Automotive Die Maintenance Schedule: Strategies to Stop Firefighting

TL;DR

Automotive die maintenance is the systematic practice of inspecting, cleaning, and restoring stamping tools before they fail, ensuring consistent part quality and maximizing press uptime. Unlike die repair, which is a reactive response to breakage, a proper maintenance schedule is proactive and based on stroke counts (e.g., sharpening every 50,000 hits) rather than calendar dates.

Effective programs rely on a "milk run" of daily visual checks combined with rigorous technical interventions—such as shimming and lubrication—at set intervals. By shifting from "firefighting" to data-driven upkeep, automotive manufacturers can protect expensive Class A tooling and meet the strict Just-In-Time (JIT) demands of the supply chain.

The 4 Tiers of Die Maintenance: Beyond "Firefighting"

In the high-pressure world of automotive stamping, confusion often exists between "repair" and "maintenance." Industry experts typically categorize shop floor maturity into four distinct levels. Understanding where your facility stands is the first step toward reducing downtime.

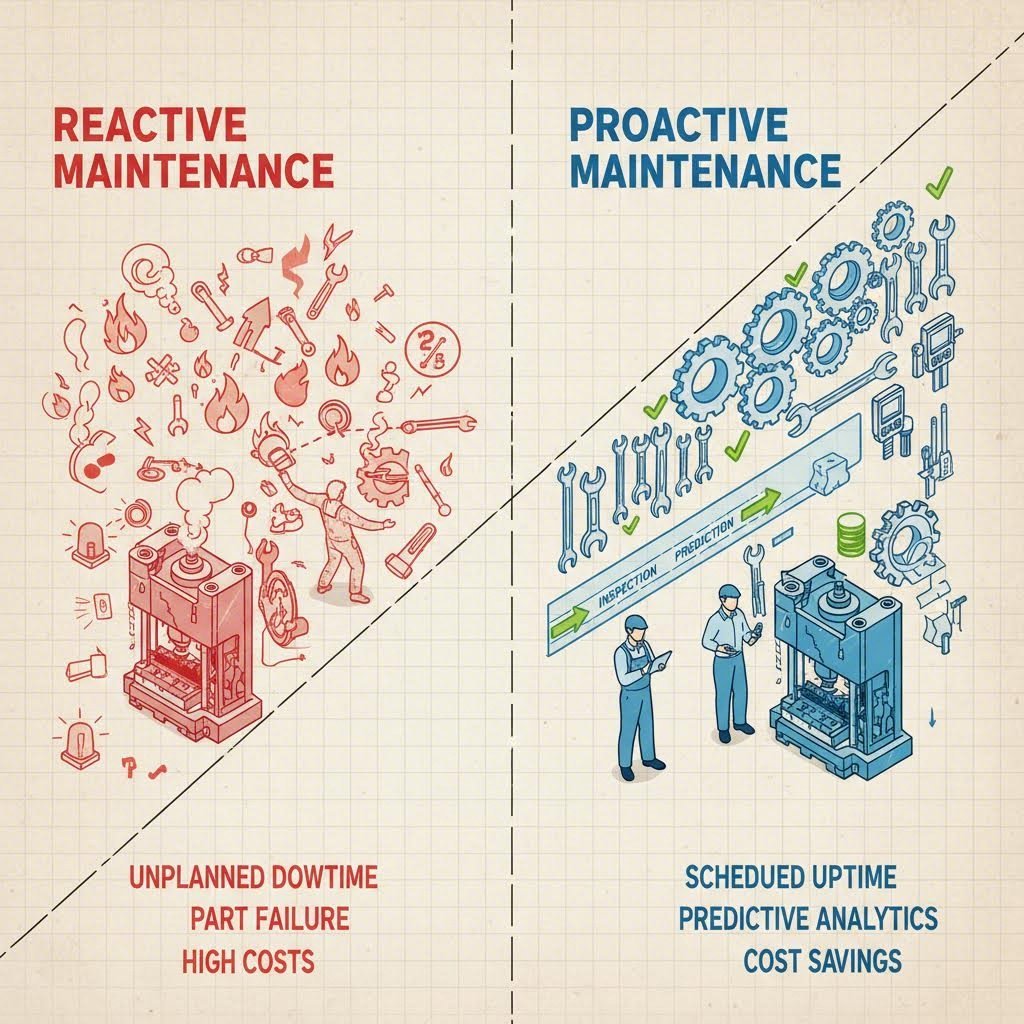

1. Reactive Repair (The Firefighting Mode)

This is the default state for many shops. Work is performed only when a die crashes, a punch breaks, or part quality falls out of tolerance. While it fixes the immediate problem, it is the most expensive strategy due to unplanned downtime, expedited shipping for spare parts, and missed delivery windows. As noted by MetalForming Magazine, many organizations underestimate their true tooling costs because they are tracking repair expenses rather than investing in genuine maintenance.

2. Preventive Maintenance (PM)

Preventive maintenance moves the shop from chaos to control. It involves scheduled tasks—cleaning, inspection, and lubrication—performed at regular intervals. The goal is to catch wear before it causes failure. However, a purely calendar-based PM schedule (e.g., "check die every Monday") can be inefficient if production volumes fluctuate wildy.

3. Predictive Maintenance (PdM)

This is the gold standard for automotive die maintenance schedules. PdM relies on data, specifically stroke counts, to dictate service intervals. If historical data shows that a specific punch dulls after 60,000 hits, the schedule triggers sharpening at 50,000 hits. This approach maximizes tool life while virtually eliminating surprise breakages.

4. Proactive Maintenance

Proactive strategies involve root cause analysis to eliminate chronic issues. Instead of constantly replacing a spring that breaks every month, a proactive team investigates why it breaks—perhaps due to incorrect preload or poor cage design—and re-engineers the tool to solve the problem permanently.

The "Milk Run": Daily & Shift-Based Inspection Schedule

A robust automotive die maintenance schedule begins on the shop floor with the operators. Often called a "milk run," these routine checks are non-negotiable for protecting complex progressive dies during high-volume runs.

Pre-Flight Visual Inspection

Before the press cycles, a visual sweep is critical. Operators must look for obvious red flags that could cause catastrophic damage:

- Foreign Object Debris (FOD): Slugs, scrap metal, or loose fasteners resting on the die shoe.

- Lubrication Systems: Verify that oil lines are connected and not leaking onto the floor.

- Safety Guards: Ensure all blocks and sensors are functioning correctly.

In-Operation Monitoring

Maintenance doesn't stop when the press starts. Every two hours, or at shift changes, operators should perform active monitoring. Listen for changes in the rhythm of the press—a "double hit" sound or guide pin noise often precedes a crash. Inspect the last strip for burrs or cosmetic defects, which indicate dulling cutting edges or loaded punches.

Creating a shift checklist is essential. It should require operators to sign off on specific checkpoints, such as stripper plate tension and blank holder operation, ensuring accountability and consistency across shifts.

Stroke-Based Intervals: The Heavy Lifting Schedule

While daily checks catch immediate hazards, the core of a professional maintenance program is the stroke-based schedule. Automotive dies typically degrade based on the volume of work performed, making stroke counters the most accurate metric for scheduling service.

The 50k to 100k Hit Benchmark

A common baseline for detailed inspection is every 50,000 to 100,000 strokes, though this varies by material type and die complexity. At this interval, the die should be pulled from the press for a bench review. Technicians should measure clearances with feeler gauges; a deviation greater than 0.02mm often signals that guide components need replacement or adjustment.

The 10x Rule for Springs

Spring failure is a leading cause of die damage. According to The Fabricator, a best practice for spring longevity is the "10x Rule." This guideline suggests that a spring should be selected to last ten times longer than the maintenance interval. If your maintenance interval is 50,000 strokes, your springs should be rated for 500,000 cycles. During the stroke-based maintenance check, test spring free-length; if a spring has lost more than 10% of its length, replace it immediately to prevent uneven stripping pressure.

| Feature | Calendar-Based (Weekly/Monthly) | Stroke-Based (Usage Driven) |

|---|---|---|

| Trigger | Time passed (e.g., every Friday) | Work performed (e.g., 50k hits) |

| Risk | Over-maintaining idle tools / Under-maintaining busy tools | Optimized to actual tool wear |

| Best For | Low-volume, general job shops | High-volume automotive production |

| Cost Efficiency | Low | High |

Critical Procedures: Sharpening, Shimming & Lubrication

When the schedule dictates a service, the quality of the work determines the tool's future performance. Three procedures—sharpening, shimming, and lubrication—are where most mistakes happen.

Sharpening Best Practices

Sharpening is not just about making the edge sharp; it's about removing fatigued metal. Technicians must select the correct grinding wheel for the die steel (e.g., D2 vs. M4) to avoid "heat checking" or micro-cracking the surface. Always grind with coolant when possible. If dry grinding is necessary, use light passes to prevent overheating the cutting sections.

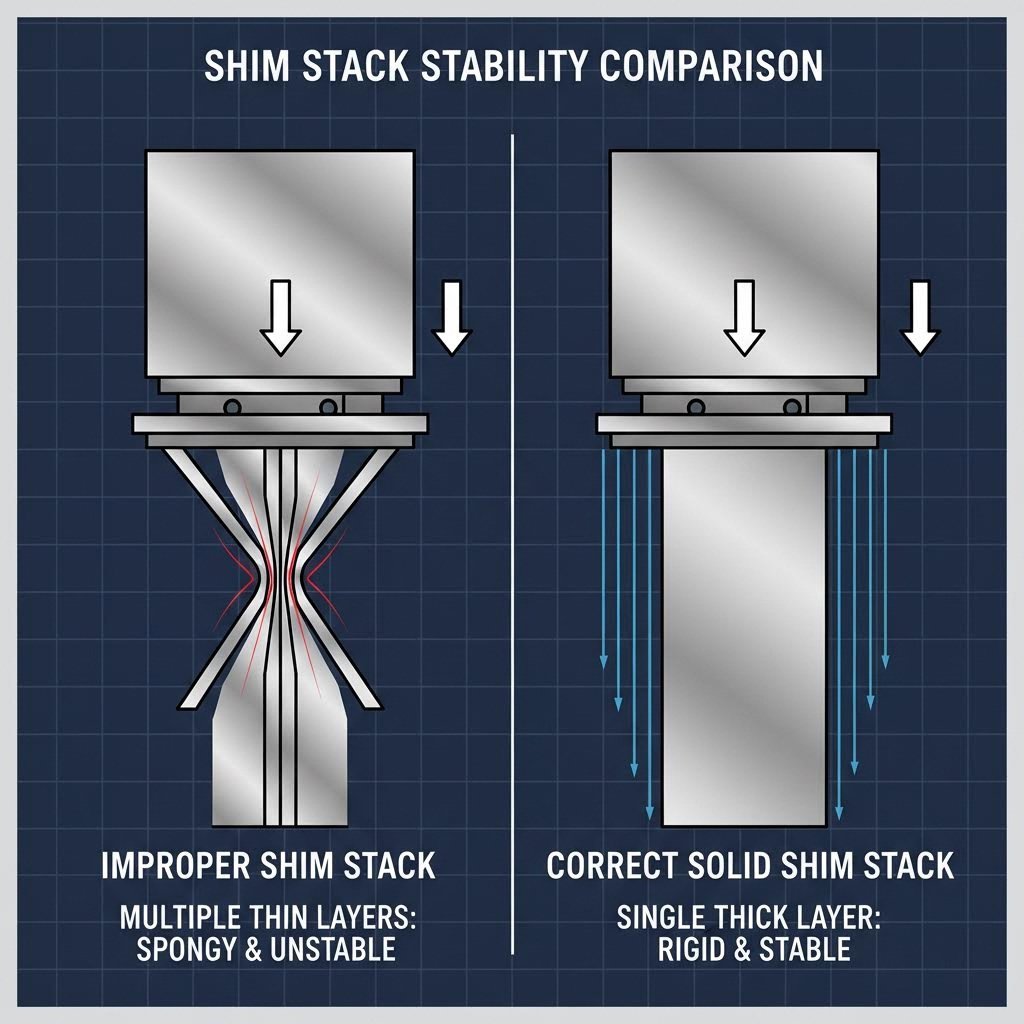

The Art of Shimming

Shimming restores the die's shut height after sharpening, but it is often done poorly. A "spongy" die section—caused by stacking multiple thin shims—can lead to deflection and inconsistent parts. Rule of thumb: Use the fewest number of shims possible. Instead of five 0.002" shims, use a single 0.010" shim. Ensure shims are cut to match the footprint of the die section exactly to provide solid support.

Lubrication Strategy

Not all lubricants are created equal. Guide pins typically require a precision oil (3-5 drops) to maintain a thin hydrodynamic film, whereas heavy wear plates may need an extreme-pressure lithium grease. Applying the wrong lubricant can attract abrasive debris or fail to separate metal-to-metal contact under load.

Automotive Specifics: Class A Surfaces & High Volume

Automotive stamping imposes unique constraints that general fabrication does not. The production of "Class A" surfaces (exterior panels) means that even microscopic debris can cause unacceptable pimples or dents, leading to expensive scrap.

Debris Control and JIT Demands

In automotive supply chains, Just-In-Time (JIT) delivery is the norm. A die failure doesn't just stop a press; it can shut down a customer's assembly line, leading to massive fines. Therefore, maintenance schedules for automotive dies must prioritize debris control. Air vents, scrap chutes, and sensor eyes must be cleaned religiously to prevent "slug pulling," where scrap is pulled back onto the die face.

Leveraging Certified Partnerships

Maintaining these rigorous standards often requires support beyond the internal toolroom. For critical high-volume programs, partnering with specialized manufacturers is essential to ensure continuity. For example, Shaoyi Metal Technology utilizes IATF 16949-certified processes to bridge the gap between prototyping and mass production, ensuring that components like control arms and subframes meet global OEM specifications for consistency and durability.

Ultimately, a successful automotive die maintenance schedule integrates internal discipline with external expertise, ensuring that documentation (often required by TS 16949 or IATF standards) is as precise as the tooling itself.

Conclusion: Moving from Expense to Investment

Implementing a structured die maintenance schedule transforms the toolroom from a cost center into a strategic asset. By adopting stroke-based intervals, enforcing daily "milk run" inspections, and adhering to strict protocols for sharpening and shimming, automotive manufacturers can dramatically extend tool life. As highlighted by Phoenix Group, the shift from reactive repair to proactive maintenance is the single most effective way to improve productivity and quality in stamping operations. The cost of maintenance is always lower than the cost of failure.

Frequently Asked Questions

1. What is the difference between die repair and die maintenance?

Die repair is a reactive process that occurs after a tool has broken or failed to produce a good part. It involves fixing damage. Die maintenance, on the other hand, is a proactive, scheduled activity designed to inspect, clean, and restore the tool while it is still functional, preventing failure from happening in the first place.

2. How often should automotive dies be maintained?

While daily visual inspections are mandatory, detailed bench maintenance should be scheduled based on stroke counts rather than time. A common industry standard is to perform a major service every 50,000 to 100,000 strokes, depending on the complexity of the die and the type of material being stamped.

3. What are the key elements of a preventive maintenance checklist?

A comprehensive checklist includes cleaning debris and sludge, inspecting springs for fatigue or breakage, checking guide pins for wear, verifying sensor function, and measuring cutting clearances. It also involves sharpening dull cutting edges and ensuring proper lubrication of all moving components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —