Door Hinge Metal Stamping: Process, Materials & Sourcing Strategies

TL;DR

Door hinge metal stamping is a high-precision manufacturing process designed to produce durable, consistent hardware at scale. By utilizing progressive die stamping, manufacturers can convert coiled sheet metal (steel, stainless, brass) into finished hinges with tight tolerances (often within ±0.003") in a single continuous run. This method offers superior efficiency compared to casting or machining, making it the industry standard for residential, commercial, and automotive applications. For procurement officers and engineers, understanding the nuances of material selection, knuckle curling mechanics, and finishing options is critical for sourcing high-quality components.

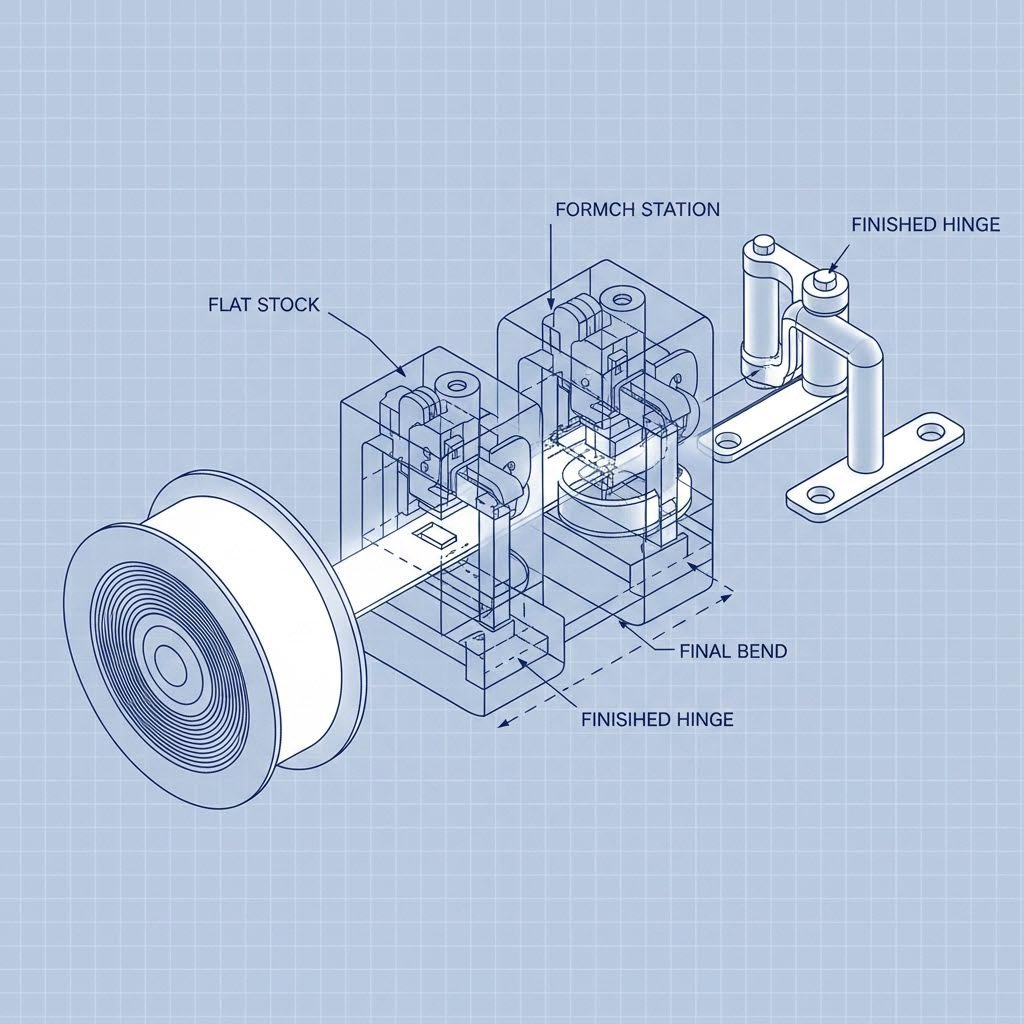

The Manufacturing Process: Progressive Die Stamping

For high-volume production runs, progressive die stamping represents the apex of efficiency in hinge manufacturing. Unlike single-stage stamping, which requires multiple handling steps, progressive dies perform a series of operations on a metal strip as it moves through the press. This method is particularly vital for manufacturing custom continuous hinges where consistency across thousands of units is non-negotiable.

The process typically follows a precise sequence:

- Feeding: The metal coil is fed into the press at a controlled speed.

- Piercing and Blanking: Punches create the screw holes and cut the outer shape of the hinge leaf.

- Forming and Bending: The flat metal is bent to create offset leaves or specific architectural features.

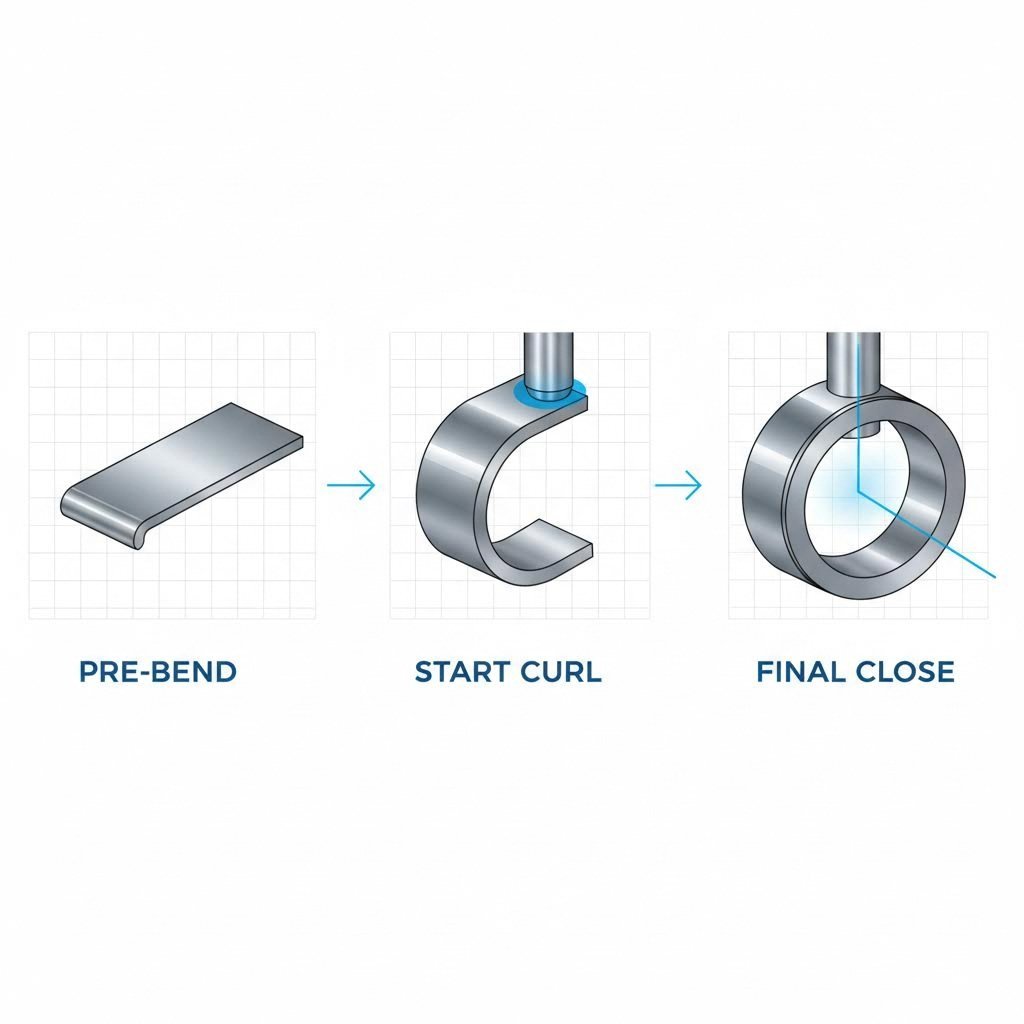

- Knuckle Curling: This is the most critical step for hinges. The metal is rolled to form the hollow knuckle that will house the pin. This requires precise tooling to ensure the knuckle is perfectly round and aligned.

While simpler methods like transfer die stamping or laser cutting (often used for custom fabrication of prototypes) offer flexibility for small batches, progressive stamping is unmatched for speed. It significantly reduces labor costs and cycle times, delivering finished parts that require minimal secondary processing.

Material Selection for Stamped Hinges

Selecting the right material is a balance of mechanical strength, corrosion resistance, and cost. The stamping process is compatible with various metals, but the application environment dictates the choice.

Common Stamping Materials

| Material | Durability | Corrosion Resistance | Best Application |

|---|---|---|---|

| Cold Rolled Steel (CRS) | High | Low (Requires Finishing) | Standard interior doors, heavy-duty industrial gates. |

| Stainless Steel (304) | Very High | High | Kitchens, bathrooms, medical environments. |

| Stainless Steel (316) | Very High | Excellent | Marine environments, coastal exteriors, chemical plants. |

| Brass | Medium | Medium (Naturally Patinas) | Decorative furniture, architectural heritage restoration. |

| Aluminum | Low-Medium | High (Naturally Oxidizes) | Lightweight cabinetry, aerospace applications. |

Cold Rolled Steel is the workhorse of the industry due to its formability and low cost, but it demands plating to prevent rust. Conversely, stainless steel offers inherent protection but requires higher tonnage presses due to its higher yield strength.

Design & Engineering Guidelines

To ensure manufacturability (DFM) and control costs, engineers must adhere to specific design constraints inherent to the metal stamping process. Ignoring these rules can lead to tool wear, part failure, or expensive secondary operations.

Key specifications include:

- Tolerances: Precision stamping can achieve tight tolerances. Leading manufacturers often cite ranges between 0.05mm to 0.15mm for critical dimensions, though this depends on material thickness.

- Hole Placement: A standard rule of thumb is to keep the distance between a hole and the edge of the part at least twice the material thickness (2T). This prevents the material from bulging or tearing during the piercing stage.

- Knuckle Ratio: The diameter of the curled knuckle must be proportional to the material thickness to avoid cracking the metal grain structure during the rolling process.

- Bend Radii: Sharp corners concentrate stress. Designers should specify a minimum bend radius consistent with the material grade to prevent fractures.

Finishing & Assembly Options

A raw stamped part is rarely the finished product. The functionality and longevity of a door hinge depend heavily on post-stamping treatments.

Surface Treatments

Since carbon steel hinges are prone to oxidation, plating is essential. Zinc plating is the industry standard for basic corrosion resistance, often supplemented with a chromate conversion coating. For high-end architectural hinges, powder coating, electropolishing (for stainless steel), or PVD coating (for decorative finishes) provide superior durability and aesthetics.

Assembly Techniques

The assembly phase involves inserting the pin into the curled knuckles. This can be done via:

- Staking: Deforming the ends of the pin so it cannot fall out.

- Spinning: creating a rivet-like head on the pin.

- Welding: Fusing the pin to one leaf for security hinges.

- Lubrication: High-cycle hinges may require grease or oil-impregnated bushings inserted during assembly to ensure smooth operation over decades of use.

Sourcing Guide: Choosing a Manufacturer

Selecting a stamping partner goes beyond comparing piece prices. Procurement teams must evaluate a supplier's engineering depth, quality certifications, and scalability. Key indicators of a reliable partner include in-house tooling maintenance, which ensures consistent quality over millions of cycles, and certifications like ISO 9001.

For projects requiring rigorous quality standards—such as automotive or heavy industrial applications—bridging the gap between prototyping and mass production is a common challenge. Shaoyi Metal Technology specializes in this transition, leveraging IATF 16949-certified precision and press capabilities up to 600 tons. Whether you need rapid prototypes or high-volume manufacturing adhering to global OEM standards, their comprehensive engineering services provide a robust solution for critical components.

When vetting suppliers, request a capability statement that details their maximum press tonnage, bed size, and quality control protocols (such as salt spray testing for corrosion resistance). A transparent supplier will welcome questions about their die maintenance programs and material sourcing channels.

Optimizing Hinge Procurement

Successful door hinge metal stamping procurement relies on a clear understanding of the trade-offs between material properties, tolerance requirements, and volume economics. By specifying the correct manufacturing process—progressive die stamping for volume, laser cutting for prototypes—and adhering to DFM guidelines, buyers can secure high-quality components that meet rigorous performance standards. Prioritize manufacturers who demonstrate transparency in their tooling capabilities and quality control processes to ensure long-term supply chain stability.

Frequently Asked Questions

1. What is the difference between metal stamping and pressing?

While often used interchangeably, "stamping" typically refers to the broader process of shaping metal using dies, which includes actions like punching, blanking, and bending. "Pressing" generally refers specifically to the application of force or pressure to form the metal. In the context of hinge manufacturing, stamping is the comprehensive term for the entire production cycle.

2. What are the four types of metal stamping?

The four primary types are Progressive Die Stamping (continuous automated process), Transfer Die Stamping (parts moved between stations mechanically), Deep Draw Stamping (forming cup-like shapes), and Micro/Miniature Stamping (for tiny, precision electronics parts). Hinges are most commonly made using progressive or transfer dies.

3. How hard is metal stamping?

The "hardness" or force required depends on the material's shear strength and thickness. Stamping stainless steel requires significantly more tonnage and harder tool steel dies than aluminum or brass. Manufacturers calculate the required press force (tonnage) based on the total length of cuts and the material's properties to prevent die breakage.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —