Density of Aluminum: Accurate Values, kg/m³ and lb/in³ Chart

Understand the Fundamentals of Aluminum Density

What Density Means for Aluminum

When you’re designing a part, estimating shipping costs, or selecting materials for a new product, the density of aluminum is one of the first numbers you’ll need. But what does it really mean? Simply put, density is the amount of mass packed into a given volume. For engineers, students, and buyers alike, knowing the density of aluminum helps predict how heavy a component will be, how it will perform under load, and how it will behave during machining or forming. Imagine comparing an aluminum extrusion to a steel one—aluminum’s low density means it’s typically about one-third the weight for an equal volume, making it a favorite for lightweight structures and transportation applications.

Standard Units and Conversions

Sounds complex? It doesn’t have to be. The key is understanding the units you’ll encounter and how to switch between them. You’ll notice that different industries and regions prefer different units. Here’s a quick reference to keep things clear:

- kg/m³ – Kilograms per cubic meter (SI unit, used in engineering and science)

- g/cm³ – Grams per cubic centimeter (common in labs and material datasheets)

- lb/ft³ – Pounds per cubic foot (used in U.S. construction and manufacturing)

- lb/in³ – Pounds per cubic inch (precision machining and aerospace)

| From | To | Conversion Factor |

|---|---|---|

| 1 g/cm³ | 1,000 kg/m³ | × 1,000 |

| 1 g/cm³ | 62.43 lb/ft³ | × 62.43 |

| 1 kg/m³ | 0.001 g/cm³ | × 0.001 |

| 1 kg/m³ | 0.0624 lb/ft³ | × 0.0624 |

| 1 lb/in³ | 27,680 kg/m³ | × 27,680 |

| 1 lb/ft³ | 16.02 kg/m³ | × 16.02 |

Specific Gravity vs Density

Ever see "specific gravity" and wonder if it’s the same as density? They’re closely related, but not identical. Specific gravity is the ratio of a material’s density to the density of water at a specified temperature (usually 4°C, where water is 1.0 g/cm³). For aluminum, the specific gravity is about 2.7, meaning it’s 2.7 times heavier than an equal volume of water. This makes it easy to compare materials, especially in industries where both density and buoyancy matter.

Core formula: density = mass ÷ volume.

Always confirm the measurement temperature for reliable results.

Measurement Conditions and Best Practices

Accurate density values depend on how and where you measure. Trustworthy figures are always reported with the measurement temperature and method—whether by geometric calculation, liquid displacement, or specialized equipment like a pycnometer. For example, the aluminum density most often cited is for pure, solid aluminum at room temperature (about 20°C or 68°F). According to leading references, the density of pure aluminum is:

- 2.70 g/cm³

- 2,700 kg/m³

- 168 lb/ft³

These values come from authoritative sources such as the MISUMI MechBlog and Kloeckner Metals. Always check the datasheet or standards body for the exact temperature and alloy composition, as even small changes in either can shift the density value.

Up next, we’ll explore how temperature, alloying, and processing can further affect the density of aluminum, and how to measure it with confidence. By understanding these fundamentals, you’ll be ready to apply density data accurately—whether you’re estimating mass, designing lightweight parts, or comparing materials for your next project.

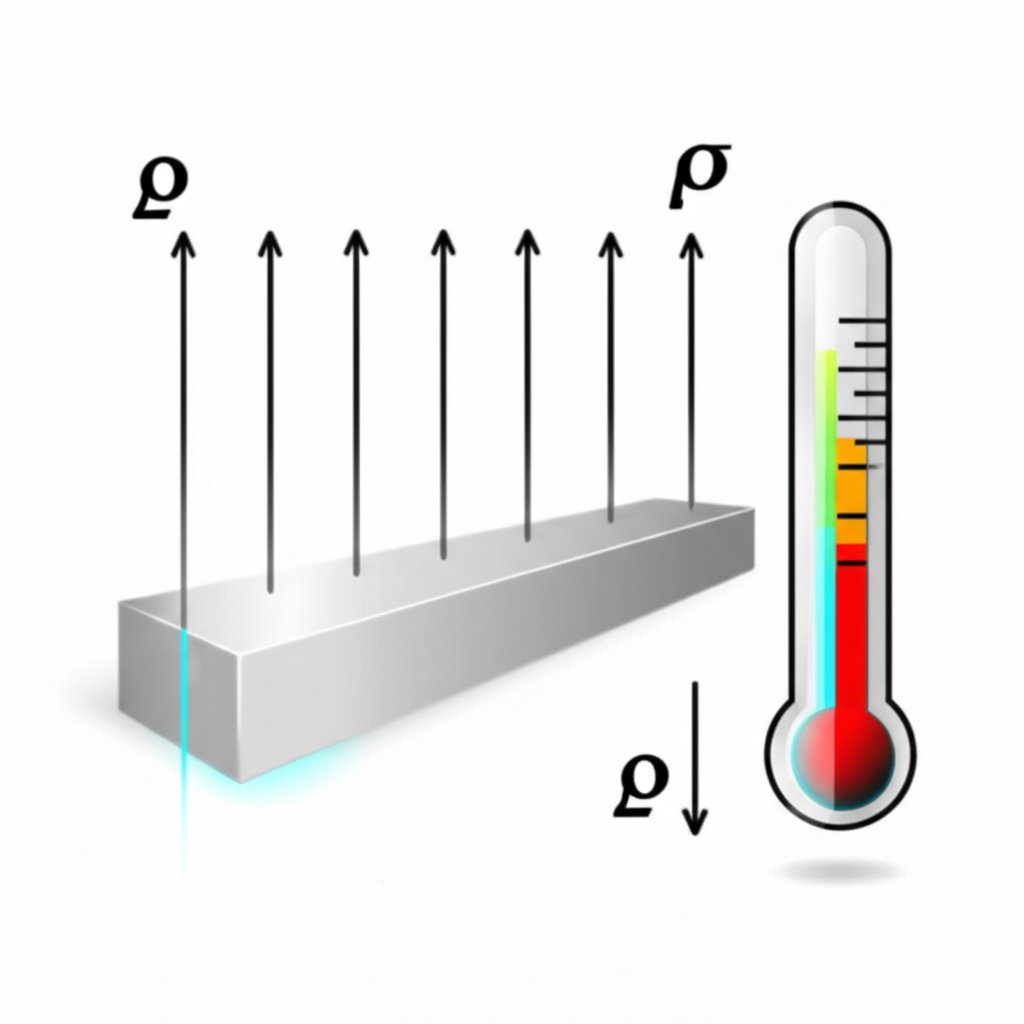

Account for Temperature When Using Aluminum Density

How Temperature Affects Aluminum Density

Ever wonder why the density of aluminum you find in handbooks sometimes comes with a temperature note? That’s because, like most materials, aluminum expands as it gets warmer. When you heat aluminum, its atoms move farther apart, so the same mass now takes up more space—meaning the density drops. For example, pure aluminum’s density is typically listed as 2,700 kg/m³ or 2.70 g/cm³ at room temperature (about 20°C). But if you increase the temperature, you’ll notice the density decreases slightly. This isn’t just academic: in aerospace, automotive, and electronics, even small changes can affect mass estimates, fit, and performance.

Using Thermal Expansion to Adjust Density

Sounds complex? Here’s a practical way to adjust for temperature effects using values from authoritative sources. The key is the linear thermal expansion coefficient (α), which tells you how much aluminum expands per degree of temperature change. For most pure aluminum and common alloys, α is about 23.4 × 10⁻⁶ /°C (for 6061 and 6063 alloys, between 20–100°C) (AMESweb). The process is straightforward:

- Get a reference density at a known temperature (e.g., 2,700 kg/m³ at 20°C from a trusted source).

- Obtain the linear thermal expansion coefficient (α) for your alloy and temperature range from a handbook or datasheet.

- Apply the volumetric expansion formula to estimate density at your target temperature:

ρ(T) ≈ ρ₀ ÷ [1 + 3·α·(T − T₀)]

Where ρ(T) is the density at temperature T, ρ₀ is the reference density at T₀ (usually 20°C), and α is the linear thermal expansion coefficient. This model assumes isotropic expansion and is a good engineering approximation for solid aluminum below its melting point.

- Document uncertainty by noting the source and temperature for both density and α. For critical calculations, always cite your references and consider measurement tolerances.

Room Temperature Versus Elevated Temperature Values

Imagine you’re designing an electrical busbar that will heat up in service. If you use the room temperature value for aluminum density kg m3 or density of aluminum in g/cm3, your mass estimate may be slightly high. For instance, published data show that pure aluminum’s density drops from 2.70 g/cm³ at 20°C to about 2.68 g/cm³ at 200°C (SinteredFilter.net). That’s a small change—about 0.7%—but significant for large parts or high-precision work.

- Always use density values reported at the temperature closest to your application.

- If your application involves high heat (near aluminum’s melting point, ~660°C), remember that the material changes phase, and solid-state formulas no longer apply. In such cases, consult high-temperature materials data or specialized handbooks.

By understanding and adjusting for temperature, you ensure your calculations for aluminum density kg/m3 and density of aluminum in g/cm3 remain accurate in real-world conditions. Next, we’ll look at how alloying and processing can further shift these values—and when you should use nominal versus measured data for your specific part or project.

How Alloys and Processing Change Effective Aluminum Density

Alloy Family Differences: 1xxx, 6xxx, and 7xxx Series

Ever wonder why the density of aluminum in your datasheet doesn’t always match what you measure in the shop? One of the biggest reasons is alloying. Pure aluminum (1xxx series) is rarely used in demanding applications because it’s soft, but it sets the baseline: its density is about 2.70 g/cm³ or 2,700 kg/m³ at room temperature. When you add elements like magnesium, silicon, zinc, or copper to create alloys, the density shifts. For example:

- 1xxx Series (nearly pure aluminum): Density remains close to 2.70 g/cm³.

- 6xxx Series (e.g., 6061): Magnesium and silicon additions keep the density around 2.70 g/cm³ (specifically, aluminum 6061 density is 2.70 g/cm³ or 0.0975 lb/in³).

- 7xxx Series (e.g., 7075): Zinc and copper raise the density slightly, with 7075 density typically at 2.81 g/cm³ (0.102 lb/in³).

Even within a series, density can shift based on precise chemistry. For example, density aluminium 6061 and density of 6061 t6 aluminum are nearly identical, but minor differences may arise from tempering and trace elements.

Processing Effects: Porosity, Heat Treatment, and More

Imagine making two parts from the same alloy—one by forging, the other by casting. You’ll notice the densities aren’t always identical. Why? Processing introduces new variables:

- Alloying additions (more alloying elements generally mean higher density)

- Casting porosity (air pockets reduce effective density)

- Voids from welding or incomplete fusion

- Work hardening (can slightly affect density by changing microstructure)

- Oxide layers and coatings (thin but can matter in small or thin parts)

- Segregation and impurities (local composition changes density)

For example, die-cast alloys like A356 may show slightly lower density than wrought products due to micro-porosity unless densified by hot isostatic pressing (HIP). Heat treatment can also close voids and improve density uniformity, especially for high-performance aerospace parts.

Tip: Use nominal handbook densities for early estimates; switch to measured values for castings, foams, or parts with known porosity.

Nominal Design Values vs Measured Part Values

When should you trust the datasheet, and when should you measure? For most design work, especially with wrought alloys like 6061 or 7075, use the nominal values from handbooks or standards. For example:

| Alloy | Density (g/cm³) | Density (kg/m³) | Source |

|---|---|---|---|

| 6061 (all tempers) | 2.70 | 2,700 | Kloeckner Metals |

| 7075 (T6) | 2.81 | 2,810 | Kloeckner Metals |

| 2011 | 2.83 | 2,830 | Sunrise Metal |

But if your part is cast, has complex geometry, or you know it contains voids (like foams or welded assemblies), direct measurement is best. Always record the temperature and method for traceability.

By understanding the effects of alloying and processing, you’ll choose the right density—whether using aluminum 6061 density for general design or measuring your own part for critical calculations. Up next, we’ll explore hands-on lab methods to measure density with confidence, even when the datasheet isn’t enough.

Measure Aluminum Density with Reliable Lab Methods

Archimedes Water Displacement Method

When you need to determine the density of aluminum precisely—especially for irregular shapes—the Archimedes water displacement method is a gold standard. Sounds complicated? It’s actually straightforward if you follow each step carefully. Here’s a step-by-step protocol you can use in any well-equipped lab, based on trusted reference procedures (Canadian Conservation Institute):

- Calibrate your gram scale: Use a balance with at least 0.01 g resolution. Make sure it’s properly zeroed and calibrated before starting.

- Record the dry mass: Suspend the aluminum object from the internal hook using a thin nylon thread or wire. Weigh the object in air and note the mass (mair).

- Prepare for immersion: Fill a beaker with tap water, ensuring the temperature is measured and recorded. Place the beaker under the balance so the object can be fully submerged without touching the sides or bottom.

- Submerge and weigh: Carefully lower the beaker until the object is completely immersed. Make sure there are no trapped air bubbles—tap the object gently if needed. Record the apparent mass in water (mwater).

-

Calculate volume and density: Use the formula below, referencing the correct density of liquid water in g/cm3 at your measurement temperature (for example, 0.998 g/cm³ at 20°C):

Density (g/cm³) = mair / [mair – mwater] × (density of liquid water in g/cm³)

Insert your measured values for the calculation.

- Correct for temperature: Always check a standard water density table to ensure you use the proper water density at your measurement temperature. Even small differences can affect your results.

- Estimate uncertainty: Consider the resolution of your gram scale, precision in reading the water meniscus, temperature measurement accuracy, and any possible buoyancy effect from the suspension wire or thread.

For example, if you measure 110.18 g in air and 69.45 g in water at 20°C, with water density 0.998 g/cm³, your calculation would be:

Density = 110.18 / (110.18 – 69.45) × 0.998 ≈ 2.70 g/cm³.

Geometric Method for Simple Shapes

If your aluminum part is a simple plate, rod, or extrusion, the geometric method is quick and reliable. Here’s how you do it:

- Measure dimensions: Use calipers or a micrometer to measure length, width, height (or diameter, for rods) with high precision. Record each value.

- Compute the volume: Calculate the volume using the appropriate geometric formula (e.g., V = length × width × height for a rectangular block).

- Weigh the object: Place the part on the gram scale and record its mass (in grams).

-

Calculate density: Divide the measured mass by the calculated volume. For example:

Density (g/cm³) = mass (g) / volume (cm³)

- Propagate measurement uncertainty: Consider the accuracy of each dimension and the scale’s precision. Estimate the combined uncertainty in your final density value.

While this method is fast, it’s only as accurate as your measurements—especially for small or thin parts where a tiny error in length or diameter can significantly affect the calculated volume.

Common Pitfalls and Uncertainty Estimation

Even with careful technique, some common issues can throw off your results. Here’s what to watch out for:

- Trapped air bubbles during immersion (causes underestimated volume and overestimated density)

- Oxide or water films clinging to the surface (can affect mass readings)

- Inaccurate temperature control (affects water density and expansion of the part)

- Rough or irregular surfaces (hard to measure volume precisely)

- Hollow sections not accounted for in geometric calculations

- Scale drift or poor calibration

For best results, always:

- Document the measurement temperature and water purity

- Check the calibration of your gram scale and measuring tools

- Use reference tables for density of liquid water in g/cm3 at your measured temperature

- Record all uncertainties and note them in your results

Tip: For engineering and design, you may need to convert your measured density to other units, such as density of aluminum lb/in3 or aluminum density lb/in3. 1 g/cm³ equals 0.03613 lb/in³. Simply multiply your result by this factor to switch units as needed.

By following these protocols and minding potential pitfalls, you’ll obtain trustworthy measurements for density of aluminum g/ml, density of aluminum lb/in3, or density of aluminum lb/ft3. This accuracy is crucial for critical applications, quality control, or whenever datasheet values don’t quite match your real-world parts. Next, we’ll show you how to use these values to build authoritative density tables for aluminum grades and alloys.

Create Trustworthy Density Tables for Aluminum Grades

Authoritative Density Reference Tables

When you need to answer, “What is the density of aluminum?,” the best approach is to consult a credible, citable density table of metals. These tables provide not only the accepted density of aluminum metal but also the variations you’ll encounter across alloys and processing types. For engineers, designers, and buyers, using a metal density chart from authoritative sources ensures your calculations and product specifications are built on solid ground.

| Material or Grade | Nominal Density (kg/m³) | Nominal Density (g/cm³) | Temperature of Value (°C) | Measurement Method/Source | Typical Range/Tolerance | Recommended Design Value |

|---|---|---|---|---|---|---|

| Pure Aluminum (Al 99.99%) | 2,700 | 2.70 | 20 | Sunrise Metal | ±10 kg/m³ | 2,700 kg/m³ |

| Aluminum 6061 (all tempers) | 2,700 | 2.70 | 20 | ASM MatWeb | ±10 kg/m³ | 2,700 kg/m³ |

| Aluminum 7075 (T6) | 2,810 | 2.81 | 20 | Sunrise Metal | ±10 kg/m³ | 2,810 kg/m³ |

| Aluminum 1100 | 2,710 | 2.71 | 20 | Sunrise Metal | ±10 kg/m³ | 2,710 kg/m³ |

| Aluminum 2011 | 2,830 | 2.83 | 20 | Sunrise Metal | ±10 kg/m³ | 2,830 kg/m³ |

| Aluminum A356 (Casting) | 2,690 | 2.69 | 20 | Sunrise Metal | Varies with porosity | 2,690 kg/m³ (if porosity is low) |

All values are based on cited reference sources at room temperature (20°C) and represent solid, fully dense material unless otherwise noted.

How to Read and Cite Density Tables

Imagine you’re comparing two alloys for a lightweight structure. You’ll see that the mass density of aluminum can shift by up to 5% between grades, so always check both the alloy designation and the temperature column. For instance, the density of aluminum 6061 is reliably 2,700 kg/m³ at 20°C, but a casting alloy like A356 may be lower if porosity is present. The “Measurement Method/Source” column points you to the original data—always cite this in your design notes or reports for traceability.

- Use the “Recommended Design Value” column for calculations unless your part’s porosity or temperature will significantly differ from standard conditions.

- If you’re working at elevated temperatures, apply the adjustment method described in the temperature section earlier.

- For more alloys, consult the full metal density chart or the Sunrise Metal alloy table.

Choosing a Conservative Design Value

Wondering how to pick a value that keeps your design safe and compliant? If the density table of metals gives a range, always select the lower end for weight-critical applications (to avoid underestimating mass) or the upper end for volume-critical designs. For castings or parts with known porosity, use a measured value or consult the manufacturer for a more accurate estimate.

Always align the table’s temperature and measurement context with your application. If you expect significant temperature swings or processing-induced porosity, adjust your density values accordingly or use the temperature correction method described earlier.

By using accepted, referenced values for the density of aluminum metal and its alloys, you build confidence into your calculations and ensure your results are defensible—whether you’re reporting to a client, passing a quality audit, or finalizing a bill of materials. Up next, we’ll compare aluminum with other metals so you can see how it stacks up for weight-sensitive designs and material selection.

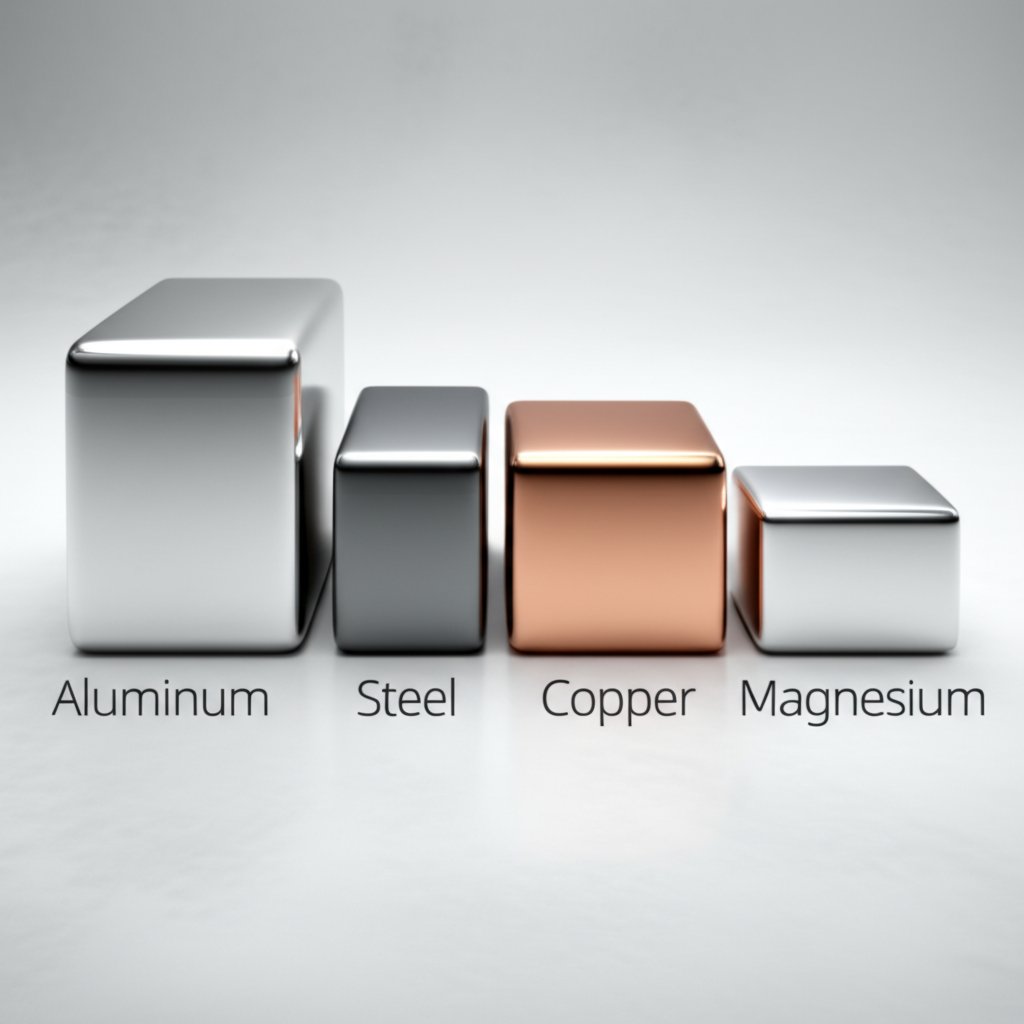

Compare Aluminum Density with Other Metals

Aluminum Versus Steel, Copper, and Magnesium: Density at a Glance

When you’re choosing materials for a new project, have you ever wondered how much weight you could save by switching from steel or copper to aluminum? Or maybe you’re curious why magnesium parts feel almost feather-light in your hand. Understanding the density of steel vs aluminum—and how both compare to copper and magnesium—can help you make informed choices for strength, weight, and cost.

| Material | Density (kg/m3) | Density (g/cm3) | Relative Weight per Equal Volume |

|---|---|---|---|

| Aluminum (6061, pure) | 2,700 – 2,720 | 2.70 – 2.72 | Baseline (1.0×) |

| Steel (carbon) | 7,850 – 7,860 | 7.85 – 7.86 | ~2.9× heavier than aluminum |

| Stainless Steel | 7,480 – 7,950 | 7.48 – 7.95 | ~2.8–2.9× heavier than aluminum |

| Copper | 8,940 – 8,960 | 8.94 – 8.96 | ~3.3× heavier than aluminum |

| Magnesium | 1,738 – 1,740 | 1.74 | ~0.65× as heavy as aluminum |

All values are for room temperature, solid, fully dense material. Always check the specific alloy and measurement temperature for your application.

For equal volume, aluminum is substantially lighter than steel and copper, and heavier than magnesium; check sourced numbers for your calculation.

Weight Implications for Parts and Assemblies

Imagine you’re replacing a steel bracket with an aluminum one of the same size. Because the steel density is about 7,850 kg/m3, and aluminum is around 2,700 kg/m3, your new part will weigh roughly one-third as much. The same swap from copper (with a copper density of nearly 8,960 kg/m3) to aluminum saves even more weight. On the other hand, magnesium is even lighter than aluminum, with a typical magnesium density of 1,740 kg/m3, making it a top pick for ultra-lightweight applications—but often at a higher cost and with more stringent corrosion precautions.

- Aluminum vs Steel: Aluminum saves significant weight, making it ideal for automotive, aerospace, and portable products. However, steel is stiffer and stronger per unit volume, so you may need to increase section size or use a higher grade for equivalent strength.

- Aluminum vs Copper: Aluminum is much lighter and less costly, though copper offers superior electrical and thermal conductivity. In power transmission, aluminum’s low density is leveraged for overhead lines, while copper remains common in compact, high-performance applications.

- Aluminum vs Magnesium: Magnesium wins for the lightest weight, but is more expensive and less corrosion-resistant. It’s used where every gram counts, such as in racing or aerospace interiors.

Material Selection by Density and Performance

How do you decide which metal to use? Density is just one piece of the puzzle. Consider these factors alongside your density calculations:

- Strength-to-weight ratio: Aluminum alloys often provide a strong balance of low density and good mechanical properties.

- Cost: Aluminum is typically less expensive than copper and magnesium, and can be more cost-effective than stainless steel for large, lightweight structures.

- Stiffness: Steel and stainless steel density values are higher, but so is their modulus of elasticity—meaning they resist bending more for the same cross-section.

- Corrosion resistance: Stainless steel and aluminum both offer good corrosion resistance, but the right choice depends on your environment and cost constraints.

Always match your density data to the correct temperature and alloy for a fair comparison. If you’re documenting your design, cite the source for each value—like the Engineers Edge densities table—and specify whether you’re using nominal or measured values. This ensures your calculations are defensible and repeatable.

Now that you’ve seen how aluminum stacks up against steel, copper, and magnesium, you’re ready to estimate weight savings and make smarter material choices. In the next section, we’ll show you how to apply these density values to real-world parts, from extrusions to sheet metal, and guide you on sourcing quality components for your projects.

Apply Density to Real Parts and Source Quality Extrusions

Using Density in Extrusion and Sheet Design

When you design a lightweight structure—be it an aluminum channel for a vehicle frame, an aluminum plate for a battery enclosure, or aluminum sheet metal for body panels—the density of aluminum becomes a practical number, not just a property in a table. Why does it matter? Because every gram counts in automotive, aerospace, and industrial applications. The unit weight of aluminum directly informs your mass estimates, shipping costs, and even compliance with regulatory weight targets.

Imagine you’re finalizing a CAD design for an automotive battery tray. You need to estimate the total mass as accurately as possible to meet performance and safety goals. That’s where trusted density values for the specific alloy and temperature—sourced from a reliable table—become essential. Getting this step right ensures your bill of materials, cost analysis, and downstream logistics are built on solid ground.

Quick Mass Estimation Workflow

Sounds complex? Here’s a streamlined approach engineers use every day to turn density data into actionable mass estimates for aluminum channel, aluminum plate, and aluminum sheet metal components:

- 1. Source density from a cited table: Always reference a reputable source for the correct alloy and temperature. For example, aluminum 6061 at room temperature is typically 2.70 g/cm³ or 2,700 kg/m³.

- 2. Compute volume from CAD: Use your CAD software to extract the exact volume of your part, including all cutouts and hollow sections.

-

3. Multiply density by volume: Calculate the mass using the formula:

Mass = Density × Volume

For instance, if your extrusion has a volume of 0.003 m³ and the density of your alloy is 2,700 kg/m³, the mass will be 8.1 kg. - 4. Adjust for design details: Make sure to subtract the volume of any holes, slots, or cavities. For complex profiles, sum the volumes of all solid regions and subtract voids.

- 5. Include uncertainty and tolerances: Factor in manufacturing tolerances and possible density variation due to alloying or processing. For high-precision work, add a margin to your estimate.

Tip: Always log your density assumptions and their sources in your CAD material library. This makes it easy to trace and update your calculations if the alloy, supplier, or process changes.

For long extrusions, you can also use the formula from industry references:

Weight per meter (kg/m) = Cross-sectional area (mm²) × Density (g/cm³) × 10⁻³

Then multiply by length for the total weight.

Sourcing Precision Extrusions for Automotive

Once you’ve nailed down your mass estimates and finalized your aluminum channel or aluminum plate design, the next challenge is sourcing high-quality extrusions that match your specifications. For automotive engineers, accuracy in density and dimensions is crucial—not only for weight targets but also for structural integrity and fit.

Partnering with a reputable supplier can make all the difference. For example, aluminum extrusion parts from Shaoyi Metal Parts Supplier offer a one-stop solution for precision automotive components. Their expertise in alloy selection, process control, and quality assurance ensures your extruded profiles meet stringent automotive standards. Understanding the density of aluminum helps you specify accurate requirements in your RFQs, set realistic weight targets, and verify delivered parts during quality checks.

Whether you’re estimating the weight of aluminum per cubic inch for a connector or calculating aluminum weight per cubic foot for a chassis member, using authoritative density values and a reliable workflow streamlines both design and procurement. This approach minimizes surprises during production and supports compliance with lightweighting, cost, and performance goals in automotive and industrial sectors.

Next, we’ll show you how to quantify and manage uncertainty in your density data—so your mass estimates stay robust, even as designs evolve.

Quantify and Manage Uncertainty in Aluminum Density Usage

Uncertainty and Tolerance in Density Data

When you’re calculating the mass of a part or selecting an alloy for a critical component, how confident are you in the density value you’re using? Sounds like a small detail, but even minor uncertainty in the mass density aluminum can lead to significant errors in weight or performance predictions. In real-world engineering, no measurement is perfect. Recognizing and managing these uncertainties is key to reliable results.

- Temperature mismatch: Density values change with temperature. Using a value at 20°C for a part that operates at 100°C introduces error.

- Instrument resolution: The limits of your scale or calipers set a floor on how precisely you can measure mass and volume.

- Porosity: Castings and welded parts may contain tiny voids, reducing effective aluminium mass density compared to nominal values.

- Surface contamination: Oxide films, dust, or oil can add mass or change volume, skewing results.

- Alloy composition variance: Small changes in alloying elements shift the density—especially in custom or recycled materials.

- Rounding in tables: Published density values are often rounded to two or three decimal places, introducing small but cumulative errors.

For example, the density aluminum listed as 2.70 g/cm³ in a handbook might actually range from 2.690 to 2.710 g/cm³ depending on measurement and alloy batch. Always check the stated tolerance or range in your source—some standards specify ±10 kg/m³ for wrought alloys. If you’re working with fine tolerances, document these uncertainties in your calculations.

Error Propagation for Mass Estimates

Imagine you’re estimating the mass of an aluminum extrusion for a high-precision assembly. The total uncertainty isn’t just about density—it also includes errors in your volume measurement. How do you combine these? The answer lies in error propagation.

According to the propagation of uncertainty principle (ChemLibreTexts):

Relative mass uncertainty ≈ relative density uncertainty + relative volume uncertainty

Assuming the errors are independent and random, add the relative uncertainties for density and volume to estimate the total relative uncertainty in mass.

Mathematically, if you have:

- Density uncertainty: Δρ/ρ (for example, 0.4% if your source gives ±10 kg/m³ on 2,700 kg/m³)

- Volume uncertainty: ΔV/V (from your calipers or displacement method)

Your mass uncertainty is simply the sum of these relative errors. For more complex cases, or if you need to account for correlated errors, refer to the full error propagation formula provided in analytical chemistry references.

Let’s say you’re converting your results to aluminum density kg/mm3 for a microcomponent. Even a tiny error in measurement can become significant at this scale, so always record and report your uncertainty alongside the calculated value.

When to Re-Measure Versus Use Nominal Values

When is it worth measuring the density of aluminum in lb/in3 for your actual part, and when is the handbook value enough? Consider these scenarios:

- Use nominal values: For standard, wrought alloys (like 6061 or 1100) in routine applications, handbook values with stated tolerances are usually sufficient.

- Measure your part: If your component is cast, welded, or has known porosity, or if the alloy composition isn’t tightly controlled, direct measurement is best.

- Critical mass estimates: For aerospace, automotive, or high-precision applications, always verify density (and volume) experimentally and propagate uncertainties through your calculations.

Documenting your uncertainty budget—listing every source of error and its estimated impact—helps you defend your design decisions and avoid surprises in production or testing.

By embracing uncertainty analysis, you’ll build more robust mass estimates and material selections. As you move to final design and procurement, keep these practices in mind to ensure your aluminum components meet both specification and performance targets.

Put Density Knowledge into Practice and Source Smartly

Key Takeaways for Using Aluminum Density Correctly

When you’re finalizing a design or preparing a quote, knowing what is aluminium density isn’t just a trivia question—it’s a foundation for accurate engineering decisions. Throughout this guide, you’ve seen how the density of aluminum shapes everything from mass estimates to compliance checks. But how do you turn this knowledge into reliable, real-world results? Here’s a checklist to keep your projects on track:

|

Trusted Sources and Documentation Practices

Imagine you’re answering a client’s question: "What’s the density of aluminum for this part?" Your answer should always be backed by recognized standards, such as values from ASM Handbooks, NIST Chemistry WebBook, or reputable material databases. Whenever possible, include the exact value, temperature, and source in your documentation. This builds confidence and ensures that mass calculations, shipping estimates, and compliance checks are based on defensible data.

Recommended Supplier for Automotive Extrusions

Ready to move from theory to practice? If your next step is sourcing precision extruded components, it pays to partner with an expert who understands how density impacts every stage—from RFQ to delivery. For automotive projects, aluminum extrusion parts from Shaoyi Metal Parts Supplier offer a one-stop solution for strong, lightweight, and quality-assured components. Their expertise ensures that your BOM weights, shipping calculations, and compliance needs are aligned with the true density of aluminum—minimizing risk and supporting your program’s success.

By applying these best practices, you’ll answer questions like what is aluminum's density with authority—and turn that knowledge into lighter, safer, and more efficient designs. Whether you’re estimating the aluminum weight per cubic inch for a connector or the weight of aluminum per cubic foot for a chassis, using verified data and trusted partners is your key to getting it right, every time.

Frequently Asked Questions about Aluminum Density

1. What is the standard density of aluminum and why does it matter?

The standard density of pure aluminum is 2.70 g/cm³ (2,700 kg/m³) at room temperature. This value is crucial for engineers and designers because it directly impacts weight calculations, material selection, and part performance. Using the correct density ensures accurate mass estimates and compliance with design requirements.

2. How does temperature affect the density of aluminum?

As temperature increases, aluminum expands and its density decreases slightly. For example, the density may drop from 2.70 g/cm³ at 20°C to about 2.68 g/cm³ at 200°C. For applications exposed to heat, always use density values referenced at the relevant operating temperature or apply a thermal expansion correction.

3. Do different aluminum alloys have different densities?

Yes, alloying elements like magnesium, silicon, zinc, or copper can shift the density of aluminum. For instance, 6061 alloy typically has a density of 2.70 g/cm³, while 7075 is denser at about 2.81 g/cm³. Always consult a trusted density table for the specific alloy you are using.

4. What is the most reliable way to measure the density of an aluminum part?

For irregular shapes, the Archimedes water displacement method is recommended. It involves weighing the part in air and in water, then using the difference to calculate density. For simple shapes, measure dimensions accurately and divide mass by calculated volume. Always document temperature, measurement method, and any uncertainty.

5. Why is knowing aluminum density important when sourcing automotive parts?

Accurate aluminum density values are essential for estimating part weight, ensuring compliance with vehicle weight targets, and preparing precise RFQs. Partnering with a certified supplier like Shaoyi Metal Parts Supplier helps translate theoretical density benefits into high-quality, lightweight automotive components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —