Bending Techniques for Car Parts: Engineering Precision for Sheet & Tube

TL;DR

Automotive fabrication relies on mastering two distinct categories of bending techniques for car parts: sheet metal forming for body panels and structural brackets, and tube bending for exhaust systems and roll cages. Success in either discipline requires precise control over technical variables like minimum bend radius, springback compensation, and grain direction.

For DIY enthusiasts, accessible methods like manual brakes and sandbag forming can yield professional results for restoration patches. Industrial applications, however, demand the repeatability of CNC press brakes and mandrel benders to maintain structural integrity under load. Whether shaping a fender or fabricating a chassis, selecting the correct alloy and method is the difference between a durable component and a fractured part.

Sheet Metal Bending: Body Panels & Structural Components

Sheet metal bending is the backbone of automotive restoration and manufacturing. It encompasses everything from fabricating simple L-brackets to forming complex compound curves for fenders and wheel tubs. The primary objective is to plastically deform the metal along a linear axis without fracturing the material's grain structure.

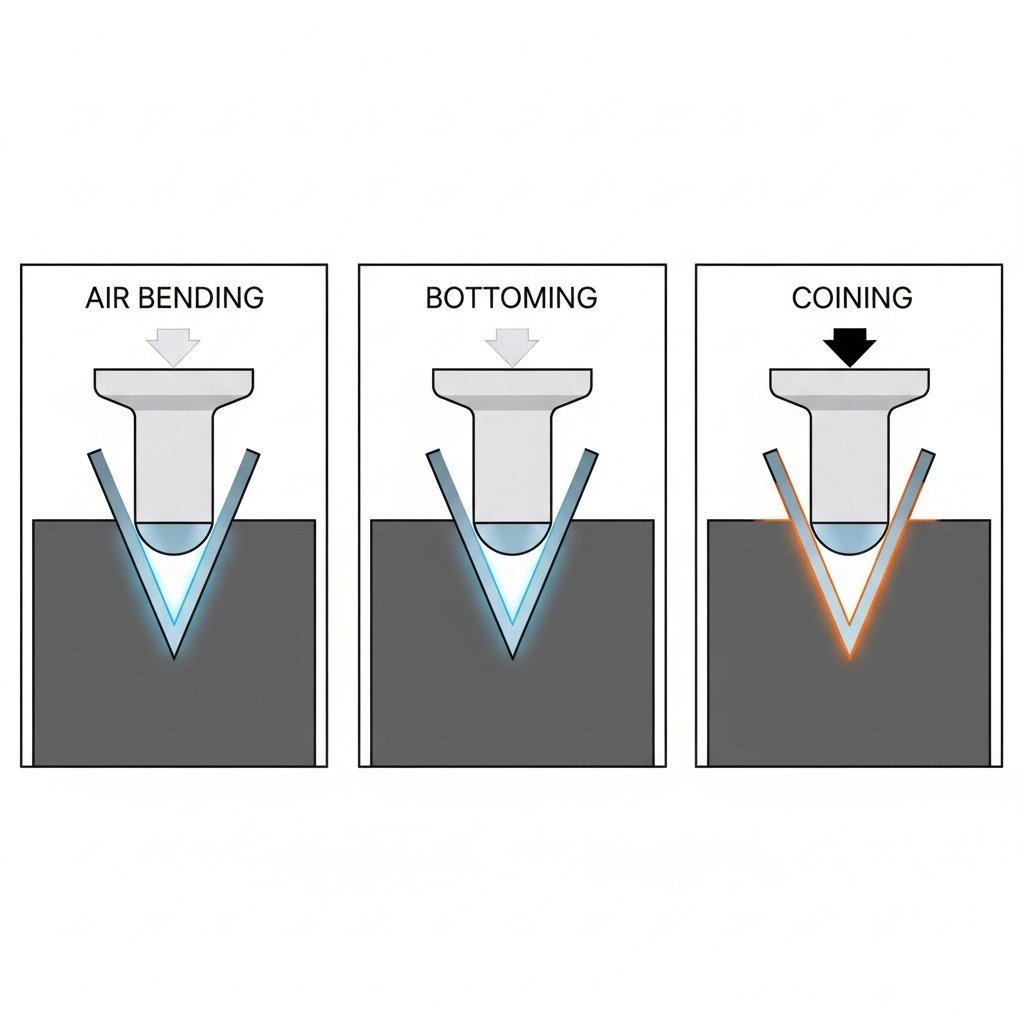

For most automotive applications, Press Brake Bending is the industry standard. It utilizes a punch and die set to force flat sheet metal into a specific angle. Understanding the three modes of press brake operation is critical for achieving the desired tolerance and bend radius.

Press Brake Methods: Precision and Force

- Air Bending: The most versatile and common technique. The punch presses the sheet into the V-die but does not press it against the bottom. The bend angle is determined by how deep the punch descends. It requires less tonnage and allows for "over-bending" to compensate for springback, making it ideal for variable car parts.

- Bottom Bending (Bottoming): The punch forces the sheet to conform strictly to the V-die's geometry. This reduces springback and offers higher precision than air bending, but it requires more force and specific tooling for each angle.

- Coining: A high-tonnage method where the punch penetrates the neutral axis of the metal, thinning it under extreme pressure. This "coins" the bend, eliminating springback entirely. While unmatched in precision, it is rarely used for standard bodywork due to the cost and tool wear.

Roll Bending for Curves

When fabricating large curved components like wheel arches, transmission tunnels, or hood skins, press brakes are insufficient. Roll Bending employs a three-roller system (pyramid setup) to gradually curve the metal. By adjusting the distance between the central and outer rolls, fabricators can achieve a smooth, consistent radius without the "kink lines" associated with incremental press braking.

| Method | Best Application | Precision | Cost/Force |

|---|---|---|---|

| Air Bending | General brackets, chassis panels | Moderate (Springback sensitive) | Low Tonnage / Low Tooling Cost |

| Bottoming | Precision structural parts | High | Medium Tonnage |

| Coining | Mass-produced OEM clips/parts | Very High (Zero Springback) | High Tonnage / High Wear |

| Roll Bending | Fenders, tunnels, sweeping curves | Variable (Operator dependent) | Low Force / Specialized Machine |

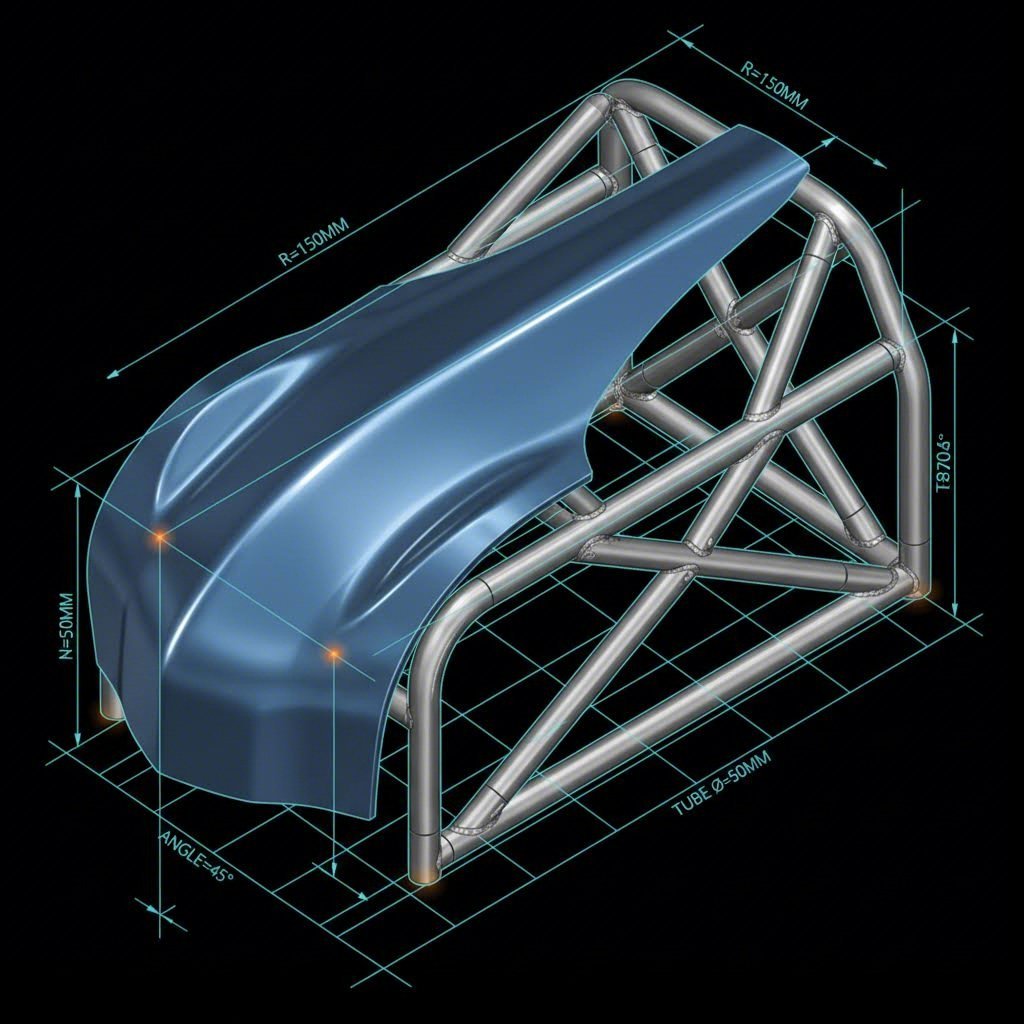

Tube Bending: Exhausts, Roll Cages & Brake Lines

Bending hollow tubing presents a unique challenge: the outer wall stretches and thins, while the inner wall compresses and thickens. Without proper support, this stress causes the tube to ovalize (flatten), kink, or wrinkle. In automotive performance, specifically for headers, exhausts, and safety cages, maintaining the tube's internal volume and structural profile is non-negotiable.

Rotary Draw vs. Ram Bending

Ram Bending (or Compression Bending) is the method found in many budget muffler shops. A hydraulic ram forces a die into the tube, which is supported by two outer rollers. While cheap and fast, it often crushes the tube slightly, restricting airflow and reducing structural strength. It is generally unsuitable for roll cages or high-performance headers.

Rotary Draw Bending is the professional standard. The tube is clamped to a rotating bend die and drawn around it. This method maintains a constant centerline radius (CLR) and produces clean, repeatable bends required for chassis work.

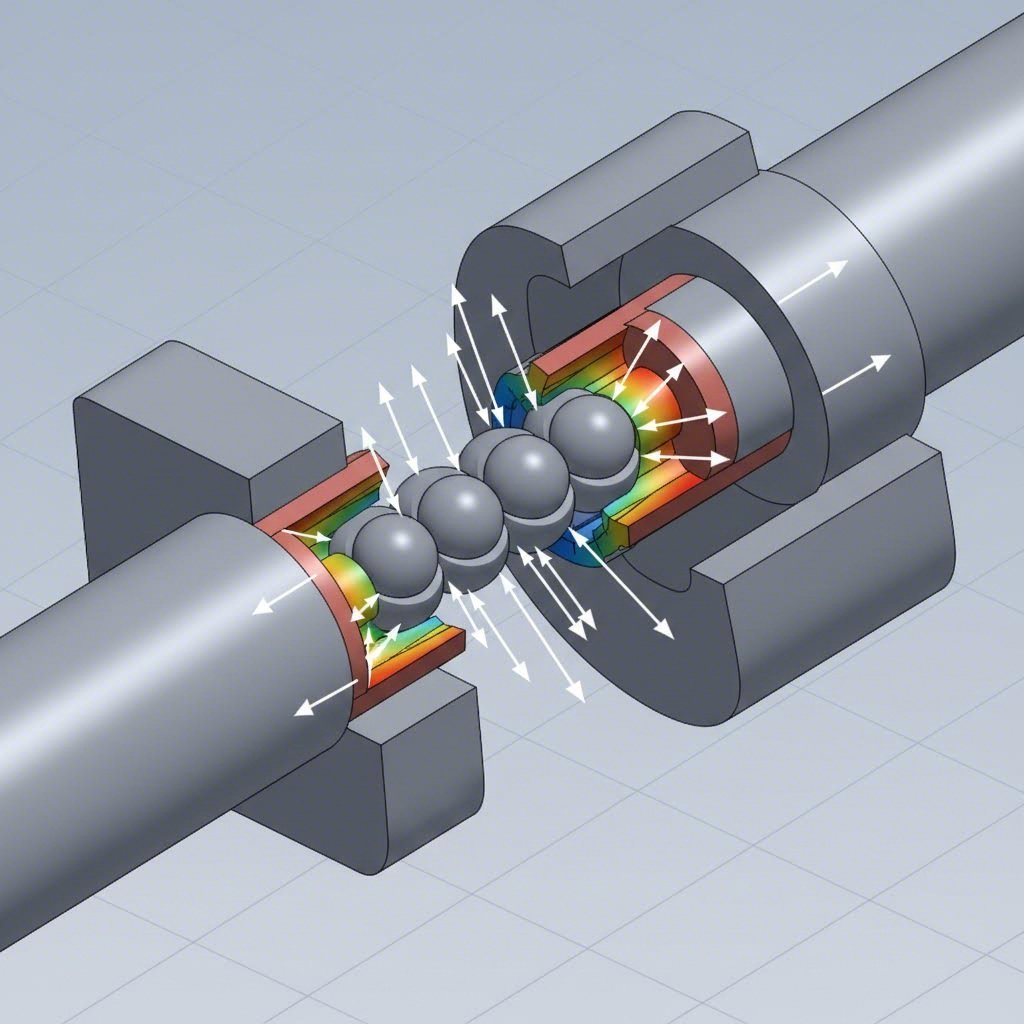

The Role of the Mandrel

For high-quality bends, especially on thin-wall stainless steel or aluminum, a Mandrel is essential. A mandrel is a solid rod or series of articulated links inserted inside the tube during the bend.

- Structural Support: It supports the inner walls to prevent collapsing or wrinkling.

- Flow Efficiency: By keeping the tube perfectly round, mandrel bending ensures maximum exhaust gas velocity.

- Aesthetics: It produces the smooth, wrinkle-free bends seen on high-end headers and intakes.

Pro Tip: When bending roll cage tubing (DOM steel or Chromoly), confirm the sanctioning body's rules (e.g., FIA, NHRA). Most prohibit wrinkle bends and mandate specific minimum bend radii (typically 3x the tube diameter) to prevent stress risers.

The Science of Bending: Design & Material Considerations

Mastering bending techniques for car parts is less about muscle and more about math. Ignoring the physical properties of the metal leads to cracked flanges and parts that don't fit.

Minimum Bend Radius

Every metal has a limit to how tightly it can be bent before the outer fibers tear. This is the Minimum Bend Radius. As a general rule for mild steel, the radius should be at least equal to the material thickness (1T). For aluminum, particularly harder alloys like 6061-T6, the radius must often be 3x-4x thickness to prevent cracking. Annealing the aluminum (heating and cooling to soften) can allow for tighter bends.

Springback and K-Factor

Metal has memory. After bending, it relaxes slightly, returning partway to its original shape. This is Springback. A 90-degree bend might require bending to 92 or 93 degrees to account for this elastic recovery. High-tensile steels (like those used in modern chassis) exhibit significantly more springback than mild steel.

To achieve dimensional accuracy, fabricators use the K-Factor, a ratio that defines the location of the neutral axis (the part of the metal that neither compresses nor stretches). Calculating the correct bend allowance using the K-Factor ensures that the final part dimensions match the CAD drawing exactly.

Tools of the Trade: DIY vs. Professional Equipment

The barrier to entry for automotive metal shaping is lower than many assume, but the gap between DIY tools and industrial production is vast. Your choice of equipment dictates the speed, repeatability, and maximum thickness you can handle.

The DIY Fabricator's Kit

For restoration hobbyists and custom mechanics, "hand" methods often offer superior control for one-off parts:

- Manual Press Brake: Simple leverage-operated brakes can handle light-gauge sheet metal for patch panels.

- Shrinker/Stretcher: Essential for creating compound curves (like window channels) by mechanically shrinking or stretching the metal's edge.

- Hammer and Dolly: The fundamental method for smoothing out sheet metal and correcting contours.

- Vise Bending: With soft jaws and a mallet, a sturdy bench vise is effectively a "zero-cost" brake for small brackets.

Scaling to Industrial Production

When moving from prototyping to mass production, techniques shift from manual manipulation to automated high-tonnage stamping. Industrial setups utilize CNC Press Brakes for complex, multi-bend sequences and hydraulic stamping presses for high-volume efficiency.

If your project demands rigorous quality standards at scale, partnering with a specialized manufacturer is often the logical next step. Companies like Shaoyi Metal Technology provide comprehensive stamping solutions, leveraging press capabilities up to 600 tons to deliver IATF 16949-certified components. Whether you need control arms or structural subframes, their expertise bridges the gap between rapid prototyping and millions of mass-produced parts.

Conclusion

The art of shaping metal for automotive applications lies in matching the technique to the component's function. While a ram-bent exhaust pipe might suffice for a farm truck, a track-focused chassis demands the precision of rotary draw bending. Similarly, a cosmetic body panel requires the smooth finish of a slip roll, whereas a structural suspension bracket relies on the defined accuracy of a press brake.

For the aspiring fabricator, the journey begins with understanding material limits—respecting the minimum bend radius and anticipating springback. Whether you are hammering a fender patch by hand or programming a CNC brake for a production run, the physics remains the same. Start with the right material, calculate your allowances, and choose the bending method that ensures safety and performance.

Frequently Asked Questions

1. What are the three primary types of press brake bending?

The three main techniques are Air Bending, Bottoming, and Coining. Air bending is the most common due to its flexibility and lower force requirements. Bottoming offers higher precision by pressing the sheet against the die, while Coining uses extreme pressure to imprint the die shape into the metal, eliminating springback entirely.

2. What is the best technique for bending car exhaust tubing?

Mandrel Bending is widely considered the best technique for automotive exhaust systems. By inserting a support rod (mandrel) inside the tube during the bend, it prevents the pipe from crushing or wrinkling. This maintains the tube's constant diameter, ensuring optimal exhaust gas flow and maximizing engine performance.

3. Why does aluminum often crack when bent for car parts?

Aluminum cracks primarily because the bend radius is too tight or the alloy is too hard (like T6 temper). Unlike mild steel, aluminum has less ductility. To prevent cracking, use a larger bend radius (typically 3x-4x material thickness), bend across the grain rather than parallel to it, or use annealed (softer) aluminum grades for complex shapes.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —