Essential Automotive Die Repair Methods for Peak Performance

TL;DR

Automotive die repair methods encompass a spectrum of activities, from proactive, preventative maintenance to reactive, complex repairs. The core principle is to systematically inspect, clean, sharpen, and optimize dies to prevent failures. When damage occurs, methods like precision grinding, laser welding, and component replacement are used to restore functionality, ensuring maximum productivity and consistent part quality in manufacturing.

Understanding Die Maintenance vs. Die Repair

In the world of automotive manufacturing, the terms 'die maintenance' and 'die repair' are often used interchangeably, but they represent fundamentally different philosophies and practices. Understanding this distinction is the first step toward creating a robust system that minimizes downtime and maximizes the lifespan of critical tooling. One approach is proactive and scheduled, while the other is reactive and often urgent.

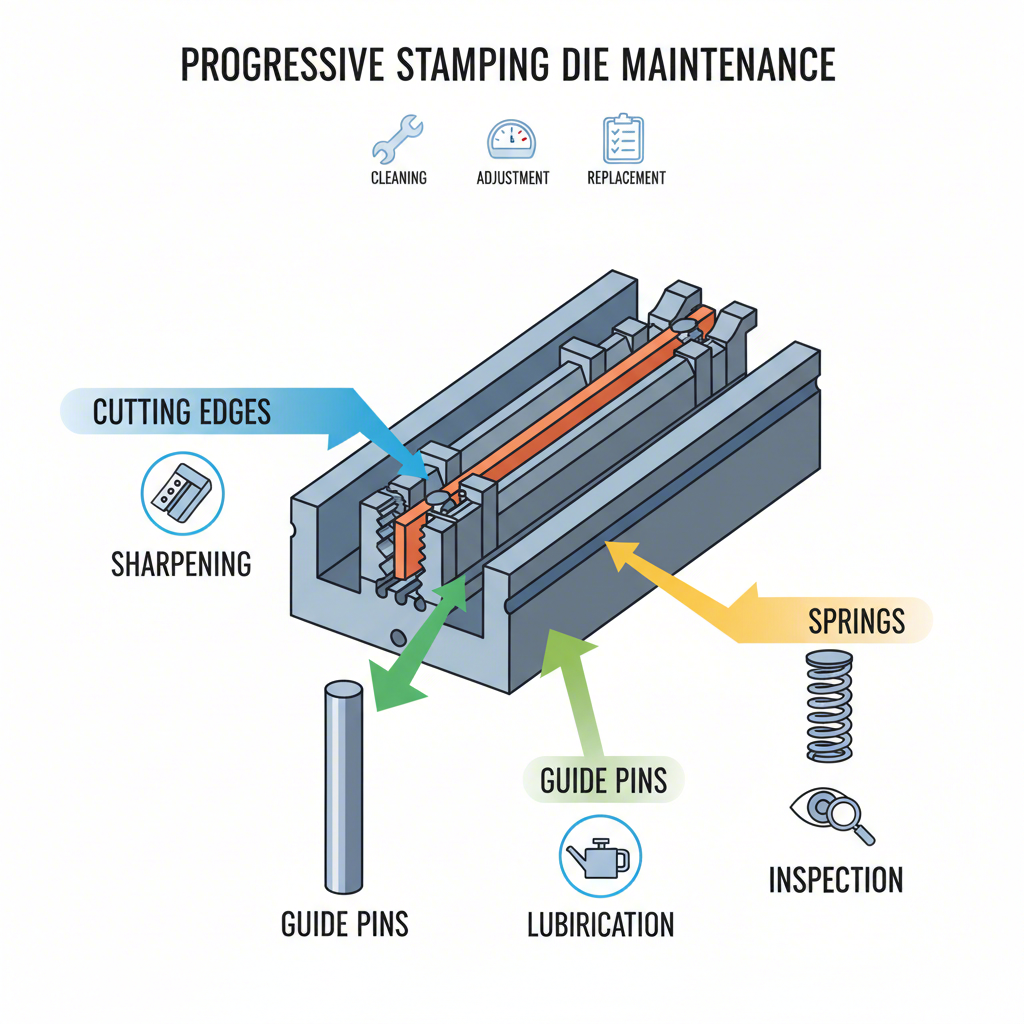

Die maintenance is a systematic, preventative strategy. Its primary goal is to prevent problems before they start. As outlined by experts, this involves routine, scheduled activities such as sharpening cutting sections, cleaning dies, inspecting for loose components like dowels or screws, and replacing parts like springs before they reach their failure point. The objective is to keep the die operating within its optimal parameters, ensuring consistent part quality and preventing unexpected production stoppages. A well-executed maintenance program is a cornerstone of efficient manufacturing, directly contributing to improved equipment reliability and reduced costs associated with scrap and defects.

Die repair, conversely, is a reactive process. It occurs when a die has already failed or is producing parts outside of specification. This could involve fixing a cracked die section, welding a damaged surface after a component failure, or addressing severe galling. While necessary, an over-reliance on repair indicates underlying issues in design, setup, or the maintenance program itself. Frequent repairs are costly, not only in terms of labor and materials but also in lost press time and production delays. A manufacturing operation that constantly finds itself in 'repair mode' is often struggling with inefficiency and unpredictable output.

To better illustrate the strategic differences, consider the following comparison:

| Aspect | Die Maintenance | Die Repair |

|---|---|---|

| Timing | Proactive and scheduled | Reactive and unscheduled |

| Goal | Prevent failure, ensure quality | Restore function after failure |

| Cost | Lower, predictable operational expense | Higher, unpredictable emergency expense |

| Impact on Production | Minimizes disruption | Causes significant downtime |

| Typical Activities | Cleaning, sharpening, inspection, lubrication | Welding, grinding cracks, replacing broken parts |

Ultimately, a successful operation prioritizes maintenance to minimize the need for repair. By implementing a rigorous preventative maintenance schedule, manufacturers can identify and address wear and tear before it leads to catastrophic failure. This data-driven approach, often managed through a formal work order system, transforms the die shop from a reactive fire-fighting unit into a proactive force for quality and productivity.

Core Methods for Die Repair and Maintenance

A comprehensive die care program relies on several fundamental methods that address the most common sources of wear and failure. These techniques, when applied correctly and consistently, form the backbone of both preventative maintenance and minor repair operations. They ensure that dies remain sharp, properly aligned, and free from contaminants that can cause damage or part defects.

Sharpening is one of the most critical maintenance tasks. Over time, the cutting edges and punch surfaces of a die naturally dull, leading to burrs on stamped parts and increased stress on the tool and press. Proper sharpening involves more than just grinding down the surface. It requires using the correct type of grinding wheel for the specific tool steel to prevent overheating, which can soften the metal and cause cracking. Furthermore, grinding the correct shear angle—the angle on the cutting sections—is essential for reducing cutting force, minimizing shock, and extending the life of both the die and the press.

Shimming is another key technique used to maintain the precise timing and alignment of die components. Shims are thin pieces of metal placed under die sections to adjust their height. However, this must be done carefully. Using too many thin shims can create a 'spongy' effect, allowing for unwanted movement that can lead to inconsistent part quality. The best practice is to use fewer, thicker shims whenever possible. During this process, it is crucial to ensure all shims are free of burrs and that there is proper clearance for screws, dowels, and slug-drop holes to prevent interference.

A disciplined cleaning and inspection routine is arguably the most important preventative measure. Regular inspection allows technicians to spot potential issues before they escalate into major repairs. A thorough process includes several key steps:

- Check for Loose Fasteners: Systematically verify that all screws and dowels are tight and in place. A loose component can lead to misalignment and catastrophic die failure.

- Inspect for Wear and Damage: Look for signs of galling (a form of wear caused by adhesion between sliding surfaces), as well as chipped or cracked die sections that may need to be replaced.

- Examine Springs and Components: Check for broken springs and replace them if they are near the end of their expected life cycle. Ensure all cutting punches are secure in their retainers.

- Clean and Lubricate: Remove all debris, slugs, and lubricant buildup from the die. After cleaning, lubricate all necessary mating surfaces to ensure smooth operation.

The tools required for these tasks can range from basic to specialized. A typical die maintenance toolkit would include:

- Precision grinding wheels (selected for the specific tool steel)

- Oilstone and diamond files for fine finishing

- Precision measurement tools like calipers and micrometers

- Torque wrenches to ensure fasteners are tightened to specification

- Cleaning supplies and appropriate lubricants

By mastering these core methods, a die shop can significantly reduce the frequency of major repairs, extend the life of its tooling, and ensure the consistent production of high-quality automotive parts.

Advanced and Rapid Repairing Techniques

While routine maintenance can prevent many issues, some types of wear or damage require more advanced technological intervention. For complex automotive panel dies, where precision is paramount and downtime is extremely costly, advanced and rapid repairing techniques are essential. These methods go beyond traditional grinding and shimming, employing sophisticated technology to restore a die's original geometry and surface properties with incredible accuracy.

One of the most effective modern methods is **Laser Welding or Cladding**. This technique uses a high-energy laser beam to melt a filler material (often an alloy powder or wire) onto the damaged or worn area of the die. This process creates a dense, metallurgically bonded repair layer that is exceptionally strong and durable. The primary advantage of laser welding is its minimal heat-affected zone (HAZ). Unlike traditional welding, which can heat a large area and risk distorting the entire die section, a laser focuses intense energy on a very small spot. This precision allows for repairs on intricate features without compromising the integrity of the surrounding tool steel.

Another high-precision method is **Electrical Discharge Machining (EDM)**. EDM is often used to repair chipping, cracks, or other local defects with surgical precision. The process uses electrical sparks to erode metal, allowing a technician to remove damaged material or add new material via micro-EDM cladding. Like laser welding, EDM has a very small heat-affected zone, making it ideal for repairing high-precision dies where maintaining dimensional stability is critical.

Beyond repairing geometry, restoring a die's surface properties is equally important. This is where **Surface Engineering and Hardening** techniques come into play. If a die's surface has lost its hardness due to wear, it can be restored through processes like re-quenching or tempering. For even greater durability, advanced surface coatings can be applied. Physical Vapor Deposition (PVD) coatings, such as Titanium Nitride (TiN) or Chromium Nitride (CrN), create an ultra-hard, low-friction layer on the die surface. This not only improves wear resistance but can also enhance material flow during the stamping process, extending the die's operational life significantly. Leading manufacturers in the automotive sector often rely on partners with deep expertise in these areas. For instance, specialists like Shaoyi (Ningbo) Metal Technology Co., Ltd. leverage advanced technologies and precision engineering to produce high-quality custom automotive stamping dies, where such repair and maintenance principles are integral to achieving the required longevity and performance for OEMs and Tier 1 suppliers.

Choosing the right advanced technique depends on the specific problem. A company might opt for laser welding to repair a high-wear corner on a forming die, followed by precision NC (Numerical Control) machining to restore the exact geometry. The decision to invest in these technologies over traditional methods often hinges on factors like die complexity, production volume, and the immense cost of unplanned downtime.

The Role and Responsibilities of a Die Maintenance Professional

Behind every well-maintained die and successful production run is a skilled die maintenance professional. This role, often titled a Tool and Die Maker or Die Maintenance Technician, is critical to the entire manufacturing ecosystem. These professionals are not simply mechanics; they are highly skilled artisans who blend mechanical aptitude with a deep understanding of metallurgy, precision machining, and the stamping process itself. Their expertise directly impacts production efficiency, part quality, and operational profitability.

The primary responsibilities of a die maintenance technician are multifaceted. Their core duty is to perform scheduled preventative maintenance and carry out necessary repairs on dies. This involves troubleshooting issues that arise during production, diagnosing the root cause of a problem—be it a dull punch, a misaligned component, or a worn forming section—and executing the proper repair. They use a wide array of specialized tools, from precision grinders and milling machines to advanced diagnostic equipment, to ensure every component of the die functions as designed.

A typical day for a die maintenance professional involves a variety of tasks. They might start by reviewing work orders from the previous production shift to prioritize their work. This could lead to carefully disassembling a die, sharpening all its cutting sections, shimming components to restore timing, and reassembling it for the next run. They are also responsible for documenting all work performed, which creates a valuable history that can be used to predict future maintenance needs and identify recurring problems that may point to a flaw in the die's design.

Becoming a proficient die maintenance technician requires a unique skill set. Key attributes include:

- Mechanical Aptitude: An intuitive understanding of how mechanical systems work is fundamental.

- Attention to Detail: The work is precise, often dealing with tolerances measured in the thousandths of an inch. A small error can lead to major production issues.

- Problem-Solving Skills: Technicians must be able to analyze a problem, identify its root cause, and devise an effective solution, often under pressure.

- Proficiency with Tools: Mastery of both hand tools and advanced machinery, including grinders, lathes, and sometimes CNC machines, is essential.

Frequently Asked Questions

1. What is a die repair?

Die repair involves the maintenance and fixing of dies, which are specialized tools used in manufacturing to cut or shape material. The responsibilities of a die repairperson include troubleshooting issues that arise during production, diagnosing the cause of a defect or failure, and using the appropriate tools and methods to restore the die to its proper working condition.

2. What does a die maintenance technician do?

A die maintenance technician is a skilled professional responsible for manufacturing and maintaining the engineering tooling used to produce components. Their work involves performing scheduled preventative maintenance, such as cleaning and sharpening, as well as carrying out complex repairs to ensure the dies function correctly, produce high-quality parts, and have a long operational life.

3. What is tool and die maintenance?

Tool and die maintenance is the systematic process of caring for tooling to ensure its longevity and performance. This includes routine activities like inspecting for wear, cleaning components, lubricating moving parts, sharpening cutting edges, and replacing worn or damaged parts. The goal of die maintenance is to prevent unexpected breakdowns and maintain the continuity and quality of the production line.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —