A2 vs D2 Steel: Which Is Right for Your Stamping Dies?

TL;DR

When selecting a material for stamping dies, the choice between A2 and D2 tool steel presents a critical trade-off. D2 tool steel offers superior wear resistance, making it ideal for long production runs and abrasive materials where die longevity is paramount. In contrast, A2 tool steel provides significantly better toughness, which helps prevent chipping or cracking in dies with complex geometries or under high-impact conditions. A2 is also easier and more cost-effective to machine, making it a versatile choice for a wide range of applications.

Foundational Properties: An Introduction to A2 and D2 Tool Steels

A2 and D2 are both high-carbon, high-chromium, cold-work tool steels, but their specific formulations give them distinct personalities. A2 is often considered a versatile, all-purpose grade, striking a balance between toughness and wear resistance. It serves as a bridge between oil-hardening steels and high-chromium steels like D2. D2, on the other hand, is a specialist, engineered for maximum wear resistance in demanding, high-volume applications.

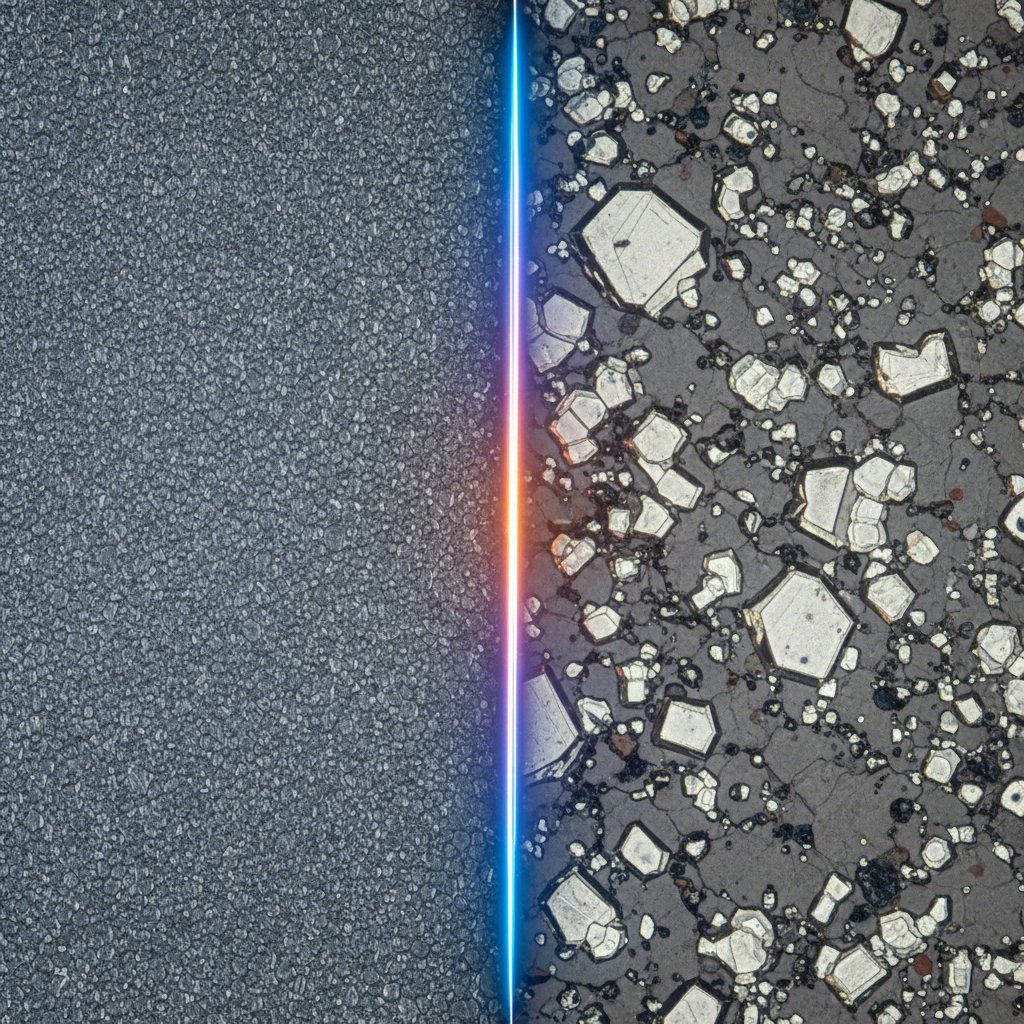

The primary difference lies in their chemical composition, which dictates their performance. D2's significantly higher chromium and carbon content is the key to its exceptional wear resistance. During heat treatment, these elements form a high volume of hard chromium carbide particles within the steel's matrix, which resist abrasion during stamping operations. A2 has a more modest alloy content, resulting in a tougher and more uniform microstructure.

The table below outlines the typical chemical compositions that define their characteristics:

| Element | A2 Tool Steel (Typical %) | D2 Tool Steel (Typical %) |

|---|---|---|

| Carbon (C) | 0.95 - 1.05 | 1.40 - 1.60 |

| Chromium (Cr) | 4.75 - 5.50 | 11.00 - 13.00 |

| Molybdenum (Mo) | 0.90 - 1.40 | 0.70 - 1.20 |

| Vanadium (V) | 0.15 - 0.50 | ≤ 1.10 |

After proper heat treatment, both steels can achieve a similar hardness, typically in the range of 57-62 HRC for A2 and 55-62 HRC for D2. However, hardness alone does not tell the full story. The performance differences in toughness and wear resistance at these hardness levels are what truly distinguish them in stamping die applications.

Core Comparison: Wear Resistance vs. Toughness in Stamping Dies

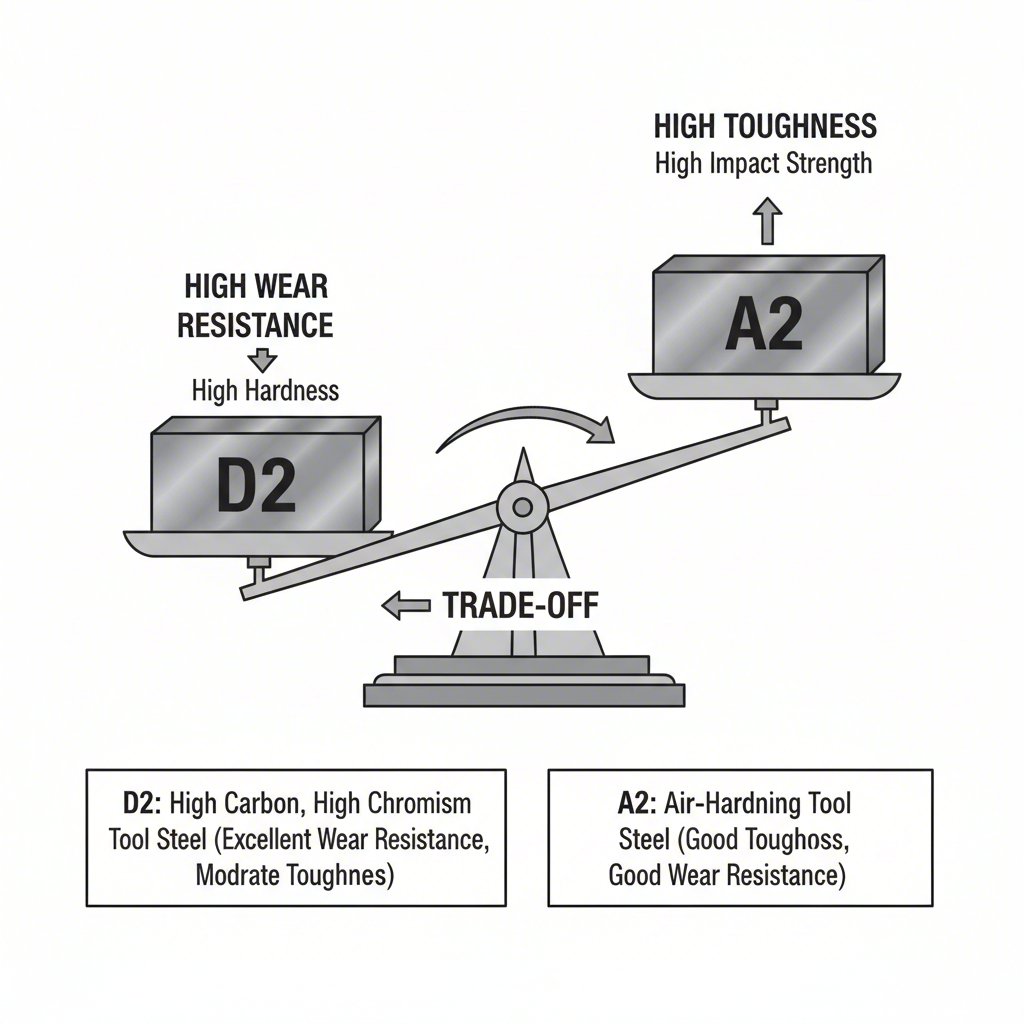

The central decision-making factor when choosing between A2 and D2 for stamping dies is the balance between wear resistance and toughness. These two properties are inversely related; gaining more of one almost always means sacrificing some of the other. Understanding this trade-off is essential for optimizing die performance and longevity.

D2 tool steel is the undisputed leader in wear resistance. Its high concentration of large, hard chromium carbides provides exceptional resistance to the abrasive forces encountered when stamping materials, especially those that are hard or contain abrasive elements like high-silicon steel. This translates to longer production runs between sharpening, reduced downtime, and a lower cost per part in high-volume scenarios. However, this high wear resistance comes at the cost of toughness. The same carbides that resist wear can also act as internal stress points, making D2 more brittle and susceptible to chipping or catastrophic failure under sudden impact or high side-loading forces.

A2 tool steel, conversely, offers superior toughness. Its lower alloy content and more refined carbide structure make it far more resistant to fracture and chipping. This makes A2 an excellent choice for dies with intricate details, sharp corners, or for applications involving heavy forming or blanking operations where impact loading is a significant concern. While its wear resistance is lower than D2's, it is still considered good and is more than adequate for short-to-medium production runs or when stamping softer materials.

A2 Tool Steel

- Pros: Superior toughness and impact resistance, less prone to chipping, better machinability.

- Cons: Lower wear resistance compared to D2, requires more frequent sharpening in high-volume applications.

D2 Tool Steel

- Pros: Exceptional wear resistance and edge retention, ideal for long runs and abrasive materials.

- Cons: Lower toughness (more brittle), susceptible to chipping under impact, more difficult to machine.

Machinability and Manufacturing Considerations

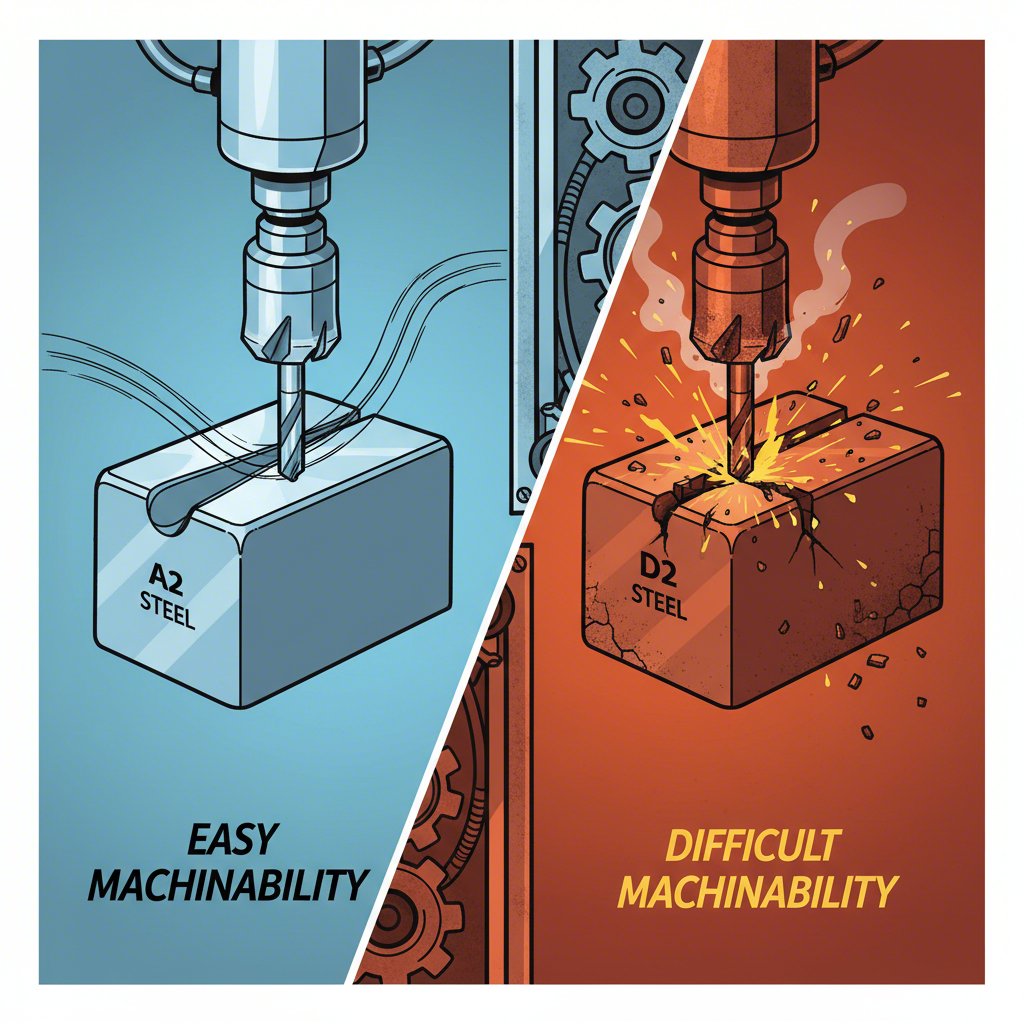

Beyond performance properties, the practical aspects of manufacturing a stamping die are critical. This is another area where A2 and D2 present a stark contrast. A2 tool steel is significantly easier to machine and grind. Its microstructure is more forgiving to cutting tools, allowing for faster machining speeds, reduced tool wear, and ultimately, lower manufacturing costs. This is a considerable advantage when producing complex dies that require extensive machining.

D2, due to its high volume of abrasive chromium carbides, is notoriously difficult to machine. It wears down cutting tools quickly, requires slower machining speeds, and may necessitate the use of specialized equipment like carbide tooling or advanced techniques such as Electrical Discharge Machining (EDM). The grinding process can also be more challenging, adding time and cost to the die-making process. These manufacturing hurdles are a key disadvantage of D2 and must be factored into the total cost equation.

Both A2 and D2 are air-hardening steels, a significant advantage that gives them excellent dimensional stability during heat treatment. This means they are less likely to warp or distort during the hardening process, which is crucial for maintaining the tight tolerances required for stamping dies. While both are stable, A2 is generally considered slightly more forgiving, whereas D2's higher alloy content can make it more sensitive to heat treatment parameters.

| Factor | A2 Tool Steel | D2 Tool Steel |

|---|---|---|

| Machinability | Good | Poor / Difficult |

| Grindability | Good | Poor |

| Heat Treatment Stability | Excellent | Very Good |

Cost-Performance Analysis and Final Recommendation

The final decision between A2 and D2 tool steel for stamping dies comes down to a comprehensive cost-performance analysis. The choice is not simply about which steel is "better," but which is the most economically viable for a specific application. This involves looking beyond the initial material price to consider manufacturing costs and the total expected life of the die.

A2 is generally less expensive as a raw material and, as discussed, costs significantly less to machine into a finished die. For short-to-medium production runs or for stamping non-abrasive materials, A2 often presents the most cost-effective solution. Its excellent toughness provides a reliable safety margin against premature die failure, making it a dependable workhorse for a wide variety of jobs.

D2's higher material and machining costs can only be justified in applications where its superior wear resistance provides a clear return on investment. For example, in a very long production run stamping abrasive stainless steel, a D2 die might last several times longer than an A2 die. This extended service life reduces the need for costly downtime for die maintenance or replacement, leading to a lower total cost of ownership despite the higher upfront investment. The choice becomes an economic calculation: will the savings from reduced downtime and fewer replacements outweigh the initial expense?

For critical projects, particularly in demanding sectors like automotive manufacturing, consulting with a specialist can be invaluable. Firms like Shaoyi (Ningbo) Metal Technology Co., Ltd. specialize in high-precision automotive stamping dies and can provide expert guidance on material selection and die design to ensure optimal performance and cost-efficiency for your specific components.

To make a final decision, use the following matrix to evaluate your application's specific needs:

| Factor | A2 Tool Steel | D2 Tool Steel |

|---|---|---|

| Wear Resistance | Good | Excellent |

| Toughness (Chip Resistance) | Excellent | Fair |

| Machinability | Good | Poor |

| Initial Cost (Material + Machining) | Lower | Higher |

| Best-Fit Application | General purpose, complex dies, medium runs, high-impact stamping | High-volume runs, abrasive materials, simple die shapes |

Frequently Asked Questions

1. Is D2 harder than A2?

While D2 can achieve a slightly higher maximum Rockwell hardness (HRC), both steels operate in a very similar hardness range (typically 55-62 HRC). The more significant difference is not in hardness but in wear resistance. D2's unique chemical composition, rich in carbon and chromium, forms a high volume of hard carbide particles. These carbides give D2 vastly superior resistance to abrasive wear, which is often perceived as being "harder" in application, even if the bulk HRC measurement is similar to A2.

2. What is A2 tool steel good for?

A2 tool steel is an exceptionally versatile material valued for its excellent balance of toughness and good wear resistance. It is ideal for a wide range of cold-work applications, including blanking dies, forming dies, stamping tools, and industrial knives. Its high toughness makes it particularly suitable for tools that are subject to impact or for dies with intricate designs that could be prone to chipping if made from a more brittle material.

3. What are the disadvantages of D2 steel?

The primary disadvantages of D2 steel stem from the same properties that give it excellent wear resistance. Its lower toughness makes it more brittle and susceptible to chipping or breaking under shock loads. It is also significantly more difficult and costly to machine and grind due to its abrasive nature. Finally, while its high chromium content provides some corrosion resistance, it is not a stainless steel and will rust if not properly maintained.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —