Automotive Lighting Component Stamping: The Engineering Guide

TL;DR

Automotive lighting component stamping is the high-precision manufacturing process used to create critical metal parts for vehicle illumination systems, including electrical terminals, heat sinks, reflector housings, and mounting brackets. Because modern LED assemblies require strict thermal management and consistent electrical conductivity, manufacturers rely on high-speed progressive die stamping to produce millions of defect-free components. Key sourcing considerations include selecting materials like aluminum for heat dissipation, copper for connectivity, and ensuring your partner holds IATF 16949 certification to meet global automotive quality standards.

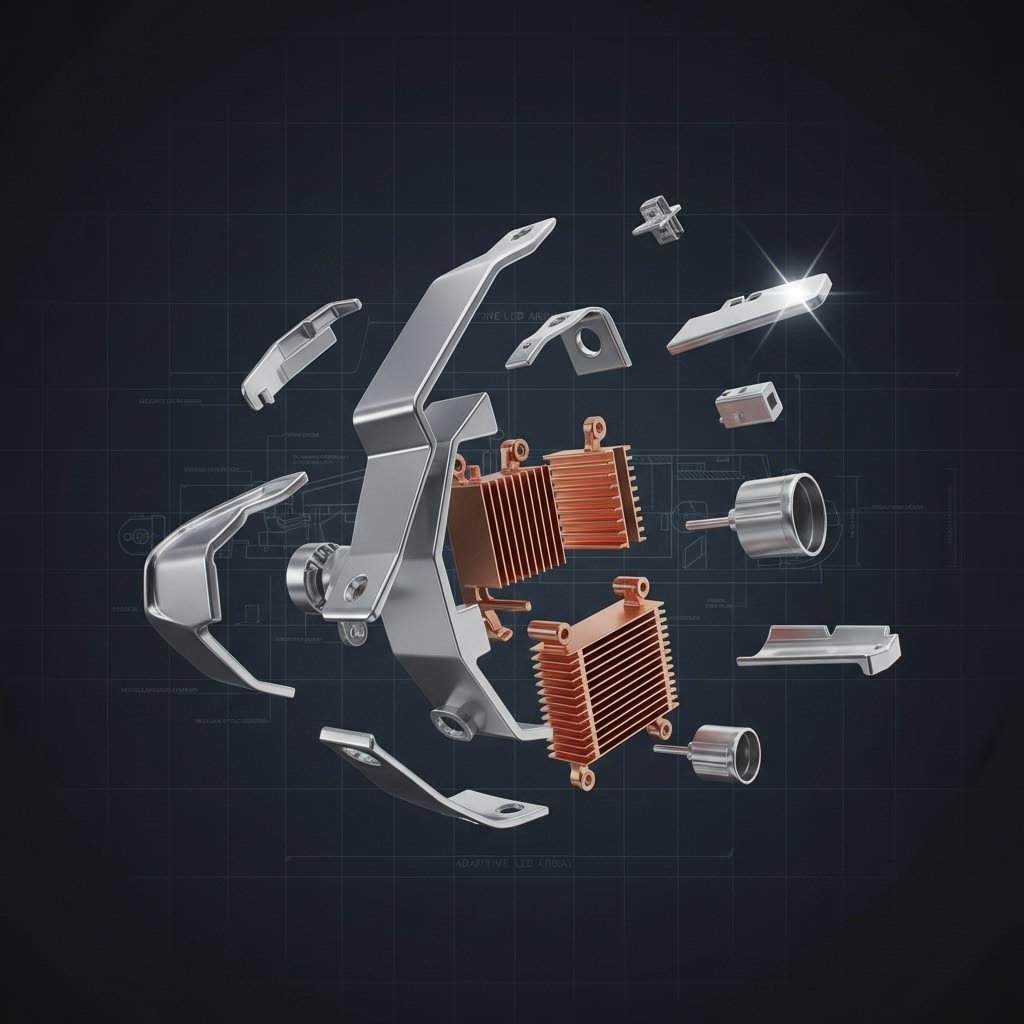

Critical Stamped Components in Modern Automotive Lighting

The shift from halogen to LED and laser-matrix lighting has transformed the complexity of stamped metal components. Automotive engineers no longer just need simple brackets; they require intricate interconnects and thermal solutions that fit into increasingly compact headlamp and taillight assemblies. High-precision stamping serves three primary functions within these systems: electrical connectivity, structural support, and thermal management.

Electrical Interconnects

The nervous system of any lighting assembly relies on stamped electrical components. Bus bars and lead frames are stamped from high-conductivity copper alloys to distribute power efficiently across LED arrays. Terminals and connectors must maintain contact integrity despite engine vibration and thermal cycling. Unlike standard consumer electronics, these automotive grade parts often feature complex geometries designed to lock securely into plastic injection-molded housings, a process known as insert molding.

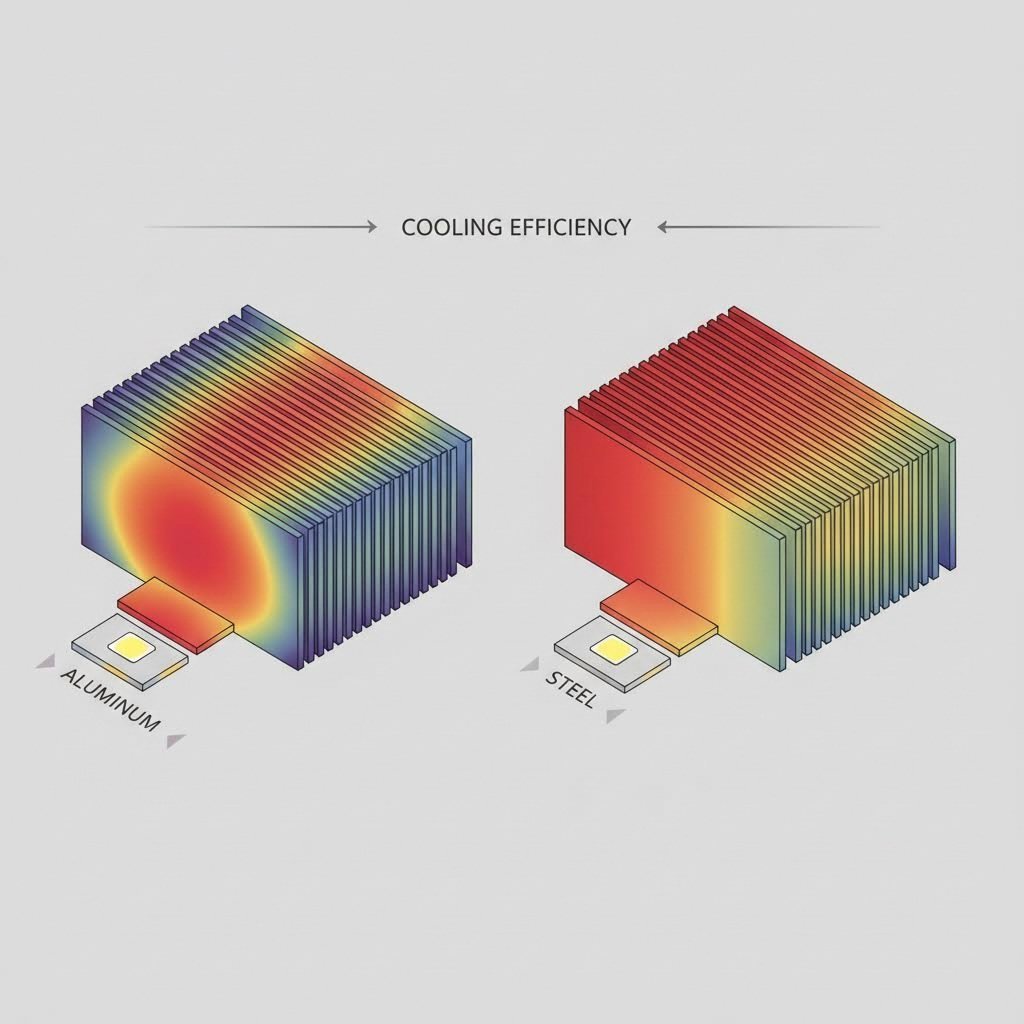

Thermal Management Components

LED longevity is directly tied to heat dissipation. Metal stamping provides a cost-effective solution for creating heat sinks and thermal spreaders. By stamping aluminum alloys, manufacturers can create lightweight components with substantial surface area to draw heat away from sensitive diodes. These parts are often integrated directly with the printed circuit board (PCB) or housing to ensure rapid thermal transfer.

Optical and Structural Hardware

While plastics dominate lenses, metal stamping remains superior for structural rigidity and optical precision in specific areas. Reflector rings and bulb shields require high-quality surface finishes to manipulate light paths without distortion. Meanwhile, heavy-gauge steel mounting brackets and retaining clips ensure the entire lighting module remains aligned and secure, even when the vehicle traverses rough terrain.

Material Selection Strategy: Conductivity, Weight, and Heat

Selecting the right material is an engineering balancing act between performance, weight, and cost. In automotive lighting component stamping, three material families dominate, each serving a distinct engineering purpose.

Copper and Brass Alloys

For electrical components, Copper C110 (Electrolytic Tough Pitch) is the standard due to its exceptional electrical conductivity (100% IACS). However, pure copper is soft. For terminals that require spring properties to maintain contact pressure, engineers often specify brass or high-performance beryllium copper alloys. These materials offer the necessary tensile strength to resist fatigue while maintaining adequate conductivity.

Aluminum Alloys

Aluminum 5052 and 6061 are the go-to choices for heat sinks and housings. Aluminum offers excellent thermal conductivity—critical for cooling high-power LEDs—at a fraction of the weight of copper or steel. It is also naturally corrosion-resistant, though it can be prone to "galling" (material adhesion) during the stamping process, requiring specialized tool coatings and lubricants.

Stainless and Cold Rolled Steel

For exterior structural parts or internal components exposed to moisture, 300-series stainless steel provides superior corrosion resistance without the need for secondary plating. For internal brackets where corrosion is less of a concern but strength is paramount, cold rolled steel remains the most cost-effective option, often finished with zinc plating or e-coating post-production.

Manufacturing Processes: Progressive Die vs. Deep Draw

The choice of stamping method depends largely on the component's geometry and the production volume. Automotive lighting projects typically involve high volumes (hundreds of thousands to millions of parts), making efficiency a primary driver.

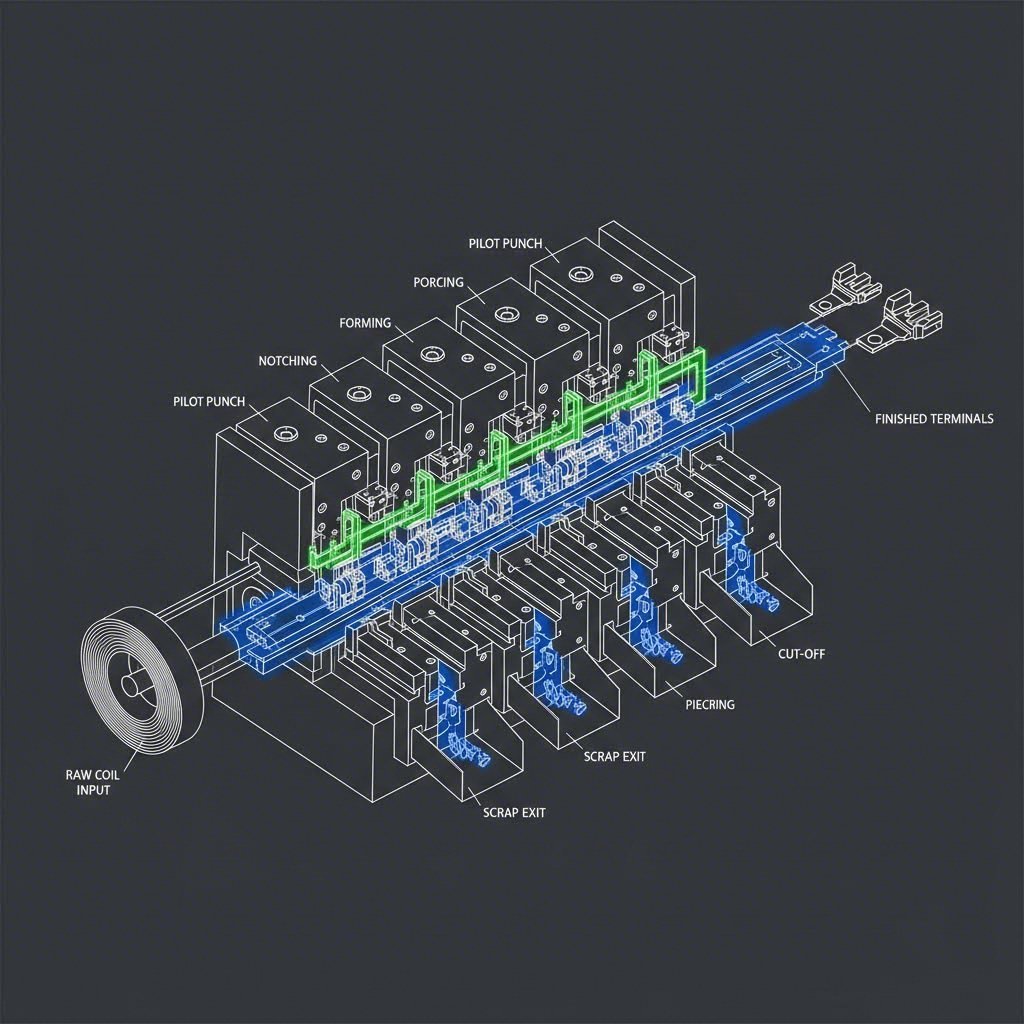

Progressive Die Stamping

Progressive die stamping is the industry standard for producing complex, small-to-medium parts like terminals, clips, and lead frames. In this process, a metal coil feeds through a series of stations within a single die. Each station performs a specific operation—cutting, bending, punching, or coining—as the strip moves forward. The finished part is separated at the final station. This method is incredibly fast, capable of running hundreds of strokes per minute, ensuring a low piece price for high-volume runs.

Deep Draw Stamping

For components that are cylindrical or box-like with significant depth—such as capacitor cans, bulb sockets, or specific reflector housings—deep draw stamping is required. This process stretches the metal sheet into a die cavity. It is technically demanding, as the material must flow without tearing or wrinkling. While slower than progressive stamping, it is the only way to create seamless, hollow metal shapes integral to sealed lighting units.

Key Challenges: Precision, Heat, and Surface Finish

Stamping for automotive lighting presents unique challenges that distinguish it from general industrial stamping. Suppliers must control variables that affect both the aesthetic and functional quality of the light.

Optical Surface Quality is paramount for reflectors and cosmetic bezels. Even microscopic scratches or die marks can scatter light unpredictably or create visible defects in a premium headlight assembly. Manufacturers use polished carbide dies and specialized handling systems to ensure parts remain pristine throughout production.

Thermal distortion is another risk. As LEDs operate, they generate localized heat. Stamped heat sinks must have perfectly flat mounting surfaces to ensure complete contact with the LED board. Any curvature or burrs can create air gaps, acting as insulators and leading to premature LED failure.

Supplier Selection: Sourcing and Certification

Choosing a stamping partner for automotive lighting is not just about price; it's about risk mitigation and scalability. The automotive supply chain demands rigid adherence to quality standards to prevent recalls and ensure safety.

The Non-Negotiable: IATF 16949

Any supplier manufacturing components for the automotive supply chain must be certified to IATF 16949. This standard goes beyond ISO 9001, emphasizing defect prevention, reduction of variation, and continuous improvement. It ensures that the stamper has robust processes for FMEA (Failure Mode and Effects Analysis) and PPAP (Production Part Approval Process), guaranteeing that every bracket or terminal meets the exact engineering specifications.

Bridging Prototype to Production

A common friction point in automotive sourcing is the transition from prototype to mass production. Engineers often need small batches for validation before committing to expensive hard tooling. Finding a partner who can handle this entire lifecycle is valuable. For instance, Shaoyi Metal Technology specializes in bridging this gap, offering comprehensive stamping solutions that scale from rapid prototyping of 50 units to high-volume manufacturing of millions. Their capabilities include press capacities up to 600 tons and strict IATF 16949 compliance, allowing them to deliver critical components like control arms alongside precision lighting parts with consistent OEM quality.

Strategic Sourcing for Light

The performance of a vehicle's lighting system relies as much on the stamped metal behind the lens as the lens itself. By understanding the interplay between material properties, stamping processes, and quality certifications, procurement teams can secure components that ensure safety, longevity, and regulatory compliance. Prioritize suppliers who demonstrate not just manufacturing capacity, but engineering competence in thermal and electrical challenges.

Frequently Asked Questions

1. What is the best material for automotive LED heat sinks?

Aluminum alloys, particularly 5052 and 6061, are the standard for LED heat sinks. They offer an optimal balance of high thermal conductivity, low weight, and cost-effectiveness compared to copper. Aluminum effectively dissipates the heat generated by high-power LEDs, preventing overheating and extending the lifespan of the lighting unit.

2. Why is progressive die stamping preferred for lighting terminals?

Progressive die stamping is preferred because it allows for the high-speed, continuous production of complex geometries with tight tolerances. Since automotive lighting requires millions of identical terminals and connectors, this process ensures consistency and a low cost per unit, which is essential for mass production.

3. Can stamped parts replace die-cast components in lighting assemblies?

Yes, in many cases. Stamped sheet metal parts are often lighter and cheaper to produce than die-cast alternatives. While die casting allows for more variable wall thicknesses, stamping is superior for thin-wall, high-strength applications like brackets, shields, and clips, contributing to overall vehicle weight reduction.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —