Stamped Steel or Cast? The Essential Control Arm ID Guide

TL;DR

A stamped steel lower control arm is a common vehicle suspension part made by pressing, cutting, and welding sheets of steel together. You can easily identify a stamped steel arm by its smooth surface and a visible weld seam where the pieces are joined. This construction differs from solid cast or forged arms, which are made from a single piece of metal and typically have a rougher, textured finish without weld seams.

Identifying Your Control Arm: A Step-by-Step Guide

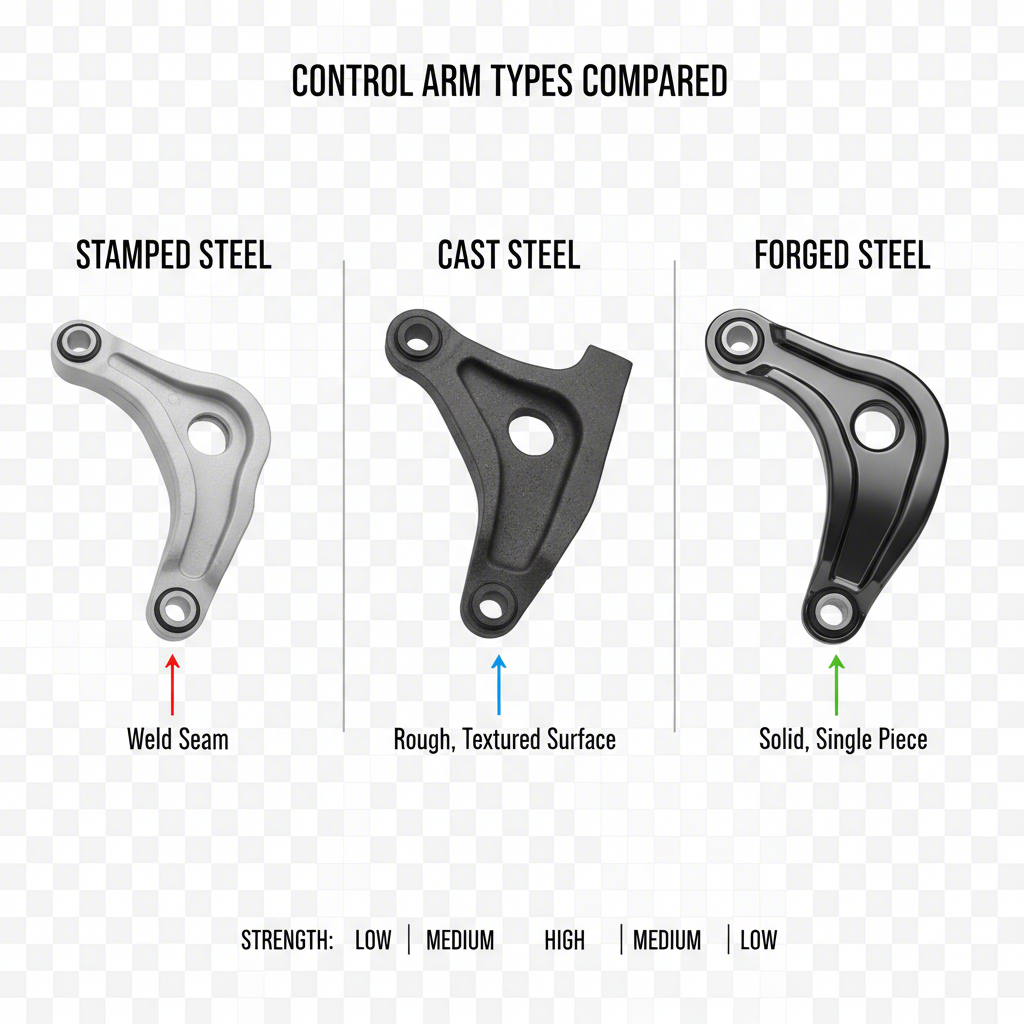

Determining the type of control arm on your vehicle, especially on popular trucks like the Chevrolet Silverado or GMC Sierra, is the most critical step before ordering replacement parts or a lift kit. The wrong choice can lead to incompatible parts and wasted time. Each type—stamped steel, cast steel, and forged steel—has a distinct appearance tied to its manufacturing process.

Understanding how they are made is the key to telling them apart. Stamped steel arms are fabricated from sheet metal that is cut, bent into shape (often like two C-channels), and then welded together. Cast steel arms are created by pouring molten steel into a mold, resulting in a single, solid piece. Forged steel arms are made by heating a solid billet of steel and pressing it into shape under extreme pressure, which aligns the metal's grain and creates exceptional strength.

Follow this simple, three-step process to positively identify your control arms:

- Perform a Visual Check: This is the most reliable method. Look closely at the arm's surface and edges. A stamped steel arm will have a clear weld seam running along its length where the metal plates were joined. It will also have a relatively smooth surface. In contrast, a cast arm will not have weld seams but may have a thin, rough line called a casting seam or parting line where the two halves of the mold met. Forged arms are typically the cleanest, appearing as a single, solid piece of metal.

- Examine the Surface and Shape: Stamped steel arms often look constructed or hollow, like two pieces of metal fused together. Cast arms have a distinctly rough, porous, or textured surface finish from the molding process. A magnet will stick to both stamped and cast steel but can help differentiate them from cast aluminum arms, which are non-magnetic and were also used on many GM trucks.

- Try the "Tap Test": While less scientific, many mechanics use this quick check. Tap the control arm with a wrench or other metal tool. A hollow-sounding ping often indicates a stamped steel arm, whereas a solid, dull thud suggests a dense cast or forged arm.

Comparison at a Glance

Use this table to quickly compare the key characteristics of each control arm type.

| Control Arm Type | Appearance | Key Identifiers | Manufacturing Process |

|---|---|---|---|

| Stamped Steel | Smooth surface, may look hollow or constructed from multiple pieces. | Visible weld seam, lighter weight, hollow sound when tapped. | Sheet metal is cut, pressed into shape, and welded together. |

| Cast Steel | Rough, textured, or porous surface. Looks like a single, solid piece. | No weld seams, may have a thin casting line, heavy and solid. | Molten metal is poured into a mold and allowed to cool. |

| Forged Steel | Smooth surface, looks like a dense, single piece of metal. | No weld seams, superior strength, often found in heavy-duty or performance applications. | A solid billet of heated steel is compressed into shape with a die. |

Stamped Steel Arms: Strength, Durability, and Common Concerns

Stamped steel control arms are the standard choice for many manufacturers due to their lower production cost and lighter weight, which can contribute to better fuel economy. For a stock vehicle used for daily driving, they are generally adequate and perform their job without issue. However, it's important to be aware of their limitations, especially when modifying a vehicle or using it for heavy-duty applications.

The primary drawback of stamped steel is its relative strength compared to forged alternatives. The forging process creates a continuous grain structure that follows the shape of the part, resulting in superior strength and resistance to fatigue. Stamped arms, being welded assemblies, have potential weak points at the seams. Some users have reported higher failure rates, particularly with the ball joints. As noted in some vehicle forums, certain stamped steel upper control arm designs may not properly retain the ball joint if it fails, which can be a significant safety concern. This makes inspecting ball joints a critical maintenance task on vehicles with these arms.

The reliability of a stamped part is heavily dependent on the manufacturing process. Expert firms in automotive stamping, such as Shaoyi Metal Technology, use advanced simulations and precision dies to ensure strength and consistency, which is critical for suspension components. High-quality manufacturing can mitigate some of the inherent weaknesses of the design, but the fundamental difference in strength compared to a forged part remains.

Pros

- Lower Cost: Cheaper to manufacture, making them a budget-friendly OEM and replacement option.

- Lighter Weight: Reduced unsprung weight can slightly improve ride quality and efficiency.

Cons

- Lower Strength: Not as strong or durable as cast or forged steel, making them less suitable for heavy-duty use.

- Potential Weld Failure: The welded seams can be a point of failure under extreme stress.

- Ball Joint Concerns: Some designs have been noted for poor ball joint retention upon failure.

Ultimately, the decision to stick with stamped steel or upgrade depends on your usage. For a standard daily driver, a quality OEM-style stamped steel replacement is often sufficient. However, if you have a lifted truck, frequently go off-road, or tow heavy loads, upgrading to a stronger forged or tubular steel control arm is a highly recommended investment in safety and durability.

Replacement and Compatibility: Avoiding Common Mistakes

Ordering the correct replacement control arm goes beyond simply matching the part to your vehicle's model and year. As many GM truck owners have discovered, compatibility is often dictated by the specific combination of control arms and steering knuckles installed at the factory. This is where many DIY projects go wrong.

For 2014–2016 Chevrolet Silverado and GMC Sierra 1500 models, GM used different materials for both the control arms and the knuckles, creating a confusing mix of parts. According to an analysis by suspension experts at ReadyLIFT, the key issue is the ball joint hole size. Stamped steel and cast aluminum control arms were typically paired with knuckles that had a larger ball joint opening. In contrast, cast steel control arms were matched with steel knuckles that had a smaller ball joint opening. This means a new control arm must have a ball joint that fits your truck's original knuckle.

This is why parts retailers like AmericanTrucks explicitly state that a given part is for models "With Stamped Steel Control Arms." They are ensuring you get the correct ball joint taper for your vehicle's setup. Ignoring this detail will result in a part that simply won't fit, causing major frustration.

To avoid ordering the wrong part, follow this checklist:

- Identify Your Current Arms: Use the guide in the first section to determine if you have stamped steel, cast steel, or cast aluminum arms. This is the most important step.

- Verify Vehicle Details: Confirm your truck's exact year, make, model, and drivetrain (2WD or 4WD).

- Read Product Descriptions Carefully: Pay close attention to fitment notes. Look for phrases like "Fits models with original stamped steel arms" or "For vehicles with steel knuckles only."

- Plan for Upgrades: If you're upgrading from stamped steel to a stronger aftermarket arm (such as the tubular options sold by suppliers like Classic Performance Products), ensure the new kit is designed for your specific knuckle type or comes with a new ball joint that is compatible.

- When in Doubt, Ask: If you are unsure, consult the part manufacturer's technical support or a trusted mechanic before purchasing.

Frequently Asked Questions

1. What is a stamped steel control arm?

A stamped steel control arm is a vehicle suspension component fabricated by pressing, cutting, and welding sheets of steel into a desired shape. This method is cost-effective and produces a lightweight part, which is why it's commonly used by auto manufacturers for original equipment. They are typically identified by their smooth finish and a visible weld seam.

2. What is the difference between stamped and forged control arms?

The main difference lies in their manufacturing process and resulting strength. Stamped arms are assembled and welded from multiple pieces of sheet metal. Forged arms are created by heating a single, solid piece of steel and compressing it into shape under immense pressure. This forging process aligns the metal's internal grain, making forged arms significantly stronger, more durable, and more resistant to stress and fatigue than their stamped counterparts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —