Custom Forged Connecting Rods: An Essential Buyer's Guide

TL;DR

Custom forged connecting rods are high-strength components essential for high-performance and modified engines. They offer superior durability over stock parts due to the forging process. The most critical decisions involve selecting the right material, such as 4340 chromoly steel or titanium, and the optimal design, typically between an H-Beam or I-Beam, to match your specific power goals and application.

Understanding the Fundamentals of Forged Connecting Rods

A connecting rod is the crucial link between the piston and the crankshaft in an internal combustion engine, converting the linear motion of the piston into the rotating motion of the crankshaft. In stock engines, these are often cast parts designed for standard operating conditions. However, for high-performance applications involving increased horsepower, torque, and RPM, a much stronger component is required. This is where the value of custom forged connecting rods becomes clear.

The forging process involves shaping metal using localized compressive forces, which aligns the grain structure of the material. This results in a component that is significantly stronger, more durable, and more resistant to fatigue and impact than a cast part, which has a more random grain structure. This superior strength is non-negotiable for engines that are turbocharged, supercharged, or built for competitive racing, where component failure can be catastrophic.

Custom rods become necessary when an engine's geometry is altered from its factory specifications. This includes changes to the crankshaft stroke, piston compression height, or cylinder bore. Off-the-shelf rods are designed for stock dimensions, but a custom-built engine requires rods with precise center-to-center lengths and end-bore dimensions to ensure proper geometry and function. As manufacturers like CP-Carrillo emphasize, creating these components is a symphony of precision involving specialists who strive for perfection in performance.

Key Materials Compared: 4340 Steel, Titanium, and Aluminum

The material chosen for a connecting rod directly impacts its performance, weight, and cost. Three materials dominate the high-performance market: 4340 chromoly steel, titanium, and specialized aluminum alloys. Each has distinct properties tailored to different applications, from street performance to professional motorsports.

4340 Chromoly Steel is the most common material for high-performance forged rods. It is an extremely strong and durable alloy that provides an excellent balance of performance and cost-effectiveness. Its robustness makes it suitable for a wide range of applications, including high-boost turbocharged engines and high-RPM naturally aspirated builds. Most major manufacturers, including Manley and SCAT, offer extensive lines of 4340 steel rods.

Titanium represents a significant step up in performance and cost. As noted by specialists like Pauter, titanium rods can be around 33% lighter than their steel counterparts while offering comparable strength. This drastic reduction in reciprocating mass allows the engine to rev faster and reduces stress on the crankshaft and bearings. This makes titanium the preferred choice for applications where every gram counts, such as professional road racing and drag racing.

Aluminum connecting rods are often used in dedicated drag racing applications. Modern aluminum alloys offer impressive strength for their low weight, but they have a finite fatigue life and are more susceptible to stretching over time compared to steel or titanium. This means they typically require more frequent inspection and replacement, making them less suitable for street or endurance applications but ideal for short-duration, high-power bursts.

| Material | Primary Advantage | Primary Disadvantage | Best Application |

|---|---|---|---|

| 4340 Chromoly Steel | High strength, durability, cost-effective | Heaviest of the three options | Street performance, turbo/supercharged builds, endurance racing |

| Titanium | Excellent strength-to-weight ratio | Very high cost | Professional racing, high-RPM engines, drag racing |

| Aluminum | Lightest weight, good for shock absorption | Limited fatigue life, requires regular replacement | Dedicated drag racing, alcohol/nitro engines |

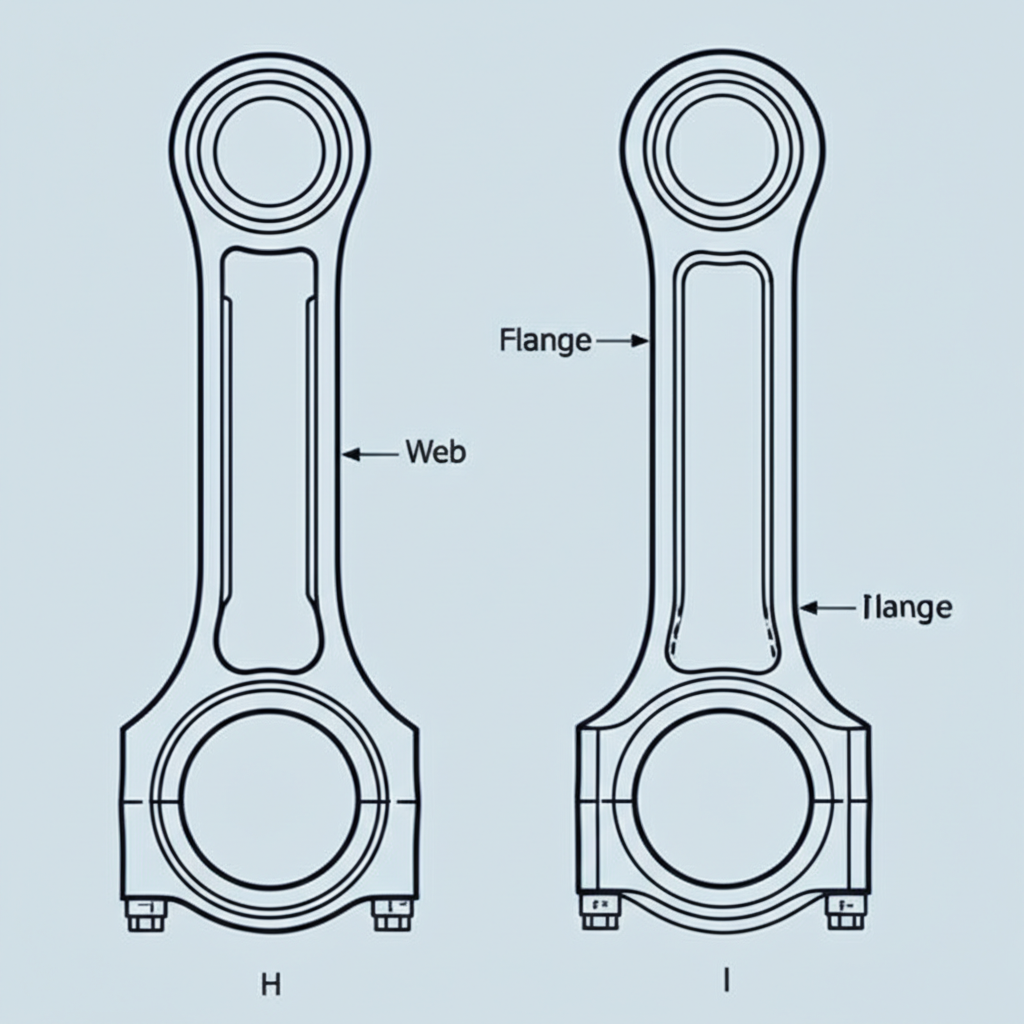

Choosing the Right Design: H-Beam vs. I-Beam

Beyond material, the structural design of the connecting rod is a critical choice. The two most prevalent designs in the performance market are the H-Beam and the I-Beam. While they may look similar to the untrained eye, their internal structures provide different characteristics regarding weight, rigidity, and stress distribution.

The H-Beam design, as its name suggests, has a cross-section shaped like the letter 'H'. This design is known for its excellent rigidity and resistance to bending forces, making it a versatile and popular choice for a wide array of high-performance applications. H-beam rods are often lighter than a comparable I-beam rod but are generally considered a robust, all-around option suitable for everything from aggressive street builds to serious racing engines. Many manufacturers offer extensive H-beam product lines for various engines.

The I-Beam design features a cross-section resembling the letter 'I'. This classic design has been refined over decades for motorsports use. A properly engineered I-beam rod can be made lighter than an H-beam rod without sacrificing strength where it matters most. They are exceptionally strong under tension (as the piston moves down) and compression (as it moves up). This efficiency makes them a preferred choice in very high-RPM and professional racing applications where minimizing reciprocating mass is paramount for performance and engine longevity.

Ultimately, the choice between H-beam and I-beam often comes down to the specific engine builder's philosophy and the application's demands. For most builds generating significant power over stock, either design from a reputable manufacturer will provide the necessary strength. However, for extreme competition use, the subtle weight and strength advantages of an I-beam might be the deciding factor.

The Custom Rod Inquiry Process: What to Expect

Ordering custom forged connecting rods is a precise process that requires detailed information about your engine to ensure a perfect fit. Manufacturers have streamlined this process, but the responsibility falls on the customer to provide accurate specifications. Based on the detailed requirements seen in forms like the Custom Rod Inquiry from ZRP, here is what you can expect:

- Gather Critical Engine Specifications: Before you can place an order, you must have all of your engine's critical dimensions. This is the most important step. Key measurements include engine make and model, cylinder bore size, crankshaft stroke, big end housing bore, and small end (wrist pin) bore.

- Define the Application and Power Level: You will need to specify how the engine will be used (e.g., street, drag race, road race) and its expected output. This includes details like maximum RPM, whether a turbocharger or supercharger will be used (and at what boost pressure), and if nitrous will be used (and the horsepower shot). This information helps the manufacturer select the appropriate material and design strength.

- Submit the Inquiry Form: With all your data in hand, you will fill out a detailed form on the manufacturer's website or through a dealer. You will input all the measurements and select any special features, such as forced pin oiling or specific bolt upgrades (like ARP 2000 or L19 bolts).

- Design, Approval, and Deposit: The manufacturer's engineers will review your specifications and may create a technical drawing for your approval. Once the design is finalized, a significant deposit (often 50%) is required to begin production. Be prepared for a lead time, as custom orders can take anywhere from a few weeks to several months depending on production schedules.

- Manufacturing and Delivery: Once the deposit is paid, the rods are manufactured to your exact specifications. After a final quality control check, the remaining balance is paid, and the rods are shipped to you or your engine builder.

Leading Manufacturers and Forging Specialists

The high-performance connecting rod market is served by several highly respected manufacturers, each with a reputation for quality and precision engineering. When investigating options, engine builders often turn to these industry leaders.

Manley Performance

Manley offers a vast catalog of connecting rods, including H-Beam and I-Beam designs. They are well-known for their "Turbo Tuff" series, specifically engineered to handle the extreme cylinder pressures of high-boost applications. Their products are made from 4340 steel forgings and are a staple in both the domestic and sport compact markets.

SCAT Crankshafts

Based in California, SCAT provides a wide assortment of H-Beam and I-Beam connecting rods made from a two-piece 4340 steel forging. They are a popular choice for many American V8 engine builds, from street performance to competitive racing, and are known for providing high-quality rotating assemblies.

CP-Carrillo

CP-Carrillo has built its reputation on a "no compromise" approach to engineering. They are recognized for their dimensional integrity and meticulous manufacturing process. Their rods are a top choice in professional motorsports, from drag racing to endurance events, where reliability and performance are paramount.

Pauter

Pauter is notable for its unique single-rib design E-4340 chrome-moly rods and its expertise in working with advanced materials. They offer custom-made rods in 4340 steel, aluminum, and titanium, catering to builders who require highly specific or lightweight components for their projects.

For those in the automotive industry looking for a partner in component creation, specialized forging services are also a key part of the supply chain. For robust and reliable components, many turn to providers of custom forging services like Shaoyi Metal Technology. They specialize in high-quality, IATF16949 certified hot forging for the automotive sector, offering services from rapid prototyping to mass production, demonstrating the industrial foundation that high-performance parts are built upon.

Frequently Asked Questions

1. Why are forged rods better than cast rods for performance engines?

Forged connecting rods are significantly stronger and more durable than cast rods. The forging process aligns the metal's grain structure, eliminating the internal voids and weaknesses common in castings. This makes forged rods highly resistant to the immense stress, high RPM, and increased cylinder pressures found in performance engines, preventing catastrophic failure.

2. What are the main design types of forged connecting rods?

The two primary designs are H-Beam and I-Beam. H-Beam rods are known for their rigidity and are a versatile choice for a wide range of high-horsepower applications. I-Beam rods are designed for incredible strength under compressive loads, making them a preferred choice for extreme horsepower engines using turbochargers, superchargers, or nitrous.

3. Do I need custom connecting rods for my engine?

You need custom connecting rods if you have modified your engine's internal geometry. If you have changed the crankshaft stroke, piston pin height, or require a non-standard length for any other reason, off-the-shelf rods will not work. Custom rods are made to your precise measurements to ensure correct and reliable engine operation.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —