From Volume To Weight: density of aluminum lb/in3 With Worked Calcs

Quick answer and why it matters

Quick answer: density of aluminum lb/in3

Use the accepted value verified from ASM International and leading engineering sources: 0.0975 lb/in³ (≈2.70 g/cm³). This is the standard density of aluminum in lb/in³ for most engineering and design calculations.

What density means for weight estimates

Ever need to estimate the weight of an aluminum part before it hits the shop floor? The density of aluminum lb/in3 is your go-to shortcut. In plain terms, density tells you how much mass is packed into a given volume. For aluminum, that’s about 0.0975 pounds for every cubic inch. Plug this value into the classic formula—mass = density × volume—and you’ll get a solid estimate of any part’s weight, whether it’s a block, sheet, or extrusion.

- Use the nominal value (0.0975 lb/in³) for quick design estimates, quoting, and most purchasing specs.

- Switch to measured values if you’re dealing with critical aerospace, defense, or precision applications where alloy and temper can shift density slightly.

- Remember: Temper (heat treatment), porosity, and alloying elements can nudge density up or down by a few tenths of a percent, but for most general fabrication, the difference is minor.

- Round conservatively upward when estimating total shipment or structural weight—this prevents underestimating and helps avoid surprises in logistics or compliance.

Why alloy and temperature matter

Sounds complex? Not really—here’s what you need to know. The density of aluminum in lb in3 can shift depending on the alloy series. Alloys with heavier elements like copper (2000 series) or zinc (7000 series) are a bit denser than pure aluminum, while magnesium additions (5000 series) can make it lighter. Temperature plays a role too: as aluminum heats up, it expands, so its density drops slightly. In most room-temperature engineering work, these effects are small—but if you’re working at elevated temperatures or with high-precision parts, it’s worth checking the spec sheet.

- For most 1000, 3000, 5000, and 6000 series alloys, stick with the nominal 0.0975 lb/in³ unless your supplier or drawing says otherwise.

- Review technical data if using specialty or high-strength grades—density can range from about 0.096 to 0.101 lb/in³ depending on composition.

Why use lb/in³ instead of metric? In American engineering and fabrication, lb/in³ lines up perfectly with inch-based part drawings, making it easy to convert volume (from CAD or hand calcs) directly into weight. This saves time and avoids conversion errors, especially when quoting, ordering, or checking compliance for aluminum density lb in3.

In summary, the density aluminum lb in3 value of 0.0975 is a reliable, industry-standard shortcut for most design and manufacturing needs. Later sections in this guide will show you how to convert units, compare alloys, and run real-world calculations—so you can put this number to work right away. If you ever need to get more granular, we’ll also cover how to measure or specify the density of al for your exact application.

Conversions and rounding rules that hold up

Exact conversion factors you can trust

When you need to translate the aluminum density lb/in3 into metric or other imperial units, precision is key. Whether you're quoting, checking compliance, or sharing specs with a global team, using the right conversion factors ensures accuracy. Here’s a quick-reference table with the essential factors for density conversions, all based on authoritative sources like NIST and ASM:

| Conversion | Exact Factor | Reference |

|---|---|---|

| 1 in³ = | 16.387064 cm³ | NIST |

| 1 lb = | 0.45359237 kg | NIST |

| 1 ft³ = | 1728 in³ | NIST |

| 1 g/cm³ = | 62.43 lb/ft³ | MISUMI |

| 1 lb/in³ = | 27,680 kg/m³ | MISUMI |

With these factors, you can move seamlessly between units—no guessing, no rounding errors until the very end.

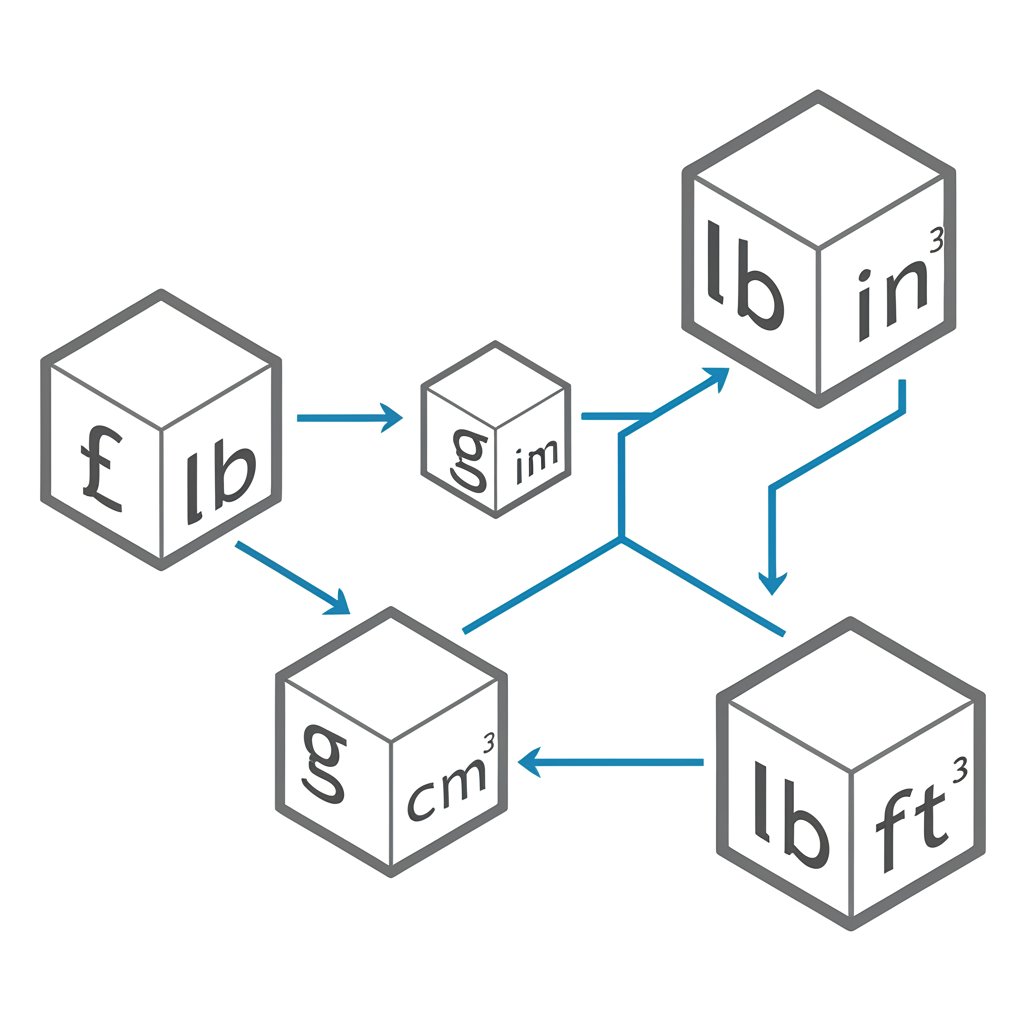

How to convert lb/in³ to g/cm³ and kg/m³

Imagine you have the density of aluminum in lb/in3 (0.0975 lb/in³) and need to use it in a metric calculation. Here’s how you do it, step by step:

- Start with the value in lb/in³: 0.0975 lb/in³

-

Convert lb to grams (1 lb = 453.59237 g):

0.0975 lb/in³ × 453.59237 g/lb = 44.225 g/in³ -

Convert in³ to cm³ (1 in³ = 16.387064 cm³):

44.225 g/in³ ÷ 16.387064 cm³/in³ = 2.698 g/cm³ - Round appropriately: 2.70 g/cm³ (3 significant figures, matching engineering convention)

For aluminum density in kg/m3:

- Start with lb/in³: 0.0975 lb/in³

- Convert using the shortcut from the table: 1 lb/in³ = 27,680 kg/m³

- Multiply: 0.0975 × 27,680 = 2698.8 kg/m³

- Round to 3 significant figures: 2,700 kg/m³

Notice how these results line up with published values for density of aluminum kg/m3 in trusted engineering tables.

Convert to lb/ft³ in two steps

Need to compare aluminum to bulk materials or check against water density in lb/in3? Here’s a quick two-step conversion from lb/in³ to lb/ft³:

- Start with lb/in³: 0.0975 lb/in³

-

Multiply by the number of in³ in a ft³ (1 ft³ = 1728 in³):

0.0975 × 1728 = 168.48 lb/ft³ - Round as needed: 168.5 lb/ft³ (for practical reporting)

For reference, water density in lb/in3 is about 0.0361 lb/in³ at room temperature, so aluminum is more than twice as dense as water by this measure.

Best practices for conversions and rounding

- Always keep conversion factors to full precision until the final step—this avoids compounding rounding errors.

- Round your final answer to 3 or 4 significant digits, unless your drawing or spec calls for more.

- Annotate the source of your conversion factors (such as NIST or ASM) in engineering notes for traceability and audit readiness.

- If you’re unsure, double-check your units—especially when moving between imperial and metric systems.

Once you’re comfortable with these conversions, you’ll be ready to dive into alloy-specific tables and real-world calculations in the next section, where we’ll see how density of aluminum g/cm3 and other units play out in actual design work.

Alloy specific density table for real design work

Common aluminum alloys by density

When specifying or estimating the weight of aluminum components, knowing the exact alloy and its density is critical. While pure aluminum has a well-known density, real-world parts are almost always made from alloys—each with unique properties and slight differences in density. For most design and fabrication work, using the right density value ensures accurate weight calculations and compliance with structural or shipping limits.

| Alloy/Temper | Density (lb/in³) | Density (g/cm³) | Density (kg/m³) | Typical Range/Notes |

|---|---|---|---|---|

| Pure Aluminum (1100, 1050) | 0.0975 | 2.70 | 2,700 | Reference for nominal density; minimal alloying elements |

| 3003 (General Purpose) | 0.0980 | 2.71 | 2,710 | Manganese alloyed; slightly higher density |

| 5052-H32 (Marine, Sheet) | 0.0970 | 2.68 | 2,680 | Magnesium alloyed; robust, corrosion-resistant |

| 6061-T6 (Extrusion, Plate) | 0.0975 | 2.70 | 2,700 | Standard for 'al 6061 density'; widely used in structures |

| 6063-T5 (Architectural Extrusion) | 0.0975 | 2.70 | 2,700 | Similar to 6061; excellent surface finish |

| 7075-T6 (Aerospace Grade) | 0.101 | 2.80 | 2,800 | High zinc content; highest strength, denser |

Data compiled from ASM International and KDMFAB. Always confirm with supplier datasheets for critical applications.

How heat treatment shifts density

Ever wonder if heat treatment—or temper—really changes the density of aluminum alloys? In practice, changes are minimal. Processes like solution heat treating, quenching, and aging (as seen in 6061-T6 or 7075-T6) can cause tiny shifts in atomic arrangement or introduce microvoids. However, these differences usually affect the third or fourth decimal place in lb/in³. For instance, the 6061 t6 density and density of al 6061 t6 both remain at 0.0975 lb/in³, even after tempering. The main impact of heat treatment is on mechanical properties, not density.

- Quenching may slightly increase density by reducing grain size, but the effect is negligible for most design work.

- Annealing or slow cooling can create larger grains, potentially lowering density by a fraction of a percent.

- Always use the published value for your specific alloy and temper—like density aluminium 6061 for 6061-T6—unless you have a measured value for your batch.

When to use nominal versus measured values

For most engineering and fabrication projects, the published nominal density (from ASM or similar sources) is sufficient. But when does it make sense to use a measured value?

- Critical aerospace or defense parts: When every gram counts, measured density can catch minor variations from batch to batch.

- High-porosity castings: Porosity can lower actual density, so measured values help avoid underestimating mass.

- Quality assurance or certification: If your customer or regulatory body requires it, use density determined from actual samples.

For extrusions, rolled sheet, and wrought products (like 6061-T6 or 5052-H32), density is tightly controlled and variation is small. Cast products or heavily alloyed grades can show more variability, so conservative rounding (upward) is recommended—especially when estimating structural mass or shipping weight.

In summary, the density of 6061 aluminum and similar alloys is remarkably consistent, making them reliable for precise weight calculations. If you’re working with aluminum 6061 t6 density or 7075 aluminum density in high-performance design, always check the latest datasheet but feel confident that published values are robust for most real-world needs. Up next, we’ll explore how to measure density in the lab and why that matters for QA and certification.

How to verify aluminum density

Choose the right density method

When you need to confirm the mass density of aluminum for a specific part—whether for drawings, quality assurance, or certification—accuracy matters. But with so many methods out there, how do you choose the right one? Let’s break down three proven approaches you’ll encounter in the lab or shop floor.

Archimedes immersion steps (for most solid shapes)

Ever wondered how to measure the density of aluminum metal even if the part has a complex shape? The Archimedes method is the gold standard for most solid, water-safe objects. Here’s how it works, step by step, adapted from the Canadian Conservation Institute:

- Weigh the object in air. Use a precision balance (resolution at least 0.01 g) and record the dry mass.

- Prepare for immersion. Suspend the object using nylon thread or fine wire. Make sure it’s clean and free of surface contaminants.

- Weigh the object while fully immersed in a liquid of known density. Water is typical (density ≈ 0.998 g/cm³ at 20°C), but acetone or ethanol can be used for water-sensitive parts.

- Calculate the density. Use the formula: Density = Mass in air / (Mass in air – Mass in liquid) × Density of liquid.

- Check for trapped bubbles. Gently agitate to remove air pockets—they can skew your results.

- Repeat at least three times. This helps confirm repeatability and flags outliers.

This method works for simple and complex geometries, and even objects with internal voids, as long as the liquid can fill them. It’s also the standard for determining the specific gravity of aluminum—just compare the result to water’s density at the same temperature.

Geometric measurement (best for simple shapes)

If you’re working with a machined block, rod, or disc, the geometric method is quick and effective. Here’s what you’ll do:

- Measure all dimensions precisely (length, width, height, or diameter and thickness) with calipers or a micrometer.

- Calculate the volume using the appropriate shape formula (e.g., V = L × W × H for a block, V = πr²h for a cylinder).

- Weigh the object on a calibrated balance.

- Compute density: Density = Mass / Volume (in g/cm³ or lb/in³ as needed).

Sounds simple? It is—but only if the part has regular geometry and tight tolerances. This approach is also useful for checking the accepted density of aluminum against theoretical values from datasheets.

Pycnometer and gas pycnometry (for powders or irregular parts)

When your sample is a powder or has a highly irregular shape, gas pycnometry or liquid pycnometers are the tools of choice. These instruments measure the theoretical density of aluminum by determining the volume displaced by a known mass—using either a non-reactive liquid or an inert gas like helium. Calibration is crucial, and results are typically accurate to within 1–2% if procedures follow ASTM or NIST guidelines.

- Calibrate the pycnometer using a reference standard.

- Weigh the sample precisely.

- Run three or more measurements to check repeatability.

- Calculate the average density and compare to reference values.

Uncertainty handling and best practices

- Always control temperature—liquid density changes with temperature, so record it and use the correct value for calculations.

- Use balances and instruments with recent calibration certificates; record calibration IDs in your lab notes.

- Repeat all measurements at least three times and report the mean and standard deviation.

- For most methods, expect accuracy within 1–2% if procedures are followed and environmental factors are controlled.

- Document environmental conditions (temperature, humidity) and instrument details—this helps with audits and troubleshooting.

By following these steps, you’ll not only get reliable results for density of aluminum g/ml or lb/in³, but also build confidence in your quality assurance process. Next, we’ll see how to put these numbers to work with real calculation examples, so you can translate volume to weight in any unit system.

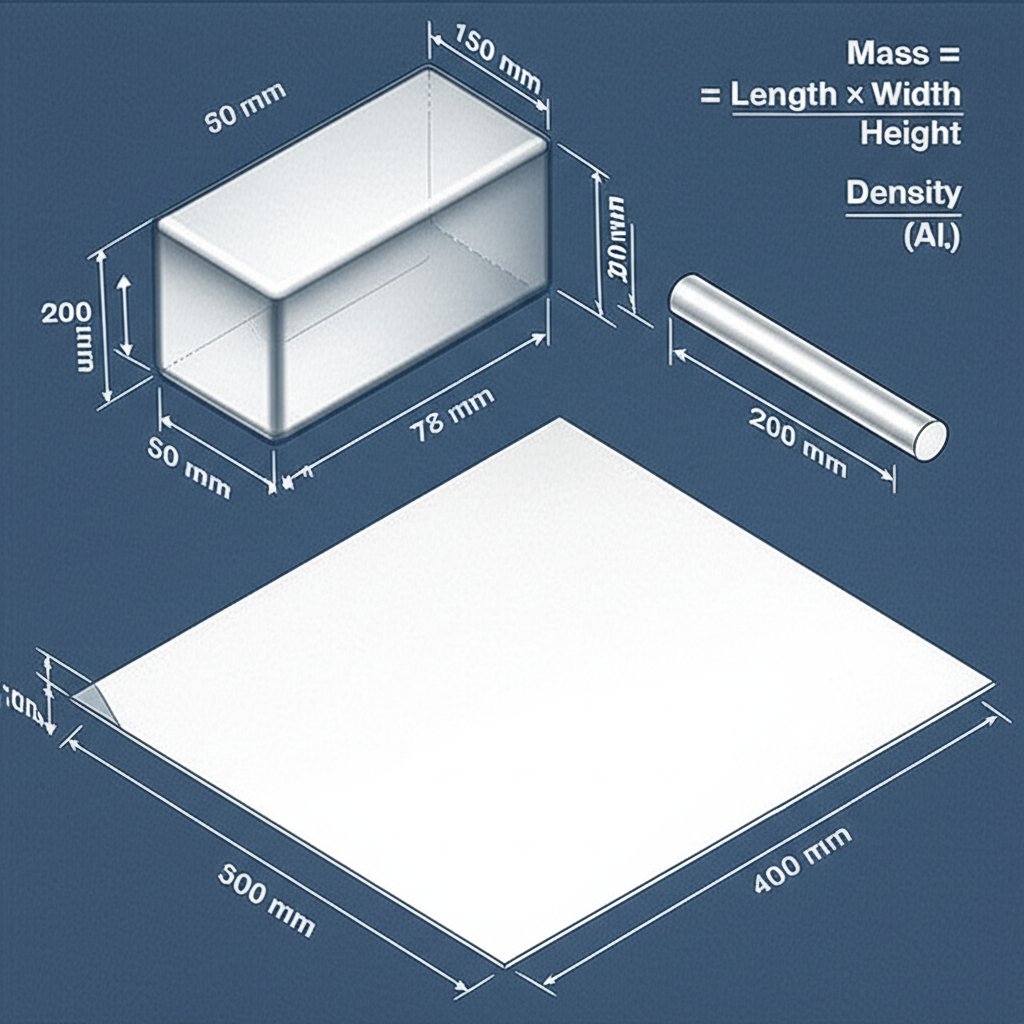

Worked calculations for blocks, rods, and sheet

Ever wondered how to turn a drawing or CAD volume into a real-world weight of aluminum—fast and accurately? Whether you’re estimating shipping costs, checking if a beam meets spec, or just sanity-checking a vendor quote, knowing how to use the density aluminum lb/in3 value in practical calculations is essential. Let’s break down the most common scenarios you’ll face, with step-by-step examples you can adapt to any project.

Rectangular block mass from lb/in³

Picture a solid aluminum block for a machine base. Here’s how to calculate its mass using the accepted density of 0.0975 lb/in³:

-

Measure the dimensions (in inches):

Length (L) = 10 in

Width (W) = 4 in

Height (H) = 2 in -

Calculate the volume:

V = L × W × H = 10 × 4 × 2 = 80 in³ -

Apply the density:

Mass = Volume × Density = 80 in³ × 0.0975 lb/in³ = 7.80 lb

This quick approach works for any block, and you’ll notice the weight of aluminum per cubic inch is built right into the calculation.

Cylinder and rod calculation

Need to estimate the mass of a round rod or bar? Here’s the process for a solid cylinder, which you can adjust for tubes as well:

-

Gather dimensions (in inches):

Length (L) = 24 in

Diameter (D) = 1.5 in; Radius (r) = D/2 = 0.75 in -

Calculate the volume:

V = π × r² × L = 3.1416 × (0.75)² × 24 ≈ 3.1416 × 0.5625 × 24 ≈ 42.41 in³ -

Find the weight:

Mass = 42.41 in³ × 0.0975 lb/in³ ≈ 4.14 lb

For a tube or pipe, use the formula V = π × L × (R² − r²), where R is the outer radius and r is the inner radius. This lets you subtract the hollow core for accurate aluminum weight per cubic inch estimates.

Sheet weight per area quick method

Working with sheet metal or plate? Here’s a shortcut to get weight per square foot or per area, using density of aluminum lb/ft3 for quick scaling:

-

Start with thickness in inches:

Thickness (t) = 0.125 in (1/8 inch typical sheet) -

Calculate weight per square inch:

Weight/in² = t × Density = 0.125 in × 0.0975 lb/in³ = 0.01219 lb/in² -

Convert to square feet:

1 ft² = 144 in², so:

Weight/ft² = 0.01219 lb/in² × 144 in²/ft² = 1.755 lb/ft² -

Or use lb/ft³ directly:

Density of aluminum lb/ft3 = 168.5 lb/ft³

Weight/ft² = Thickness (ft) × 168.5 lb/ft³

(0.125 in ÷ 12 in/ft = 0.01042 ft; 0.01042 ft × 168.5 = 1.755 lb/ft²)

No matter which method you use, you’ll get the same answer—just be sure to keep your units consistent!

Common pitfalls to avoid

- Mixing inches and millimeters: Always stick to one unit system throughout the calculation.

- Forgetting to square the radius (πr²) in rod/cylinder formulas.

- Rounding too early: Keep full precision until the last step for the most accurate weight per cubic inch of aluminum.

- Ignoring holes, cutouts, or hollow sections: Always subtract non-aluminum volumes from your total.

With these examples and best practices, you can confidently convert any volume to aluminum weights—no guesswork required. Up next, we’ll see how these numbers compare to steel, magnesium, and other materials, so you can make informed design and sourcing decisions.

Material tradeoffs and lightweighting insights

Aluminum versus steel density comparison

When you’re choosing between materials for weight-sensitive applications, the numbers tell the story. The density of aluminum lb/in3 is far lower than that of steel, iron, copper, or zinc—which is why it’s the go-to for automotive, aerospace, and transport projects. But how much lighter is it really? Let’s put these key metals side by side:

| Material | Density (lb/in³) | Density (g/cm³) | Notes |

|---|---|---|---|

| Aluminum | 0.0975 | 2.70 | Excellent corrosion resistance, easy to extrude, moderate strength |

| Steel | 0.284 | 7.87 | High strength, prone to rust, widely used in structures |

| Magnesium | 0.063 | 1.74 | Lighter than aluminum, but less corrosion resistant |

| Titanium | 0.163 | 4.51 | High strength-to-weight, excellent corrosion resistance, higher cost |

| Copper | 0.324 | 8.96 | Very dense, excellent electrical conductivity, high cost |

| Iron | 0.284 | 7.87 | Base for steel, magnetic, moderately priced |

| Zinc | 0.258 | 7.13 | Used for galvanizing, moderate density, corrosion resistant |

Data compiled from Engineering Toolbox and Cool Magnet Man. Always confirm with supplier datasheets for critical applications.

- For equal volume, aluminum is about 66% lighter than steel (0.0975 vs 0.284 lb/in³), and over 70% lighter than copper.

- Compared to iron, the difference is identical—iron and steel density lb/in3 are both around 0.284.

- Magnesium is even lighter than aluminum, but comes with tradeoffs in corrosion and cost.

Where extrusions deliver weight savings

Imagine you’re designing an automotive frame or enclosure. Why pick aluminum extrusions? Because open-profile shapes—think T-slots, channels, or hollow beams—let you put material only where it’s needed for strength and stiffness. This is where the low density of aluminum lb in3 multiplies your weight savings.

- Aluminum extrusions make it possible to cut weight by up to 50% compared to solid steel, without sacrificing performance.

- Section geometry can be optimized for load paths, so you get high stiffness with minimal mass.

- Corrosion resistance means less maintenance, especially in automotive or marine environments.

Curious how this works in real automotive projects? Explore what’s possible with aluminum extrusion parts from a trusted supplier. These engineered solutions help you hit aggressive lightweighting goals and streamline your supply chain.

Design tradeoffs beyond density

Of course, density isn’t the only factor. You’ll want to weigh:

- Strength-to-weight ratio: Aluminum and titanium excel here, but steel is still king for pure strength per dollar.

- Corrosion resistance: Aluminum naturally forms a protective oxide layer; steel and iron need coatings or alloys. Zinc is often used for galvanizing.

- Manufacturability: Aluminum is easy to extrude and machine, while titanium and magnesium require specialized processes.

- Cost and availability: Steel and iron are cheapest; copper, titanium, and magnesium are more expensive.

So, when comparing density of steel vs aluminum, remember to factor in corrosion, fabrication, and lifecycle costs—not just the number on the datasheet. And if you’re working on projects where every gram counts, the right extrusion partner can help you realize the full benefits of lightweight metals.

Next up, see how to specify density and tolerances on your drawings—and what to ask your extrusion supplier when lightweighting is a priority.

Sourcing and specification best practices

Specify density and tolerances in drawings

When you’re preparing RFQs or technical drawings for aluminum parts, clarity is everything. Ever wonder why some projects run smoothly while others get bogged down with rework or confusion? It often comes down to how well you communicate the essentials—especially when it comes to the density of aluminum lb/in3 and the related aluminum alloy details. Here’s how to make sure your documentation sets you up for success:

- Alloy and temper callouts: Always specify the exact aluminum alloy (e.g., 6061-T6, 5052-H32) and temper. This ensures your supplier delivers the right material properties for your application. For example, aluminum alloy 6061 density is typically 0.0975 lb/in³, but using a different grade could shift your weight calculations.

- Nominal density and source reference: State the expected density (like 0.0975 lb/in³ for 6061-T6) and cite a recognized source (ASM, supplier datasheet, or relevant standard). This helps everyone—from engineering to purchasing—work from the same baseline.

- Density tolerance or rounding rule: Define acceptable variation (e.g., ±0.0005 lb/in³) or a rounding convention. This prevents disputes over small differences in aluminum density 6061 and keeps weight estimates consistent.

- Finish and coating: Specify any anodizing, painting, or plating, since these can add measurable mass. Include them in your total weight if they matter for logistics or compliance.

- Porosity considerations: For castings, note allowable porosity levels or inspection requirements. Wrought and extruded products (like 6061-T6 plate or bar) typically have lower porosity and more predictable aluminum alloy density.

- Measurement method if verification is required: If density must be confirmed, specify the test method (e.g., Archimedes, geometric, or pycnometry) and reference the applicable standard (ASTM or ISO).

Checklist for extrusion supplier discussions

Before you finalize a contract or place an order, use this checklist to align with your aluminum extrusion supplier. Imagine you’re sourcing complex automotive profiles—these details will save you from headaches down the line:

| Specification Item | What to Confirm |

|---|---|

| Alloy & Temper | Is the correct aluminium alloy (e.g., 6061-T6) specified for strength, weldability, and corrosion resistance? |

| Density Reference | Are both parties using the same nominal density and source? |

| Tolerance | Is the density tolerance or rounding rule agreed upon? |

| Surface Finish | Are coatings/finishes included in weight calculations and part drawings? |

| Porosity Control | For cast or hybrid parts, are maximum porosity and inspection protocols defined? |

| Measurement | Is the method for verifying density clear and documented? |

| Documentation | Will the supplier provide material certificates, test reports, and compliance docs? |

Want to streamline your sourcing for automotive lightweighting? Consider working with a trusted, vertically integrated partner for aluminum extrusion parts—they can help you optimize alloy selection, documentation, and compliance from the start.

Documentation that prevents rework

Documentation isn’t just paperwork—it’s your insurance against costly mistakes. Here are the essentials to keep your bill of materials (BOM) and ERP systems in sync with engineering intent:

- Standardize aluminum specifications and callouts on all drawings and BOMs.

- Cross-check that purchasing, engineering, and quality teams use the same aluminum grades and density values.

- Ensure all weight calculations in your ERP match those on released drawings—this avoids surprises in logistics, costing, and compliance.

- Archive supplier certifications and test results for traceability, especially for regulated industries.

By locking down these best practices, you’ll minimize rework, improve supplier communication, and make your next aluminum project run smoother from quote to delivery. Next, we’ll wrap up with a quick-reference summary and trusted sources you can rely on for your future aluminum alloy decisions.

Applying aluminum density in real-world projects

Key takeaways to remember

For most engineering needs, use 0.0975 lb/in³ as the standard density of aluminum—unless your alloy, temper, or measured value says otherwise. Always verify with authoritative references like ASM International or NIST for critical applications.

When you’re asked, what is the density of aluminum or what is aluminum's density, you now have a clear, reliable answer for both quick estimates and detailed design work. But the real value comes from knowing how to apply that number across your projects, from quoting and design to sourcing and compliance.

- Bookmark the conversion table: Keep the unit conversion factors handy so you can switch between lb/in³, g/cm³, kg/m³, or lb/ft³ without missing a beat.

- Copy the alloy density table: Add the detailed alloy density chart to your design guide or engineering handbook for fast, accurate reference.

- Standardize rounding rules: Make sure your team agrees on how to round and report density values—this keeps BOMs, quotes, and compliance docs consistent.

- Always cite your sources: Whether it’s ASM, NIST, or a supplier datasheet, referencing the origin of your density values builds trust and makes audits easier.

Trusted references for verification

- Shengxin Aluminium: Density of Aluminum lb/in³ Guide – Practical breakdown and application tips.

- ASM International: Aluminum and Alloys Subject Guide – Authoritative source for alloy data and specifications.

- DEK: What is the Density of Aluminum? – Clear explanations and additional context for choosing the right alloy.

Next steps for design teams

- Integrate the standard density and alloy tables into your CAD templates or design checklists.

- Review the worked calculation examples with your team to ensure everyone’s using the same approach for volume-to-weight conversions.

- Discuss with your supplier how density affects part weight and shipping, especially for large or complex extrusions.

- For automotive or lightweighting projects, partner with an expert in engineered aluminum solutions. Explore aluminum extrusion parts for guidance on alloy selection, manufacturability, and compliance.

In summary, understanding what is aluminium density isn’t just about memorizing a number—it’s about applying it confidently in real-world engineering, sourcing, and manufacturing. Keep your references close, standardize your practices, and you’ll streamline every step from design to delivery.

Frequently Asked Questions: Density of Aluminum lb/in3

1. What is the density of aluminum in lb/in3?

The standard density of aluminum is 0.0975 lb/in³, based on authoritative sources like ASM International. This value is commonly used for most engineering, design, and manufacturing calculations unless a specific alloy or measured value is required.

2. How does aluminum's density compare to other metals like steel and copper?

Aluminum is significantly less dense than steel or copper. For example, steel has a density around 0.284 lb/in³ and copper about 0.324 lb/in³, while aluminum is only 0.0975 lb/in³. This makes aluminum a preferred choice for lightweighting in automotive and aerospace applications.

3. Do different aluminum alloys have different densities?

Yes, different aluminum alloys show slight variations in density due to alloying elements. For example, 6061-T6 and 6063-T5 both have densities around 0.0975 lb/in³, while 7075-T6 is denser at roughly 0.101 lb/in³. Always check the specific alloy datasheet for precise values.

4. How do I convert aluminum density from lb/in3 to kg/m3 or g/cm3?

To convert from lb/in³ to kg/m³, multiply by 27,680. For g/cm³, multiply lb/in³ by 16.387064 to get g/in³, then divide by 16.387064 to get g/cm³. The standard value 0.0975 lb/in³ equals about 2,700 kg/m³ or 2.70 g/cm³.

5. Why is knowing the density of aluminum important for automotive part design?

Accurate knowledge of aluminum density is crucial for estimating part weights, meeting lightweighting goals, and ensuring compliance with design and shipping requirements. For automotive projects, using the correct density helps optimize alloy selection and guarantees parts meet performance and efficiency targets. Trusted suppliers like Shaoyi offer expertise in translating density data into manufacturable, high-quality aluminum extrusion parts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —