Key Principles of Die Design for Complex Automotive Shapes

TL;DR

Die design for complex automotive shapes is a specialized engineering process that creates tools (dies) to transform flat sheet metal into precise, three-dimensional components. Success hinges on using advanced techniques like deep draw stamping and selecting the correct die type, such as progressive or transfer dies. The primary goal is to manage material properties and metal flow to produce intricate parts without costly defects like tearing or wrinkling.

Fundamentals of Die Forming for Automotive Parts

At its core, die design is the art and science of controlled metal deformation. All sheet metal forming operations rely on two fundamental forces: tension and compression. When a flat sheet of metal is pressed into a die, some areas are stretched (tension) while others are compressed, causing the material to flow and take the shape of the die. Mastering this process is essential for creating everything from a simple bracket to a complex fender. The primary challenge, especially with the advanced alloys used in modern vehicles, is achieving the desired geometry without compromising the material's integrity.

Complex automotive shapes, such as body panels or structural components, introduce significant challenges. Unlike simple bends, these parts require uneven material flow across multiple axes. This increases the risk of common defects. For example, excessive tension can cause the metal to thin out and split, while uncontrolled compression can lead to wrinkling. According to industry experts at The Fabricator, most part defects originate during these forming operations, making a robust die design the first line of defense against production failures.

The design process must therefore balance the desired shape with the material's inherent formability. Engineers must carefully consider the metal's thickness, tensile strength, and elongation properties. A successful die design guides the metal into its final shape smoothly and uniformly, often using a sequence of operations like drawing, bending, and flanging. Each step is precisely calculated to shape the part incrementally, minimizing stress and ensuring a flawless finish.

A Comparative Guide to Stamping Die Types

Not all dies are created equal; the right choice depends on the part's complexity, production volume, and required operations. Understanding the primary types of stamping dies is crucial for any manufacturing process. Each design offers a unique combination of speed, precision, and cost-effectiveness tailored to specific tasks. From simple cuts to intricate multi-stage forming, the die type dictates the efficiency and quality of the final product.

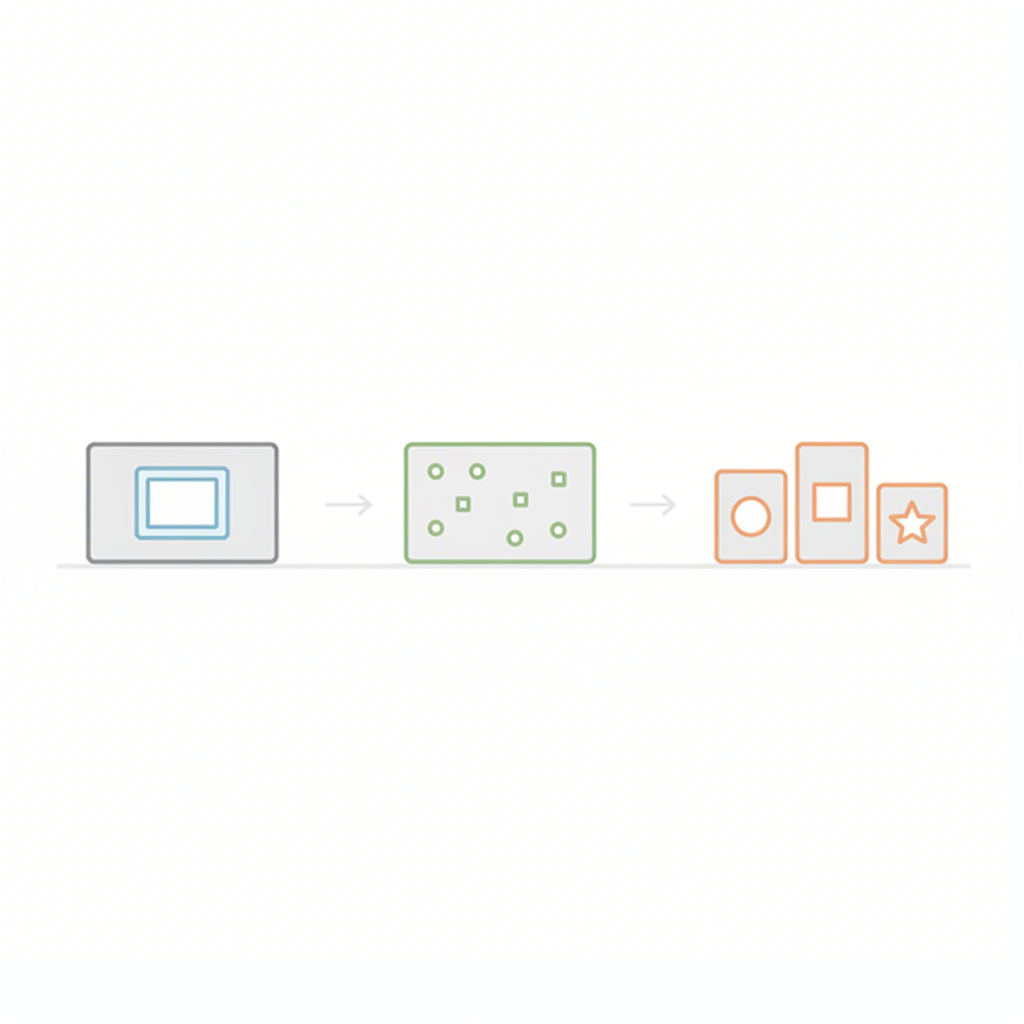

The most common types of stamping dies include Blanking, Piercing, Compound, Progressive, and Transfer dies. Blanking dies are used to cut the initial flat shape, or 'blank,' from a larger sheet of metal. Piercing dies, conversely, punch holes or slots into the part. More advanced designs combine these steps. A compound die, for instance, can perform a cutting and punching operation in a single press stroke, offering high precision for simpler parts. For high-volume production of complex parts, progressive and transfer dies are the industry standard.

A progressive die, also known as a multi-station die, contains a series of stations that perform sequential operations on a strip of sheet metal. The strip is fed through the die, and with each press stroke, a different operation (e.g., piercing, bending, coining) is performed until a finished part is ejected at the final station. A transfer die operates on a similar principle, but it handles individual blanks that are transferred from one station to the next, which is ideal for larger or more complex parts like deep-drawn components.

Selecting the right die type is a critical decision that impacts cost, speed, and quality. The choice often requires collaboration with a specialized manufacturing partner. For instance, industry leaders like Shaoyi (Ningbo) Metal Technology Co., Ltd. work closely with automotive clients to develop custom progressive and transfer dies, leveraging advanced simulations to ensure optimal performance for mass production.

To clarify the differences, here is a comparison of the key stamping die types:

| Die Type | Primary Function | Best For (Application) | Key Advantage |

|---|---|---|---|

| Blanking Die | Cuts a flat shape (blank) from sheet metal | Creating the initial workpiece for further operations | Simple, foundational first step |

| Piercing Die | Punches holes or slots into a part | Creating features like mounting holes | High precision for internal cutouts |

| Compound Die | Performs multiple cutting operations in one stroke | High-precision, low-volume flat parts like washers | Excellent dimensional accuracy |

| Progressive Die | Performs multiple operations sequentially on a metal strip | High-volume, complex parts | High speed and efficiency |

| Transfer Die | Performs multiple operations on a single part transferred between stations | Large or deep-drawn parts (e.g., body panels) | Versatility for complex geometries |

Mastering the Deep Draw Process for Complex Geometries

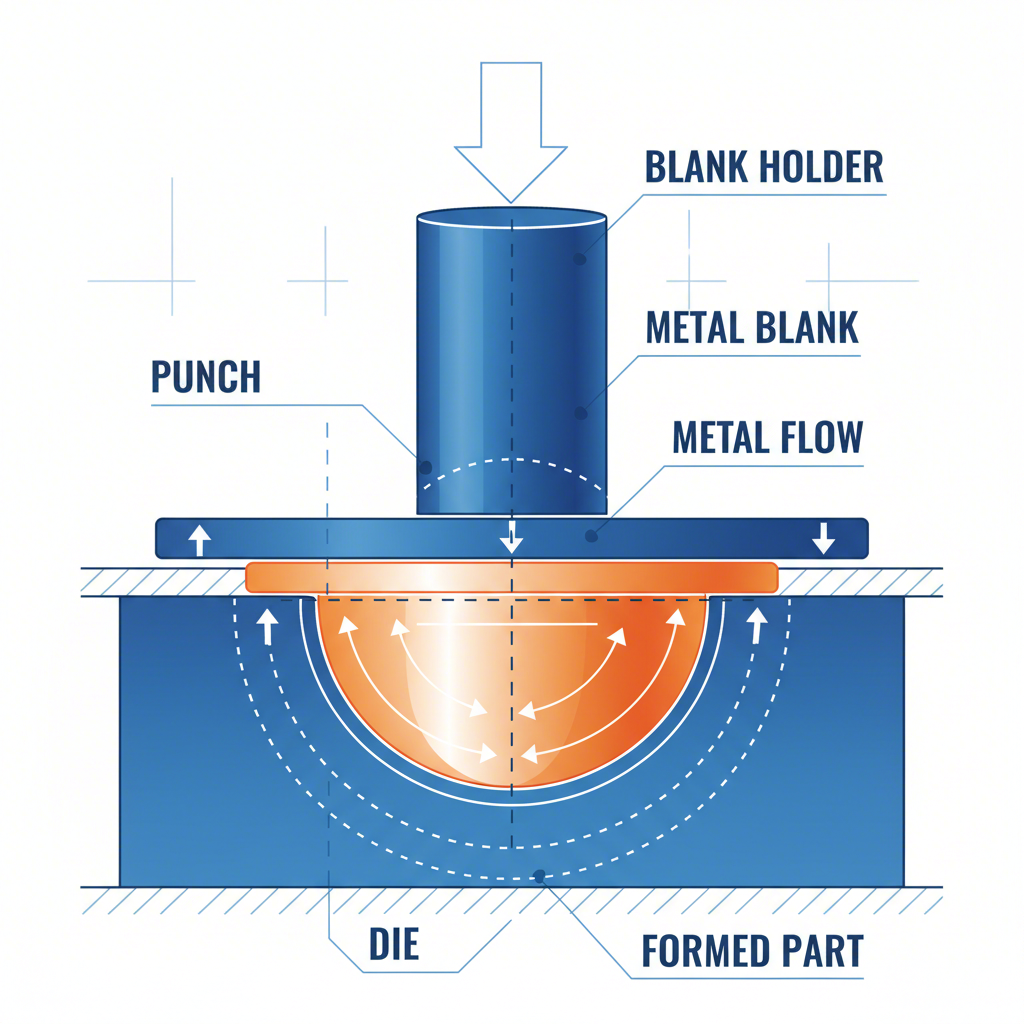

For creating seamless, hollow automotive components like oil pans, fuel tanks, and fenders, deep draw stamping is an indispensable process. As detailed in in-depth engineering guides, this technique transforms a flat metal blank into a three-dimensional shape by forcing it into a die cavity with a punch. The term 'deep' applies when the part's depth is greater than its diameter. This process puts immense stress on the material, making precise die design absolutely critical to success.

A successful deep draw operation depends on the flawless interaction of several key die components. The punch is the male component that pushes the metal into the die. The die cavity is the female component that shapes the exterior of the part. Crucially, a blank holder applies controlled pressure to the edges of the blank as it is drawn into the cavity. This pressure is the secret to a successful draw, as it prevents wrinkles from forming while allowing the material to flow smoothly over the die radius.

Preventing defects in deep drawing requires adherence to strict design principles. Engineers must manage the draw ratio (the relationship between the blank diameter and the punch diameter) to avoid excessive thinning or tearing. Proper lubrication is also vital to reduce friction and heat, which can cause the material to fail. As experts from Alsettevs explain, sophisticated die designs may incorporate multiple drawing stages to form a part incrementally, reducing stress at each step.

To ensure a high-quality finished part, designers should follow these essential guidelines:

- Use Generous Corner and Fillet Radii: Sharp corners concentrate stress and can lead to fractures. Larger radii promote smoother metal flow.

- Maintain Uniform Wall Thickness: The design should aim for consistent thickness throughout the part to prevent weak spots.

- Select the Right Material: Choose materials with high ductility and formability that can withstand the stresses of the drawing process.

- Optimize Blank Holder Force: Too little force causes wrinkling, while too much force restricts metal flow and causes tearing. This must be precisely calibrated.

Beyond Stamping: An Overview of Die Cutting for Intricate Designs

While stamping and forming are used to shape metal, die cutting is a related process focused on cutting materials into precise shapes. This distinction is important, as die cutting is often used for automotive components where precision outlines are more critical than three-dimensional form. This process is highly versatile and can be used on a wide range of materials, from metal foils and plastics to foam and rubber for components like gaskets, seals, and interior trim.

Several die cutting techniques exist, each suited for different applications. Flatbed die cutting uses a steel rule die pressed onto a material sheet, similar to a cookie cutter, and is ideal for lower volumes or thicker materials. Rotary die cutting is a high-speed process where a cylindrical die cuts material fed from a continuous roll, making it perfect for high-volume production of smaller parts. Both methods offer excellent repeatability and cost-effectiveness.

For the most complex and intricate automotive designs, laser die cutting provides unmatched precision. As explained by manufacturing specialists at American Micro, this technique uses a high-powered laser guided by a computer to cut shapes without any physical die. This allows for extremely fine details, sharp corners, and rapid prototyping, as designs can be changed instantly in the software. It is particularly useful for cutting advanced materials or creating complex patterns for automotive interiors and electronics.

Driving Automotive Innovation with Precision Die Design

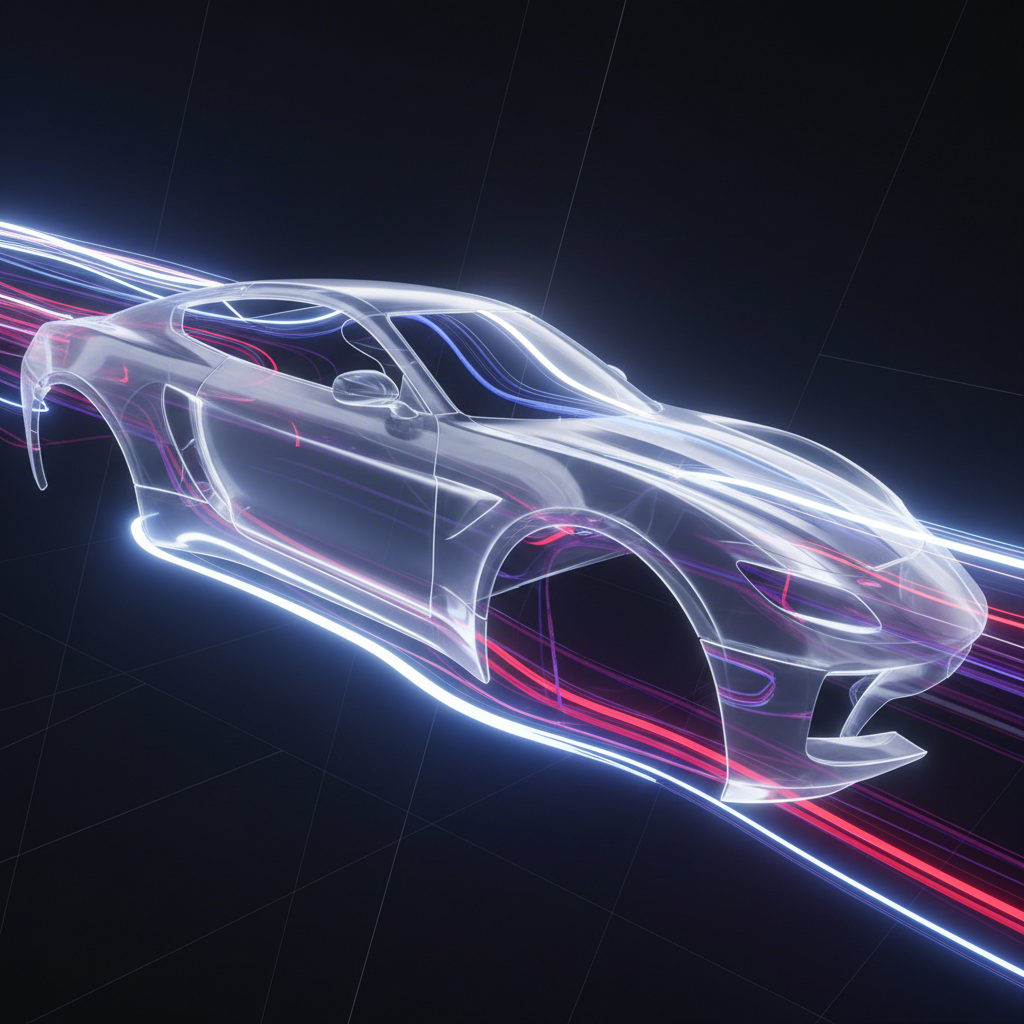

Ultimately, the ability to create complex automotive shapes is a direct result of sophisticated die design. From the fundamental physics of metal forming to the selection of highly specialized stamping dies, every decision impacts the final part's quality, durability, and cost. Processes like deep draw stamping push the boundaries of what is possible with sheet metal, enabling the creation of stronger, lighter, and more aerodynamic vehicles.

As automotive technology continues to advance, the demand for even more intricate components will grow. A deep understanding of these design principles, combined with advanced tools like CAE simulation and partnerships with expert manufacturers, will remain essential for driving innovation and maintaining a competitive edge in the industry. Mastering die design is not just about shaping metal; it's about shaping the future of mobility.

Frequently Asked Questions

1. What are the fundamentals of stamping die design?

The fundamentals of stamping die design revolve around controlling the deformation of sheet metal using tension and compression. A successful design must account for the material's properties (like thickness and strength), the desired geometry, and the forces required to shape the part without causing defects like splits or wrinkles. It involves selecting the right die type and precisely calculating factors like punch and die radii and blank holder pressure.

2. What is the difference between a progressive die and a transfer die?

A progressive die performs multiple operations on a continuous strip of metal that is fed through the die. The part remains attached to the strip until the final station. A transfer die works with individual, separated blanks that are mechanically moved from one station to the next. Progressive dies are generally faster for smaller parts, while transfer dies are better suited for larger or more complex components that cannot be easily manipulated while attached to a strip.

3. What are the key components of a draw die?

The primary components of a draw die include the punch (the male tool that pushes the metal), the die cavity (the female tool that forms the metal), and the blank holder (which applies controlled pressure to the material's edge). Other critical elements are the die radii, over which the metal flows, and draw beads, which can be added to further control material flow and prevent wrinkles in complex parts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —