Exhaust Hanger Metal Stamping: Engineering Specs & Manufacturing Standards

TL;DR

Exhaust hanger metal stamping is the dominant manufacturing method for OEM and high-volume aftermarket automotive suspension components due to its superior repeatability and cost-efficiency. While simple wire forms exist, stamped brackets provide the necessary structural rigidity to manage NVH (Noise, Vibration, and Harshness) in modern exhaust systems. For engineers and procurement managers, the critical decision matrix involves selecting the right material—typically SAE 1008 mild steel for economy or 409/304 stainless steel for corrosion resistance—and matching it with the appropriate stamping process, such as progressive die stamping for volume production. This guide explores the engineering specifications, material science, and manufacturing standards required to source durable exhaust hangers.

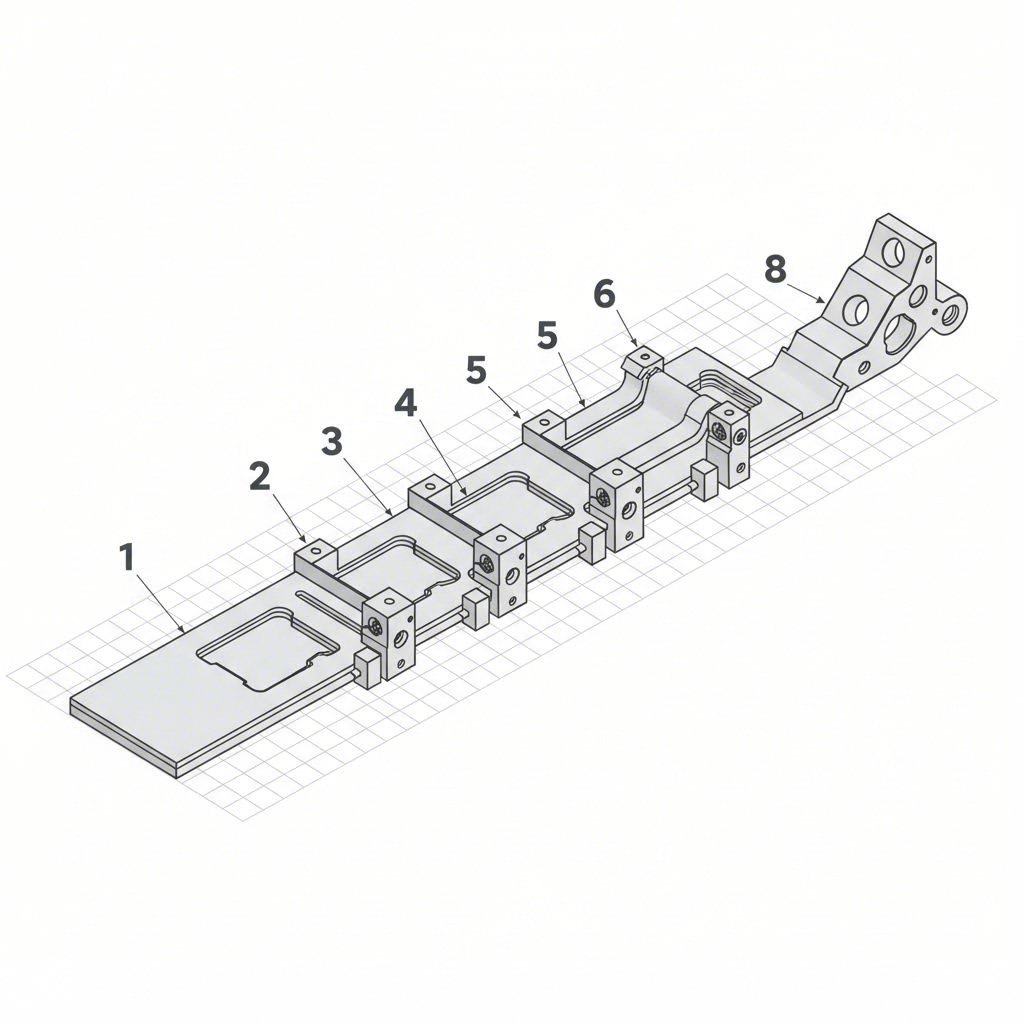

The Anatomy of a Stamped Exhaust Hanger

An exhaust hanger is more than a simple hook; it is a tuned system designed to isolate the vehicle chassis from the intense vibrations and thermal expansion of the exhaust drivetrain. The stamped metal component acts as the rigid interface, while the rubber isolator (or "biscuit") provides damping.

There are three primary configurations manufactured via metal stamping:

- Stamped Bracket Assemblies: These are complex shapes formed from sheet metal, often featuring strengthening ribs to prevent fatigue. They are typically welded to the vehicle chassis or the exhaust pipe.

- Rod-Type with Stamped Flanges: A steel rod is bent to shape and welded to a stamped flat flange. This hybrid design allows for flexible routing while maintaining a secure bolt-on point.

- Bonded Rubber-to-Metal Hangers: As detailed by Custom Rubber Corp, these high-performance units involve molding the rubber directly onto the stamped metal support ring. This process requires the metal stamping to be free of oil and burrs to ensure the heat-activated adhesive bonds correctly, preventing delamination under stress.

Material Science: 409 vs. 304 vs. Mild Steel

Selecting the raw material is the single most impactful engineering decision affecting the longevity and cost of the part. Automotive standards generally dictate the use of materials that can withstand road salts, thermal cycling, and constant vibration.

SAE 1008/1018 Mild Steel

Mild steel is the standard for dry-end applications (closer to the tailpipe) where temperatures are lower, or for hangers that will be subsequently e-coated or zinc-plated. It offers excellent formability with minimal springback (the tendency of metal to return to its original shape after stamping). However, without a protective coating, it fails rapidly in salt spray tests.

409 Stainless Steel (Ferritic)

This is the industry workhorse for exhaust components. It contains roughly 11% chromium, providing adequate corrosion resistance at a lower cost than 304. Manufacturers like E&E Manufacturing specialize in stamping 409 for muffler shells and hangers because it balances durability with stampability. It may develop surface rust (patina) but rarely structurally fails.

304 Stainless Steel (Austenitic)

Used for premium or "cold-end" aesthetic parts, 304 offers superior corrosion resistance due to higher nickel content. However, it presents a manufacturing challenge: work hardening. As the metal is stamped, it becomes harder and more brittle. tooling must be designed with specific coatings (like TiCN) to prevent galling, and press speeds may need adjustment.

| Material Grade | Corrosion Resistance | Stampability | Cost Factor | Typical Application |

|---|---|---|---|---|

| SAE 1008 (Coated) | Low (depends on coating) | Excellent | $ | Chassis-side brackets |

| 409 Stainless | Medium (Ferritic) | Good | $$ | OEM Muffler hangers |

| 304 Stainless | High (Austenitic) | Difficult (Work Hardens) | $$$ | Luxury/Aftermarket |

The Manufacturing Process: Progressive vs. Transfer Dies

Understanding the stamping process helps procurement officers evaluate a supplier's capacity and quality potential. The choice between progressive and transfer dies depends largely on production volume and part complexity.

Progressive Die Stamping

For high-volume OEM contracts (50,000+ units/year), progressive die stamping is the standard. A continuous strip of metal is fed into the press, and the part is formed in stages (blanking, piercing, forming, coining) with each stroke. This ensures high dimensional repeatability, crucial for automated assembly lines.

Transfer Die & Single Stage

For lower volumes or larger, deeper parts, transfer dies move the workpiece between stations using mechanical fingers. This allows for more complex geometries that might tear the metal in a progressive die strip. Specialized suppliers often employ presses with significant tonnage—up to 600 tons—to handle thicker gauges required for heavy-duty truck hangers.

Secondary Operations & Assembly

A raw stamping is rarely the finished product. As noted by Erin Industries, the manufacturing workflow often includes secondary tube bending, swaging, and welding (MIG/TIG/Spot) to create complete hanger assemblies. The integration of these services under one roof reduces logistics costs and quality disputes.

Engineering for Durability & NVH

The engineering "secret" of a quality exhaust hanger lies in its ability to act as a vibration filter. A hanger that is too stiff will transmit engine noise into the cabin; one that is too soft will allow the exhaust to sway and hit the underbody.

NVH Isolation: Stamped brackets are often designed with specific "tuned" stiffness. Engineers add ribbing or flanges to the stamped profile not just for strength, but to shift the part's natural resonant frequency away from the engine's operating frequencies. This prevents the hanger from buzzing or cracking due to resonance fatigue.

Fatigue Life: The bend radii in stamped stainless steel must be carefully calculated. If a bend is too sharp, micro-cracks can form during the stamping process (especially in work-hardening 304 stainless). Over time, the thermal expansion of the exhaust system will cause these cracks to propagate, leading to failure. Leading manufacturers utilize simulation software to predict thinning and cracking risks before the die is even cut.

Sourcing Guide: Selecting a Manufacturer

When vetting a metal stamping partner for exhaust components, look beyond simple price-per-part metrics. The ability to scale from prototype to mass production without compromising quality is paramount. Suppliers should hold certifications like IATF 16949, which is mandatory for most automotive supply chains.

Key questions to ask potential suppliers include:

- Tonnage Capacity: Do they have presses capable of handling high-strength stainless steel? For example, manufacturers like Shaoyi Metal Technology utilize presses up to 600 tons to ensure precision forming of thick-gauge components, bridging the gap between rapid prototyping and high-volume output.

- Tooling Capabilities: Do they design and build dies in-house? In-house tooling reduces lead times for engineering changes.

- Testing Facilities: Can they perform salt spray testing (ASTM B117) and tensile testing on-site to verify material specs?

Conclusion

Exhaust hanger metal stamping is a discipline that merges metallurgical science with precision manufacturing. Whether using 409 stainless for an OEM run or mild steel for a chassis bracket, the success of the part depends on accurate process selection and strict adherence to geometric tolerances. By understanding the interaction between material properties and die dynamics, buyers can ensure they source components that withstand the rigorous demands of the automotive underbody environment.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —