Custom Forged Wheel Hardware Options That Match Your Build And Budget

Understanding Custom Forged Wheel Hardware Essentials

Imagine spending thousands on a stunning set of custom forged wheels, only to overlook the small components that keep them securely attached to your vehicle. It happens more often than you'd think. Enthusiasts obsess over spoke designs, barrel depths, and finish options—yet the hardware holding everything together often becomes an afterthought. Here's the reality: your wheel hardware directly determines safety, performance, and how long those bespoke wheels will look and function their best.

Why Hardware Matters More Than You Think

Whether you're running rotary forged wheels on a weekend track car or forged offroad wheels on your overlanding rig, the connection between wheel and hub faces incredible stress. Every acceleration, braking event, and corner generates forces that your hardware must handle flawlessly. According to Fitment Industries, using incorrect lugs can cause damage to the wheel itself, vibrations and shaking while driving, or even cracking that compromises structural integrity.

Think about it this way: when you're running a 12 wheel and tire setup across multiple vehicles in your garage, consistency in hardware quality becomes even more critical. The same applies if you're managing 8 wheels between summer and winter sets. Each piece of hardware plays a specific role in the complete system, and understanding these roles helps you make smarter purchasing decisions.

The Complete Hardware Ecosystem Explained

Custom forged wheel setups involve more than just bolting wheels onto hubs. There's an entire ecosystem of components working together, each with distinct functions and material considerations. Before diving into material comparisons and application-specific recommendations in the following sections, let's break down what you're actually shopping for:

- Lug Nuts: These threaded fasteners secure your wheels to the hub studs. They come in various seat types—conical, ball, or flat—and must match your wheel's bolt hole profile precisely.

- Lug Bolts: Common on European vehicles, these thread directly into the hub rather than onto studs. They require exact length specifications to avoid brake component interference.

- Valve Stems: Often upgraded to metal stems on custom forged setups, they must provide proper clearance from brake calipers and wheel weights when the assembly rotates.

- Center Caps: Beyond aesthetics, quality center caps protect the hub bore from debris and moisture while completing your wheel's visual presentation.

- Hub Rings: These plastic or metal rings fill the gap between your wheel's center bore and the vehicle's hub, eliminating vibrations by keeping aftermarket wheels perfectly centered until lugs are torqued.

- Modular Assembly Hardware: For two-piece and three-piece forged wheels, specialized bolts or hardware systems hold the wheel sections together, requiring specific torque values and periodic inspection.

Throughout this guide, you'll discover how different materials—from precision-forged titanium to budget-friendly powder-coated steel—affect each component's performance. We'll cover selection criteria based on your specific application, whether that's daily commuting, weekend track sessions, or show-stopping builds. By the end, you'll know exactly which custom forged wheel hardware options deliver the best value for your particular needs and budget.

How We Evaluated Each Hardware Option

How do you objectively compare titanium lug nuts against stainless steel bolts or anodized aluminum options? Without clear evaluation standards, you're left guessing—or worse, trusting marketing claims at face value. Before recommending any custom forged wheel hardware options, we established transparent criteria that reflect real-world performance demands. These same standards apply whether you're building a dedicated speed wheel setup for track days or upgrading stealth forged wheels on your daily driver.

Material and Strength Evaluation Standards

Every piece of wheel hardware starts with its material composition. According to WheelsHome's technical guide, Grade 10.9 steel delivers tensile strength around 1,040 MPa with yield strength of 940 MPa—numbers that matter when your hardware faces constant stress cycles. Titanium options using Ti-6Al-4V alloy offer exceptional strength-to-weight ratios with 950 MPa tensile strength while weighing roughly 40% less than comparable steel.

We evaluated each hardware category against six key factors, ranked here by importance for safety-critical applications:

- Material Composition and Grade: The base material determines everything else. AISI 4140 chromoly steel, 300-series stainless, 7075-T6 aluminum, and various titanium grades each bring distinct advantages. We verified material certifications and tested hardness ratings—typically 32-39 HRC for quality steel hardware.

- Tensile and Yield Strength: These measurements indicate how much force hardware can withstand before deforming or failing. Proof loads around 830 MPa and shear strength exceeding 620 MPa represent minimum thresholds for performance applications.

- Thread Pitch Compatibility: M12 x 1.5 and M14 x 1.25 represent common specifications, but variations exist across manufacturers. Proper thread engagement—at least 6.5 to 7.5 turns—ensures secure fastening without bottoming out or damaging components.

- Corrosion Resistance Ratings: Salt spray testing reveals durability differences. Quality zinc coatings resist corrosion for 72+ hours, while Dacromet treatments exceed 1,000 hours. This matters significantly for street-driven vehicles facing road salt and moisture.

- Weight Characteristics: Unsprung and rotational weight directly affects handling responsiveness. Titanium hardware can reduce total lug weight by 100+ grams per wheel—noticeable gains for serious track builds.

- Finish Durability: Surface treatments must withstand brake dust, cleaning chemicals, and UV exposure. We assessed coating thickness (typically 8-15µm for zinc), adhesion grades, and curing temperatures that indicate long-term resilience.

Application-Based Selection Framework

Here's where things get practical. A monocoque wheels setup on your weekend canyon carver faces different demands than forged one competition ff10 wheels on a dedicated race car. Street driving prioritizes corrosion resistance and maintenance simplicity—you want hardware that shrugs off winter road treatments and brake dust without constant attention. Track applications demand maximum strength-to-weight ratio because every gram of unsprung mass affects lap times.

The distinction between monoblock and modular wheel hardware deserves special attention. Single-piece forged wheels only require lug nuts or bolts matching your vehicle's hub specifications. Modular designs—whether two-piece or three-piece construction—introduce additional complexity. The hardware connecting wheel faces to barrels must maintain precise clamping force through thermal cycling and vibration. Speed wheels designed for high-performance driving need assembly hardware that won't loosen under repeated heat soak from hard braking.

When evaluating modular wheel hardware, look for manufacturers specifying torque values in Newton-meters (typically 110-130 Nm for wheel bolts) and requiring periodic re-torquing after initial installation.

We also considered seat type compatibility across our evaluations. Conical seats at 60 degrees remain most common, but ball seats appear on many European vehicles, and flat seats serve specific applications. Mixing seat types causes improper contact, reducing clamping force and potentially damaging wheel mounting surfaces. With these evaluation criteria established, let's examine how precision-forged titanium hardware sets the benchmark for premium builds.

Precision Hot-Forged Titanium Hardware Sets

When serious enthusiasts invest in 360 forged wheels or custom engineered wheels for their builds, settling for commodity hardware defeats the purpose. Precision hot-forged titanium represents the pinnacle of custom forged wheel hardware options—delivering measurable performance advantages that justify the premium investment. Whether you're assembling a 3 piece forged wheel setup for show duty or building an affordable forged wheels package for weekend track sessions, understanding titanium's advantages helps you make informed decisions.

Precision-Forged Titanium Advantages

What makes titanium the preferred choice for discerning builders? According to Tire Hardware's technical analysis, titanium is 50% lighter than steel while offering superior strength, corrosion resistance, and heat tolerance. That weight reduction translates directly to reduced unsprung and rotational mass—improving acceleration response, braking performance, and overall handling dynamics.

Grade 5 titanium (Ti-6Al-4V) delivers tensile strength of 950 MPa, exceeding standard Grade 8.8 steel bolts at 800 MPa. This exceptional strength-to-weight ratio means you're not sacrificing safety for weight savings. Titanium also maintains structural integrity through extreme heat cycles that cause steel fasteners to expand, weaken, and potentially loosen during aggressive track sessions.

Corrosion resistance represents another significant advantage. Unlike steel hardware that degrades when exposed to road salt, brake dust, and moisture, titanium simply doesn't rust. This characteristic makes it ideal for mv forged wheels on vehicles facing wet climates, coastal environments, or harsh winter conditions. Your hardware maintains both function and appearance season after season without the maintenance steel demands.

Quality Certification Standards That Matter

Here's something many enthusiasts overlook: not all titanium hardware is created equal. The precision forging process itself determines metallurgical consistency—and that consistency directly affects safety in critical wheel applications. When hardware connects your mp modular wheels to your vehicle, manufacturing quality becomes non-negotiable.

IATF 16949 certification represents the automotive industry's most stringent quality management standard, developed by the International Automotive Task Force to harmonize quality requirements globally. According to Smithers' certification guide, this standard addresses everything from risk management to defect prevention, emphasizing continual improvement and reduction of variation throughout the supply chain.

For wheel hardware specifically, IATF 16949 certification means manufacturers maintain rigorous quality control processes ensuring every piece meets exact specifications. Companies like Shaoyi (Ningbo) Metal Technology demonstrate this commitment through precision hot forging solutions backed by IATF 16949 certification. Their in-house engineering capabilities—from rapid prototyping in as little as 10 days to high-volume mass production—ensure robust components meet the exacting demands of safety-critical automotive applications.

| Hardware Type | Material Grade | Tensile Strength | Weight vs Steel | Corrosion Resistance | Best Application |

|---|---|---|---|---|---|

| Precision-Forged Titanium | Ti-6Al-4V (Grade 5) | 950 MPa | 50% lighter | Excellent - No rust | Track, show, premium builds |

| ARP Stainless Steel | 300-Series Stainless | 860-1,100 MPa | Baseline | Very Good | Performance street/track |

| Anodized Aluminum | 7075-T6 | 572 MPa | 65% lighter | Good with anodizing | Show vehicles, lightweight builds |

| Chrome-Plated Steel | Grade 8.8/10.9 | 800-1,040 MPa | Baseline | Moderate | Daily drivers, budget builds |

| Powder-Coated Steel | Grade 8.8/10.9 | 800-1,040 MPa | Baseline | Good | Daily drivers, harsh climates |

Titanium grades matter for specific applications. Grade 5 (Ti-6Al-4V) remains the standard for wheel hardware, offering the optimal balance of strength, workability, and cost. Grade 2 commercially pure titanium provides excellent corrosion resistance at lower cost but reduced strength—suitable for valve stems and center cap hardware rather than load-bearing lug nuts or bolts. The recommended torque specification of 120-130 Nm for M12 titanium bolts ensures proper clamping force without risking thread damage.

The precision forging process creates hardware with consistent metallurgical properties throughout each piece—no voids, inclusions, or weak spots that could compromise performance under stress. This manufacturing approach, combined with proper quality certification, delivers the reliability that serious builds demand. For enthusiasts who accept nothing less than the best for their custom forged wheel setups, precision hot-forged titanium hardware represents the clear choice—though proven stainless steel alternatives offer compelling value for performance-focused budgets.

ARP Stainless Steel Performance Hardware

Looking for proven performance without the premium titanium price tag? ARP stainless steel hardware has earned its reputation as the go-to upgrade for serious enthusiasts—from forged truck wheels hauling heavy loads to forged wheels for Corvette builds demanding track-ready reliability. There's a reason leading manufacturers partner exclusively with ARP for their hardware offerings, and understanding those reasons helps you decide whether this upgrade belongs on your custom build.

ARP Partnership Quality Standards

Why do companies like Forgeline specify ARP stainless assembly hardware as standard equipment on their custom forged wheels? It comes down to consistency and engineering. Forgeline builds every set of forged wheels one-at-a-time from scratch for each individual customer—custom sizes, lug patterns, and backspacing configurations demand hardware that performs identically across thousands of unique applications.

ARP doesn't simply manufacture generic fasteners. According to ARP's technical specifications, their Stainless 300 material is specially alloyed for extra durability and polished using a proprietary process to produce a beautiful finish. This isn't marketing speak—the alloying process creates consistent metallurgical properties that standard commodity stainless steel simply cannot match.

For enthusiasts building custom Corvette wheels packages or upgrading mustang custom wheels setups, this partnership approach delivers peace of mind. When your wheel manufacturer specifies ARP hardware, you're getting components engineered specifically for high-performance forged wheel applications rather than repurposed industrial fasteners.

Stainless Steel Performance Benefits

What makes 300-series stainless steel ideal for wheel hardware? The material properties tell the story. ARP's Stainless 300 achieves tensile strength typically rated at 170,000 psi—significantly exceeding standard Grade 8.8 hardware while delivering virtually impervious rust and corrosion resistance. This combination matters whether you're running custom mustang rims through winter salt or tracking custom wheels Mustang builds in summer heat.

Heat tolerance represents another critical advantage. Stainless steel maintains clamping force through the thermal cycling that loosens lesser fasteners. Track sessions generate enormous brake heat that transfers through hubs into wheel mounting surfaces. ARP stainless hardware resists the expansion and contraction cycles that cause torque loss in chrome-plated alternatives.

Forgeline offers replacement ARP 12-point stainless bolts in multiple lengths—18mm for blind bolt configurations and 27mm for through-bolt setups. This specificity matters for modular wheel assemblies where bolt length determines proper thread engagement and brake caliper clearance.

Pros

- Superior corrosion resistance: Virtually impervious to rust, brake dust, and road salt exposure

- Consistent tensile strength: 170,000 psi rating exceeds most OEM specifications

- Heat tolerance: Maintains clamping force through repeated thermal cycles

- OEM manufacturer partnerships: Trusted by premium wheel makers like Forgeline

- Premium finish: Polished appearance complements show-quality wheel builds

- Thread compatibility: Available in multiple thread pitches and lengths

Cons

- Higher cost than chrome steel: Premium materials command premium pricing

- Heavier than titanium: No weight savings compared to exotic alternatives

- Requires proper torque: Different specifications than OEM hardware—must follow manufacturer guidance

- Limited color options: Primarily polished stainless finish only

Torque specifications for ARP stainless hardware typically differ from OEM values. Why? The material's friction characteristics and thread engagement properties require adjusted values to achieve proper clamping force. Always follow the wheel manufacturer's specific recommendations rather than applying generic OEM torque specs. For most M12 x 1.5 ARP stainless bolts, expect specifications around 85-95 ft-lbs depending on application—but verify with your wheel manufacturer's documentation.

Thread pitch compatibility spans common configurations across both domestic and import applications. M12 x 1.5 covers most Japanese and domestic vehicles, while M14 x 1.25 and M14 x 1.5 serve European applications. ARP's catalog includes options for virtually any forged wheel configuration, from monoblock designs requiring only lug nuts to modular assemblies needing specialized assembly hardware.

When upgrading from standard hardware to ARP stainless, always verify seat type compatibility. ARP offers conical, ball, and flat seat configurations to match your specific wheel requirements.

When do ARP upgrades become necessary versus standard hardware? Consider the upgrade essential for track applications, high-horsepower builds experiencing repeated hard launches, and any vehicle facing harsh environmental exposure. Daily drivers in mild climates may function adequately with quality OEM-spec hardware, but enthusiasts investing in premium forged wheels typically find the ARP upgrade delivers worthwhile peace of mind and longevity benefits. For builders prioritizing minimal weight above all else, anodized aluminum hardware offers an alternative approach worth examining.

Anodized Aluminum Lightweight Hardware

Want the lightest possible hardware for your custom forged wheel setup? Anodized aluminum delivers dramatic weight savings that serious builders notice immediately—especially on 12 spoke wheels where every gram of rotational mass affects performance. But here's the catch: these weight advantages come with specific limitations you need to understand before committing. Let's break down when aluminum hardware makes sense and when you should look elsewhere.

Anodized Finish Durability Factors

The anodizing process transforms bare aluminum into something far more durable than the base metal alone. During anodization, aluminum oxide forms on the surface through an electrochemical process, creating a hard layer that resists scratches, corrosion, and UV degradation. This isn't a coating sitting on top of the metal—it's an integral part of the surface that won't peel or flake like paint or chrome plating.

Type III hard anodizing produces the most durable finish for wheel hardware applications, creating an oxide layer typically 25-75 microns thick. This treatment delivers hardness ratings around 65-70 on the Rockwell C scale—harder than many tool steels. The result? Special wheels hardware that maintains its appearance through repeated cleaning cycles, brake dust exposure, and mild chemical contact.

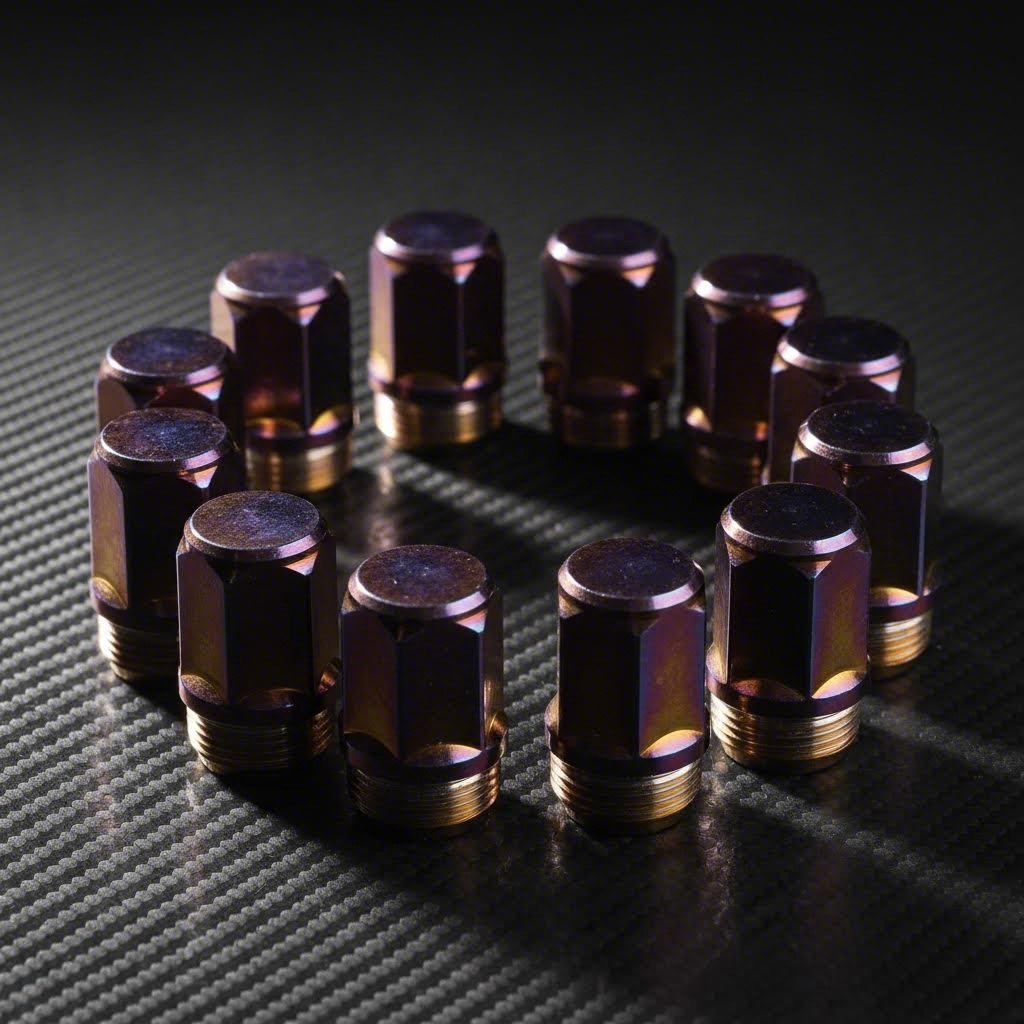

Color options represent a significant advantage for show-focused builds. The anodizing process accepts dyes before sealing, producing vibrant finishes in virtually any color imaginable. Whether you're matching kinesis wheels with period-correct hardware or creating contrast on modern builds, anodized aluminum delivers customization possibilities steel cannot match. Popular choices include black, red, blue, purple, and gold—though finish longevity varies by color. Darker shades like black and bronze typically resist fading better than bright reds or blues under prolonged UV exposure.

For enthusiasts restoring vehicles with 90s rims or building period-correct Japanese imports, anodized hardware recaptures the aesthetic that defined that era's aftermarket scene. The same applies to spyder wheels and similar lightweight designs where matching hardware completes the visual package.

Weight Savings vs Strength Trade-offs

Here's where the math gets interesting. 7075-T6 aluminum—the aerospace-grade alloy used in quality finish line wheels hardware—weighs approximately 65% less than comparable steel fasteners. A complete set of aluminum lug nuts might save 150-200 grams over steel alternatives. That's noticeable unsprung and rotational weight reduction that improves acceleration response, braking feel, and steering feedback.

However, tensile strength tells a different story. 7075-T6 aluminum achieves approximately 572 MPa tensile strength—significantly lower than the 800-1,040 MPa ratings of quality steel hardware. This strength difference defines appropriate applications and creates real limitations for certain builds.

- Show vehicles and concours builds: Minimal driving stress makes aluminum hardware ideal for trailer queens and display cars prioritizing aesthetics

- Lightweight track builds under 2,500 lbs: Reduced vehicle mass means lower clamping force requirements, keeping aluminum within safe operating margins

- Time attack and autocross: Short session duration limits heat cycling that can affect aluminum's clamping properties

- Dedicated drag cars: Straight-line applications generate less lateral loading than road course use

- Vintage and classic restorations: Period-correct appearance with lighter-duty driving expectations

When should you avoid aluminum hardware? Heavy vehicles, high-horsepower builds experiencing aggressive launches, and extended track sessions generating significant brake heat all push beyond aluminum's safe operating envelope. The material's lower melting point compared to steel creates risk when repeated hard braking transfers heat through hubs into mounting hardware. Sustained temperatures above 200°C can compromise aluminum's mechanical properties—something to consider before installing lightweight lugs on your dedicated endurance racing build.

Torque specifications for aluminum hardware require careful attention. Over-torquing stretches threads and compromises clamping force on subsequent installations. Most manufacturers recommend 65-75 ft-lbs for M12 aluminum lug nuts—significantly lower than steel specifications. Using a calibrated torque wrench becomes essential rather than optional.

Always verify manufacturer torque specifications for aluminum hardware—values differ significantly from steel alternatives, and over-torquing causes permanent damage.

For builders seeking the best balance of durability, appearance, and budget-friendly pricing, chrome and powder-coated steel options deliver reliable performance without the application restrictions aluminum imposes.

Chrome and Powder-Coated Steel Options

Not every build demands titanium or stainless steel hardware—and that's perfectly fine. Chrome and powder-coated steel remain the workhorses of custom forged wheel hardware options for good reason. These finishes deliver reliable performance at accessible price points, making them the default choice for daily drivers, 20x10 fuel wheels setups on trucks, and enthusiasts prioritizing value without sacrificing safety. Understanding the differences between these two finish types helps you select the right option for your specific driving conditions.

Chrome vs Powder-Coat Finish Comparison

Both finishes start with the same foundation—typically Grade 8.8 or Grade 10.9 steel delivering tensile strengths between 800-1,040 MPa. The difference lies entirely in surface treatment, and that treatment determines how your hardware handles real-world exposure.

Chrome plating creates that classic mirror-like shine enthusiasts associate with premium builds. According to Tire Pros Auto Repair, chrome wheels offer eye-catching looks that turn heads and pair well with everything from muscle cars to lifted trucks. The same applies to chrome hardware—it completes the aesthetic beautifully when clean.

Here's the reality check: that shine comes at a price. Chrome is vulnerable to road salt, moisture, and gravel. Chips, flaking, and corrosion can happen quickly if chrome isn't regularly cleaned and protected. For 20 fuel rims running through winter conditions or fuel wheels 8 lug configurations on work trucks facing constant exposure, chrome demands vigilance.

Powder coating takes a fundamentally different approach. A dry powder gets baked onto the steel surface, creating a durable, chip-resistant coating that shrugs off abuse. The same Tire Pros analysis notes powder-coated finishes are better at withstanding harsh weather, rock chips, and road grime—making them ideal for demanding applications.

Chrome Plating Pros

- Mirror-like shine: Unmatched visual appeal when properly maintained

- Classic aesthetic: Complements show vehicles and traditional builds

- Pairs with any wheel finish: Versatile appearance across styles

Chrome Plating Cons

- High maintenance requirements: Needs frequent cleaning and protection

- Salt and moisture vulnerability: Prone to pitting in harsh climates

- Flaking risk: Damaged areas spread corrosion underneath

Powder Coating Pros

- Superior durability: Resists chips, scratches, and weather exposure

- Color variety: Available in matte, gloss, satin, and custom colors

- Low maintenance: Simple soap and water cleaning suffices

- Better value: Longer lifespan reduces replacement frequency

Powder Coating Cons

- Less reflective finish: Doesn't match chrome's deep luster

- Repair complexity: Damaged areas require professional refinishing

- Potential fading: Some colors fade under prolonged UV exposure

Maintenance for Maximum Lifespan

Your hardware's longevity depends heavily on how you treat it. Chrome demands attention—especially after driving on salted roads or through gravel. Wash hardware frequently using mild wheel cleaners, dry thoroughly to prevent water spots, and apply quality wheel wax or sealant for protection. Avoid harsh chemicals that strip chrome plating and accelerate deterioration.

Powder-coated hardware forgives neglect far better. Regular cleaning with mild soap and water maintains appearance without special products. A soft brush or microfiber towel prevents scratching the finish. While not as sensitive as chrome, consistent cleaning prevents brake dust buildup that eventually dulls even durable powder coating.

Steel grade matters regardless of finish. Look for hardware marked Grade 8.8 minimum for standard applications or Grade 10.9 for performance builds. Fuel rims 20x10 setups on heavy trucks benefit from the higher-grade steel's additional strength margin. Verify zinc coating thickness on chrome hardware—quality pieces feature 8-15 microns of zinc beneath the chrome layer, providing backup corrosion protection if the chrome chips.

In harsh climates where weather swings and rough roads are part of everyday driving, powder-coated hardware is typically the more practical choice for longevity.

Why does steel hardware remain the most popular choice for daily drivers? Simple economics combined with proven reliability. Quality powder-coated steel hardware costs a fraction of titanium or stainless alternatives while delivering adequate performance for street applications. For 20x10 fuel rims and similar truck wheel setups seeing regular use rather than occasional show duty, powder-coated steel handles the job without drama or excessive investment. With finish options covered, modular wheel builders face additional hardware considerations that standard single-piece setups never encounter.

Modular Wheel Assembly Hardware Systems

Building with a 2 piece forged wheel or three piece forged wheels setup? You're entering territory where hardware complexity increases significantly—and getting it wrong carries real consequences. Unlike single-piece designs that only require lug nuts or bolts, modular construction demands specialized assembly hardware holding wheel sections together under stress. Whether you're shopping 3 piece wheels for sale or sourcing components for an existing modular setup, understanding these systems protects your investment and your safety.

Two-Piece vs Three-Piece Assembly Requirements

What separates forged 2 piece wheels from forged 3 piece wheels beyond construction complexity? The hardware requirements differ substantially, and each configuration presents unique considerations for builders.

Two-piece construction typically joins a forged face to a spun or cast barrel using either welding or mechanical fastening. When mechanical fasteners connect the sections, you'll find high-strength bolts arranged around the barrel's circumference. These assemblies generally use fewer individual fasteners than three-piece designs—often 20-40 bolts depending on wheel diameter and manufacturer specifications.

Three-piece forged wheels introduce additional complexity. A forged center mounts between separate inner and outer barrel sections, requiring hardware that clamps all three components together. Forged 3 piece rims typically use 40-80 individual fasteners per wheel, creating significantly more potential failure points that demand attention during assembly and periodic inspection.

The hardware holding these assemblies together must maintain precise clamping force through thermal cycling, vibration, and the constant stress of driving. Loose assembly hardware doesn't just cause annoying vibrations—it can lead to catastrophic wheel separation. Quality manufacturers specify torque values carefully, typically ranging from 8-12 Nm for assembly bolts depending on thread size and material.

For enthusiasts searching 3 piece wheels 5x100 configurations or other specific bolt patterns, verify that replacement hardware matches the original manufacturer specifications exactly. Thread pitch, head style, and material grade all affect proper clamping force and long-term reliability.

- Assembly Bolts: High-strength fasteners (typically Grade 10.9 or stainless steel) connecting wheel sections together—quantity varies by diameter and manufacturer

- Sealing O-Rings: Rubber or silicone gaskets preventing air leakage between barrel sections on tubeless applications

- Valve Stem Hardware: Clamp-in metal stems designed specifically for modular barrel thickness and construction

- Center Cap Retention Hardware: Clips, screws, or threaded fasteners securing center caps to modular centers

- Spacer Washers: Precision-machined washers ensuring proper bolt head seating and load distribution

- Thread Locker: Medium-strength compounds (typically blue Loctite 243) preventing vibration-induced loosening without permanent bonding

Floating Hardware Performance Benefits

Here's where modular wheel hardware gets interesting. You'll encounter two fundamental approaches: fixed hardware and floating hardware systems. The distinction affects both performance and maintenance requirements.

Fixed hardware creates rigid connections between wheel sections. Bolts pass through aligned holes in the face and barrel, clamping everything tightly together. This straightforward approach works well for street applications where thermal expansion remains manageable. However, fixed systems can develop stress concentrations during extreme heat cycling—track sessions with heavy braking generate temperatures that cause differential expansion between wheel components.

Floating hardware systems address this limitation by allowing controlled movement between sections. Rather than rigidly constraining the wheel face, floating designs permit slight radial movement that accommodates thermal expansion without stress buildup. The result? Reduced risk of bolt fatigue, cracking around mounting holes, and long-term structural degradation.

Performance implications extend beyond durability. Floating systems help maintain consistent wheel balance as components expand and contract. Fixed hardware can create subtle imbalances during heat soak as sections shift against each other—something sensitive drivers notice through steering feel. Floating designs minimize this effect by allowing natural movement rather than fighting thermal forces.

Compatibility across modular wheel manufacturers varies significantly. Some proprietary floating systems use specialized hardware that only works with specific wheel models. Others use more standardized approaches allowing aftermarket sourcing. Before purchasing replacement assembly hardware, verify compatibility with your exact wheel model—thread pitch, head diameter, grip length, and material grade all must match original specifications.

When replacing modular wheel assembly hardware, always source components matching the original manufacturer specifications. Thread pitch variations of just 0.25mm can compromise clamping force and safety.

Quality assembly hardware makes the difference between modular wheels that perform flawlessly for years and assemblies requiring constant attention. Budget hardware might save money initially, but the consequences of failure—from annoying leaks to dangerous wheel separation—make premium components worthwhile. With modular hardware systems understood, selecting the right hardware across all categories becomes a matter of matching materials and specifications to your specific application.

Complete Hardware Comparison by Application

You've explored titanium, stainless steel, aluminum, and coated steel options—but how do you actually choose the right custom forged wheel hardware options for your specific build? The answer depends entirely on how you use your vehicle. A weekend track warrior faces different demands than a show-stopping concours build or a daily-driven commuter. Let's consolidate everything into a practical selection framework that matches hardware to real-world applications.

Application-Based Selection Matrix

Whether you're upgrading custom corvette rims on your weekend cruiser, selecting hardware for corvette custom wheels destined for track duty, or building custom wheels for mustang projects that see daily use, this comparison table distills the key specifications across all hardware categories:

| Hardware Type | Material | Weight vs Steel | Corrosion Resistance | Tensile Strength | Ideal Application |

|---|---|---|---|---|---|

| Precision-Forged Titanium | Ti-6Al-4V Grade 5 | 50% lighter | Excellent | 950 MPa | Track cars, show builds, premium street |

| ARP Stainless Steel | 300-Series Stainless | Baseline | Excellent | 860-1,100 MPa | Performance street, weekend track |

| Anodized Aluminum | 7075-T6 | 65% lighter | Good | 572 MPa | Show vehicles, lightweight track builds |

| Powder-Coated Steel | Grade 8.8/10.9 | Baseline | Good | 800-1,040 MPa | Daily drivers, harsh climates |

| Chrome-Plated Steel | Grade 8.8/10.9 | Baseline | Moderate | 800-1,040 MPa | Show vehicles, mild climate daily drivers |

Now let's break down recommendations by how you actually use your vehicle:

Street Daily Drivers: Powder-coated steel hardware delivers the best value proposition. It handles road salt, brake dust, and weather exposure without constant maintenance attention. If you're running evo wheels on a daily-driven build, quality Grade 10.9 powder-coated hardware provides reliable performance at accessible pricing. Reserve stainless steel upgrades for vehicles facing particularly harsh environments or extended ownership periods where corrosion resistance justifies the premium.

Weekend Track Cars: ARP stainless steel represents the sweet spot for track applications. The material's heat tolerance maintains clamping force through repeated brake heat soak—something chrome-plated alternatives struggle with. For evo 8 wheels setups seeing regular track sessions, stainless hardware resists the thermal cycling that loosens lesser fasteners. Titanium makes sense for dedicated competition builds where every gram matters, but stainless delivers 90% of the performance at 60% of the cost.

Show Vehicles: Anodized aluminum or titanium hardware completes the visual package on concours builds. When your evo 8 rims exist primarily for display, the weight limitations of aluminum hardware become irrelevant. Choose finishes that complement or contrast your wheel design—titanium's burnt gold or aluminum's vibrant anodized colors create visual impact that steel cannot match.

Hub Rings and Valve Stems: The Overlooked Essentials

Here's what many enthusiasts miss when ordering wheels for evo builds or any aftermarket wheel setup: hub rings and valve stems affect fitment quality as much as the lug hardware itself.

Hub-centric rings fill the gap between your wheel's center bore and the vehicle's hub diameter. Without them, you're relying entirely on lug hardware to center the wheel—a recipe for vibrations and uneven load distribution. Quality hub rings come in plastic (adequate for street use) or aluminum (preferred for performance applications). Measure your vehicle's hub diameter and wheel center bore precisely; even 0.5mm discrepancies cause noticeable vibration.

Valve stems require attention often overlooked during hardware selection. Standard rubber stems suffice for street wheels, but forged wheel applications typically demand clamp-in metal stems. Why? Metal stems handle higher pressures, resist centrifugal forces at speed, and look far better than rubber alternatives on premium wheels. Verify stem hole diameter matches your replacement stems—sizes vary between manufacturers, and improper fitment causes slow leaks.

Critical Questions for Your Wheel Manufacturer

When requesting quotes on custom forged wheels, the right questions prevent compatibility nightmares and ensure you receive hardware matched to your specific application:

- What seat type do your wheels require? Conical (60-degree), ball, or flat seats must match your hardware exactly—mixing types causes improper contact and reduced clamping force.

- What thread pitch and shank length specifications apply? Verify M12 x 1.5, M14 x 1.25, or other thread specifications match your vehicle. Shank length must provide adequate thread engagement without bottoming out.

- Do you include hub rings sized for my vehicle? Some manufacturers include vehicle-specific hub rings; others require separate purchase. Confirm sizing before installation.

- What torque specifications do you recommend? Aftermarket wheels often require different torque values than OEM. Get specific numbers rather than generic ranges.

- For modular wheels: What assembly hardware is included, and what are the re-torque intervals? Three-piece designs typically require hardware inspection and re-torquing after initial break-in.

- What valve stem type and diameter does your wheel accept? Confirm compatibility before discovering mismatches at installation.

Verifying hardware compatibility requires more than matching thread pitch. Check that lug nut or bolt shank length provides proper thread engagement—typically 6.5-7.5 full turns minimum. Confirm your hardware's seat type matches the wheel's mounting surface angle. Measure center bore and hub diameter to specify correct hub rings. And always verify clearance between hardware heads and any aesthetic features like wheel spokes or cap retention features.

Never assume hardware from one wheel brand works with another. Even wheels with identical bolt patterns may require different seat types, shank lengths, or thread specifications.

With these comparison tools and questions in hand, you're equipped to select hardware matching both your application demands and your budget. The final step? Turning these recommendations into specific purchase decisions and understanding proper installation techniques that protect your investment.

Final Recommendations and Smart Selection Guide

Ready to pull the trigger on your custom forged wheel hardware options purchase? After examining titanium, stainless steel, aluminum, and coated steel alternatives across multiple applications, the patterns become clear. The right hardware selection balances your specific driving demands, environmental conditions, and budget constraints—while never compromising the safety margins that keep your forged billet wheels securely attached mile after mile.

Top Picks by Budget and Application

Whether you're sourcing hardware for forged customs on a show build or selecting fasteners for custom bolt pattern wheels destined for track duty, these ranked recommendations synthesize everything we've covered into actionable guidance:

- Precision Hot-Forged Titanium Hardware: The premium choice for serious builds demanding the ultimate combination of strength, weight savings, and corrosion resistance. Ti-6Al-4V Grade 5 delivers 950 MPa tensile strength at 50% weight reduction versus steel—measurable advantages for downforce rims setups on dedicated track cars and lightweight 6 lug wheels builds where every gram counts. For enthusiasts seeking this level of hardware, working with IATF 16949-certified manufacturers like Shaoyi (Ningbo) Metal Technology ensures consistent metallurgical properties through precision hot forging processes. Their rapid prototyping capabilities—delivering components in as little as 10 days—make custom titanium hardware accessible for specialty builds without extended lead times.

- ARP Stainless Steel Hardware: The performance enthusiast's sweet spot balancing capability and value. Tensile strength exceeding 170,000 psi combined with virtually impervious corrosion resistance handles track heat cycling and harsh weather exposure equally well. Ideal for weekend warriors and spirited street builds where titanium's premium isn't justified but steel's maintenance demands aren't acceptable.

- Quality Powder-Coated Grade 10.9 Steel: The practical choice for daily drivers and budget-conscious builds. Superior durability compared to chrome plating, adequate strength for street applications, and accessible pricing make this the default selection for most enthusiasts. Reserve upgrades for specific performance demands rather than spending premium dollars on hardware that won't be stressed.

What about specialized wheel configurations or other specialized setups? The same hierarchy applies regardless of wheel size or configuration. Match material selection to your actual use case rather than aspirational driving you rarely do. That said, investing in quality hardware always costs less than replacing damaged wheels or—worse—dealing with wheel separation incidents.

Installation Best Practices

Selecting the right hardware means nothing without proper installation technique. According to Alcoa Wheels' technical guidance, the difference between safe installations and problematic ones often comes down to preparation and procedure.

Surface Preparation Matters: Before any hardware touches your wheels, clean all mating surfaces thoroughly. This includes the hub or drum face, wheel mounting surface, and the hardware itself. Debris between contact surfaces prevents proper seating and can cause torque loss over time. For modular assemblies, verify O-ring sealing surfaces are free from contamination that could cause slow leaks.

Proper Lubrication Protocol: Add 1-2 drops of oil directly on the stud threads before installing lug nuts. For two-piece flange nuts, also lubricate between the nut and the free-spinning washer. This lubrication ensures consistent friction values that allow accurate torque readings. Dry threads create variable friction that throws off torque specifications—you might hit the target number while achieving significantly different clamping force.

Torque Sequence and Technique: Install all lug nuts hand-tight first, then tighten to specification using a star or crisscross pattern. Start at the 12 o'clock position, move to 6 o'clock, then alternate around the wheel. According to Alcoa's specifications, the lug nut must move at least a quarter turn before arriving at final torque—if it's already at specification before that movement, investigate potential cross-threading or other issues.

Using impact guns set to maximum torque damages fasteners and wheel mounting surfaces. Never exceed manufacturer torque specifications, and always use a calibrated torque wrench for final verification.

Post-Installation Verification: After completing installation and performing a brief test drive, recheck torque within 5-100 miles as recommended by industry guidelines. This isn't re-torquing in the traditional sense—you're verifying that initial torque values remain stable after the assembly has settled through heat cycles and vibration. Use a dial indicator or clicker-type torque wrench to confirm specifications without adding additional force.

Ongoing Maintenance Schedule: Establish periodic torque verification as part of your regular maintenance routine. Monthly checks suit track-driven vehicles experiencing repeated heat cycling. Seasonal verification works adequately for street-driven builds. Document each check for reference—patterns of torque loss indicate potential hardware or mounting surface issues requiring investigation.

For enthusiasts investing in precision-forged titanium or custom hardware solutions, the value of working with properly certified manufacturers extends beyond the hardware itself. IATF 16949 certification—the automotive industry's most stringent quality management standard—ensures every piece meets exact specifications through controlled manufacturing processes. Companies maintaining this certification demonstrate commitment to defect prevention and continual improvement that matters for safety-critical components.

Your custom forged wheel hardware choices ultimately reflect priorities: maximum performance demands titanium, balanced capability favors stainless steel, and practical value points toward quality powder-coated steel. Whatever direction you choose, proper installation technique and ongoing maintenance protect both your investment and your safety. The wheels get the attention—but the hardware makes everything possible.

Frequently Asked Questions About Custom Forged Wheel Hardware

1. What hardware options are available for custom forged wheels?

Custom forged wheels offer several hardware options including precision hot-forged titanium (50% lighter than steel with 950 MPa tensile strength), ARP stainless steel (excellent corrosion resistance at 170,000 psi), anodized aluminum (65% weight savings for show vehicles), and chrome or powder-coated steel (budget-friendly for daily drivers). Modular two-piece and three-piece wheels also require specialized assembly hardware like high-strength bolts, sealing O-rings, and thread locker. IATF 16949-certified manufacturers like Shaoyi Metal Technology produce precision-forged titanium hardware with consistent metallurgical properties for safety-critical applications.

2. Are titanium wheel studs and lug nuts worth the upgrade?

Titanium wheel hardware is worth the upgrade for track cars, show builds, and premium street applications. Ti-6Al-4V Grade 5 titanium delivers 950 MPa tensile strength while weighing 50% less than steel, reducing unsprung and rotational mass for improved acceleration, braking, and handling. Titanium also offers superior corrosion resistance—it simply doesn't rust even in coastal or winter conditions. However, titanium costs significantly more than stainless steel alternatives. For weekend track warriors, ARP stainless steel provides 90% of the performance at 60% of the cost, making it the sweet spot for most performance enthusiasts.

3. What is the difference between two-piece and three-piece forged wheels?

Two-piece forged wheels join a forged face to a barrel using welding or 20-40 mechanical fasteners around the circumference. Three-piece forged wheels mount a forged center between separate inner and outer barrel sections, requiring 40-80 individual fasteners per wheel. This increased complexity demands more attention during assembly and periodic inspection. Both designs use specialized assembly hardware including high-strength Grade 10.9 bolts, sealing O-rings for tubeless applications, and thread locker to prevent vibration-induced loosening. Floating hardware systems allow controlled movement between sections to accommodate thermal expansion during track use.

4. How do I choose the right wheel hardware for my vehicle application?

Match hardware material to your driving demands: powder-coated Grade 10.9 steel works best for daily drivers facing road salt and weather exposure at accessible pricing. ARP stainless steel suits weekend track cars and spirited street builds, handling heat cycling while resisting corrosion. Precision-forged titanium serves dedicated competition vehicles and show builds where weight savings and premium aesthetics justify the investment. Always verify seat type compatibility (conical, ball, or flat), thread pitch specifications, and proper shank length providing 6.5-7.5 full thread turns. Hub rings sized for your vehicle prevent vibrations, and metal valve stems suit performance applications.

5. What torque specifications should I use for aftermarket wheel hardware?

Aftermarket wheel hardware often requires different torque values than OEM specifications due to material properties and friction characteristics. ARP stainless steel typically requires 85-95 ft-lbs for M12 x 1.5 bolts, while titanium hardware uses 120-130 Nm specifications. Aluminum hardware needs lower values around 65-75 ft-lbs to prevent thread damage. Always follow your wheel manufacturer's specific recommendations rather than generic OEM specs. Apply 1-2 drops of oil on stud threads before installation, tighten in a star pattern, and verify torque within 5-100 miles after installation. Use a calibrated torque wrench—never rely on impact guns for final torque.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —