Custom Forged Brake Calipers Advantages: From Metallurgy To Track

Understanding Custom Forged Brake Calipers and Why They Matter

When milliseconds separate a podium finish from the rest of the pack, or when hauling a heavy load down a mountain grade demands absolute confidence in your brakes, serious automotive enthusiasts and professionals refuse to settle for mass-produced alternatives. They turn to custom forged brake calipers. But what exactly makes these components the gold standard for performance brake calipers?

A custom forged brake caliper represents the intersection of two powerful concepts: personalized engineering specifications tailored to your exact application and the superior metallurgical properties that only the forging process can deliver. Unlike off-the-shelf aftermarket brake calipers, these components are designed around your vehicle's weight, intended use, and performance goals.

Why Forging Changes Everything in Brake Caliper Manufacturing

Imagine a blacksmith hammering red-hot metal into shape. The forging process works on the same principle but with immense hydraulic pressure. According to KTG Auto, heated aluminum billets are compressed under extreme force, aligning the metal's internal grain structure while eliminating porosity and internal defects. This creates a denser, stronger component compared to cast alternatives where molten metal is simply poured into molds.

The result? Forged calipers deliver exceptional strength-to-weight ratios and maintain structural integrity under the punishing conditions of repeated high-temperature braking cycles. When reading an a-premium brake caliper review or evaluating any brake component, understanding this fundamental manufacturing difference helps you recognize why forged options command premium pricing.

The Custom Advantage: Beyond Off-the-Shelf Performance Parts

Here's what separates truly custom brake calipers from standard performance upgrades. When you spec a custom forged caliper, you're not just selecting from predetermined options. You're working with engineers to optimize bore sizes, piston configurations, mounting geometry, and material grades specifically for your application.

What are good brake calipers for your build? That depends entirely on your unique requirements. A weekend track warrior needs different specifications than someone towing heavy loads through mountain passes. Custom forging bridges this gap by delivering both the manufacturing excellence of forged components and the precision tailoring that mass production cannot offer.

Throughout this article, you'll gain the metallurgical knowledge and practical insights needed to understand why forging creates superior brake components and how custom specifications transform that potential into real-world performance advantages.

The Metallurgical Science Behind Forged Caliper Superiority

Ever wonder why professional racing teams obsess over manufacturing methods when selecting automotive brake calipers? The answer lies deep within the metal itself. Understanding what brake calipers do under extreme stress reveals why the forging process creates fundamentally superior components. Let's break down the science that separates good brake calipers from exceptional ones.

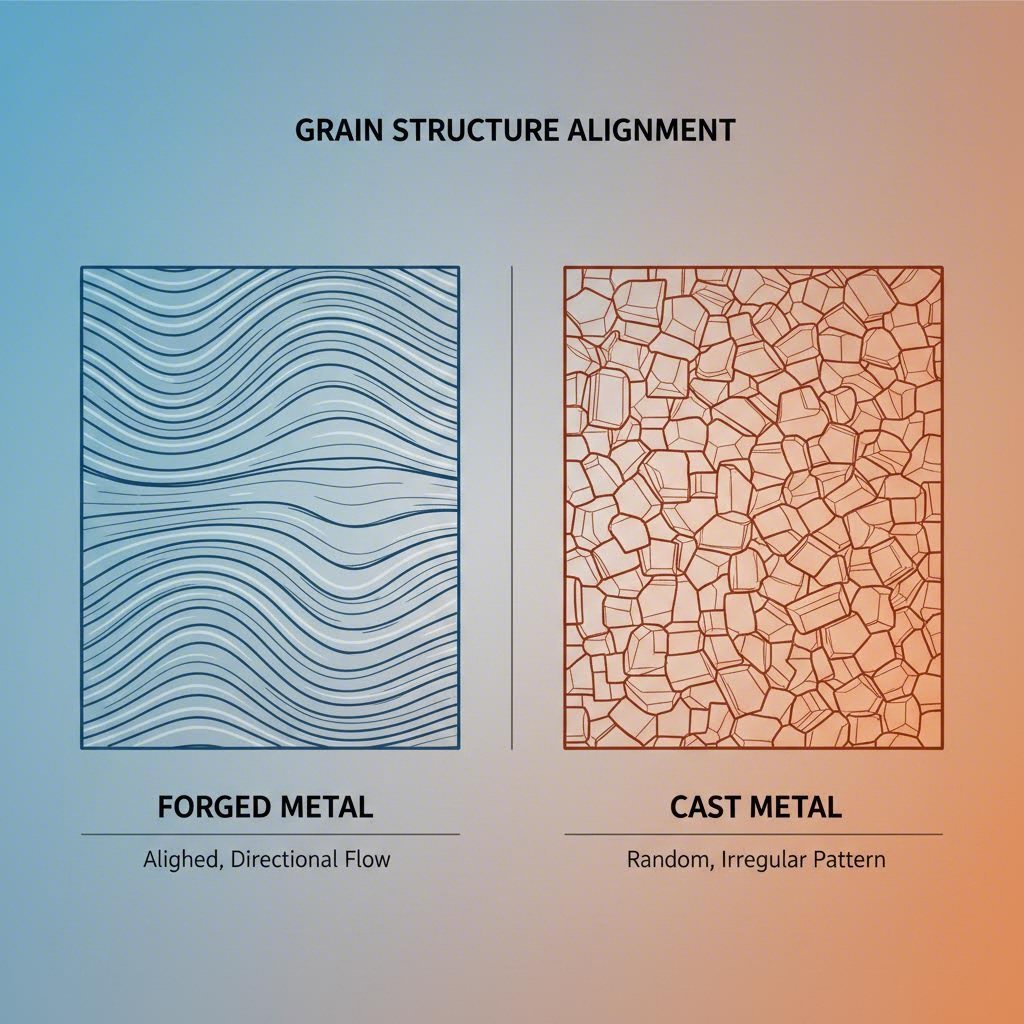

When a heated aluminum or steel billet enters a forging press, something remarkable happens at the molecular level. According to Trenton Forging, the grain structure of metal refers to how the underlying lattice structure solidifies and orients within the material. Forging doesn't just shape metal - it transforms its internal architecture.

Grain Structure Alignment and What It Means for Strength

Picture the grains in metal like the fibers in wood. Just as wood is strongest along its grain direction, metal exhibits directional strength based on how its crystalline grains align. Here's where forging truly shines.

During the forging process, metal undergoes controlled deformation under elevated temperatures. The compressive forces deliberately align grains in the direction of maximum strength. As Trenton Forging explains, this produces components with exceptional fatigue and impact resistance because the grain flow can be controlled to match the stress requirements of the finished part.

For brake calipers, this means the internal grain structure follows the contours of the caliper body, reinforcing the areas that experience the highest stress during hard braking. When you're exploring options like a brembo caliper rebuild kit for maintenance, understanding this grain advantage helps explain why forged bodies outlast their cast counterparts.

What's calipers' biggest enemy during aggressive braking? Repeated stress cycles that eventually cause fatigue failure. Forged components resist this because their continuous grain flow eliminates weak points where cracks typically initiate.

Porosity Elimination Through Compression Forging

Sounds complex? Think of porosity as microscopic air bubbles trapped within metal. In cast components, these voids form naturally as molten metal solidifies. According to The Federal Group USA, castings are more prone to defects like voids, cavities, and shrinkage because of how molten metal solidifies in the mold.

Forging eliminates this problem through sheer compressive force. When thousands of tons of pressure squeeze heated metal into shape, any potential voids are literally crushed out of existence. The result is near-perfect density throughout the component.

Why does this matter for your brakes? Each microscopic void represents a potential stress concentrator - a weak point where cracks can originate under repeated thermal and mechanical cycling. Forged calipers start life without these hidden flaws, providing a more reliable foundation for demanding applications.

Here's how the three primary manufacturing methods compare in their metallurgical outcomes:

- Forging (Compression Forming): Heated billets compressed under extreme pressure. Results in aligned grain structure, eliminated porosity, superior density, and exceptional fatigue resistance. Grain flow follows component contours for directional strength.

- Casting (Molten Pour): Molten metal poured into molds and allowed to solidify. Creates isotropic properties (uniform in all directions) but produces random grain orientation, potential voids and shrinkage defects, and lower overall density. Better suited for complex geometries where strength is less critical.

- Billet Machining (Subtractive): Solid metal blocks machined to final shape. Maintains pre-worked grain structure but cutting exposes grain ends, potentially compromising fatigue resistance. As Trenton Forging notes, machining often cuts through the unidirectional grain flow pattern, making the material more prone to stress corrosion cracks.

The strength-to-weight ratio advantages of forged automotive brake calipers stem directly from this grain alignment. Because forged metal is denser and stronger in the directions that matter, engineers can design thinner walls and remove more material without sacrificing structural integrity. You get lighter components that actually outperform heavier cast alternatives.

This metallurgical superiority translates directly to performance where it counts - on the track and on the street. With the science established, the next logical question becomes how these manufacturing differences play out across specific performance metrics like weight, heat management, and durability under real-world conditions.

Forged vs Cast vs Billet Brake Calipers Compared

Now that you understand the metallurgical foundations, how do these manufacturing differences translate into measurable performance advantages? When evaluating different kinds of calipers for your build, having concrete comparisons across key performance dimensions makes the decision clearer. Let's examine how forged, cast, and billet brake calipers stack up when it matters most.

The following table provides a comprehensive comparison across the metrics that serious enthusiasts and professionals care about:

| Performance Dimension | Forged Calipers | Cast Calipers | Billet Calipers |

|---|---|---|---|

| Weight Characteristics | Lightest option due to optimized density allowing thinner walls without strength loss | Heaviest; requires thicker walls to compensate for lower material strength | Moderate weight; depends heavily on design and material removal during machining |

| Structural Integrity | Superior; aligned grain structure provides exceptional rigidity under load | Adequate for street use; may exhibit slight deformation under extreme braking | Good strength but machining cuts through grain flow, creating potential weak points |

| Heat Management | Excellent; dense material structure promotes efficient heat dissipation | Reduced efficiency; internal porosity can trap heat and slow thermal transfer | Good thermal properties; solid material conducts heat well |

| Fatigue Resistance | Outstanding; continuous grain flow eliminates crack initiation points | Lower; microscopic voids serve as stress concentrators over time | Moderate; exposed grain ends can develop stress corrosion cracks |

| Typical Applications | Professional racing, high-performance street cars, track day vehicles | Standard passenger vehicles, daily drivers, budget-friendly upgrades | Custom show cars, limited production runs, specialized applications |

Weight Savings Without Compromising Structural Integrity

You'll notice something counterintuitive when examining what are calipers on cars built for serious performance: the strongest options are often the lightest. How is this possible?

Forged calipers achieve this through density optimization. According to EATHU Metals, the forging process refines the grain structure, making it denser while simultaneously increasing strength. This means engineers can confidently design thinner caliper walls and strategically remove material from non-critical areas without worrying about structural failure.

The principle works like this: when material strength increases, you need less of it to handle the same loads. Forged fixed calipers can feature aggressive weight-reduction machining after forging because the underlying metal can handle it. Cast calipers require thicker, heavier construction to achieve comparable strength ratings.

For track applications where unsprung weight directly impacts handling responsiveness, this advantage compounds. Lighter calipers mean your suspension can react faster to surface changes, improving both grip and driver feedback. Premium options like rear Brembo calipers on high-performance vehicles leverage forging specifically to achieve this balance of strength and weight savings.

Heat Dissipation Characteristics Across Manufacturing Methods

Imagine pushing hard through a mountain descent or completing multiple hot laps at your local circuit. Your brakes convert kinetic energy into heat - enormous amounts of it. How efficiently your calipers manage this thermal load determines whether you maintain consistent stopping power or experience dangerous brake fade.

Forging specifically benefits brake caliper performance during repeated thermal cycling in two critical ways:

- Dense Material Promotes Faster Heat Transfer: Without internal voids to interrupt thermal pathways, heat moves efficiently through forged caliper bodies to the surrounding air. EATHU Metals notes that forged calipers exhibit superior heat dissipation due to their dense material structure, helping lower brake fluid temperatures and maintain system stability.

- Structural Stability Under Thermal Stress: Forged calipers maintain their rigidity even when temperatures climb. This ensures consistent pad-to-rotor contact throughout hard braking sessions, preventing the uneven wear and reduced performance that occurs when lesser calipers flex under heat.

Cast calipers face a double disadvantage here. Their internal porosity not only reduces heat transfer efficiency but can also trap heat in localized areas. During intense braking, this leads to uneven thermal expansion and accelerated brake fade - exactly when you need your brakes most.

How Design Type Influences Forging Benefits

When comparing floating calipers vs fixed designs, forging enhances each type differently. Understanding these distinctions helps you match manufacturing method to your specific application.

Fixed Calipers: These designs clamp the rotor from both sides with pistons on each half. Forging benefits fixed calipers by providing the extreme rigidity needed to prevent body flex under high clamping forces. According to EATHU Metals, forged brake calipers are more rigid, reducing elastic deformation during braking and ensuring tighter, more stable contact between brake pads and rotor. This translates to faster braking response and more direct force transmission - critical for track applications.

Floating Calipers: These single-sided designs rely on sliding pins to center over the rotor. While simpler and lighter, floating calipers still benefit from forging through improved thermal stability and fatigue resistance. The sliding mechanism experiences less binding when the caliper body maintains dimensional stability under heat cycling.

For demanding applications like dedicated track cars or heavy-duty towing, forged fixed calipers represent the performance benchmark. They combine the inherent advantages of multi-piston fixed designs with the metallurgical superiority of forging. Speaking of pistons, the relationship between forging and advanced piston configurations opens another dimension of performance optimization worth exploring.

Piston Configurations and Custom Specification Options

Here's where custom forged brake calipers truly separate themselves from off-the-shelf alternatives: piston configuration flexibility. You've probably seen references to a Brembo 4 piston caliper or 6 piston Brembo calipers in performance catalogs, but have you considered why forging specifically enables these advanced multi-piston designs to perform at their peak?

The answer lies in structural rigidity. When multiple pistons push against brake pads simultaneously, they generate enormous clamping forces that try to spread the caliper body apart. Inferior caliper bodies flex under this load, reducing braking efficiency and creating inconsistent pad contact. Forged bodies resist this deformation, allowing engineers to push piston counts and bore sizes to levels that would compromise lesser designs.

How Forging Enables Advanced Multi-Piston Designs

Imagine squeezing a cardboard box versus an aluminum block. Which one maintains its shape under pressure? The same principle applies to high performance brake calipers. When you're running 6 or 8 pistons generating combined clamping forces measured in thousands of pounds, the caliper body must remain absolutely rigid.

Forged caliper bodies deliver this rigidity through their aligned grain structure and eliminated porosity. The continuous grain flow creates a unified structural framework that distributes stress evenly throughout the caliper. This means:

- Zero Flex Under Load: Forged bodies maintain dimensional stability even during maximum braking force application, ensuring all pistons apply equal pressure to the pads.

- Consistent Pad Contact: Without body distortion, brake pads remain flat against the rotor surface, maximizing friction material engagement and heat distribution.

- Predictable Pedal Feel: Rigid caliper bodies eliminate the spongy sensation that occurs when lesser materials flex, delivering the direct feedback performance drivers demand.

- Extended Component Life: Reduced flex means less fatigue cycling of the caliper body, extending service life even under aggressive track use.

Premium performance calipers like premium monoblock designs showcase what becomes possible when high-end engineering meets advanced material science. These designs leverage optimized structural geometry to support aggressive piston configurations while maintaining featherweight construction.

Matching Piston Configuration to Your Driving Demands

So how do you choose the right piston count for your application? More isn't always better - it's about matching configuration to your specific requirements. Here's a breakdown of common piston configurations and their ideal applications:

- 2-Piston Designs: Best suited for lightweight vehicles, rear axle applications, and street-focused builds where simplicity and cost-effectiveness matter. Adequate clamping force for daily driving with occasional spirited use.

- 4-Piston Designs: The sweet spot for enthusiast street cars and light track duty. Provides excellent pad coverage and clamping force while keeping weight manageable. A solid choice for performance street driving.

- 6-Piston Designs: Ideal for dedicated track vehicles, heavier performance cars, and drivers who regularly push their brakes to the limit. The additional pistons distribute clamping force more evenly across larger pad surfaces.

- 8-Piston Designs: Reserved for professional racing applications, heavy vehicles requiring maximum stopping power, and specialized builds where ultimate braking performance justifies the complexity and cost.

Beyond piston count, custom forged calipers offer specification options that mass-produced alternatives simply cannot match. This is where the "custom" in custom forged brake calipers delivers real-world advantages.

Bore Size Optimization: Piston diameter directly affects clamping force and pedal feel. Larger bores generate more force but require more pedal pressure and fluid volume. Custom specifications allow you to dial in the exact bore sizes that balance stopping power with pedal effort for your driving style.

Piston Staging: Advanced multi-piston calipers often use progressively sized pistons - smaller at the leading edge, larger at the trailing edge. This staging compensates for pad taper wear and maintains even pad contact throughout the braking event. Custom forged designs let you specify staging ratios optimized for your specific pad compounds and rotor sizes.

Vehicle Weight and Brake Bias: A 2,400-pound track car needs vastly different brake specifications than a 4,500-pound performance sedan. Custom specifications account for your vehicle's weight distribution, allowing precise front-to-rear brake bias tuning that enhances both stopping power and stability under hard braking.

The forging advantage becomes even more pronounced when you consider that aggressive piston configurations demand corresponding structural integrity. Each additional piston adds stress points that would challenge cast or billet alternatives. Forged bodies handle these loads without compromise, making them the foundation of choice for serious brake system upgrades.

With piston configurations and custom specifications understood, the next step is exploring how these advantages translate across different vehicle applications - from street performance builds to dedicated track machines and heavy-duty workhorses.

Application-Specific Benefits Across Vehicle Types

Now that you understand the metallurgical science and piston configurations, here's the question that really matters: does your specific application actually warrant the investment in custom forged brake calipers? The honest answer depends entirely on how you use your vehicle. Let's break down the considerations for each major application type so you can make an informed decision.

Track Day Warriors vs Street Performance Builds

Picture yourself rolling into the paddock for your monthly track day. Your brakes will endure dozens of hard stops from triple-digit speeds, with minimal cooling time between sessions. Now compare that to your spirited weekend drive through mountain roads. Both scenarios demand upgraded brake calipers, but the requirements differ dramatically.

Performance Street Driving Considerations:

- Thermal Demands: Street driving involves intermittent hard braking with extended cooling periods. While forged calipers provide superior heat management, standard performance brake kits with calipers may suffice for occasional aggressive use.

- Weight Sensitivity: Street performance builds benefit from reduced unsprung weight, but the handling improvements are less noticeable than on a dedicated track car. The weight savings remain valuable but not critical.

- Daily Livability: Consider cold-weather performance and noise levels. Custom forged designs can be specified with bore sizes that maintain comfortable pedal feel for daily driving while still delivering when pushed.

- Budget Reality: If your performance driving is limited to weekend canyon runs and the occasional autocross event, premium performance calipers from established manufacturers may deliver sufficient capability without the custom premium.

Dedicated Track Day Vehicle Considerations:

- Sustained Heat Cycling: Multiple back-to-back sessions push brake temperatures far beyond street driving scenarios. Forged calipers maintain rigidity and consistent performance when lesser components start flexing and fading.

- Aggressive Pad Compounds: Track-focused pads generate extreme clamping forces and temperatures. The structural integrity of forged bodies prevents the caliper distortion that compromises pad contact with high-performance compounds.

- Reduced Unsprung Weight: Every pound matters on track. The weight savings from forged construction directly translate to improved lap times through better suspension response and reduced rotational mass.

- Rebuild Economics: Serious track users rebuild calipers regularly. Forged bodies withstand more rebuild cycles without fatigue degradation, improving long-term cost-effectiveness despite higher initial investment.

For enthusiasts running vehicles like a Dodge Charger with Brembo calipers from the factory, upgrading to custom forged units makes sense when you're consistently pushing beyond what the OEM equipment can handle. If you're experiencing brake fade after two or three hot laps, that's your signal that forged construction could transform your track experience.

Heavy-Duty Applications Where Forged Strength Shines

When you think about custom forged brake caliper advantages, motorsport applications probably come to mind first. But some of the most compelling use cases exist in the heavy-duty segment where brake system upgrades can mean the difference between a controlled descent and a terrifying runaway situation.

Towing and Hauling Considerations:

- Sustained Load Braking: Descending mountain grades with a heavy trailer creates prolonged brake heat buildup that overwhelms conventional systems. Forged calipers' superior heat dissipation maintains stopping power when you need it most.

- Increased Clamping Requirements: Heavier vehicles demand higher clamping forces. The structural rigidity of forged bodies ensures consistent force application even with aggressive piston configurations needed for heavy loads.

- Fatigue Resistance Under Repetitive Stress: Commercial and heavy-duty applications involve thousands of braking cycles under load. Forged components resist the fatigue cracking that can develop in cast alternatives over extended service life.

- Safety Margin: When towing at or near capacity limits, having brakes that maintain full capability throughout the journey isn't just about performance - it's about arriving safely.

Professional Racing Applications:

- Non-Negotiable Reliability: At the professional level, brake failure isn't just inconvenient - it's potentially catastrophic. Forged calipers' eliminated porosity and aligned grain structure provide the reliability margin that racing demands.

- Precise Specification Control: Professional teams require exact brake balance tuning for different tracks and conditions. Custom forged calipers allow specification of precise bore sizes and piston staging that off-the-shelf options cannot match.

- Maximum Performance Envelope: When tenths of seconds determine race outcomes, the rigidity and weight advantages of forged construction deliver measurable competitive advantages.

- High Performance Brake Discs Integration: Racing applications typically pair premium calipers with carbon-ceramic or specialized iron rotors. Forged caliper mounting precision ensures optimal rotor engagement with these expensive brake disc investments.

Ford Performance brakes packages for Mustang track variants demonstrate how manufacturers recognize the connection between serious performance and forged construction. When factory engineers specify forged calipers for their highest-performance offerings, it validates the technology's real-world advantages.

Making the Right Investment Decision

Here's the decision framework that helps you determine when custom forged calipers justify the investment:

| Factor | Standard Performance Calipers May Suffice | Custom Forged Calipers Recommended |

|---|---|---|

| Track Frequency | 1-3 track days per year | Monthly track days or racing series participation |

| Vehicle Weight | Under 3,500 lbs with moderate power | Over 3,500 lbs or high power-to-weight ratios |

| Driving Intensity | Occasional spirited driving, autocross | Consistent limit driving, wheel-to-wheel racing |

| Current Brake Issues | Wanting better feel or appearance | Experiencing fade, inconsistent performance, or caliper flex |

| Towing/Hauling | Occasional light loads on flat terrain | Regular heavy towing, mountain driving with loads |

| Performance Goals | Improved street performance | Competitive lap times, maximum safety margin |

Be honest with yourself about your actual use case. A custom forged caliper setup delivering a 15% improvement in fade resistance provides minimal real-world benefit if you never push your brakes hard enough to experience fade in the first place. Conversely, if you're leaving performance on the table because your brakes can't keep up with your driving, the investment in forged construction pays dividends every time you hit the track.

Understanding where your application falls on this spectrum is essential preparation for the next step: navigating the custom ordering process and knowing what questions to ask when specifying your ideal brake caliper setup.

The Custom Ordering Process and What Buyers Need to Know

You've decided that custom forged brake calipers align with your performance goals. Now comes the critical next step: navigating the custom ordering process without getting overwhelmed or making costly specification errors. How much are brake calipers going to cost for your specific application? What information do you need before contacting manufacturers? Let's demystify this process so you can approach suppliers with confidence.

Unlike ordering standard aftermarket parts where you simply match a part number to your vehicle, custom forged calipers require a consultative approach. You're essentially partnering with engineers to create a component tailored to your exact requirements. The quality of that partnership - and the final product - depends largely on your preparation.

Critical Questions for Your Custom Caliper Manufacturer

Walking into a manufacturer conversation unprepared is like visiting a tailor without knowing your measurements. Before committing to any supplier, you need answers to these essential questions:

- Material Grade Options: What aluminum alloys or steel grades does the manufacturer offer? Common options include 6061-T6 and 7075-T6 aluminum, each with different strength-to-weight characteristics. Higher-grade materials typically command premium pricing but deliver measurable performance advantages.

- Heat Treatment Processes: How does the manufacturer process calipers after forging? According to GDST Brake Calipers, after casting or forging, brake caliper bodies undergo heat treatment to enhance strength and durability, ensuring they can withstand high temperatures and mechanical stress during braking. Ask specifically about T6 tempering for aluminum or case hardening for steel components.

- Quality Certifications: Does the manufacturer hold IATF 16949 certification? This automotive-specific quality management standard demonstrates rigorous process control and traceability. Manufacturers like Shaoyi (Ningbo) Metal Technology maintain this certification, indicating their commitment to consistent quality across production runs.

- Testing Protocols: What validation does each caliper undergo before shipping? Reputable manufacturers perform pressure testing for leaks, dimensional inspections, and piston movement verification. Some also conduct salt spray testing for corrosion resistance and high-temperature testing for heat tolerance.

- Lead Times and Prototyping: How long from order to delivery? Can they provide rapid prototypes for fitment verification? Some manufacturers offer prototyping capabilities in as little as 10 days, which can accelerate your custom development significantly.

- Minimum Order Quantities: What's the MOQ for custom specifications? According to industry standards, MOQs for custom brake calipers typically range from 50-100 pieces per model, though some manufacturers accommodate smaller initial orders for new clients.

- Warranty Coverage: What defects are covered and for how long? Quality manufacturers typically offer 12-month or 30,000-kilometer warranties on their brake calipers.

Understanding Lead Times and Production Realities

When budgeting for custom forged calipers, timing matters as much as cost. Standard delivery times run approximately 40-45 days after order confirmation for production runs. However, the complete timeline from initial inquiry to installed calipers involves several phases:

Phase 1 - Specification Development (1-3 weeks): You'll work with engineers to finalize bore sizes, piston configurations, mounting geometry, and material selections. This collaborative phase determines everything about your final product.

Phase 2 - Prototyping (Optional but Recommended): For complex applications, having a prototype manufactured for fitment verification prevents expensive production errors. Rapid prototyping from specialized manufacturers can deliver test units in as few as 10 days.

Phase 3 - Production (40-45 days typical): Once specifications are locked, production begins. This includes forging, heat treatment, CNC machining, surface treatment, assembly, and quality control testing.

Phase 4 - Shipping and Delivery (1-2 weeks international): Manufacturers located near major shipping hubs, such as those near Ningbo Port, can expedite global delivery logistics.

Preparing Your Specification Package

Before contacting manufacturers, gather this information to streamline the consultation process:

- Vehicle Specifications: Year, make, model, weight, power output, and any suspension or chassis modifications that might affect brake geometry.

- Intended Use Profile: Be specific about your driving mix - percentage of street driving versus track time, typical track lengths, session durations, and whether you participate in timed competition.

- Mounting Constraints: Wheel diameter and offset, existing rotor sizes, and any clearance limitations from suspension components or wheel designs.

- Current System Issues: What problems are you solving? Brake fade, inconsistent pedal feel, caliper flex, or simply upgrading for increased capability?

- Aesthetic Preferences: Color requirements, finish type preferences, and whether you want custom branding or specific visual elements.

Cost Considerations and Value Proposition

Let's address the elephant in the room: how much are calipers for cars when you're going the custom forged route? The honest answer is that custom forged brake calipers represent a significant investment compared to off-the-shelf alternatives. When comparing caliper Brembo price points to custom specifications, expect custom forged options to command premiums ranging from 30% to over 100% depending on complexity.

However, calipers car cost calculations should factor in more than initial purchase price:

- Longevity: Forged calipers survive more rebuild cycles than cast alternatives, reducing long-term replacement costs for serious track users.

- Performance Optimization: Custom specifications eliminate the compromise inherent in off-the-shelf sizing, potentially improving lap times or reducing stopping distances measurably.

- Resale Value: Well-documented custom brake systems from certified manufacturers can enhance vehicle resale value, particularly for track-focused builds.

- Safety Margin: The peace of mind from knowing your brakes were engineered specifically for your application has real value, especially in demanding conditions.

Many enthusiasts wonder about painting brake calipers near me versus factory finishing options. While aftermarket caliper painting services are widely available, custom manufacturers typically offer professional powder coating, anodizing, or high-temperature paint as part of the production process. How much to paint brake calipers separately can range from $50-200 per caliper, making factory finishing during production often more cost-effective for custom orders.

The key to maximizing your custom forged caliper investment is thorough preparation before the first manufacturer conversation. Know your specifications, understand your priorities, and partner with certified manufacturers who can guide you through the engineering decisions.

With your specification package prepared and manufacturer questions ready, you're positioned to make informed decisions about your custom brake caliper project. The final consideration before committing involves aesthetic customization options that complement the performance advantages you've invested in.

Aesthetic Customization and Professional Finishing

You've invested in custom forged brake calipers engineered for your exact specifications. Now comes a question that blends form with function: how do you finish these premium components? The right finishing choice protects your investment while making a visual statement every time someone peers through your wheels. But here's what many enthusiasts miss - finishing decisions for forged calipers involve more than just picking your favorite color.

Unlike mass-produced alternatives, custom forged calipers warrant professional finishing that matches their premium construction. According to Carzwerk, brake caliper paint serves as a protective barrier against dirt, grime, and heat generated from intense braking. For forged components designed to endure track temperatures and repeated thermal cycling, the finishing method you choose directly impacts both longevity and performance.

Professional Finishing Options for Forged Calipers

Three primary finishing methods dominate the custom brake caliper market, each with distinct advantages depending on your application. Understanding these differences helps you make an informed decision rather than simply defaulting to the most familiar option.

| Finishing Method | Durability | Heat Resistance | Color Options | Cost Considerations |

|---|---|---|---|---|

| Anodizing | Excellent - creates integral oxide layer that won't chip or peel | Outstanding - withstands 1,200°F+ without degradation | Limited palette; blacks, silvers, and some colors; depends on alloy | Moderate to high; requires specialized equipment and expertise |

| Powder Coating | Very good - thicker than paint, highly chip-resistant | Good - most formulations handle 400-500°F; high-temp versions available | Extensive; virtually unlimited color matching possible | Moderate; professional application recommended for best results |

| High-Temperature Paint | Good - requires proper prep and may need touch-ups over time | Very good - quality auto caliper paint withstands 900°F+ | Wide selection; most accessible color variety | Lowest initial cost; DIY possible but professional yields better results |

Anodizing stands apart because it doesn't add a coating - it transforms the aluminum surface itself. According to Products Finishing, anodized surfaces increase corrosion protection, wear resistance, and improve appearance. The oxide layer becomes part of the metal rather than sitting on top, which explains why anodized finishes won't chip or flake even under aggressive track use. For aluminum forged calipers, this process creates exceptional durability with heat resistance that exceeds any applied coating.

Powder coating offers the best balance of durability and color flexibility. The electrostatic application process creates a thicker, more uniform coating than traditional paint. Carzwerk notes that powder coating is a professional-grade option that's more durable than traditional paint, making it ideal for enthusiasts who want specific color matching without sacrificing protection.

High-temperature paint provides the most accessible entry point. Quality formulations withstand temperatures up to 900°F or higher, sufficient for most street and light track applications. How much to paint calipers using this method? DIY spray applications run $20-50 in materials, while professional brush-on applications with proper preparation typically cost $50-100 per caliper.

Color Customization That Withstands Track Temperatures

When selecting colors for custom painted brake calipers, practical considerations extend beyond personal preference. Your color choice affects both visibility and thermal behavior - factors that matter when you're pushing these components to their limits.

Color Selection Guidance:

- Red: The classic performance statement. High visibility behind wheels, universally recognized as a performance indicator. Works well across most vehicle colors.

- Black: Understated elegance that complements luxury and stealth builds. Shows brake dust more readily but pairs beautifully with dark wheels.

- Brake Caliper Silver: OEM-inspired finish that maintains a factory appearance while still showcasing upgraded components. Excellent for builds prioritizing sophistication over flash.

- Yellow: High visibility option popular with track-focused builds. Creates strong visual contrast behind most wheel designs.

- Custom/Brand Colors: Match your vehicle's paint code or racing livery. Requires professional color matching but creates cohesive visual identity.

How much does it cost to paint brake callipers professionally? Expect to pay $250-500 for a complete four-caliper professional finish including proper preparation, high-temperature primer, multiple color coats, and clear coat protection. This investment makes sense for forged calipers given their premium value and extended service life.

Caliper Covers vs Paint: An Honest Assessment

You've probably seen caliper covers marketed as an alternative to custom caliper paint. Let's address this comparison honestly.

Caliper covers are decorative shells that clip over existing calipers, creating the appearance of larger, more impressive brake components. They cost significantly less than professional finishing and require no disassembly. However, they present significant drawbacks for anyone running forged calipers:

- Heat Trapping: Covers create an insulating layer that reduces heat dissipation - directly undermining one of the primary advantages of forged construction.

- Authenticity Concerns: Experienced enthusiasts immediately recognize covers as cosmetic additions rather than genuine performance components.

- Fitment Issues: Covers may interfere with custom caliper geometries or larger-than-stock dimensions common in forged applications.

- Durability Questions: Plastic or thin metal covers can rattle, discolor, or degrade under the thermal cycling that forged calipers handle effortlessly.

For anyone who has invested in custom forged brake calipers, covers represent a false economy. You've already purchased components worth showcasing - finishing them properly protects that investment while displaying the genuine article.

Maximizing Your Finishing Investment

Given the premium nature of forged calipers, professional finishing during the manufacturing process often delivers better value than aftermarket application. When specifying your custom calipers, ask manufacturers about integrated finishing options. Factory-applied powder coating or anodizing ensures proper surface preparation and eliminates the risk of damage during shipping or installation before finishing.

If you're finishing calipers post-purchase, proper preparation determines success. Remove all brake fluid residue, degrease thoroughly, and ensure complete disassembly before any coating application. Skipping these steps leads to adhesion failures that waste your finishing investment.

Whether you choose anodizing for maximum durability, powder coating for color flexibility, or high-temperature paint for accessibility, the finishing you select should complement the engineering excellence of your forged calipers. With both performance and appearance optimized, you're ready to make the final decision about your custom brake caliper project.

Taking the Next Step Toward Custom Forged Brake Calipers

You've journeyed from metallurgical science through piston configurations, application-specific considerations, and finishing options. Now it's time to synthesize everything into actionable guidance that helps you move forward with confidence. What brake calipers deserve your investment, and how do you ensure you're partnering with the right manufacturer?

Custom forged brake calipers deliver measurable advantages through aligned grain structure, eliminated porosity, and superior density - but these benefits only matter when matched to applications that demand them.

Making the Right Investment Decision

Let's distill the key insights from this deep dive into a clear decision framework. Custom calipers represent a significant investment, and understanding who benefits most ensures you're spending wisely.

Custom forged brake calipers are ideal for:

- Dedicated track enthusiasts running monthly events or competitive racing series who experience brake fade with standard equipment

- Heavy-duty applications involving regular towing, hauling, or mountain driving where sustained braking loads demand superior heat management

- High-performance builds where vehicle weight exceeds 3,500 lbs or power-to-weight ratios push braking demands beyond stock capability

- Professional racing applications requiring precise brake balance tuning and non-negotiable reliability

- Enthusiasts seeking specific specifications that off-the-shelf options cannot provide - custom bore sizes, piston staging, or mounting geometry

When prioritizing your selection, focus on:

- Manufacturer certifications: IATF 16949 certification indicates rigorous quality control and process consistency

- Material grades and heat treatment: Verify the specific aluminum alloys or steel grades offered and their corresponding temper specifications

- Engineering support: Partner with manufacturers offering in-house engineering capabilities who can guide specification decisions

- Prototyping capabilities: Rapid prototyping accelerates development and catches fitment issues before production commitment

- Production flexibility: Manufacturers capable of both small prototype runs and high-volume production provide long-term partnership value

The forging advantage compounds across every performance metric - weight savings, structural rigidity, heat dissipation, and fatigue resistance. When your application demands the best, forged construction delivers.

Your Path to Superior Braking Performance

Ready to move forward? Success in your custom forged caliper project depends on partnering with qualified manufacturers who understand both the metallurgy and the application demands. Look for suppliers demonstrating:

- Precision hot forging expertise: The forging process itself determines grain alignment and density optimization

- Automotive-specific experience: Brake components demand understanding of thermal cycling, fatigue requirements, and safety criticality

- Complete service capability: From initial consultation through CNC machining, heat treatment, finishing, and quality verification

- Efficient logistics: Strategic manufacturing locations near major ports streamline global delivery timelines

Manufacturers like Shaoyi (Ningbo) Metal Technology exemplify these capabilities, combining IATF 16949 certification with in-house engineering for robust automotive components. Their strategic location near Ningbo Port enables efficient global delivery, while rapid prototyping capabilities - as fast as 10 days - accelerate your custom development timeline. Whether you need initial prototypes for fitment verification or high-volume production for racing series commitments, working with manufacturers offering this full spectrum ensures your project succeeds.

Beyond the caliper bodies themselves, consider how custom brake caliper paint or professional finishing integrates with your build's visual identity. Many qualified forging manufacturers offer integrated finishing options that protect your investment while delivering the aesthetic statement your custom calipers deserve.

Your brake calipers rotors and complete braking system represent the critical interface between driver input and vehicle response. Investing in custom forged construction ensures that interface performs flawlessly when it matters most.

The path from understanding custom forged brake caliper advantages to actually installing them on your vehicle requires deliberate steps: define your specifications, prepare your vehicle information, engage qualified manufacturers, and commit to the engineering partnership that delivers optimal results. With the knowledge you've gained, you're equipped to navigate this process confidently and achieve the braking performance your application demands.

Frequently Asked Questions About Custom Forged Brake Calipers

1. Are upgraded calipers worth it?

Custom forged brake calipers are worth the investment for specific applications. Track enthusiasts running monthly events, heavy-duty towing scenarios, and vehicles exceeding 3,500 lbs benefit most from forged construction. The aligned grain structure eliminates porosity, providing superior heat dissipation and fatigue resistance that prevents brake fade during demanding use. However, for occasional spirited street driving, standard performance calipers may suffice. Evaluate your annual track frequency, vehicle weight, and driving intensity before committing. IATF 16949 certified manufacturers ensure quality, making the premium investment worthwhile for serious performance applications.

2. Are OEM brake calipers better than aftermarket?

OEM calipers offer guaranteed fitment and quality but lack customization for specific performance needs. Custom forged aftermarket calipers surpass OEM options when your application demands optimized specifications. Unlike mass-produced OEM components, custom forged calipers allow tailored bore sizes, piston configurations, and material grades matched to your vehicle weight and intended use. For factory-spec daily driving, OEM suffices. For track use, heavy towing, or high-performance builds, aftermarket forged calipers from certified manufacturers deliver measurable advantages in rigidity, weight savings, and thermal management that OEM alternatives cannot match.

3. Why are Brembo calipers better?

Brembo calipers earn their reputation through motorsport-proven forging processes that deliver superior stiffness, thermal control, and pedal feel. Their forged construction aligns grain structure for exceptional strength-to-weight ratios while eliminating porosity that causes heat-related failures. However, custom forged calipers from qualified manufacturers can match or exceed these benefits when specifications are tailored to your exact application. The key advantage of any forged caliper, including Brembo, lies in the manufacturing process itself rather than brand alone. Look for IATF 16949 certification and in-house engineering capabilities when evaluating alternatives.

4. What are the advantages of monoblock calipers?

Monoblock forged calipers are machined from a single piece of forged metal, eliminating joints or seams that can flex under extreme clamping forces. This single-piece construction delivers enhanced rigidity, translating to more responsive pedal feel and consistent pad-to-rotor contact during aggressive braking. Combined with forging's aligned grain structure, monoblock designs maximize the metallurgical advantages of the forging process. They excel in track applications where multi-piston configurations generate enormous forces. The trade-off is higher manufacturing complexity and cost, making them ideal for dedicated performance vehicles rather than street-only builds.

5. How long does it take to get custom forged brake calipers manufactured?

Custom forged brake caliper production typically spans 40-45 days after order confirmation, but the complete timeline includes additional phases. Specification development with engineers requires 1-3 weeks to finalize bore sizes, piston configurations, and material grades. Optional rapid prototyping for fitment verification can be completed in as few as 10 days. International shipping adds 1-2 weeks depending on location. Manufacturers strategically located near major ports like Ningbo expedite global delivery. Plan for 8-12 weeks total from initial inquiry to installation, allowing buffer time for any specification adjustments during the engineering consultation phase.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —