Custom Forged Wheel Brands List: From Elite Motorsport To Street

What Makes a Wheel Truly Custom Forged

When you're searching for a custom forged wheel brands list, you'll quickly discover that the term "custom" gets thrown around loosely. Some manufacturers slap the label on any wheel with multiple finish options. Others use it to describe basic sizing variations. But genuine custom forged wheels? They represent something fundamentally different from what most aftermarket catalogs offer.

Imagine the difference between a tailored suit and one pulled off a department store rack. That's essentially what separates bespoke forged wheels from standard aftermarket options. True custom manufacturing means every specification, from offset to barrel depth, is engineered specifically for your vehicle and driving goals.

Why Custom Forged Wheels Command Premium Status

The premium pricing of brands like HRE rims or Forgiato wheels isn't arbitrary. It stems from a manufacturing process that transforms raw 6061-T6 aluminum through extreme heat and intense pressure. According to JC Forged Wheels, the forged aluminum develops a highly aligned grain structure free of voids, making it significantly stronger than cast alternatives.

During production, a single forging can lose 70-80% of its original mass through precision CNC machining. Complex designs may require 8-10 hours of machine time per wheel. Premium finishes, like the brushed treatments you'll find on high-end Vossen wheels, can add another 8 hours of artisan work. This isn't mass production; it's precision craftsmanship.

Forged wheels deliver an unmatched strength-to-weight ratio because the extreme pressure during manufacturing eliminates porosity, cavities, and internal inconsistencies that plague cast alternatives, resulting in wheels that are simultaneously lighter and stronger.

The Engineering Behind Bespoke Wheel Manufacturing

What truly defines "custom" in forged wheel manufacturing? It comes down to vehicle-specific engineering. Genuine bespoke manufacturers don't simply resize existing molds. They calculate precise specifications including load ratings, bolt patterns, and hub-centric fitment tailored to your exact application.

The raw aluminum block undergoes transformation through pressurized forging machines that align the metal's internal grain structure. This process, whether creating monoblock designs or multi-piece configurations featuring forged carbon fiber elements, produces wheels capable of withstanding conditions that would crack standard cast alternatives.

Throughout this guide, you'll discover manufacturers organized by actual use case and quality tier rather than alphabetical order. Whether you're building a track weapon, a luxury show car, or an aggressive off-road rig, you'll find recommendations matched to your specific goals. We'll cover everything from elite motorsport heritage brands like Forgiato to performance-focused manufacturers that deliver exceptional value. The goal is simple: help you understand which brands genuinely earn their premium positioning and which construction methods align with your driving demands.

Understanding Forged Wheel Construction Types

Before diving deeper into our custom forged wheel brands list, you need to understand what you're actually buying. Most enthusiasts hear terms like "monoblock" or "3-piece" tossed around without ever grasping why these distinctions matter. Here's the reality: construction type directly impacts weight, repairability, customization potential, and your final invoice. Understanding these differences separates informed buyers from those who overpay for features they don't need.

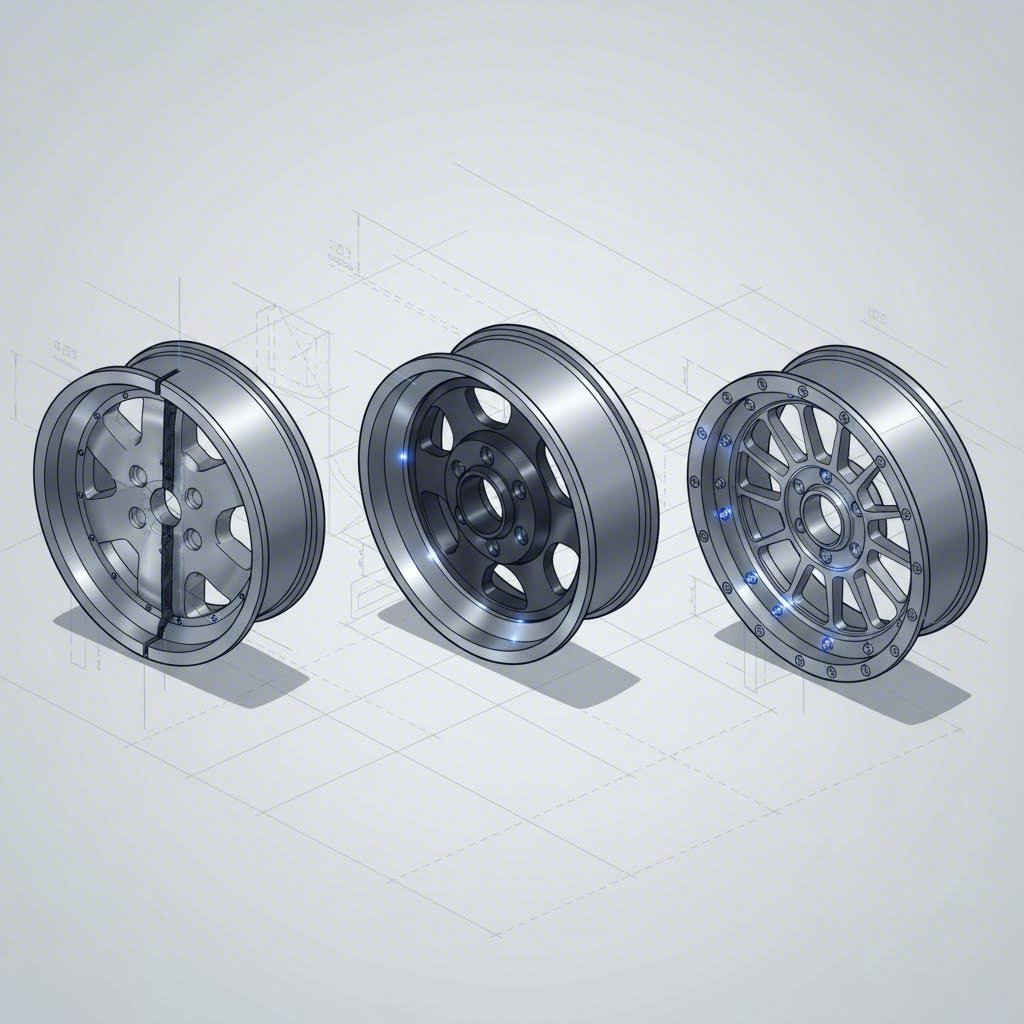

Monoblock vs Multi-Piece Construction Explained

Think of a monoblock forged rim as carved from a single sculpture. According to Deviate Motoring, the process starts with aerospace-grade 6061-T6 aluminum bar stock that gets pressed through a massive forging machine before CNC mills carve out the final spoke pattern. The result? A unified structure with no joints, welds, or fasteners to compromise integrity.

Now picture 2 piece forged wheels as a precision marriage between a forged center and a spun-forged barrel. The center section, featuring your chosen spoke design, bolts or welds directly to the outer hoop. This construction opens up offset flexibility that monoblock designs simply cannot match. Need an aggressive concave up profile with specific backspacing? Two-piece construction makes it possible.

Three-piece designs take modularity further. You get a forged center, an inner barrel, and an outer lip, all held together with perimeter bolts and sealed with high-temperature silicone. This configuration delivers the ultimate customization when comparing alloy vs premium wheels. Want a polished outer lip with a brushed center? Chrome wheels on the lip section with a matte black face? Three-piece construction accommodates virtually any combination.

How Forging Methods Impact Performance and Price

Here's where many forged wheels brands get confusing for buyers. You'll encounter terms like "rotary forged," "flow formed," or "spun forged," and wonder if they're legitimate alternatives to traditional forging.

According to JC Forged Wheels, rotary forging is actually a hybrid manufacturing technique. The process begins with a low-pressure cast wheel face, but then the barrel section gets spun under intense heat while pressure rollers stretch and compress the material. This aligns the grain structure in the barrel, creating forged-like properties in that specific area while the spoke face remains cast.

The practical outcome? Rotary forged wheels weigh significantly less than pure cast alternatives and cost roughly a quarter of fully forged options. They bridge the gap nicely for enthusiasts who want performance improvements without the premium price tag. However, they're not true forged wheels throughout, and the cast spoke face lacks the impact resistance and crisp machining detail of CNC-carved forged centers.

| Construction Type | Weight Characteristics | Customization Level | Typical Price Range | Best Applications |

|---|---|---|---|---|

| Monoblock Forged | Lightest option (25-30% lighter than cast) | Limited offset/width options | $800-$2,500+ per wheel | Track cars, weight-focused builds |

| 2-Piece Forged | Slightly heavier than monoblock | Good offset flexibility | $600-$1,800 per wheel | Street performance, daily drivers |

| 3-Piece Forged | Heaviest forged option | Maximum customization | $1,000-$3,000+ per wheel | Show cars, luxury builds, custom fitments |

| Rotary Forged (Flow Formed) | Lighter than cast, heavier than forged | Limited to manufacturer specs | $250-$600 per wheel | Budget performance, street upgrades |

The construction you choose should align with your actual driving goals. Chasing lap times at the track? Monoblock designs minimize unsprung weight where every gram counts. Building a show-quality luxury cruiser? Three-piece construction lets you dial in exact specifications while offering easier repair if a lip gets curbed. Daily driving with occasional spirited runs? Two-piece forged or quality rotary forged options often deliver the best value proposition.

With this foundation in place, you're ready to explore the specific manufacturers that excel within each category. The premium tier brands we'll examine next have built their reputations on decades of motorsport development and uncompromising material standards.

Premium Tier Custom Forged Wheel Brands

Now that you understand construction types, let's examine the manufacturers who've earned their place at the top of any custom forged wheel brands list. These aren't companies that simply assemble wheels; they're engineering houses with decades of motorsport victories, proprietary technologies, and manufacturing standards that justify their premium positioning. When you're investing thousands per wheel, you deserve to know exactly what separates these elite brands from everyone else.

Motorsport-Proven Manufacturers

Racing has always been the ultimate proving ground for wheel technology. The loads, impacts, and thermal stresses experienced during competition expose weaknesses that never surface during casual street driving. The manufacturers below have built their reputations by winning championships, then translating that race-developed expertise into street applications.

- HRE Performance Wheels - Based in San Diego, California, HRE builds every wheel to order using aerospace-grade 6061-T6 aluminum in a TUV-certified facility. Their motorsport pedigree includes Le Mans, Grand-Am, and Pikes Peak competition. HRE forged wheels span multiple series: Monoblok designs for ultimate weight savings, 2-Piece FMR construction for custom stance applications, 3-Piece options for maximum flexibility, FlowForm offerings at more accessible price points, and their cutting-edge CRBN carbon fiber line for exotic builds. Custom offsets, widths, and bolt patterns are standard, meaning you can achieve factory-flush or aggressive fitment without spacers.

- Forgeline - This American-made manufacturer started in 1994 when brothers Steve and Dave Schardt identified a gap between expensive BBS offerings and heavy steel alternatives. According to Grassroots Motorsports, Forgeline's innovation involved forging blanks that already resembled finished centers, reducing material waste and machining costs. By 1995, their forgeline rims helped P.D. Cunningham's RealTime Racing Honda Prelude win the World Challenge championship. Within years, 50% of World Challenge teams were running Forgeline. Today they offer over 100 styles across one-piece, two-piece, and three-piece constructions, all manufactured at their Dayton, Ohio headquarters.

- BBS - The legendary German manufacturer has been engineering high-performance wheels for over 50 years. BBS racing wheels have won over 250 series championships across Formula 1, touring cars, prototypes, World Rally Championship, and motorcycle racing. In 1992, BBS developed the first forged magnesium wheels in Formula 1 for Ferrari. Their bbs rims serve OE applications for BMW, Ferrari, and Porsche, meaning they understand factory-level tolerance and durability specifications. Since 1995, BBS has been consistently voted "Best Brand" by sport auto magazine in Germany, validating their reputation among enthusiasts and professionals alike.

Heritage Brands That Define Industry Standards

Beyond pure motorsport credentials, certain manufacturers have shaped the entire custom wheel industry through innovation and uncompromising quality standards. These heritage brands command premium pricing because they've invested decades perfecting proprietary alloys, in-house engineering capabilities, and finish techniques that competitors struggle to replicate.

- American Racing - With nearly 70 years of heritage, American Racing established the custom wheel category during the muscle car era. Their legacy demonstrates how racing-derived technology eventually reaches street enthusiasts who demand both style and substance.

- Savini Wheels - Known for luxury applications, savini wheels combine Italian design influence with precision forging technology. Their multi-piece offerings allow extensive customization for high-end builds where visual impact matters as much as performance.

- Vellano Wheels - Specializing in luxury and exotic vehicle applications, vellano wheels emphasize hand-crafted finishes and bespoke sizing. Their focus on show-quality builds has earned a following among collectors and automotive influencers.

- Vossen - Blending contemporary design with quality construction, vossen rims have become synonymous with modern luxury styling. Their product range spans from entry-level flow formed options to fully forged precision series, making premium aesthetics accessible across multiple price points.

What truly justifies premium pricing from these manufacturers? It comes down to several factors that cheaper alternatives simply cannot replicate. First, proprietary alloy formulations developed through years of metallurgical research. BBS emphasizes that no other wheel manufacturer uses a wider range of materials, processes, or construction methods. Second, in-house engineering teams that calculate precise stiffness-to-weight ratios rather than simply chasing the lightest possible design. As BBS notes, many aftermarket companies overlook stiffness and durability in pursuit of weight savings, leading to buyer's remorse when wheels flex under load or fail prematurely.

Third, racing development programs that expose designs to conditions exponentially more demanding than street driving. Forgeline's evolution from welded two-piece wheels to fully bolted three-piece construction came directly from observing how modern sticky tires and heavier cars stressed their original designs. Fourth, finish quality that involves hours of hand-polishing, brushing, or multi-stage powder coating rather than automated mass-production techniques. BC forged manufacturers and other premium brands invest in artisan finishing that cheaper brands simply cannot afford.

For enthusiasts who require elite-tier quality but need options beyond top-dollar pricing, the next category of performance-focused manufacturers delivers exceptional engineering at more accessible price points. These brands have earned devoted followings by combining racing heritage with value-conscious positioning.

Performance Forged Brands for Enthusiasts

Not everyone needs a set of wheels that costs more than their monthly mortgage payment. The good news? Some of the most respected names in motorsport offer exceptional forged quality at price points that won't require a second job. These performance-focused manufacturers have earned devoted followings by delivering race-proven engineering without the premium-tier markup. If you're building a weekend track weapon or simply want lightweight wheels for spirited daily driving, the brands below represent the sweet spot between quality and value.

Japanese Engineering Excellence in Forged Wheels

When discussing japanese wheel brands, two names consistently dominate the conversation: RAYS Engineering and Work Wheels. These manufacturers haven't just participated in JDM culture; they've defined it through decades of innovation and motorsport success.

RAYS Engineering, the parent company behind volk rims, stands at the pinnacle of racing wheel technology. According to Performance Plus Tire, RAYS supplies wheels for the highest levels of motorsport including Formula 1 and GT1 World Championships. Their massive 10,000-ton forging press creates wheels with superior strength-to-weight ratios, while anti-slip bead knurling originally developed for Formula 1 prevents tire slippage during high-torque applications.

The legendary TE37, introduced in 1996, weighed just 3.7kg (8.15lb) for the 15x6-inch version. That's remarkable even by today's standards. What separates RAYS from competitors claiming similar performance? Everything stays in-house in Japan rather than being outsourced overseas. Their internal JWL+R SPEC2 standards exceed Japan's minimum safety requirements, giving you confidence that every wheel can handle abuse far beyond street conditions.

Work wheels represent another pillar of jdm wheel brands with their own distinct approach. While RAYS focuses on maximum weight reduction, Work has built a reputation for combining motorsport capability with aggressive styling that defines the Japanese tuning aesthetic. Their extensive catalog includes options for everything from time attack builds to VIP sedans, demonstrating versatility that few manufacturers can match.

Performance Brands for Enthusiast Budgets

Beyond Japanese manufacturers, several brands deliver exceptional forged quality without requiring elite-tier budgets. Understanding which suits your specific needs prevents overspending on features you'll never use.

BC Forged has earned a strong following among enthusiasts seeking custom specifications at accessible pricing. According to BC Forged North America, every wheel is made per order, meaning you're not limited to off-the-shelf sizing. Their North American operations provide direct communication throughout the ordering process, addressing a common frustration with overseas manufacturers where language barriers complicate custom requests.

Rohana wheels occupy an interesting position in the market, blending luxury aesthetics with performance-oriented construction. Their rotary forged options deliver significant weight savings over cast alternatives while maintaining the aggressive concave profiles that photograph well and perform admirably on the street. For enthusiasts prioritizing visual impact alongside genuine engineering improvements, rohana wheels often deliver the best of both worlds.

You might also encounter tsw rims and kosei rims during your research. TSW emphasizes exceptional balance of strength and durability according to industry evaluations, making them solid contenders for daily-driven performance vehicles. Kosei, while less prominent in enthusiast circles, manufactures OEM wheels for several automakers, meaning their quality control meets factory standards.

| Brand | Origin Country | Signature Technology | Price Tier | Ideal Vehicle Application |

|---|---|---|---|---|

| RAYS (Volk Racing) | Japan | 10,000-ton forging press, anti-slip bead knurling | $232-$782 per wheel | Track cars, time attack, weight-focused builds |

| Work Wheels | Japan | Multi-piece modular construction, JDM styling heritage | $400-$900 per wheel | Street performance, VIP builds, show cars |

| BC Forged | Taiwan/USA Distribution | Made-to-order custom specifications | $500-$1,200 per wheel | Custom fitments, enthusiast builds |

| Rohana | USA | Rotary forged with deep concave profiles | $350-$700 per wheel | Luxury sport sedans, stance builds |

So which brands suit daily performance driving versus dedicated weekend track use? The distinction matters more than most buyers realize. For daily drivers with occasional spirited runs, Rohana and BC Forged rotary forged options deliver meaningful weight savings and styling upgrades without the premium you'd pay for pure motorsport engineering. The construction handles street conditions admirably while shaving unsprung mass compared to heavy cast alternatives.

Weekend track warriors should prioritize RAYS and Work wheels. The fully forged construction withstands repeated heat cycling from aggressive braking, maintains precise tolerances lap after lap, and resists the impacts that occur when you push limits. RAYS' motorsport heritage means their designs have already survived conditions exponentially more demanding than any track day you'll experience. That proven durability justifies the price difference when wheels face genuine stress rather than occasional highway pulls.

These performance-focused manufacturers prove you don't need to empty your savings account for quality forged wheels. However, some applications demand specialized engineering that general-purpose wheel brands cannot provide. Truck and off-road enthusiasts face unique load requirements, bolt pattern considerations, and durability demands that the next category of manufacturers specifically addresses.

Truck and Off-Road Forged Wheel Specialists

When you scroll through the hundreds of wheel brands claiming off-road capability, how do you separate genuine forged rims for trucks from marketing hype? The truck and SUV segment has exploded with manufacturers promising strength and style, yet most lack the engineering depth required for serious applications. Lifted rigs carrying recovery gear, overland setups hauling water and fuel, and dually workhorses towing heavy loads all demand specifications that standard performance wheels simply cannot deliver.

Here's the reality: forged truck wheels face unique challenges that passenger car applications never encounter. We're talking about load ratings exceeding 3,000 pounds per wheel, bolt patterns like 8x180 and 8x6.5 that require specialized tooling, and sizing considerations for vehicles sitting on 6-inch lift kits. The manufacturers who've mastered this segment have invested heavily in engineering specifically for these demands.

Heavy-Duty Forged Wheels for Trucks and SUVs

American Force has established itself as the dominant name in premium truck rims. According to their manufacturing documentation, each wheel begins as a solid block of 6061 aluminum and undergoes extreme heat and pressure during forging. This process creates metal that is denser, more uniform, and stronger than cast alternatives. Their highly specialized team operates 25+ HAAS CNC mills, often requiring hours of machining for a single wheel.

What truly distinguishes American Force? Their finishing capabilities. They remain the only company in the industry using CNC polishing centers for wheels, operating three dedicated machines that produce the most consistent mirror polish available anywhere. Whether you want simple gloss black powder coating or a totally unique brushed finish, their in-house department handles requests that would overwhelm lesser manufacturers.

Understanding load ratings becomes critical when shopping forged truck wheels. According to Hardrock Offroad's engineering guidelines, wheel load capacity represents the maximum weight each wheel can safely support. The calculation takes 50% of your vehicle's gross axle weight rating (GAWR). For example, a Toyota 4Runner TRD Pro with a rear GAWR of 3,439 pounds requires wheels rated for at least 1,720 pounds each. Add camping gear, recovery equipment, and passengers, and you'll want wheels exceeding this minimum significantly.

Off-Road Forged Options That Handle Abuse

Off-road environments create stresses that highway driving never approaches. Rock impacts, sudden weight transfers during articulation, and shock loads from drops all place extraordinary demands on your wheels. Beadlock wheels have become increasingly popular for serious off-road applications because they mechanically clamp the tire bead to the wheel, preventing tire separation during low-pressure crawling. Rim beadlock configurations allow enthusiasts to air down significantly without risking a tire popping off the bead during aggressive maneuvering.

Not every off-road wheel requires beadlock capability, though. Many enthusiasts simply need strong, lightweight forged options that handle trail abuse better than cast alternatives. The manufacturing method plays a huge role in load capacity, with flow formed and forged wheels generally providing higher load ratings due to their enhanced material density and grain structure.

Brands Categorized by Application:

- Luxury Truck Builds: American Force, Fuel Forged, and TIS Forged wheels deliver show-quality finishes with the structural integrity to handle heavy full-size trucks. These manufacturers specialize in large-diameter applications (22-26 inches) with custom offsets tailored for lifted platforms. Expect premium pricing but exceptional finish quality and engineering depth.

- Aggressive Off-Road Use: Manufacturers like Method Race Wheels and Fifteen52 focus on trail durability over chrome-plated aesthetics. Their designs prioritize impact resistance, proper load ratings for overlanding setups, and compatibility with beadlock-capable configurations. Weight savings matter here since every pound of unsprung mass affects suspension response on technical terrain.

- Show-Quality Dually Wheels: American Force dominates the dually wheels segment with specialized offerings for 8-lug platforms. Their CNC polishing technology produces mirror finishes that stand out at truck shows while maintaining the load ratings required for towing applications. Custom widths accommodate various tire setups from street stance to functional hauling configurations.

Bolt pattern considerations add another layer of complexity when shopping truck rims. Common heavy-duty patterns include 8x180 (modern GM HD trucks), 8x6.5 (older GM and current Ram HD), and 8x170 (Ford Super Duty). Unlike passenger car applications where 5x114.3 or 5x120 patterns fit numerous vehicles, truck patterns are less interchangeable. Verify exact specifications before ordering, especially for dually applications where inner and outer wheels require specific configurations.

Sizing for lifted vehicles demands attention to backspacing and offset calculations. A wheel that fits perfectly on a stock-height truck may experience rubbing issues when you add a 6-inch lift and 37-inch tires. Quality manufacturers like American Force offer extensive offset options specifically because they understand this market. Their designers and engineers use Finite Element Analysis software to test strength and durability, and physical destructive testing ensures every wheel meets SAE guidelines before reaching customers.

With hundreds of brands claiming capability in this segment, how do you verify that a manufacturer delivers genuine quality rather than marketing promises? The next section provides concrete guidance on authentication, certification standards, and the red flags that reveal questionable claims.

How to Verify Authentic Forged Wheel Quality

You've researched construction types, explored premium manufacturers, and identified brands that match your application. But here's an uncomfortable truth: the wheel market is flooded with products claiming "forged" status that don't deserve the label. When you're investing serious money based on a custom forged wheel brands list, you need concrete tools to separate authentic engineering from marketing manipulation. This verification process protects your investment and, more importantly, your safety.

Spotting Fake Forged Wheel Claims

How do you identify the best forged wheels versus cleverly marketed imitations? Start by recognizing the most common red flags that signal questionable authenticity.

Pricing stands as your first indicator. According to Driver Motorsports, fake wheels often gain popularity due to their lower cost and similarity to real wheels. When you encounter cheap forged rims priced at $200-300 per wheel, you're almost certainly looking at cast alternatives with forged-style marketing. Genuine forged manufacturing requires expensive equipment, skilled labor, and hours of CNC machining time. Those costs cannot magically disappear.

Vague manufacturing claims provide another warning sign. Authentic manufacturers proudly detail their forging presses, alloy specifications, and machining processes. Companies hiding behind generic terms like "premium construction" or "advanced manufacturing" typically have something to conceal. Driver Motorsports notes that replica wheels often utilize terms resembling legitimate certifications but use different words to create confusion. Watch for acronyms like "RAW," "KIKI," or "BORN" that mimic established standards without actually meeting them.

The difference between true forged wheel blanks and cast alternatives becomes apparent in construction details. Genuine forged centers feature crisp machining lines, consistent spoke thickness, and multi-stage paint processes. Replica manufacturers take shortcuts, resulting in single-coat finishes that chip easily and designs lacking the fine detail precision CNC equipment produces. If a wheel looks slightly "soft" in its edges or the finish appears thin, trust your instincts.

Certification and Testing Standards That Matter

Certifications serve as your objective verification tool, but understanding what each actually means prevents being fooled by meaningless stamps. According to Konig Wheels, different standards serve different regions and purposes, and a stamp alone doesn't guarantee quality.

JWL (Japan Light Alloy Wheel) certification represents a globally recognized standard for wheel manufacturing. However, here's what most buyers don't realize: a wheel can be stamped JWL without third-party verification. Manufacturers can conduct their own testing and apply the stamp if they meet requirements internally. This self-certification system means the stamp indicates capability rather than guaranteed compliance.

VIA certification addresses this gap. Unlike JWL, VIA requires wheels to be processed and approved by the Vehicle Inspection Association directly. This independent third-party testing confirms that wheels not only meet but exceed industry requirements. When evaluating affordable forged wheels, VIA certification provides stronger assurance than JWL alone.

TÜV certification carries particular weight in European markets. According to Konig, TÜV standards require additional testing beyond baseline requirements, and manufacturers targeting non-German markets often skip this certification simply because the extra testing costs money. A wheel lacking TÜV isn't automatically inferior, but presence of this certification signals commitment to rigorous standards.

Verification Steps for Authenticating Forged Wheels:

- Check manufacturer documentation: Request forging certificates, alloy specifications, and testing reports. Legitimate manufacturers provide this information readily. Hesitation or vague responses suggest potential misrepresentation.

- Understand weight specifications: Compare stated weights against known benchmarks for similar sizes. The best forged rims should weigh significantly less than cast equivalents. If claimed weights seem too good or suspiciously match cast alternatives, investigate further.

- Recognize quality finish indicators: Examine paint depth, machining precision, and edge definition. Multi-stage finishing processes create visual depth that single-coat replicas cannot replicate. Look for consistent grain patterns in brushed finishes and uniform coverage in painted surfaces.

- Verify certification claims independently: Don't trust stamps alone. Contact certifying bodies when possible, or research whether a manufacturer appears in official certified supplier databases. Counterfeiters replicate stamps easily; verifying through official channels catches these fakes.

- Research brand history and manufacturing facilities: Established forged wheel manufacturers openly discuss their production processes, facility locations, and equipment investments. Companies hiding behind vague claims often lack legitimate manufacturing capability.

When you're searching for cheap forged wheels that deliver genuine value rather than compromised quality, focus on rotary forged or flow formed options from established manufacturers. These construction methods offer significant weight savings over cast alternatives at lower price points than fully forged wheels. They represent honest value rather than misrepresented products claiming forged status they haven't earned.

Armed with these verification tools, you can confidently evaluate any brand claiming forged construction. The final step involves matching authenticated manufacturers to your specific build goals, ensuring the wheels you purchase align perfectly with your intended application.

Choosing the Right Brand for Your Application

You've explored construction types, verified authentication methods, and discovered manufacturers across every quality tier. Now comes the practical question: which brands actually match your specific build goals? Random brand lists don't help when you're trying to decide between a set of RAYS for weekend track sessions or Vossen rims for a show-quality luxury build. Your application determines everything, from construction priorities to finish durability requirements.

Think about it this way. A wheel engineered for endurance racing faces completely different stresses than one designed to photograph well at car meets. The good wheel brands for one application might be entirely wrong for another. Understanding these distinctions prevents expensive mismatches between your wheels and your actual driving demands.

Matching Wheel Brands to Your Build Goals

Wheel weight affects different driving scenarios more dramatically than most enthusiasts realize. According to Performance Plus Tire, lighter rims boost acceleration, braking, and handling while reducing stress on suspension components. These represent real performance gains beyond visual appeal.

For track-focused applications, every gram of unsprung mass matters. When you're braking hard into turn one, lighter wheels respond faster to suspension inputs and recover more quickly from weight transfer. RAYS engineering demonstrates this principle with their TE37, which weighed just 8.15 pounds for a 15x6-inch wheel when introduced. That's approximately 30% lighter than comparable cast alternatives.

Show car selections prioritize different characteristics. Finish depth, spoke intricacy, and customization options matter more than shaving ounces. Three-piece construction allows exact offset specifications and lip combinations that photograph dramatically. A garage queen rarely faces the thermal cycling and impact stresses that would expose finish vulnerabilities, making elaborate multi-stage paint processes worthwhile investments.

Daily performance drivers occupy the middle ground. You need wheels that survive parking lot hazards and seasonal road conditions while still delivering meaningful performance improvements. According to industry testing, flow-formed options from brands like Konig and Motegi deliver excellent balance between weight savings and real-world durability at accessible pricing.

Application-Specific Recommendations

The best car wheel brands for your situation depend entirely on how you'll actually use your vehicle. Here's how leading manufacturers align with specific applications:

| Use Case | Recommended Brands | Key Features to Prioritize | Budget Considerations |

|---|---|---|---|

| Track/Motorsport Builds | RAYS (Volk Racing), Forgeline, BBS, OZ Racing | Minimum weight, maximum stiffness, heat resistance, proven motorsport heritage | $500-$1,500+ per wheel; prioritize performance over finish options |

| Luxury and Show Vehicles | HRE, Vossen, Savini, Vellano, ADV.1 | Custom finishes, precise fitment, multi-piece customization, hand-finished details | $1,500-$4,000+ per wheel; finish quality justifies premium |

| Daily Performance Drivers | Konig, Enkei, BC Forged, Rohana, TSW | Durability, corrosion resistance, reasonable weight savings, value proposition | $250-$800 per wheel; flow-formed offers best value |

| Aggressive Off-Road Applications | Method Race Wheels, American Force, Fuel Forged, Black Rhino | Load ratings, impact resistance, beadlock capability, proper bolt patterns | $375-$1,200+ per wheel; don't compromise on load capacity |

Why does a track-focused choice differ so significantly from a show car selection? Beyond weight considerations, the stress profiles are completely different. Track wheels experience repeated thermal cycling as brakes heat during aggressive sessions. According to Performance Plus Tire, Enkei's Spec-E testing protocols demand 20% more cycles for rotary bending fatigue and dynamic radial fatigue tests than standard JWL requirements. That extra testing margin translates to confidence when you're pushing limits lap after lap.

Show vehicles face different challenges. UV exposure, cleaning chemicals, and the occasional parking lot encounter test finish durability rather than structural strength. The best rim brands for show applications invest in multi-stage finishing processes. Vossen, for example, uses aerospace-grade 6061-T6 aluminum with heat treatment, then applies finishes designed to maintain appearance through years of careful ownership.

Daily drivers need wheels that handle real-world abuse without constant worry. Curb rash happens. Road salt attacks finishes every winter. Potholes appear without warning. The top wheel brands for daily use engineer for these realities. Powder-coated finishes from manufacturers like Fuel Off-Road provide superior resistance to corrosion, scratches, and fading compared to painted alternatives. Konig's flow-formed construction delivers measurable advantages including increased tensile strength, improved shock resistance, and superior fatigue resistance at price points that won't devastate your budget if a wheel needs replacement.

Off road wheel brands face the most demanding conditions of all. According to Hardrock Offroad engineering guidelines, wheel load capacity calculations require 50% of your vehicle's gross axle weight rating per wheel. Add recovery gear, camping equipment, and passengers, and you'll want significant margin above minimum requirements. Method Race Wheels maintains load ratings up to 4,500 pounds per wheel, while their patented Bead Grip technology enables lower tire pressures without risking tire separation.

Consider finish durability carefully based on your actual usage patterns. A garage queen can justify elaborate brushed aluminum or chrome treatments that require careful maintenance. A daily driver benefits from more forgiving finishes like matte black powder coating or simple machined faces that hide minor imperfections. The best truck wheel brands understand this distinction, offering everything from show-quality mirror polish to rugged utilitarian finishes designed for working trucks.

With your application requirements clearly defined and appropriate brands identified, the final step involves understanding what to expect from the custom wheel ordering process itself. Lead times, quality certifications, and manufacturer communication standards all impact your experience beyond the wheels themselves.

Navigating the Custom Wheel Buying Process

You've identified the perfect wheel brands for your application, verified their authenticity, and matched specifications to your build goals. Now comes the part that catches many enthusiasts off guard: actually ordering custom forged wheels involves a procurement process significantly more complex than clicking "add to cart." Understanding lead times, manufacturer communication expectations, and quality standards transforms a potentially frustrating experience into a smooth transaction. Let's walk through what separates successful custom wheel purchases from disappointments.

Streamlining Your Custom Wheel Purchase

The journey from deposit to delivery involves multiple stages that premium aftermarket wheel brands handle differently than mass-market alternatives. According to La Forge Industries, the process begins with comprehensive consultation covering specifications like bolt pattern, offset, width, and hub bore. Reputable manufacturers encourage showroom visits because photos and videos cannot capture the true essence of finishes, colors, and designs.

Expect the following timeline for truly custom builds:

- Initial Consultation: 1-2 weeks for detailed specifications and design preferences

- 3D Rendering and Approval: 1-3 weeks for visual representation and Finite Element Analysis validation

- Production and Machining: 6-12 weeks depending on complexity and manufacturer backlog

- Finishing and Quality Control: 1-3 weeks for color application and inspection

- Shipping: 1-2 weeks for secure delivery with protective packaging

That means a fully custom set from the best wheel manufacturers typically requires 10-20 weeks from order to doorstep. Planning ahead prevents disappointment when your build timeline depends on wheel delivery. Some manufacturers offer expedited options, but rushing precision work rarely ends well.

Custom wheel offset specifications deserve particular attention during consultation. Unlike off-the-shelf wheels with predetermined backspacing, bespoke manufacturers calculate exact measurements for your specific suspension geometry. Precise measurements ensure a perfect fit according to your preferences while avoiding rubbing issues or improper wheel positioning.

What to Expect from Premium Manufacturers

Quality control separates legitimate premium wheels from those simply charging premium prices. According to Flexiforge Wheel, reliable forged wheel companies conduct rigorous testing including rotary fatigue testing, impact testing, and radial load testing. These protocols verify structural integrity under peak loads before any wheel reaches customers.

Certifications provide objective verification of manufacturing standards. ISO 9001 certification confirms that a company follows strict quality control processes and best practices across all production stages. For wheel manufacturers specifically, this means every step from design to final inspection meets high standards, reducing defects and ensuring reliable products.

IATF 16949 certification is vital for wheel manufacturers supplying major automakers. It covers the entire production process, ensuring high-quality standards at every stage with focus on continuous improvement and defect prevention.

This certification matters because it represents the most rigorous quality management standard in the automotive industry. Manufacturers holding IATF 16949 certification have demonstrated capability to meet OEM-level requirements consistently. When evaluating aftermarket wheel brands, this certification signals manufacturing excellence that matches or exceeds factory specifications.

Consider how precision forging expertise translates across automotive components. Shaoyi (Ningbo) Metal Technology exemplifies the manufacturing standards buyers should seek, with IATF 16949 certification and rapid prototyping capabilities supporting automotive component manufacturing. Their quality control protocols and in-house engineering represent the precision forging standards that ensure component reliability across the industry. Understanding these benchmarks helps you evaluate whether your chosen wheel manufacturer operates at comparable levels.

Communication expectations vary significantly between manufacturers. Premium brands typically provide:

- Dedicated project managers or sales representatives

- Regular production updates with photography

- 3D renderings for design approval before machining begins

- Transparent lead time estimates with proactive delay notifications

- Detailed documentation including forging certificates and test reports

If a manufacturer cannot provide these basics, reconsider whether they truly operate at the level their pricing suggests. The best aftermarket wheels come from companies invested in customer experience, not just product output.

Finally, understand warranty terms before committing. Structural warranties typically cover manufacturing defects for 1-3 years, while finish warranties vary dramatically. Some premium manufacturers offer lifetime structural warranties, demonstrating confidence in their engineering. Others provide minimal coverage that should raise questions about quality consistency. Ask specifically about coverage for track use, as some warranties exclude competition or high-performance driving scenarios.

Your custom forged wheel investment represents both financial commitment and trust in a manufacturer's capabilities. By understanding procurement timelines, demanding appropriate certifications, and setting clear communication expectations, you ensure the wheels you receive match the quality your build deserves.

Frequently Asked Questions About Custom Forged Wheel Brands

1. What are the best replica wheel brands?

While replica wheels offer budget-friendly alternatives, they differ significantly from authentic forged wheels. Brands like Performance Replicas and Factory Reproductions provide OEM-style options at lower costs. However, genuine forged wheels from manufacturers like RAYS, Forgeline, or BC Forged deliver superior strength-to-weight ratios, better impact resistance, and certifications like JWL and VIA that replicas typically lack. For performance applications, investing in authentic forged construction provides measurable safety and durability advantages.

2. What wheel brands are made in the USA?

Several premium forged wheel manufacturers operate entirely within the United States. Forgeline produces all wheels at their Dayton, Ohio headquarters with over 100 styles available. American Racing's Forged line uses 6061 forged aluminum crafted domestically. American Force manufactures truck wheels in-house with 25+ CNC mills and proprietary polishing technology. HRE operates a TUV-certified facility in San Diego, California. These American manufacturers offer made-to-order customization, faster lead times for domestic buyers, and direct communication throughout the ordering process.

3. How can I verify if forged wheels are authentic?

Authentic forged wheel verification involves multiple checkpoints. First, examine pricing—genuine forged wheels cost $500-$3,000+ per wheel due to intensive manufacturing. Request forging certificates and alloy specifications from manufacturers. Check for JWL, VIA, or TÜV certifications, noting that VIA requires independent third-party testing. Compare stated weights against known benchmarks since forged wheels should weigh 25-30% less than cast alternatives. Inspect finish quality for multi-stage paint depth and precise machining lines. Legitimate manufacturers openly share production processes and facility details.

4. What is the difference between monoblock and multi-piece forged wheels?

Monoblock forged wheels are machined from a single aluminum block, creating the lightest option with no joints or fasteners to compromise integrity. Two-piece forged wheels combine a forged center with a spun-forged barrel, offering greater offset flexibility for custom fitments. Three-piece construction uses a forged center, inner barrel, and outer lip held together with perimeter bolts, providing maximum customization for lip width, finish combinations, and easier repair. Monoblock suits track applications prioritizing weight, while multi-piece designs excel for show cars requiring specific stance specifications.

5. Which forged wheel brands are best for trucks and off-road vehicles?

American Force dominates the premium truck segment with specialized 8-lug applications, CNC polishing technology, and load ratings exceeding 3,000 pounds per wheel. Fuel Forged and TIS Forged offer show-quality finishes for lifted builds. Method Race Wheels focuses on trail durability with patented Bead Grip technology enabling lower tire pressures. For dually wheels, American Force provides mirror-polish finishes with proper load ratings for towing. Always verify load capacity calculations—50% of your vehicle's gross axle weight rating per wheel—before purchasing for heavy-duty applications.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —