs forged aluminum. Each component category has distinct requirements that favor one material over the other.

| Component Category | Recommended Material | Key Reasoning |

|---|---|---|

| Suspension Arms | Forged Aluminum | Heat resistance, fatigue life, repairability, predictable failure modes |

| Drive Shafts | Forged Aluminum | Thermal management, cyclic stress tolerance, established manufacturing |

| Brake Calipers | Forged Aluminum | Superior heat dissipation, machinability, service accessibility |

| Body Panels | Forged Carbon Fiber | Maximum weight savings, aesthetic appeal, low thermal stress |

| Interior Trim | Forged Carbon Fiber | Premium appearance, weight reduction, complex shape capability |

| Wheels (Street Use) | Forged Aluminum | Repairability, cost-effectiveness, proven durability |

| Wheels (Racing) | Either (application dependent) | Carbon for weight-critical classes; aluminum for endurance/reliability |

| Engine Components | Forged Aluminum | Thermal tolerance, fatigue resistance, precision machinability |

When comparing carbon vs aluminum rims for street vehicles, forged aluminum wins on practicality. According to Evolve GT, aluminum provides a versatile and cost-effective option for teams looking for a balance between performance and affordability. The repairability advantage alone justifies this choice for daily-driven vehicles where curb encounters and road debris are inevitable realities.

The carbon fiber vs aluminum weight advantage becomes decisive only when every gram translates to measurable performance gains. Professional racing teams justify carbon wheels vs aluminum wheels based on lap time calculations, not aesthetic preferences. For weekend track enthusiasts, forged aluminum delivers 90% of the performance at a fraction of the cost and with vastly superior damage tolerance.

Aerospace and Racing Applications

When cost becomes secondary to performance, the material selection calculus shifts dramatically. Carbon fiber racing applications demonstrate where the premium pricing finds justification.

In professional motorsport, weight savings compound across every vehicle system. Lighter wheels reduce unsprung mass, improving suspension response. Lighter body panels lower center of gravity, enhancing cornering capability. The cumulative effect can mean seconds per lap. At that level, the carbon fibre vs aluminium debate resolves clearly in favor of carbon for weight-critical components.

Aerospace-Specific Considerations

- Drone components: Forged carbon fiber's strength-to-weight ratio maximizes flight time and payload capacity

- Satellite structures: Thermal stability and weight savings justify premium material costs

- Aircraft interior panels: Weight reduction across thousands of flights generates measurable fuel savings

- Helicopter components: Rotational weight reduction improves response and efficiency

Racing-Specific Applications

- Body panels: Forged carbon fiber provides maximum weight reduction with excellent aerodynamic surface quality

- Chassis components: Mixed material approaches optimize strength-to-weight across different stress conditions

- Safety structures: Aluminum often preferred for predictable deformation characteristics in crash scenarios

- Transmission components: Forged aluminum handles heat and cyclic loading in critical drivetrain applications

The carbon fiber bow hunting industry offers an interesting parallel. Competitive archers select carbon fiber components where weight distribution affects shooting accuracy, accepting premium pricing for measurable performance gains. Recreational users often choose aluminum alternatives that deliver excellent performance at more accessible price points.

Consumer Product Considerations

Beyond automotive and aerospace, material selection for consumer products follows similar logic but with different priority weightings. Aesthetic appeal, brand positioning, and user experience often influence decisions alongside pure performance metrics.

| Product Category | Recommended Material | Primary Selection Drivers |

|---|---|---|

| Mobility Equipment | Forged Carbon Fiber | User fatigue reduction, ease of transport, daily usability |

| Sports Equipment | Application Dependent | Weight vs durability requirements vary by sport |

| Electronics Housings | Forged Carbon Fiber | Premium positioning, thermal stability, electromagnetic properties |

| Outdoor Equipment | Forged Aluminum | Durability, repairability, cost-effectiveness |

The carbon fiber wheelchair market exemplifies perfect material-application alignment. Users transport their chairs multiple times daily, and every pound saved reduces fatigue and improves independence. The premium cost justifies itself through quality of life improvements that compound over years of daily use.

Sporting goods demonstrate nuanced selection. A carbon fiber bow delivers performance advantages competitive archers demand, while recreational shooters might prefer aluminum's durability and value. Tennis rackets, golf clubs, and cycling components follow similar patterns: professional and serious amateur users justify carbon fiber costs, while casual participants often choose capable aluminum alternatives.

Making Your Material Decision

The decision framework simplifies to three key questions:

- Does weight savings translate to measurable performance gains? If yes, carbon fiber deserves serious consideration.

- Is repairability important for your use case? If yes, forged aluminum provides significant practical advantages.

- Does thermal management impact performance or safety? If yes, aluminum's superior conductivity often proves decisive.

Choose forged carbon fiber when weight savings deliver measurable returns that justify premium pricing. Choose forged aluminum when durability, repairability, thermal management, or cost-effectiveness take priority.

With application-specific guidance now clear, one question remains: how do you synthesize all these factors into a final decision for your specific situation? The concluding section brings together everything we've examined into actionable recommendations.

Final Recommendations and Smart Material Choices

You've examined the mechanical properties, thermal characteristics, cost implications, and application-specific trade-offs. Now it's time to synthesize everything into clear, actionable guidance. Whether you're sourcing components for a racing program, specifying parts for production vehicles, or selecting materials for aerospace applications, these final recommendations will help you make confident decisions.

The forged carbon fiber vs forged aluminum debate doesn't have a universal winner. Each material dominates specific scenarios while falling short in others. Understanding which scenarios match your needs determines whether you'll extract maximum value from your investment.

Making Your Final Decision

Let's distill the comparison into its essential truth. Is carbon fiber the right choice for your application? That depends entirely on your priorities and constraints.

Forged carbon fiber wins when weight savings deliver measurable performance returns that justify premium pricing. Forged aluminum wins when durability, repairability, thermal management, and cost-effectiveness take priority.

Consider these decision factors in order of importance for your specific application:

- Weight sensitivity: How much performance improvement does each gram saved deliver? Professional racing and aerospace applications often justify any weight reduction cost. Street vehicles and consumer products rarely generate comparable returns.

- Thermal demands: Will your component experience significant heat generation or temperature cycling? Brake systems, drivetrain components, and high-stress suspension parts favor aluminum's superior thermal conductivity.

- Damage tolerance: What happens when something goes wrong? Aluminum's repairability extends service life and reduces replacement costs. Carbon fiber damage typically means complete replacement.

- Budget constraints: Does the 3-5x price premium for carbon fiber generate proportional value? Be honest about whether you're buying performance or aesthetics.

- Supply chain reliability: Can you accept longer lead times and limited repair options? Aluminum's mature supply chain offers predictability that carbon fiber cannot match.

The Verdict for Different User Profiles

Your optimal material choice aligns with your specific use case. Here's how different user profiles should approach the decision.

Professional Racing Teams

When lap times justify any expense, forged carbon fiber earns its place for body panels, aerodynamic components, and weight-critical structures. However, even at the highest levels, forged aluminum remains preferred for heat-critical brake components, safety structures requiring predictable deformation, and drivetrain elements experiencing cyclic thermal stress. The smartest teams use both materials strategically rather than choosing one exclusively.

Performance Enthusiasts and Track Day Participants

Forged aluminum delivers the best value proposition. You get significant weight reduction over cast alternatives, excellent durability for repeated use, and repairability when the inevitable incident occurs. Save the carbon fiber budget for components where it delivers maximum impact, like carbon fiber apparel and lightweight safety equipment, rather than spreading premium pricing across your entire build.

Automotive Manufacturers and Suppliers

Volume production favors forged aluminum's established manufacturing infrastructure and predictable costs. For manufacturers choosing forged aluminum components, partnering with IATF 16949 certified manufacturers ensures quality and reliability for critical automotive parts. This certification demonstrates commitment to automotive-specific quality management, defect prevention, and continuous improvement.

Organizations like Shaoyi (Ningbo) Metal Technology combine IATF 16949 certification with manufacturing flexibility that addresses real-world supply chain needs. Their capability spanning rapid prototyping in as little as 10 days to high-volume mass production means you can validate designs quickly before committing to production volumes. With in-house engineering ensuring components like suspension arms and drive shafts meet exact specifications, and strategic location near Ningbo Port enabling fast global delivery, certified manufacturing partners streamline procurement while maintaining rigorous quality control.

Aerospace and Defense Contractors

Weight savings often justify carbon fiber's premium pricing when measured against fuel costs over aircraft lifespans or payload capacity improvements. However, aluminum maintains its position for components requiring thermal management, field repairability, or predictable failure characteristics. Mixed-material approaches typically optimize overall system performance.

Consumer Product Developers

Match material to user value perception. Premium markets like high-end electronics, luxury goods, and carbon fiber apparel benefit from carbon fiber's aesthetic appeal and lightweight properties. Mass-market products generally favor aluminum's cost-effectiveness and durability, reserving carbon fiber for accent elements or marketing differentiation.

The smartest material decisions aren't about choosing the "best" material. They're about matching material characteristics to application requirements while respecting budget realities and supply chain constraints.

Your Path Forward

Armed with this comprehensive comparison, you can now approach material selection with confidence. Remember that aluminium vs carbon fibre decisions rarely come down to a single factor. The winning choice balances multiple considerations specific to your application, budget, and performance requirements.

For components where forged aluminum makes sense, prioritize suppliers with proven quality systems and manufacturing flexibility. For applications demanding forged carbon fiber's weight advantages, ensure your budget accounts for premium pricing and limited repairability.

Whether you're building race cars, specifying aircraft components, or developing consumer products, the right material choice amplifies your design intent. Choose wisely, source carefully, and let material properties work for your goals rather than against them.

Frequently Asked Questions About Forged Carbon Fiber vs Forged Aluminum

1. Are carbon fiber wheels better than forged aluminum?

It depends on your use case. Carbon fiber wheels offer superior weight savings, reducing unsprung mass by 40-50% compared to aluminum, which improves acceleration and handling. However, forged aluminum wheels provide better durability, repairability, and cost-effectiveness for daily driving. Carbon fiber wheels are more vulnerable to impact damage and typically require complete replacement when damaged, while aluminum wheels can often be repaired. For track-focused applications where lap times justify premium pricing, carbon fiber excels. For street use, forged aluminum delivers the best balance of performance and practicality.

2. What is the strength difference between forged carbon fiber and forged aluminum?

Forged carbon fiber demonstrates a significantly higher strength-to-weight ratio compared to forged aluminum. In bending tests against 6082-T6 aluminum, forged carbon resisted nearly double the load before failure (220 kg vs. 120 kg). However, forged aluminum offers higher elastic modulus (approximately 70 GPa vs. 30-50 GPa), meaning it resists deformation more effectively under load. Aluminum also provides superior fatigue resistance in cyclic loading applications and more predictable failure modes, making it preferred for safety-critical components like suspension arms and brake systems.

3. How much more expensive is carbon fiber compared to aluminum?

Carbon fiber costs approximately 5-10 times more than aluminum in raw material terms, with aluminum at $1.50-$2.00 per pound versus carbon fiber at $10-$20+ per pound. For complete wheel sets, carbon fiber options range from $5,000-$15,000 or more, while comparable forged aluminum sets run $1,500-$4,000. Manufacturing complexity adds further costs for carbon fiber, requiring specialized equipment and skilled technicians. Additionally, carbon fiber components typically require complete replacement when damaged, whereas aluminum components can often be repaired, affecting total cost of ownership.

4. Which material handles heat better for automotive applications?

Forged aluminum excels in heat management with thermal conductivity of 130-200 W/m·K compared to just 5-10 W/m·K for forged carbon fiber. This makes aluminum 15-30 times more effective at dissipating heat. For brake components, engine parts, and any application where heat buildup impacts performance or safety, aluminum is the clear choice. Carbon fiber's lower thermal conductivity can cause heat accumulation during repeated braking, potentially softening resins and compromising performance. However, carbon fiber offers better dimensional stability under temperature changes due to lower thermal expansion.

5. Can forged carbon fiber components be repaired when damaged?

Forged carbon fiber has extremely limited repair options compared to forged aluminum. While minor cosmetic scratches to clear coat layers might be addressable, any structural damage typically requires complete component replacement. The composite nature of carbon fiber means internal damage like delamination or fiber breakage may be invisible from the surface yet compromise structural integrity. Forged aluminum, conversely, can be welded, machined, straightened, and refinished. This repairability gap significantly impacts ownership costs, especially for applications prone to damage from road debris or impacts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —