Essential Fixes for Common Automotive Stamping Die Defects

TL;DR

Common automotive stamping die defects are imperfections that occur during the metal forming process, most often including wrinkles, splits, springback, and burrs. These flaws typically arise from a few core issues: incorrect press settings, worn or misaligned tooling, and inconsistencies in the sheet metal material itself. Addressing these root causes is crucial for producing high-quality, dimensionally accurate components and avoiding costly production delays.

The 'Big Three' Stamping Defects: Wrinkles, Splits, and Springback

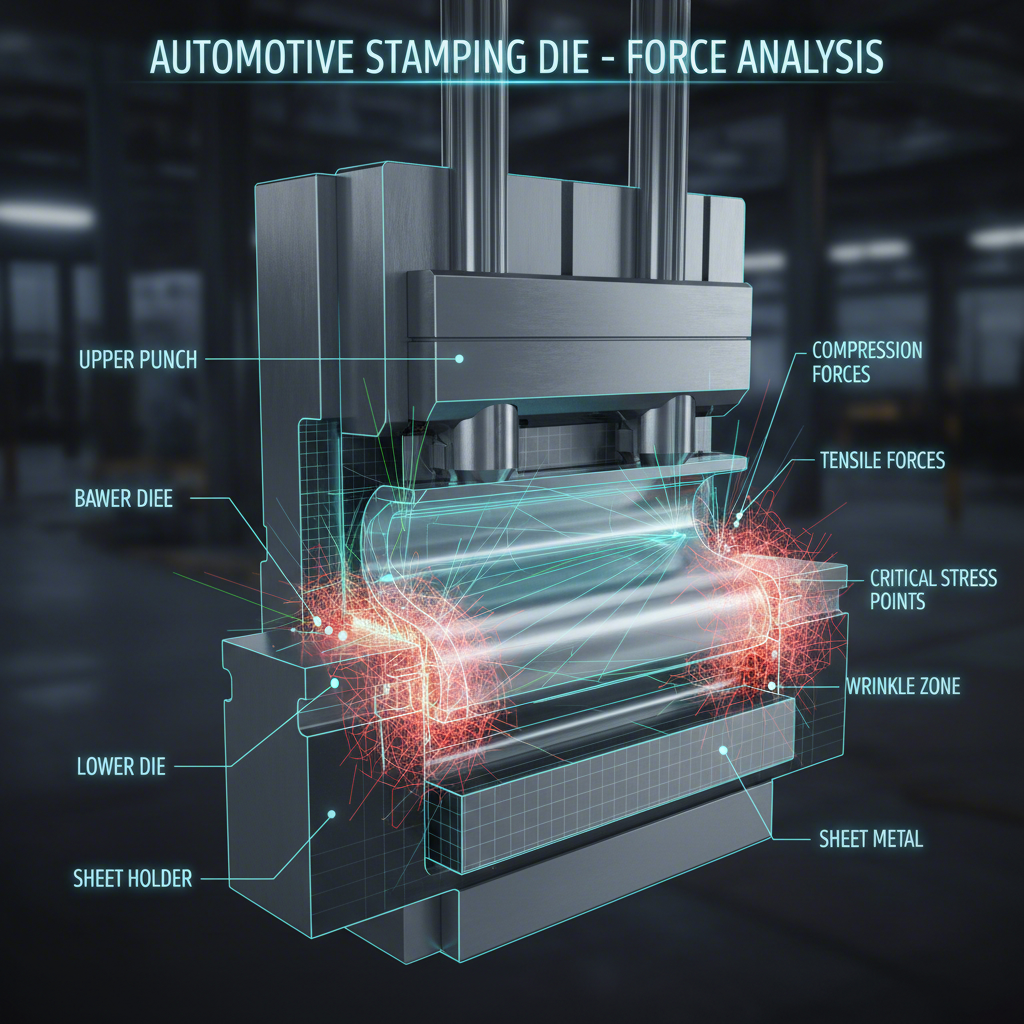

In the world of automotive metal stamping, three defects stand out for their frequency and impact on part quality: wrinkles, splits, and springback. Understanding the distinct causes and characteristics of each is the first step toward effective prevention and resolution. Each of these flaws points to a specific imbalance of forces and material properties within the stamping process.

Wrinkles are wave-like or folded imperfections that appear on the surface of a part, particularly in flanges or curved areas. According to insights from stamping simulation experts, wrinkles occur when compressive strains cause the sheet metal to buckle or overlap. This often happens when the binder or blank holder force is insufficient, allowing too much material to flow uncontrolled into the die cavity. Thinner materials are generally more susceptible to wrinkling because they have less structural resistance to these compressive forces.

Splits, also known as tearing or fractures, are the opposite problem. They occur when the sheet metal is stretched beyond its formability limits, causing it to crack or tear open. This defect indicates that the material has exceeded its ultimate tensile strength. Common causes include die radii that are too sharp, excessive blank holder force that restricts material flow, or selecting a material grade with insufficient ductility for a deep drawing operation. Identifying the forming limit diagram (FLD) for a given material is key to predicting and preventing these failures.

Springback is a more subtle but equally challenging defect where the metal part elastically returns to a shape slightly different from the die's geometry after the forming pressure is released. This phenomenon is especially prevalent in high-strength steels (HSS) and advanced high-strength steels (AHSS), which have a higher degree of elasticity. As noted by Die-Matic's analysis, if not accounted for, springback can lead to significant dimensional inaccuracies, affecting how parts fit together in the final vehicle assembly.

| Defect | Primary Cause | Appearance | Common Solution |

|---|---|---|---|

| Wrinkling | Insufficient binder force; uncontrolled material flow (compressive stress). | Wavy folds or creases on the part surface. | Increase and optimize blank holder pressure; add or adjust draw beads. |

| Splitting/Tearing | Material stretched beyond its forming limit (tensile stress). | A visible fracture or tear in the metal. | Optimize die radii; select a more ductile material; reduce blank holder force. |

| Springback | Elastic recovery of the material after forming. | Dimensional deviation from the intended shape. | Compensate tooling (over-bending); induce positive stretching. |

Solving these core defects requires a strategic approach. For wrinkles, the primary solution is to increase the blank holder force to better control material flow. For splits, solutions involve optimizing the tool geometry, such as enlarging the draw radii to reduce stress concentration, or selecting a more formable material. To counteract springback, engineers often employ tool compensation, where the die is designed to 'over-bend' the part, anticipating the elastic recovery so it settles into the correct final shape.

Common Surface and Edge Imperfections: Burrs, Cracks, and Mismatches

Beyond the major forming defects, a number of surface and edge imperfections can compromise the quality, safety, and functionality of stamped automotive parts. Issues like burrs, surface cracks, and mismatched edges often point to problems with tooling maintenance, alignment, or the cutting process itself. Though sometimes considered minor, these defects can cause significant problems in automated assembly and affect the final product's integrity.

Burrs are sharp, raised edges of excess material that remain on a part after a cutting, blanking, or punching operation. According to Franklin Fastener, the most common cause is a dull cutting edge on the stamping die or improper clearance between the punch and the die. When the clearance is too large or the edges are worn, the metal is torn rather than cleanly sheared. These sharp protrusions can interfere with part assembly, create safety hazards for technicians, and even break off to become contaminants in sensitive systems.

Surface cracks differ from the full splits seen in deep drawing. These are smaller, localized fractures that may not penetrate the full thickness of the material but still represent a structural weakness. They often result from using a material with poor surface quality or from localized stress concentrations during forming. Improper blank holder force can also contribute, creating tension that leads to micro-fractures on the part's surface. These defects can be critical, as they may propagate over time due to vibration and stress, leading to premature component failure.

Mismatched edges occur when trimmed or formed edges do not align correctly, resulting in an uneven or stepped finish. This defect is typically a sign of tool misalignment, where the upper and lower halves of the die are not perfectly synchronized. It can also be caused by an incorrect bending angle or improper material feeding. Mismatched edges can prevent parts from fitting together correctly, leading to gaps, rattles, and compromised structural joints in the final assembly.

Preventing these surface and edge defects relies heavily on rigorous process control and maintenance. A proactive approach is always more effective and less costly than reactive fixes. Here are several key prevention techniques:

- Implement a Strict Tool Maintenance Schedule: Regularly inspect and sharpen all cutting edges on punches and dies to prevent burrs. Ensure proper punch-to-die clearance is maintained according to material type and thickness.

- Verify Tool and Press Alignment: Consistently check the alignment of the die set within the press to avoid mismatched edges. Worn guide pins and bushings should be replaced promptly.

- Control Blank Holder Force: Calibrate and monitor the blank holder force to ensure it is sufficient to prevent wrinkling but not so excessive that it causes surface cracks or splits.

- Select High-Quality Materials: Work with reputable suppliers to ensure the sheet metal has a consistent thickness and a clean, defect-free surface suitable for the intended forming operation.

- Ensure Proper Lubrication: Use the correct type and amount of lubricant to reduce friction between the die and the workpiece, which helps prevent galling, scratches, and surface cracks.

Root Cause Analysis: Uncovering the Source of Stamping Failures

While it is essential to identify and correct individual stamping defects, a more powerful strategy is to understand and address their underlying root causes. Most stamping failures can be traced back to a handful of core areas: the tooling itself, the process control parameters, and the raw material. By focusing on these foundational elements, manufacturers can move from a reactive, problem-solving mode to a proactive, defect-prevention mindset.

Tooling Issues are a primary source of defects. Worn or broken punches, dull cutting edges, and improper die setup are frequent culprits. For example, as highlighted by multiple stamping experts, a dull cutting edge is the direct cause of burrs. Similarly, die breakage, while less common, can occur from using incorrect materials in the tool itself or applying excessive force. The precision and durability of the die are paramount. Partnering with expert die makers is critical to success. For instance, leading manufacturers like Shaoyi (Ningbo) Metal Technology Co., Ltd. specialize in custom automotive stamping dies, leveraging advanced simulations and IATF 16949 certification to build high-quality tooling designed to minimize defects from the outset.

Process Control is another critical area. Incorrect press settings can wreak havoc on production quality. As noted by Die-Matic, improper tonnage (force), stroke speed, or dwell time can directly produce defects like springback, thinning, and cracks. A misaligned material feed can lead to off-center parts and mismatched edges. Insufficient or incorrect lubrication can cause galling and surface scratches. These parameters must be carefully calibrated for each specific job and monitored throughout the production run to ensure consistency.

Finally, Material Inconsistencies can introduce defects even when tooling and processes are perfectly optimized. Variations in sheet metal thickness, hardness, or chemical composition from one coil to another can lead to unpredictable results. A process that works perfectly for one batch of material may produce wrinkles or splits on the next if the material's properties have changed. This underscores the importance of strong supplier relationships and incoming material inspection to ensure consistency.

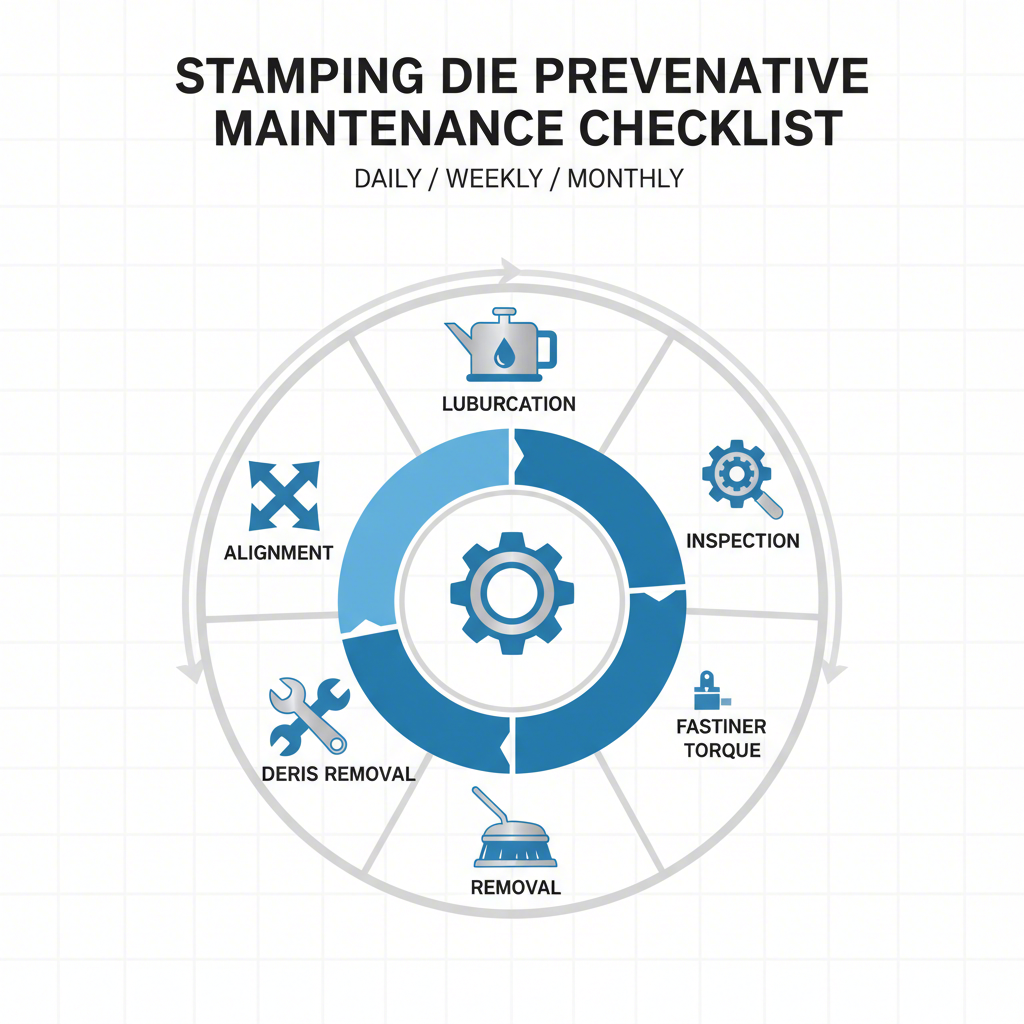

Adopting a preventative maintenance program is the most effective way to address these root causes before they lead to defects. A robust program should include the following:

- Regular Tool Inspection and Servicing: Dies should be cleaned, inspected for wear, and sharpened at scheduled intervals, not just when problems arise.

- Press Calibration and Monitoring: Regularly verify press settings like tonnage, parallelism, and speed to ensure they remain within specified tolerances.

- Lubrication System Checks: Ensure lubrication systems are functioning correctly and applying the appropriate amount of the correct lubricant.

- Material Certification and Testing: Require material certifications from suppliers and perform spot checks on incoming coils to verify properties like thickness and hardness.

- Operator Training: Well-trained operators are the first line of defense. They should be skilled in proper die setup, material handling, and the early detection of emerging defects, as emphasized by sources like Keats Manufacturing.

From Diagnosis to Prevention: A Proactive Approach

Successfully managing common automotive stamping die defects requires a shift from simply identifying flaws to proactively preventing them. Understanding the interconnectedness of tooling, process parameters, and material quality is fundamental. Defects like wrinkles, splits, and burrs are not random events; they are symptoms of an underlying issue in the manufacturing system. By focusing on root cause analysis and implementing rigorous preventative maintenance, manufacturers can significantly improve part quality, reduce scrap, and enhance overall efficiency.

The key takeaways are clear: invest in high-quality, precision-engineered tooling; establish and maintain meticulous process controls for every production run; and demand consistency in raw materials. A commitment to regular equipment inspection, die maintenance, and continuous employee training forms the foundation of a robust quality control system. Ultimately, this proactive approach not only solves current problems but also builds a more resilient and reliable production environment for the future.

Frequently Asked Questions

1. What is the most common cause of burrs in metal stamping?

The most common cause of burrs is a dull cutting edge on the stamping die or punch. Another frequent cause is excessive clearance between the punch and the die. When these conditions exist, the metal is torn or extruded rather than being cleanly sheared, leaving a sharp, raised edge on the part.

2. How can springback be controlled in high-strength steel parts?

Controlling springback, especially in high-strength steels, typically requires a combination of strategies. The most common method is to compensate the tooling by 'over-bending' the part, so it elastically relaxes into the desired shape. Other techniques include inducing positive stretching in the part to increase its stiffness or using multi-stage forming processes to manage stresses more effectively.

3. Can the wrong lubricant cause stamping defects?

Yes, improper lubrication is a significant cause of several stamping defects. Insufficient lubrication can lead to increased friction, causing surface defects like scratches, scuffing, and galling. It can also contribute to excessive heat buildup, which can affect both the tooling and the material properties. Using the wrong type of lubricant can also be ineffective or even react negatively with the material.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —