Die Casting's Environmental Impact: A Balanced Analysis

TL;DR

The environmental impact of die casting presents a complex picture. While traditional methods contribute to waste generation and high energy consumption, the process also offers significant sustainability advantages. Key benefits include the exceptional recyclability of materials like aluminum and zinc, superior energy efficiency compared to other manufacturing methods, and the ability to produce lightweight, durable parts that reduce the environmental footprint of end products.

The Environmental Footprint of Die Casting: A Balanced View

In modern manufacturing, die casting is a cornerstone process, valued for its precision and efficiency in producing complex metal parts for industries from automotive to aerospace. However, as environmental stewardship becomes a global priority, the industry's ecological footprint is under increasing scrutiny. The environmental impact of die casting is not a simple matter of good or bad; it's a nuanced issue with both significant challenges and compelling sustainable benefits.

On one hand, the process has inherent environmental drawbacks. Traditional die casting is energy-intensive, especially during the melting phase, which often relies on fossil fuels and contributes to carbon emissions. The process can also generate considerable waste, including scrap metal, slags, and other byproducts that require careful management to avoid landfill issues. Furthermore, some associated materials, such as certain lubricants and coatings, can pose pollution risks if not handled correctly.

On the other hand, die casting is a powerful enabler of sustainability. As highlighted by experts at Lupton & Place, its alignment with the 'reduce, reuse, recycle' mantra is a core strength. The process is a near-net-shape method, meaning it produces very little scrap, and any waste metal is typically remelted and reused in-house. This material efficiency is a major environmental advantage. The durability of the molds, which can be used thousands of times, also reduces waste over the long term.

This duality means the overall environmental performance of a die casting operation depends heavily on the specific materials used, the efficiency of the machinery, and the robustness of its waste and energy management systems. Below is a summary of the key environmental considerations:

- Pros: High material efficiency (near-net-shape), exceptional recyclability of alloys, production of lightweight and durable parts, and lower energy consumption compared to many alternative processes.

- Cons: High energy consumption during melting, generation of scrap and waste materials, and potential for harmful emissions from furnaces and lubricants.

Key Environmental Concerns in Traditional Die Casting

While modern practices have made significant strides, it's crucial to understand the specific environmental challenges posed by traditional die casting methods. These concerns primarily fall into three categories: waste generation, energy consumption, and harmful emissions. Acknowledging these issues is the first step toward implementing effective mitigation strategies and transitioning to more sustainable operations.

Waste generation is one of the most visible impacts. As noted by PFA, Inc., the process can produce significant quantities of scrap metal, especially from runners, gates, and overflow wells that are part of the mold design. In addition to solid metal scrap, the melting process creates dross and slag, which are byproducts that must be managed. If not properly handled, these waste streams can contribute to landfill burden and represent a loss of valuable material.

Energy consumption is another major factor. The melting furnaces required to bring metals like aluminum and zinc to a molten state are incredibly energy-intensive. According to industry analyses, the melting stage can account for more than half of a die casting plant's total carbon footprint. In facilities powered by fossil fuels, this high energy demand directly translates to significant greenhouse gas emissions, contributing to climate change.

Finally, the process can release harmful emissions into the atmosphere. Research indicates that melting and casting can be associated with human toxicity problems caused by metal emissions and the release of ozone precursors. These emissions can originate from the metal alloys themselves or from the combustion of fuels in the furnaces. Die release agents and lubricants, when atomized and sprayed onto hot dies, can also create airborne pollutants if not properly ventilated and filtered.

These challenges are summarized in the table below:

| Impact Type | Source in Process | Common Pollutants / Waste |

|---|---|---|

| Waste Generation | Casting Process, Trimming | Scrap Metal (runners, gates), Dross, Slags |

| Energy Consumption | Melting Furnaces, Holding Furnaces | High Carbon Footprint (from electricity/gas) |

| Harmful Emissions | Melting, Die Lubrication | Metal Particulates, Volatile Organic Compounds (VOCs), Greenhouse Gases |

Pathways to Sustainability: How Die Casting Reduces Environmental Impact

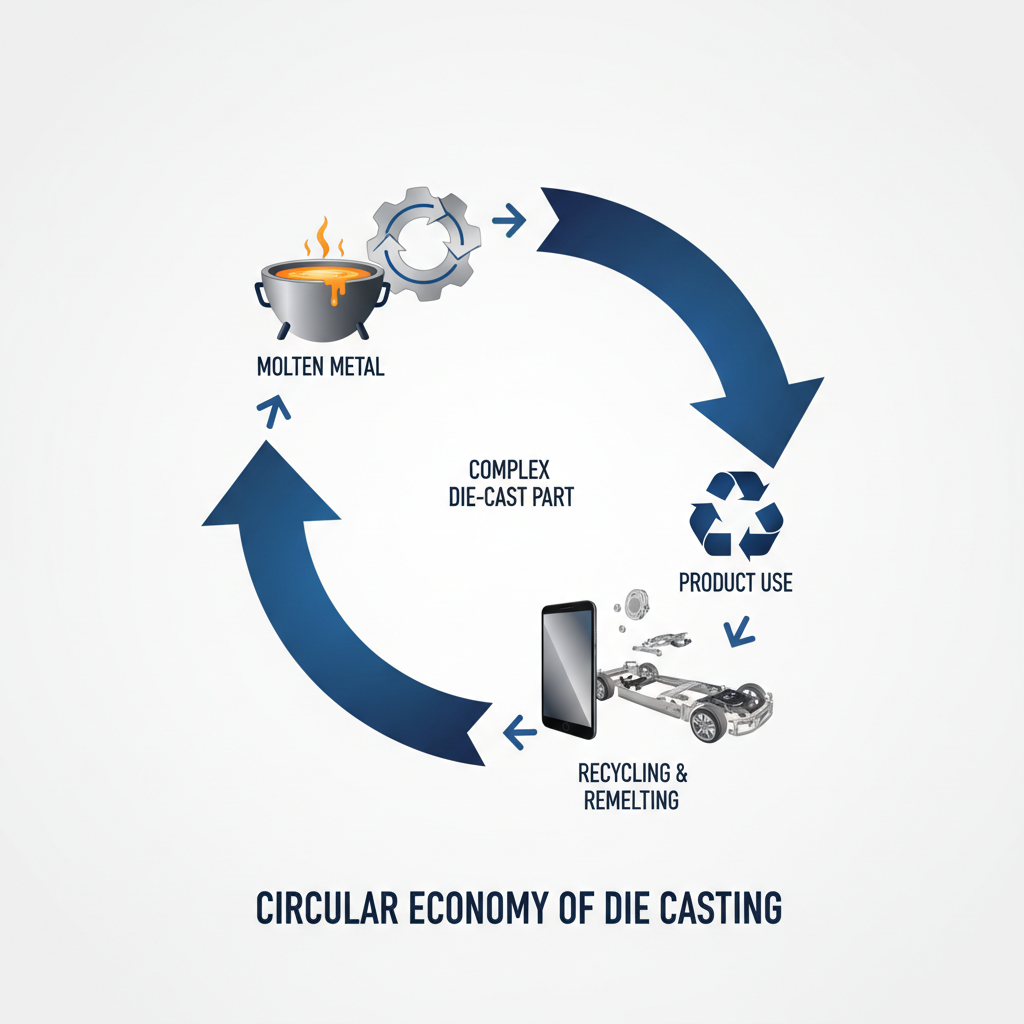

Despite its challenges, die casting offers powerful pathways to sustainability that often outweigh the negatives, especially when modern technologies and best practices are employed. The industry's capacity for reducing environmental impact is rooted in material recyclability, process efficiency, and the functional benefits of the components it produces. These advantages make it a key technology for a circular economy.

The most significant environmental benefit is the superior recyclability of the alloys used. Metals like aluminum, zinc, and magnesium can be recycled indefinitely without losing their structural properties. As highlighted by MRT Castings, many operations primarily use secondary (recycled) aluminum alloys, which dramatically reduces the environmental toll associated with mining and refining virgin ore. Using recycled aluminum requires up to 95% less energy than producing it from raw materials, leading to a massive reduction in the overall carbon footprint.

Energy efficiency during the manufacturing process itself is another key advantage. Die casting is a high-speed, high-volume process that, according to Neway Precision, uses considerably less energy than conventional manufacturing methods like extensive machining from a solid block of metal. Because it is a near-net-shape process, it minimizes the need for energy-intensive secondary operations, saving both time and resources.

Furthermore, die casting enables component consolidation and lightweighting, which have profound downstream environmental benefits. A single, complex die-cast part can often replace an assembly of several components made from different materials like steel and plastic. This simplifies manufacturing, reduces material usage, and lowers the weight of the final product. In the automotive industry, this lightweighting is critical for improving fuel efficiency and extending the range of electric vehicles. Companies specializing in high-precision components, such as AmTech International, play a vital role by manufacturing the custom dies and metal parts that make these advanced, consolidated designs possible for leading automotive suppliers.

To maximize these benefits, manufacturers can follow several key steps:

- Prioritize Recycled Materials: Actively source and specify secondary alloys with high recycled content to minimize the embodied energy of products.

- Optimize Energy Use: Invest in high-efficiency melting furnaces and implement smart scheduling to reduce idle energy consumption.

- Implement Closed-Loop Systems: Establish robust systems to collect, sort, and remelt all in-house scrap metal, minimizing waste sent to landfill.

- Design for Lightweighting: Collaborate with clients to design components that are strong yet lightweight, leveraging the unique capabilities of the die casting process.

- Adopt Modern Technologies: Utilize process simulation software and advanced machinery to improve yield and reduce defects, further enhancing material and energy efficiency.

The Critical Role of Aluminum in Eco-Friendly Die Casting

While various metals are used in die casting, aluminum stands out as the material of choice for eco-conscious manufacturing. Its unique combination of properties—being lightweight, strong, and infinitely recyclable—makes it a cornerstone of sustainable product design. The decision to use aluminum can dramatically reduce the environmental impact of a component throughout its entire lifecycle, from production to end-of-life.

The primary environmental advantage of aluminum is its recyclability. Producing primary aluminum from bauxite ore is an energy-intensive process. However, recycling aluminum saves approximately 95% of that energy. This means that a die-cast part made from secondary (recycled) aluminum has a significantly lower carbon footprint than one made from virgin material. Because aluminum does not degrade during recycling, it can be reused over and over, creating a closed-loop system that is central to the circular economy.

Aluminum's low density is another critical factor. It is about one-third the weight of steel, allowing for the production of lightweight components without sacrificing strength. This is particularly impactful in the automotive and aerospace industries, where weight reduction is directly linked to fuel efficiency and lower emissions. A lighter vehicle consumes less fuel or, in the case of electric vehicles, requires less energy to operate, extending its range and reducing its overall environmental footprint.

The die casting process itself is also particularly well-suited to aluminum. The metal has a relatively low melting point compared to ferrous metals, which reduces the energy required for the melting stage. Its excellent thermal conductivity allows for faster cooling and shorter cycle times, increasing production efficiency and further lowering energy consumption per part. When considering the entire lifecycle, aluminum die casting consistently proves to be a more sustainable option for many applications.

Here is a simplified comparison of how aluminum stacks up against other common materials for a hypothetical component:

| Factor | Aluminum Die Casting | Steel Stamping | Plastic Injection Molding |

|---|---|---|---|

| Component Weight | Low | High | Very Low |

| Energy to Produce | Medium (high if virgin) | High | Low |

| End-of-Life Recyclability | Excellent (infinitely recyclable) | Good (recyclable) | Poor (often downcycled or landfilled) |

| Lifecycle Impact | Low (especially with recycled content) | High | Medium (fossil fuel-based) |

Navigating the Future of Sustainable Manufacturing

Embracing sustainable practices in die casting is no longer a choice but a necessity for a resilient and competitive manufacturing future. The journey involves a conscious shift from traditional methods to a holistic approach that considers the entire lifecycle of a product. By focusing on material choice, energy efficiency, waste minimization, and innovative design, the die casting industry can solidify its role as a key contributor to a global circular economy.

The evidence is clear: the environmental impact of die casting is not fixed but is a direct result of the choices made by manufacturers and product designers. Opting for recycled aluminum, investing in energy-efficient technology, and designing for lightweighting are not just environmental wins—they also lead to economic benefits through cost savings and enhanced product performance. As regulations tighten and consumer demand for green products grows, these sustainable practices will become the standard for industry leaders.

Ultimately, the path forward requires collaboration across the supply chain. From material suppliers committed to providing high-quality recycled alloys to end-users who prioritize sustainable design, every stakeholder has a part to play. By continuing to innovate and adopt responsible practices, die casting will continue to be an essential and increasingly sustainable manufacturing process for generations to come.

Frequently Asked Questions

1. Is die casting eco-friendly?

Die casting can be highly eco-friendly, primarily due to the materials used. Almost all metals common in die casting, such as aluminum, zinc, and magnesium, are fully recyclable. The process itself is also efficient, producing minimal waste (near-net-shape) and allowing for any scrap to be remelted and reused. When paired with recycled alloys and energy-efficient machinery, it is considered a very sustainable manufacturing method.

2. What is the main disadvantage of die casting?

The primary disadvantage of die casting is the high initial cost of tooling. The dies, or molds, are made from hardened steel and require significant investment and lead time to produce. This makes the process most cost-effective for high-volume production runs where the cost of the mold can be spread across thousands or millions of parts. For low-volume production, the tooling cost can be prohibitive.

3. What are the hazards of die casting?

The main hazards in a die casting facility are related to the high temperatures and high pressures involved. Workers face risks of severe burns from molten metal or hot surfaces. Other potential hazards include injuries from moving machinery, cuts from sharp castings or flash, and slips or falls. Proper personal protective equipment (PPE), rigorous safety protocols, and good housekeeping are essential to mitigate these risks.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —