Forged vs Machined Auto Parts: Strength or Precision?

TL;DR

When choosing between forged vs. machined automotive parts, the primary trade-off is between strength and precision. Forging creates stronger, more durable components ideal for high-stress applications by aligning the metal's internal grain structure. In contrast, machining offers superior precision for complex designs and is generally more cost-effective for prototypes and low-volume production runs.

Understanding the Core Manufacturing Processes

To make an informed decision, it is essential to understand the fundamental differences between forging and machining. These two methods shape metal in fundamentally opposite ways, which directly impacts the final component's performance, cost, and application suitability.

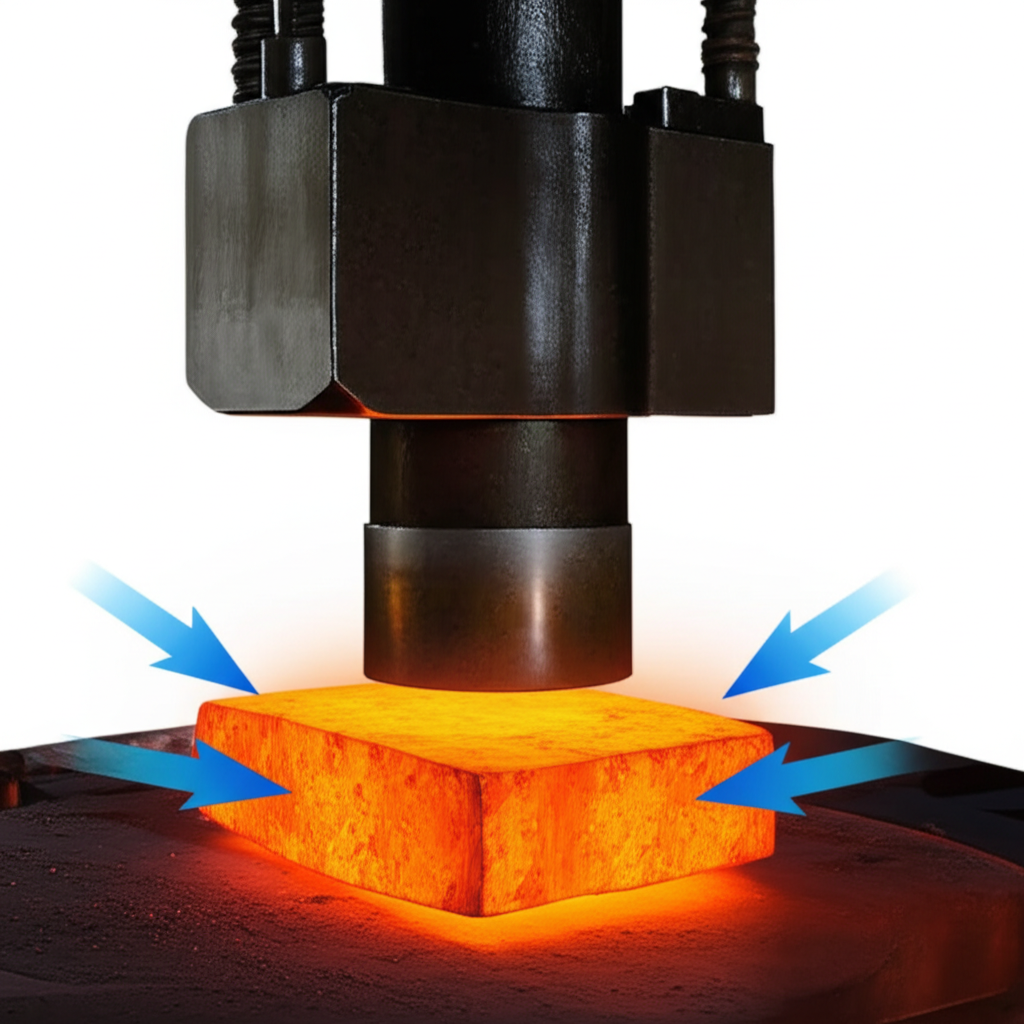

What Is Forging?

Forging is a manufacturing process that involves shaping metal using localized compressive forces. The metal is typically heated to a malleable temperature and then hammered or pressed into a die to form the desired shape. This method doesn't remove material but rather reshapes it, forcing the internal grain structure of the metal to align with the part's contour. This grain alignment is the primary reason forged parts exhibit exceptional strength and resistance to impact and fatigue. Think of it like the grain in a piece of wood; a long plank is strongest when the force is applied along the grain, not against it. Forging achieves a similar effect in metal.

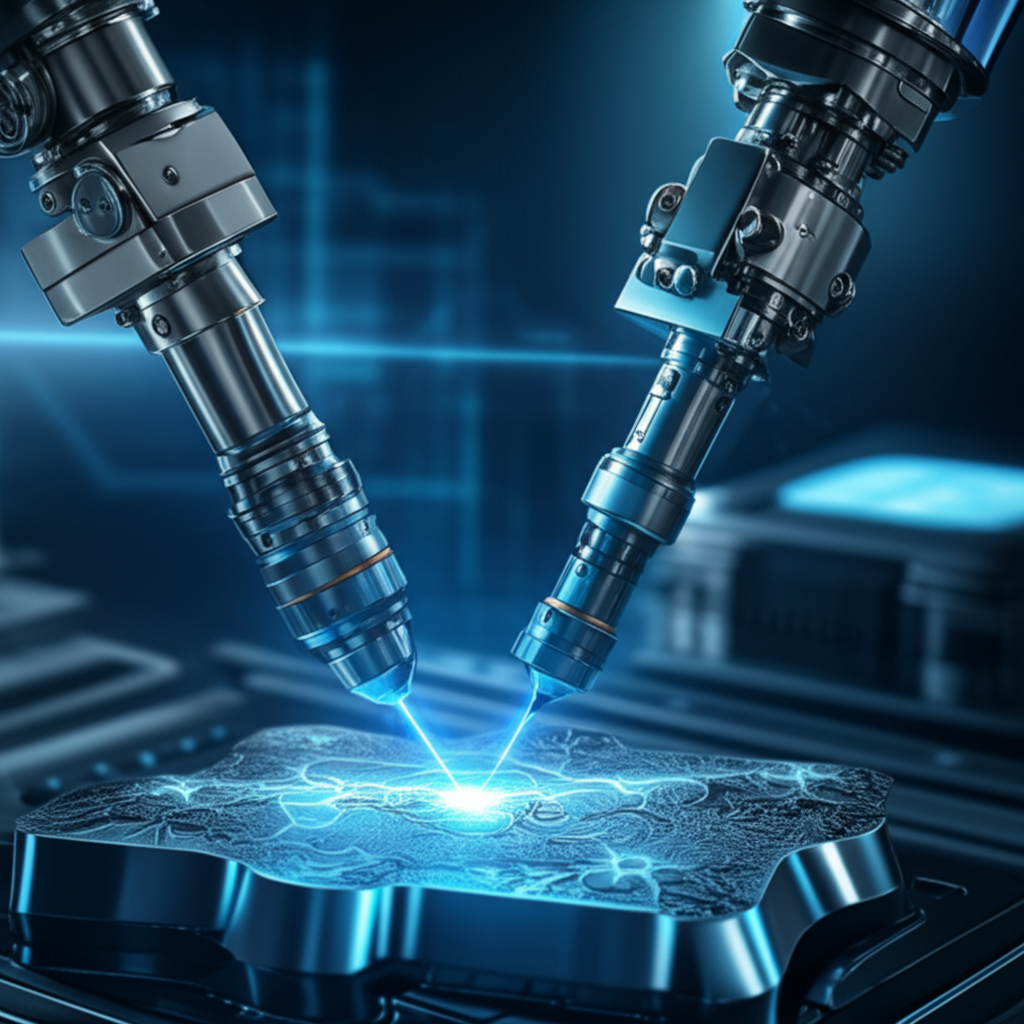

What Is Machining?

Machining is a subtractive process that starts with a solid block of metal, often called a billet, and cuts away material to achieve the final shape. This is typically performed using Computer Numerical Control (CNC) machines, which can execute highly precise and complex cuts, drills, and turns. Unlike forging, machining cuts through the metal's natural grain structure, which can create potential weak points. However, its major advantage lies in its ability to produce parts with extremely tight tolerances and intricate geometries that would be impossible to achieve through forging alone.

Structural Integrity: Why Forging Creates Stronger Parts

The single most significant advantage of forging in automotive applications is its ability to produce parts with superior mechanical properties. When a component is subjected to high stress, extreme temperatures, or repetitive impact—such as a crankshaft or connecting rod—structural integrity is non-negotiable. Forging delivers this reliability by fundamentally altering the metal's internal structure for the better.

The process of applying immense pressure refines the metal's grain structure, eliminating internal voids and porosity that can occur in other methods like casting. This creates a dense, uniform material. More importantly, it creates what is known as 'grain flow.' The metal's grains are elongated and forced to follow the shape of the component, creating continuous, unbroken lines of strength. This directional alignment dramatically improves several key properties:

- Tensile Strength: The ability to resist being pulled apart.

- Impact Resistance: The capacity to absorb sudden shocks without fracturing.

- Fatigue Life: The endurance to withstand repeated cycles of stress over time.

Because of this enhanced structural integrity, forged parts can often be designed to be lighter than their machined or cast counterparts without sacrificing strength. For automotive performance, where reducing unsprung weight is critical, this strength-to-weight ratio is a massive benefit.

Precision, Complexity, and Cost: Where Machining Excels

While forging wins on raw strength, machining dominates in applications demanding precision, design flexibility, and cost-effectiveness for smaller volumes. The subtractive nature of CNC machining allows for a level of detail and accuracy that forging cannot match on its own. For parts with complex internal channels, intricate surface features, or requirements for an exceptionally smooth finish, machining is often the only viable option.

The economic considerations also differ significantly. Forging requires the creation of expensive, hardened steel dies, representing a substantial upfront investment. This makes it most economical for high-volume production runs where the tooling cost can be amortized over thousands of units. In contrast, machining has minimal tooling costs and can be programmed quickly, making it ideal for prototypes, custom parts, or small production batches where flexibility is key.

For businesses requiring high-volume forged components, partnering with a specialized provider is essential to manage these complexities. For instance, for companies needing reliable, high-volume production, providers like Shaoyi Metal Technology offer specialized automotive forging services, from in-house die manufacturing to mass production, ensuring both IATF16949 certified quality and efficiency.

Here is a summary of the key trade-offs:

| Factor | Forging | Machining |

|---|---|---|

| Tooling Investment | High (requires custom dies) | Low (minimal tooling) |

| Per-Unit Cost (High Volume) | Lower | Higher |

| Per-Unit Cost (Low Volume) | Higher | Lower |

| Design Complexity | Moderate | Very High |

| Final Precision / Tolerances | Lower (often needs secondary machining) | Very High (micron level) |

| Material Waste | Low (near-net shape) | High (subtractive process) |

Application Guide: Choosing the Right Process for Automotive Parts

Translating these technical differences into practical decisions requires looking at specific automotive applications. The choice between forged vs. machined parts ultimately depends on the component's role, the stresses it will endure, and the production requirements.

Choose Forging for High-Stress, Critical Components

Forging is the undisputed choice for parts where failure could be catastrophic. These components are typically found in the engine, drivetrain, and suspension systems, where they are subjected to immense and continuous stress. The superior strength and fatigue resistance of forged parts ensure long-term reliability and safety. Common examples include:

- Crankshafts and Connecting Rods: These endure constant rotational and reciprocating forces inside the engine.

- Gears and Transmission Shafts: Must handle high torque and wear.

- Steering Knuckles and Control Arms: Critical for vehicle safety and handling.

- Wheel Hubs and Axle Components: Support the vehicle's weight and absorb road impacts.

Opt for Machining for Prototypes and Intricate Designs

Machining is the ideal solution for parts where precision is more critical than ultimate strength, or when production volumes are low. Its flexibility allows engineers to quickly create and iterate on designs without committing to expensive tooling. It is also essential for creating complex shapes that cannot be forged. Typical applications include:

- Custom Brackets and Mounts: Often require specific geometries for unique builds.

- Complex Housings: Such as those for electronic control units (ECUs) or sensors.

- Prototype Parts: For testing fit and function before committing to mass production.

- Aftermarket Performance Parts: Where customization and low-volume production are common.

In many cases, a hybrid approach is used where a part is first forged to achieve its basic shape and strength, then finish-machined to achieve the precise final dimensions and features. This combines the best of both worlds, delivering a strong and precise component.

Making the Final Decision

Selecting between forged and machined automotive parts is a critical engineering and business decision. Forging delivers unparalleled strength and durability for high-stress, high-volume components by optimizing the metal's grain structure. Machining provides superior precision, design flexibility, and cost-effectiveness for prototypes, custom work, and complex parts. By carefully evaluating the specific application's mechanical demands, production volume, design complexity, and budget, manufacturers can choose the process that delivers the optimal balance of performance and value.

Frequently Asked Questions

1. What are the advantages of forging over machining?

The primary advantage of forging is superior mechanical strength. The forging process aligns the metal's grain structure, enhancing its tensile strength, impact resistance, and fatigue life. It is also more cost-effective for high-volume production and results in less material waste compared to the subtractive process of machining.

2. Are forged parts better?

Forged parts are better in applications where strength, durability, and resistance to high stress or impact are the most important factors. For components like engine crankshafts or suspension parts, forging is superior. However, for parts requiring extreme precision, intricate designs, or for low-volume production, machined parts are often the better choice.

3. What are the disadvantages of forged steel?

The main disadvantages of forging include high initial tooling costs for dies, which can make it expensive for small production runs. The process also offers less dimensional precision and control over the final shape compared to machining, often requiring secondary machining operations to meet tight tolerances. Additionally, it is not suitable for creating parts with very complex internal geometries.

4. Why is milling and turning (machining) better than forging?

Machining, which includes milling and turning, is better than forging when high precision, tight tolerances, and complex geometric shapes are required. It is also more flexible and cost-effective for prototyping and small-batch production because it does not require expensive custom tooling. For components that are not subjected to extreme stress, machining provides an effective and affordable manufacturing solution.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —