Custom Forged Wheel Concavity Types: From Flat Face To Super Concave

Understanding Wheel Concavity and Why It Transforms Vehicle Appearance

When you look at a set of aftermarket wheels and feel that unmistakable pull toward them, chances are you're responding to their concavity. This single design element - the inward curve of the wheel face from the outer lip toward the hub - creates the dramatic visual depth that separates head-turning builds from ordinary ones. Whether you're drawn to the subtle sophistication of shallow concave wheels or the aggressive stance of deep dish wheels, understanding these profiles is essential before investing in custom forged wheels.

Think of concavity as the wheel's visual personality. A wheel with significant concavity appears to have a center that's "sunk in," creating shadows and depth that catch the eye from every angle. In contrast, a flat face profile - common on many OEM wheels - lacks this dimensional quality. The difference between concave up vs concave down orientations and varying depth levels can completely transform how your vehicle presents itself on the street or at shows.

What Makes Wheel Concavity So Visually Striking

Concave wheels create an optical illusion of depth and motion, even when your vehicle is stationary. This effect occurs because the spokes angle inward toward the hub, generating natural shadow lines that add dimension to the wheel face. Premium brands like Work Wheels and Forgiato rims have built their reputations largely on mastering these concave profiles, recognizing that enthusiasts crave this visual impact.

The right concavity level doesn't just change how your wheels look - it fundamentally transforms your vehicle's entire presence, making it appear wider, more planted, and unmistakably intentional.

Why Concavity Matters for Your Build

Selecting the appropriate concavity isn't purely an aesthetic decision. It directly impacts fitment requirements, brake clearance, and how your wheels interact with your vehicle's suspension geometry. The same wheel design can look dramatically different depending on width and offset combinations, which is why understanding the full spectrum of concavity types - from flat face to super concave - matters before you commit to a purchase.

This guide bridges the gap between what looks good and what actually fits your build. Rather than focusing on a single style, we'll walk you through every concavity level, explain the technical factors that determine depth, and help you match the right profile to your specific stance goals. By the end, you'll have the knowledge to make confident, informed decisions about your custom forged wheel investment.

The Five Main Concavity Types from Flat Face to Super Concave

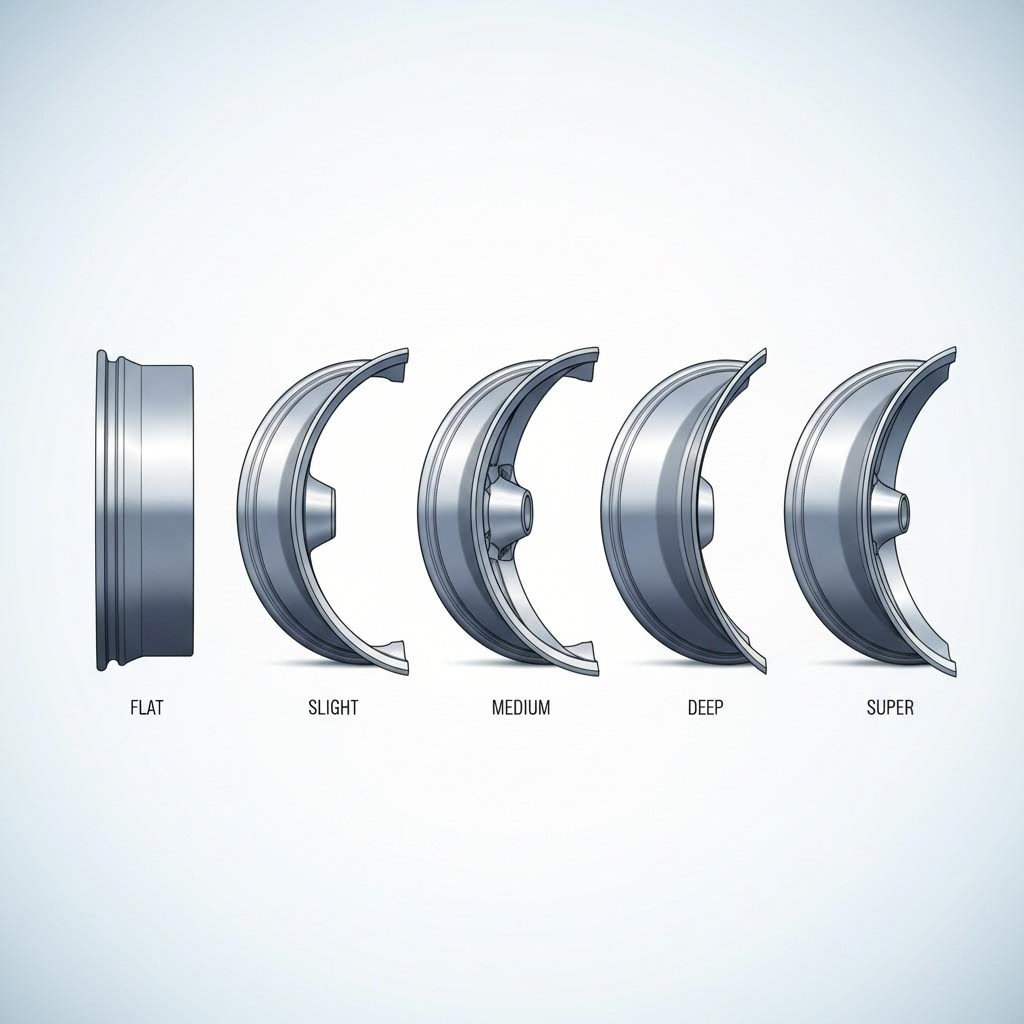

Now that you understand why concavity matters, let's break down the specific profiles available in the custom forged wheel market. Each concavity type creates a distinct visual effect, and knowing the differences helps you communicate exactly what you want when working with manufacturers. From barely-there curves to show-stopping depth, here's your complete breakdown of concave rims and their characteristics.

Flat Face vs Shallow Concave Profiles

At the subtle end of the spectrum, you'll find two options that prioritize understated elegance over aggressive styling.

Flat face wheels feature spokes that run nearly parallel to the wheel's outer edge. When viewed from the side, there's minimal to no inward curve - the face profile appears almost flush with the barrel. Many OEM wheels use this design because it maximizes brake clearance and works with a wide range of vehicle specifications. For enthusiasts, flat face designs offer a clean, classic aesthetic that complements vintage builds or vehicles where subtle refinement is the goal.

Moving slightly deeper, low or shallow concave profiles introduce a gentle inward sweep. You'll notice the spokes begin angling toward the hub, creating soft shadow lines that add visual interest without demanding attention. This concave wheel style works beautifully on daily drivers where you want upgraded aesthetics without an overly aggressive appearance. Think of it as the gateway to concavity - noticeable when you look closely, but refined enough for professional settings.

Medium to Super Concave Explained

When you're ready to make a statement, medium through super concave profiles deliver the dramatic depth that turns heads.

Medium concave represents the sweet spot for many enthusiasts. The spoke angle becomes pronounced enough to create clear depth perception, with noticeable shadows forming between the lip and hub. This profile offers balanced aesthetics - aggressive enough to stand out, yet versatile enough to complement most vehicle styles. Deep concave wheels in this category work exceptionally well with flush fitments.

Deep concave takes the visual impact significantly further. Here, the spoke angle is dramatic, creating pronounced shadow lines that give the wheel a three-dimensional quality. When you see deep dish concave wheels on a build, they immediately draw your eye. The face appears to sink substantially inward, and the rims concave profile becomes a defining feature of the vehicle's stance. Wheels deep dish styling in this category typically requires more aggressive offsets and careful consideration of brake clearance.

Super concave represents maximum achievable depth - the show-stopper category. These rims with deep dish profiles push engineering limits, with spoke angles so aggressive that the hub area appears dramatically recessed. Super concave designs are typically reserved for show cars, wide-body builds, or vehicles where visual impact is the primary goal. The deep lip wheels in this category create unmistakable presence from any viewing angle.

What physically creates these different levels? Three key factors work together: the spoke angle relative to the barrel, the face profile geometry, and the overall barrel depth. As concavity increases, spokes must angle more steeply inward while maintaining structural integrity - which is why forged construction becomes essential at deeper levels.

| Type Name | Visual Characteristics | Spoke Angle Range | Best Suited For | Typical Applications |

|---|---|---|---|---|

| Flat Face | Minimal depth, spokes parallel to face, clean profile | 0° - 5° | Classic aesthetics, maximum brake clearance | OEM replacements, vintage builds, luxury sedans |

| Low/Shallow Concave | Subtle inward curve, soft shadows, understated aggression | 5° - 12° | Daily drivers, refined appearance | Executive sedans, entry-level sports cars |

| Medium Concave | Noticeable depth, clear shadow lines, balanced look | 12° - 20° | Versatile builds, flush fitments | Sports cars, performance sedans, SUVs |

| Deep Concave | Pronounced spoke angle, dramatic shadows, strong presence | 20° - 30° | Aggressive stance, wide-body kits | Modified sports cars, muscle cars, show vehicles |

| Super Concave | Maximum depth, extreme spoke angle, show-stopping impact | 30°+ | Maximum visual impact, show builds | Show cars, extreme builds, wide-body applications |

Understanding where your preference falls on this spectrum is the first step. However, achieving your desired concavity depends heavily on technical specifications like offset and width - factors we'll explore next to help you understand exactly how these measurements translate into the visual depth you're after.

How Offset Width and Backspacing Determine Concavity Depth

You've identified your preferred concavity style - but here's what many enthusiasts discover too late: achieving that look depends entirely on getting the technical specifications right. The same wheel design can appear dramatically different based on three interconnected measurements. Understanding how offset, width, and backspacing work together gives you the power to predict exactly how your custom forged wheels will look before you order.

How Offset Creates the Concave Look

Offset is the single most influential specification when it comes to visual concavity. But what exactly is it? Offset measures the distance in millimeters from the hub mounting surface to the true centerline of the wheel. This measurement comes in three forms: positive, zero, and negative.

Here's how each affects your concave appearance:

- Positive offset (+) - The mounting surface sits closer to the wheel's outer face (fender side). This pushes the wheel inward toward the brakes, resulting in a flatter face profile with less visible concavity.

- Zero offset (0) - The mounting surface aligns exactly with the wheel's centerline, creating a balanced starting point for moderate concavity.

- Negative offset (-) - The mounting surface moves toward the inner edge (brake side) of the wheel. This is where the magic happens for concave enthusiasts - it creates that "pushed out" look with deeper visible dish.

Consider this real-world example: a wheel in 20x10 ET+15 will look significantly more concave than the same wheel in 20x10 ET+50. Why? Because that mounting hub sits 35mm closer to the wheel's centerline, allowing the face to "dip inwards" more dramatically. The more negative your offset, the more aggressive your stance and the deeper your concavity appears.

When shopping for 5x114.3 wheels, 5x120 wheels, or 5x112 wheels, always compare offset values across your options. A 10mm difference in offset can completely change how concave your wheels appear once mounted.

Width and Backspacing Effects on Concavity

Width works hand-in-hand with offset to determine your final concavity appearance. Imagine two wheels with identical offsets - a 20x8.5 and a 20x12. Despite sharing the same offset value, they'll look completely different when mounted.

A wider wheel creates more real estate for the concave profile to develop. According to Forgelite Wheels, "A wheel in 20x8.5 ET+35 will appear to have a flatter face profile (less concavity) than a wheel in 20x12 ET+35." That extra width provides the depth needed for spokes to angle more aggressively toward the hub.

Now, what about backspacing? While offset measures from the centerline, backspacing measures from the mounting surface to the back edge of the wheel. It's an older measurement that's less commonly used today, but understanding it helps when dealing with custom wheel offset calculations or fitting wheel spacers.

Key specification factors affecting concavity appearance:

- Offset value - Lower (more negative) numbers create deeper concave looks

- Wheel width - Wider wheels allow for more pronounced concavity at the same offset

- Backspacing - Determines how far the wheel extends inward toward suspension components

- Brake clearance requirements - Larger calipers may force flatter face profiles, especially on front wheels

- Hub centric rings - Ensure proper centering but don't directly affect concavity

Here's a practical example to illustrate these interactions: imagine you're considering a popular 20x10 wheel. At ET+35, you'll get moderate concavity suitable for a flush fitment. Drop that to ET+15, and suddenly you're looking at noticeably deeper dish with potential fender poke. The same wheel design transforms based purely on these numbers.

When reading wheel specifications while shopping, look for listings formatted like "20x10 ET+25" or "20x10 +25mm." That final number tells you everything about how the wheel will sit relative to your fenders and how much concavity you'll actually see. For aggressive builds, offsets between 0 and -30mm typically deliver the deep concave appearance enthusiasts crave - though you'll likely need fender modifications to accommodate them.

Understanding these relationships empowers you to request specific combinations from manufacturers. But achieving extreme concavity while maintaining structural integrity requires the right construction method - which is exactly why forged wheels open doors that cast alternatives simply cannot.

Why Forged Construction Enables Superior Concavity Options

So you've found your ideal concavity level and know exactly which offset and width combination will achieve it. But here's a question worth asking: can any wheel actually deliver that aggressive spoke angle without compromising safety? The answer depends entirely on how the wheel is manufactured. Forged wheels don't just look better with deep concavity - they're the only construction method that makes extreme concave profiles structurally possible.

Forged vs Cast Concavity Limitations

Understanding the difference between forged and cast construction reveals why premium brands like Vossen and Forgiato rely heavily on forging for their most aggressive designs.

Cast wheels - which account for roughly 90% of OEM wheels - are made by pouring molten aluminum into a mold. While cost-effective, this process creates microscopic voids and inconsistencies within the material. According to Forgelite Wheels, manufacturers must add "redundant material to spokes and barrels to increase their strength, thus making the wheel heavy." Those bulkier spokes simply cannot achieve the steep angles required for deep or super concave profiles without becoming structurally compromised.

Flow-formed (also called rotary forged) wheels offer a middle ground. The barrel undergoes a spinning and pressing process that strengthens it, but the spoke face remains cast. This limits how aggressively the spokes can angle inward while maintaining adequate strength.

Forged wheels change the equation entirely. Starting with aerospace-grade 6061-T6 aluminum, the material is compressed under 8,000 to 10,000 tons of pressure before CNC machining carves out the design. This process eliminates porosity and creates a uniform grain structure with exceptional strength-to-weight ratios. The result? Manufacturers can use significantly less material while achieving the same - or greater - structural integrity.

What does this mean for concavity? Thinner spokes. More aggressive angles. Deeper profiles. Designs that would crack or fail in cast aluminum become entirely feasible in forged construction. When you see 360 forged wheels with dramatic concave faces, you're looking at engineering that simply isn't possible with other manufacturing methods.

Monoblock 2-Piece and 3-Piece Construction Differences

Within the forged wheel category, three distinct construction types offer varying levels of concavity customization. Choosing between them involves balancing aesthetics, flexibility, and budget.

Monoblock Forged Wheels

Monoblock wheels are milled from a single block of forged aluminum - no seams, no bolts, just one solid piece. This construction delivers maximum strength and the lightest possible weight, making it ideal for performance applications.

- Highest strength-to-weight ratio of any wheel type

- Cleanest aesthetic with no visible hardware

- Precise concavity options determined during design phase

- Limited flexibility once manufactured - what you see is what you get

- Best suited for buyers who know their exact specifications upfront

The trade-off? Concavity is locked in during the design process. You'll choose from predetermined sizes and offsets rather than customizing each dimension independently. Vossen wheels and similar premium manufacturers offer multiple monoblock designs with varying concave levels, but each design has fixed parameters.

2-Piece Forged Wheels

Two-piece construction separates the center (face) from the outer barrel, joining them with aerospace-grade hardware. This split creates opportunities monoblock designs cannot match.

- Greater width and offset flexibility than monoblock

- Ability to mix and match center designs with different barrel depths

- Easier repair potential - damaged barrels can be replaced without discarding the center

- Moderate weight increase compared to monoblock due to hardware

- Visible bolts can be styled as a design feature or hidden

For concavity hunters, 2-piece construction offers a significant advantage: the same center design can be paired with different barrel widths to achieve varying concave appearances. Want deeper dish on your rear wheels? Simply specify a wider barrel with adjusted offset while keeping matching face designs front and rear.

3-Piece Forged Wheels

Three-piece wheels take modularity to its logical extreme, separating the center from both inner and outer barrel halves. This is where ultimate concavity control lives.

- Maximum customization for width, offset, and concavity

- Independent control of inner and outer lip depths

- Easiest to repair - individual components are replaceable

- Most finish and color combination options

- Premium pricing reflects complex manufacturing and assembly

With 3-piece forged wheels, you can specify exactly how deep you want your outer lip while independently adjusting inner clearance for brakes and suspension. This granular control makes 3-piece construction the go-to choice for show builds and wide-body applications where super concave profiles are non-negotiable. Forgiato wheels and HRE rims frequently use this construction for their most aggressive offerings.

The table below summarizes how each construction type serves different concavity goals:

| Construction Type | Concavity Flexibility | Weight | Customization Level | Ideal Use Case |

|---|---|---|---|---|

| Monoblock | Fixed per design | Lightest | Limited to preset options | Performance builds with known specs |

| 2-Piece | Moderate - adjustable via barrel | Moderate | Good flexibility | Balanced performance and customization |

| 3-Piece | Maximum - full independent control | Heaviest | Near-unlimited options | Show cars, extreme builds, wide-body kits |

Here's what many wheel shoppers miss: manufacturers like Vossen offer multiple construction options across their lineup, but they rarely explain why each exists. Now you know. Monoblock delivers when weight and strength matter most. Two-piece offers the sweet spot of flexibility and performance. Three-piece unlocks concavity levels that make bystanders stop and stare.

Forged carbon fiber represents the cutting edge of this technology, combining carbon fiber barrels with forged aluminum centers for even greater weight reduction. While still emerging, this hybrid construction points toward where BBS rims and other innovators are headed.

The strength-to-weight advantage of forging doesn't just enable prettier wheels - it enables designs that would literally fall apart in cast construction. When you're chasing deep or super concave profiles, forged construction isn't optional. It's the foundation that makes everything else possible.

With construction method understood, the next question becomes practical: which concavity level actually works for your specific vehicle stance goals? Let's connect aesthetic preferences to real-world fitment requirements.

Choosing the Right Concavity for Your Desired Vehicle Stance

You've selected your preferred concavity level and understand how forged construction makes it possible. Now comes the critical question: will that dramatic deep concave profile actually work with your vehicle's stance goals? Matching concavity to fitment style isn't just about aesthetics - it's about understanding the practical trade-offs that come with each combination. Let's connect what looks good on screen to what actually fits in your wheel wells.

Matching Concavity to Flush Aggressive or Tucked Fitments

Every wheel build falls into one of three stance categories, and each has an ideal concavity range that delivers the best visual results without creating fitment nightmares.

Flush Fitment - This is the sweet spot most enthusiasts target. The wheel face aligns nearly perfectly with the fender edge, creating a seamless transition from body to wheel. When executed properly, flush fitment looks intentional and refined without appearing dangerous or impractical.

For flush builds, medium concave typically delivers the best results. Why? This concavity level offers enough visual depth to create interest without requiring extremely aggressive offsets that push the wheel too far outward. You'll maintain reasonable suspension geometry while achieving that "factory plus" appearance that suggests the vehicle was designed with these exact wheels in mind.

Aggressive Fitment - Here's where things get dramatic. Aggressive stance means the wheel extends past the fender line, creating that unmistakable "poke" that demands attention. This style often requires fender rolling, pulling, or wide-body modifications to prevent tire rub.

Deep to super concave profiles shine in aggressive applications. When your 20 inch concave rims or 22 inch concave rims extend beyond the fender, that extra concavity depth creates dramatic shadow lines visible from any angle. The combination of poke and depth makes the wheel appear even more substantial. However, achieving this look requires significantly lower offsets - often between 0 and -30mm - which directly impacts suspension geometry and may necessitate adjustable components.

Tucked Fitment - The opposite of aggressive, tucked fitment positions the wheel entirely within the fender line. This style is common on bagged vehicles that need clearance for air suspension travel, or on street cars prioritizing practicality over aggressive appearance.

Shallow to medium concave works best for tucked setups. Since the wheel sits recessed from the fender edge, you're viewing it at an angle that actually enhances perceived depth. Going super concave on a tucked setup often wastes visual potential - that extreme spoke angle gets lost when the wheel isn't prominently displayed.

| Stance Goal | Recommended Concavity | Typical Offset Range | Modifications Often Needed | Best Wheel Sizes |

|---|---|---|---|---|

| Flush | Medium Concave | +15 to +35mm | Minor fender rolling (if any) | 18-20 inch |

| Aggressive | Deep to Super Concave | 0 to -30mm | Fender rolling, pulling, or wide-body kit | 20-22 inch concave wheels |

| Tucked | Shallow to Medium Concave | +30 to +50mm | Air suspension recommended | 18-21 inch |

Clearance Considerations for Deep Concave Designs

Here's where many builds run into trouble: brake caliper clearance. That stunning super concave profile you've been eyeing might look incredible in renderings, but physics has the final say.

According to Vorenzo Forged, "Performance cars often have larger front brake calipers, which require wheels with a flatter face to clear the calipers properly." This creates an interesting challenge: your front and rear wheels may need different concavity levels to function properly.

Consider this common scenario with concave 22 inch rims on a performance vehicle:

- Front wheels - Larger brake calipers (often 6-piston on performance packages) require more spoke clearance, limiting you to medium concave or requiring specific spoke designs that route around the caliper

- Rear wheels - Smaller rear brakes (typically 2 or 4-piston) allow for deep or super concave profiles with minimal clearance concerns

- Result - Many builds feature medium concave fronts with deep concave rears, creating a staggered appearance that actually enhances the aggressive look

The trade-offs become more significant as you chase deeper concavity:

- More aggressive offset requirements may push wheels beyond fender lines, requiring body modifications

- Lower offsets can affect steering geometry, potentially requiring adjustable suspension components

- Wider wheels with deep concave may require significant fender work or wide-body installation

- Beadlock wheels and rim beadlock designs add additional clearance considerations for off-road applications

- Dually wheels face unique concavity constraints due to dual-wheel mounting requirements

The key insight? Work backwards from your brake and suspension setup. Measure your caliper dimensions, understand your current offset, and calculate available clearance before falling in love with a specific concavity level. Many manufacturers provide spoke-to-caliper clearance specifications - use them.

For those running 20 inch concave wheels, you'll generally have more design flexibility than with larger diameters. The additional sidewall height provides a buffer for minor clearance issues. Moving up to 22 inch concave wheels tightens tolerances considerably, making proper planning essential.

Understanding these fitment realities doesn't limit your options - it focuses them. Knowing that your vehicle's brake package restricts front concavity to medium levels means you can confidently spec deep concave rears for maximum visual impact where it counts most. This targeted approach often creates more striking builds than attempting uniform super concave on all four corners.

With stance goals and clearance requirements mapped out, let's explore how these concavity principles apply across different vehicle segments - because what works on a lowered sports car plays very differently on a lifted truck or luxury SUV.

Popular Concavity Applications Across Vehicle Types

The concavity level that transforms one vehicle might look completely wrong on another. A super concave profile that dominates on a widebody sports car could appear awkward on a lifted truck. Understanding how different vehicle segments embrace concavity helps you visualize what actually works for your specific build - and why the same wheel design creates dramatically different impressions across platforms.

Truck and SUV Concave Wheel Trends

Concave truck wheels have exploded in popularity over the past several years, bringing a styling element once reserved for sports cars into the truck and SUV market. But the application looks fundamentally different than on lower vehicles.

For trucks like F150 wheels and full-size SUVs, medium concave profiles typically deliver the best visual balance. Why? The elevated ride height means you're often viewing these wheels from slightly below eye level, which naturally enhances perceived depth. Going super concave on a lifted truck can actually look excessive - the exaggerated spoke angles compete with the vehicle's already commanding presence.

Street-oriented truck builds favor these specifications:

- Wheel sizes - 20x10 to 22x12 for proportional appearance on larger vehicles

- Concavity level - Medium to deep concave for aggressive aesthetics without overwhelming the design

- Bolt patterns - 5x114.3 and 6x135 cover most domestic truck applications

- Offset range - Typically +0 to -25mm for that "pushed out" stance without excessive poke

Off-road builds present unique considerations. Jeep rims and dedicated trail vehicles often prioritize function over extreme styling. Shallow to medium concave works well here, providing visual interest while maintaining clearance for larger brake packages and avoiding spoke damage from trail debris. The rugged environment means those dramatic super concave profiles face practical limitations - exposed spokes catch rocks and mud more readily.

Sports Car and Muscle Car Concavity Styles

This is where deep and super concave profiles truly come alive. Lower ride heights, wider fenders, and performance-focused aesthetics create the perfect canvas for aggressive concavity.

Modern sports cars and performance vehicles often feature widebody kits specifically designed to accommodate extreme wheel setups. According to Performance Plus Tire, "Forgeline's three-piece modular forged concave wheels feature deep profiles that deliver a modern, muscular look with custom sizes from 18″ to 22″ diameters." These builds leverage that extra fender width to run significantly lower offsets, allowing for maximum concavity while maintaining proper fitment.

Muscle cars deserve special attention. Mustang wheels and mustang rims have become synonymous with concave styling, blending classic American muscle aesthetics with modern wheel technology. The combination works exceptionally well because:

- Wide rear fenders accommodate staggered setups with deeper rear concavity

- Lower front calipers (compared to European sports cars) allow medium concave front profiles

- Classic five-spoke designs translate beautifully into concave interpretations

- The muscular body lines complement rather than compete with aggressive wheel depth

Popular muscle car concavity combinations include:

- Front - 20x9 with medium concave, offset around +25 to +35mm

- Rear - 20x11 or 20x12 with deep concave, offset around +10 to +20mm

- Bolt pattern - 5x114.3 covers most modern Mustangs, Camaros use 5x120

European luxury vehicles take a different approach. BMW wheels and bmw rims typically favor subtle to medium concave profiles that complement rather than dominate the vehicle's refined design language. These builds prioritize sophistication - the concavity adds depth and presence without screaming for attention.

For BMW applications and similar European platforms:

- Wheel sizes - 19x8.5 to 20x10 maintain proportional appearance

- Concavity level - Shallow to medium for understated aggression

- Bolt pattern - 5x120 is standard across most BMW platforms

- Offset range - +25 to +40mm for flush fitments that respect factory body lines

Here's an insight that experienced builders understand: the same wheel design tells completely different stories across vehicle types. A medium concave profile appears aggressive on a lowered BMW but merely adequate on a full-size truck. Conversely, deep concave that looks perfectly proportioned on a Mustang might overwhelm a compact sports car's fenders. Context matters as much as the wheel itself.

Understanding these segment-specific applications helps you set realistic expectations. If you're building a truck, chasing super concave might not deliver the impact you're imagining. If you're working with a widebody sports car, medium concave might leave visual potential on the table. Match your concavity ambitions to what actually works for your platform.

With vehicle-specific applications understood, the next step involves working with manufacturers who can execute your vision. The custom ordering process for precision concavity requires clear communication and quality-focused partners who understand both the aesthetics and engineering involved.

The Custom Ordering Process for Precision Concavity

You've identified your ideal concavity level, understand the offset and width specifications needed, and know which construction type suits your build. Now comes the part that separates custom forged wheels from off-the-shelf alternatives: working directly with manufacturers to create wheels built specifically for your vision. This process offers unparalleled control over your final result - but it requires understanding what to expect and what questions to ask.

True custom forged wheels allow you to specify exact offset and width combinations that achieve your desired concavity appearance. Unlike catalog wheels where you're limited to predetermined specifications, custom orders put you in control of dimensions that directly impact how deep and aggressive your concave profile appears. This flexibility is precisely why serious enthusiasts pursue custom forged truck wheels and concave forged wheels rather than settling for mass-produced alternatives.

Working with Manufacturers on Custom Concavity Specifications

The difference between a successful custom wheel project and a frustrating one often comes down to manufacturer support. Reputable manufacturers don't just take your order - they provide engineering guidance to ensure your specifications actually work with your vehicle.

Imagine ordering forged billet wheels with aggressive specifications only to discover they don't clear your brake calipers or cause suspension interference. Quality manufacturers prevent this by offering fitment consultations before production begins. They'll review your vehicle's specifications, discuss your stance goals, and recommend offset and width combinations that deliver your desired concavity while ensuring proper function.

According to 41 Forged, the custom ordering process typically begins with detailed discussions about "your vehicle and the specific requirements for your custom wheel order." This collaborative approach ensures you're not guessing at specifications - you're working with experts who understand how concavity, offset, and width interact.

For forged offroad applications and forged off road builds, this engineering support becomes even more critical. Trail use introduces stress factors that street applications don't face, making proper specification essential for both aesthetics and durability.

- Initial consultation - Contact the manufacturer with your vehicle details, desired concavity level, and stance goals. Provide current wheel specifications and any modifications (suspension, brakes, body work) that affect fitment.

- Specification development - The manufacturer recommends specific offset, width, and construction combinations based on your inputs. This is where their engineering expertise translates your aesthetic vision into buildable specifications.

- Rendering approval - Most quality manufacturers provide detailed renderings showing wheel concavity and lip depth before production. 41 Forged notes they deliver "detailed renderings within 2-4 business days, showcasing wheel concavity and/or lip depth." Review these carefully - they're your preview of the final product.

- Deposit and production authorization - Once specifications are confirmed, expect a deposit requirement (typically 50%) to begin manufacturing. This protects both parties given the fully custom nature of the product.

- Manufacturing phase - Custom forged wheels typically require 4-8 weeks for production, depending on complexity and current demand. Premium forged wheels concave profiles with complex finishes may extend this timeline.

- Quality inspection and final approval - Reputable manufacturers photograph completed wheels for your approval before shipping. This final checkpoint ensures everything matches your specifications.

- Balance payment and shipping - After approval, the remaining balance is collected and wheels ship with tracking. Expect 3-4 weeks for international delivery.

Quality Standards in Custom Forged Wheel Production

When you're investing in custom forged wheels, you need assurance that precision manufacturing delivers components meeting both aesthetic and structural requirements. This is where industry certifications become your quality guarantee.

According to Flexiforge Wheel, "IATF 16949:2016 certification is vital for wheel manufacturers supplying major automakers. It covers the entire production process, ensuring high-quality standards at every stage." This certification focuses on continuous improvement and defect prevention - exactly what you need when structural integrity is non-negotiable.

What should you look for in a quality-focused manufacturer?

- IATF 16949 certification - Indicates automotive-grade quality management systems

- JWL and VIA certifications - Japanese standards confirming wheels meet rigorous safety requirements through independent third-party testing

- Documented testing protocols - Impact testing, rotary fatigue testing, and radial load testing verify structural performance

- Material traceability - Quality manufacturers track aluminum alloy sourcing and heat treatment specifications

Companies like Shaoyi (Ningbo) Metal Technology exemplify this quality-first approach, maintaining IATF 16949 certification while offering precision hot forging capabilities for automotive components. Their rapid prototyping - available in as little as 10 days - allows buyers to verify specifications before committing to full production runs. This combination of quality certification and engineering flexibility represents what serious wheel buyers should seek in manufacturing partners.

Geographic location also impacts your ordering experience. Manufacturers near major shipping ports can significantly expedite global delivery. Shaoyi's location near Ningbo Port, for example, streamlines international logistics and reduces transit times for customers worldwide. When you're waiting 4-8 weeks for manufacturing, shaving time off shipping makes a meaningful difference.

The best custom forged wheel manufacturers don't just build what you order - they help you order what actually works, combining engineering expertise with precision manufacturing to deliver wheels that look exactly as intended while performing flawlessly.

For those pursuing affordable forged wheels, the custom process might seem intimidating. However, working directly with manufacturers often proves more cost-effective than premium branded alternatives while delivering superior customization. The key is finding partners who balance quality certifications with responsive engineering support - ensuring your concave forged wheels meet exact specifications without unexpected compromises.

Understanding this process empowers you to approach manufacturers as an informed buyer. You know which concavity level you want, the specifications needed to achieve it, and the quality standards that ensure structural integrity. Armed with this knowledge, you're ready to make final decisions about your wheel investment with complete confidence.

Making Your Final Concavity Decision with Confidence

You've explored the full spectrum of concavity options, understood the technical specifications that create each look, and learned how different vehicle types embrace these profiles. Now it's time to translate that knowledge into action. Whether you're drawn to the timeless elegance of 5 spoke concave wheels or the aggressive stance of deep dish designs, making an informed decision comes down to weighing four critical factors against your specific build goals.

Key Takeaways for Choosing Your Concavity Type

Before finalizing your order, consider how these decision factors apply to your situation:

- Aesthetic preference - Do you want understated refinement or head-turning drama? Shallow concave suits daily drivers and luxury builds, while deep profiles command attention on show cars and aggressive street builds.

- Vehicle stance goals - Flush fitments pair naturally with medium concave. Aggressive poke demands deep or super concave to maximize visual impact. Tucked setups benefit from shallow to medium profiles that enhance perceived depth.

- Fitment requirements - Your brake package, suspension geometry, and fender clearances dictate what's actually achievable. Those stunning forged concave rims mean nothing if they don't clear your calipers.

- Budget considerations - Three-piece construction offers maximum concavity control but commands premium pricing. Monoblock designs deliver excellent value when preset specifications match your needs.

Here's what many enthusiasts overlook: request multiple specification options from your manufacturer. Ask to see renderings of the same wheel design in different width and offset combinations. A wheel in 20x9 ET+35 tells a completely different visual story than that same design in 20x11 ET+15. This comparison reveals exactly how much concavity you'll actually see once mounted - before you commit thousands of dollars.

The perfect concavity level isn't the deepest one available - it's the one that matches your aesthetic vision while respecting your vehicle's fitment realities.

For buyers unsure where to start, medium concave offers exceptional versatility. It works across most vehicle types, accommodates standard brake packages, and delivers noticeable depth without requiring aggressive modifications. You can always go deeper on your next set once you understand how concavity interacts with your specific platform.

For those building show cars or wide-body vehicles where maximum visual impact is non-negotiable, deep to super concave profiles deliver the dramatic presence that stops traffic. Just ensure your brake clearance and suspension geometry can support those aggressive specifications.

Next Steps in Your Custom Wheel Journey

Whether you're shopping for concave wheels 5x114 3 applications, exploring concave wheels 5x120 options for your BMW, or seeking concave rims for trucks, arm yourself with the right questions before contacting manufacturers:

- What concavity levels are available in my required bolt pattern and wheel size?

- Can you provide renderings showing the same design at different offset specifications?

- What brake caliper clearance does each concavity level provide?

- Do you offer staggered concavity setups (medium front, deep rear)?

- What certifications verify your forged construction quality?

- What is the typical lead time for custom specifications?

This guide has given you the foundation for informed conversations with wheel manufacturers and retailers. You understand what creates concavity, how specifications affect appearance, and which profiles suit different vehicle types. From bmw concave wheels to concave mustang rims, the principles remain consistent - only the applications change.

Your perfect wheel setup exists. Armed with this knowledge, you're ready to find it.

Frequently Asked Questions About Custom Forged Wheel Concavity

1. What is wheel concavity and why does it matter?

Wheel concavity refers to the inward curve of the wheel face from the outer lip toward the hub. This design element creates visual depth through shadow lines and dimensional quality that flat-face wheels lack. Concavity matters because it dramatically affects your vehicle's stance and presence, making it appear wider, more planted, and intentional. The right concavity level also impacts fitment requirements, brake clearance, and suspension geometry.

2. What are the different types of concave wheels?

There are five main concavity types: Flat face features minimal depth with spokes parallel to the face. Low/shallow concave introduces subtle inward curves for understated refinement. Medium concave offers balanced aesthetics with noticeable shadow lines. Deep concave creates dramatic spoke angles for aggressive presence. Super concave delivers maximum achievable depth for show-stopping visual impact, typically reserved for wide-body builds and show cars.

3. How does offset affect wheel concavity appearance?

Offset is the most influential specification for visual concavity. Lower or negative offset values push the mounting surface inward, creating deeper visible dish and more pronounced concavity. For example, a 20x10 ET+15 wheel appears significantly more concave than the same wheel in 20x10 ET+50. The mounting hub position relative to the wheel centerline directly determines how much the face dips inward.

4. Why are forged wheels better for deep concave designs?

Forged wheels undergo 8,000-10,000 tons of compression, eliminating porosity and creating uniform grain structure with superior strength-to-weight ratios. This allows manufacturers to use thinner spokes at more aggressive angles while maintaining structural integrity. Cast wheels require bulkier spokes that cannot achieve steep angles without compromising safety. Three-piece forged construction offers maximum concavity control with interchangeable components. IATF 16949 certified manufacturers like Shaoyi ensure precision forging meets exact specifications.

5. What concavity level works best for different vehicle types?

Medium concave suits trucks and SUVs where elevated ride height naturally enhances perceived depth. Sports cars and muscle cars excel with deep to super concave profiles that complement wide fenders and lowered suspensions. European luxury vehicles typically favor shallow to medium concave for refined sophistication. For flush fitments, medium concave delivers optimal results, while aggressive stance builds benefit from deep to super concave with appropriate fender modifications.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —