Custom Extruded Aluminum Bushings for Automotive Mastery

TL;DR

We manufacture custom extruded aluminum bushings designed for demanding automotive applications. These precision-engineered components offer a superior combination of lightweight durability, high strength, and corrosion resistance. By leveraging advanced extrusion and CNC machining processes, we deliver custom bushings that enhance vehicle performance, longevity, and efficiency, tailored to your exact specifications.

Why Choose Custom Extruded Aluminum for Automotive Bushings?

In the automotive industry, every component's performance is critical. Custom extruded aluminum bushings are increasingly the preferred choice over traditional materials like steel or rubber for several compelling reasons. The primary advantage lies in aluminum's exceptional strength-to-weight ratio. As manufacturers strive to improve fuel economy and reduce emissions, lightweighting vehicles without sacrificing durability is paramount. Aluminum parts weigh significantly less than their steel counterparts, contributing directly to better vehicle performance and efficiency.

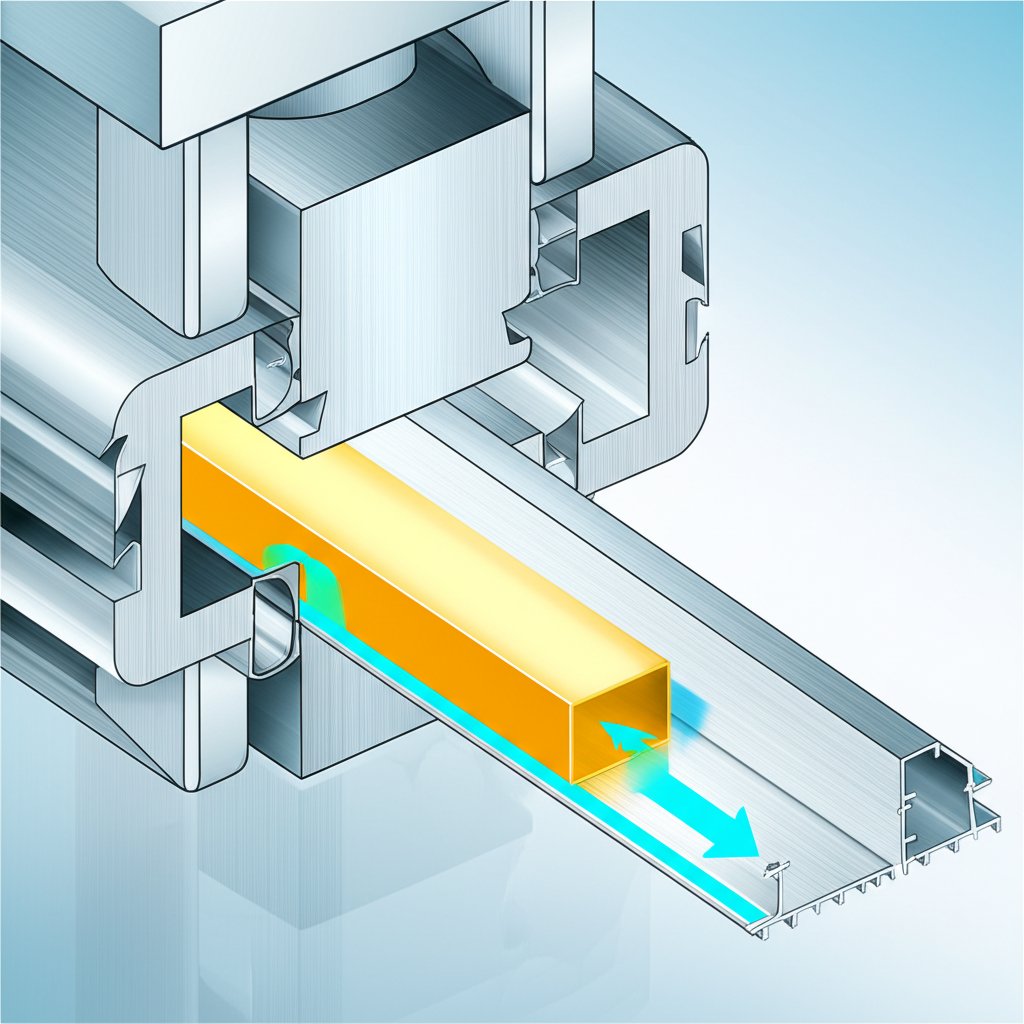

The extrusion process itself further enhances the inherent strengths of aluminum. Pushing heated aluminum alloy through a custom die compacts the material, resulting in a dense, uniform grain structure that is incredibly strong and resilient. This process allows for the creation of complex cross-sectional profiles that are impossible to achieve with standard machining alone. The result is a bushing designed for optimal performance in high-stress environments like vehicle suspensions and chassis.

Beyond strength and weight, aluminum offers natural corrosion resistance, a crucial attribute for parts exposed to harsh road conditions and environmental elements. Unlike steel, which can rust and degrade, aluminum forms a protective oxide layer that shields it from moisture and salt. This leads to a longer service life for critical components, ensuring reliability and reducing maintenance costs over the vehicle's lifetime. These benefits make aluminum an ideal material for high-performance automotive applications.

Our Manufacturing Process: From Design to Precision Part

Creating a custom aluminum bushing that meets the stringent demands of the automotive sector requires a meticulous, multi-stage manufacturing process. It's a journey from a simple concept to a precisely engineered component, ensuring every part delivers on performance and reliability. For automotive projects requiring this level of detail, partnering with a specialist is key. For example, a trusted partner like Shaoyi Metal Technology provides a comprehensive one-stop service, managing everything from initial design to full-scale production under a strict IATF 16949 certified quality system, which is a critical standard for automotive suppliers.

The process generally follows these key steps:

- Consultation and Design: The process begins with a thorough consultation to understand your specific application, performance requirements, and operating conditions. Clients typically provide technical drawings or 3D models. At this stage, engineers review the design for manufacturability and may suggest modifications to optimize for strength, weight, and cost-effectiveness.

- Material Selection: Based on the design requirements, a specific aluminum alloy is chosen. Different alloys offer varying properties related to strength, machinability, and corrosion resistance. This critical choice ensures the finished bushing can withstand its intended operational stresses.

- Extrusion: A heated billet of the selected aluminum alloy is forced through a hardened steel die. This forms a long, continuous profile with the exact cross-sectional shape of the bushing. This step is what defines the fundamental geometry and structural integrity of the part.

- Cutting and CNC Machining: The extruded profile is then cut to the required lengths. From there, each piece undergoes precision CNC (Computer Numerical Control) machining. This step is crucial for achieving tight tolerances, creating features like grooves or flanges, and ensuring a perfect fit. Processes like CNC turning and milling are used to refine the part to its final, exact dimensions.

- Finishing and Quality Assurance: After machining, the bushings may undergo surface treatments to enhance their properties. Options like anodizing can increase surface hardness and corrosion resistance, while powder coating can provide a durable, colored finish. Finally, every part undergoes rigorous quality assurance checks, often using tools like a Coordinate Measuring Machine (CMM), to verify that all dimensions and specifications meet the client's requirements before shipping.

Automotive Applications and Solutions

Custom extruded aluminum bushings are integral to modern vehicle performance, providing stability and reducing friction in numerous critical systems. Their unique properties make them suitable for a wide range of high-stress applications where precision and durability are non-negotiable.

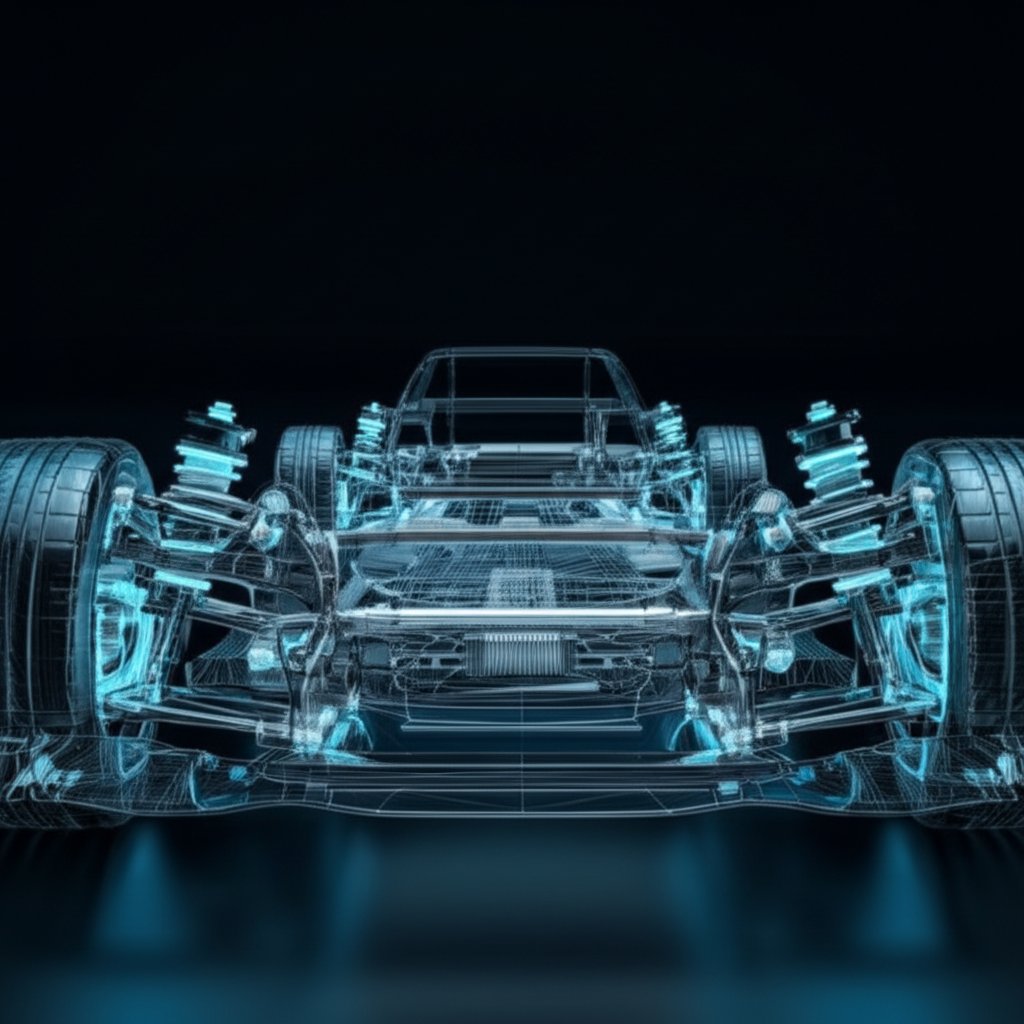

One of the most common applications is in vehicle suspension systems. Bushings are used in control arms, shock absorber mounts, and steering joints to absorb vibration, reduce noise, and allow for controlled movement between components. Aluminum's stiffness provides a more direct and responsive feel for the driver compared to softer rubber bushings, enhancing handling and stability, especially in performance vehicles.

They are also vital in the vehicle's chassis and subframe. The subframe, which supports the engine, transmission, and suspension, is subject to immense mechanical stress. According to insights from ODMetals, custom aluminum extrusions are ideal for subframes because they provide the necessary strength and stiffness while protecting against fatigue and environmental stress. Similarly, aluminum bushings are used in engine mounts and other chassis components to maintain alignment and manage vibrations, contributing to a smoother and quieter ride.

Furthermore, aluminum extrusions play a role in crash management systems. Aluminum alloys can be designed to absorb a higher amount of impact energy than steel of a similar strength, crumpling in a predictable way to protect vehicle occupants. Bushings and other extruded profiles are used in cross-car beams and bumpers, where their combination of low weight and high energy absorption is a significant safety advantage. This makes them essential not only for performance but for the fundamental safety structure of the vehicle.

Material Specifications and Alloy Options

Selecting the right aluminum alloy is a critical step that dictates the final performance characteristics of the bushing. While many grades are available, a few are particularly well-suited for the demanding automotive environment. Each alloy offers a unique balance of strength, corrosion resistance, machinability, and cost. The choice depends entirely on the specific application, from light-duty interior components to high-load suspension parts. For instance, Beska Mold highlights that aluminum is often chosen for its lightweight and corrosion-resistant properties in applications like electric vehicles and aerospace interiors.

Below is a comparison of common aluminum alloys used for custom bushings:

| Alloy | Key Properties | Best For (Application) |

|---|---|---|

| 6061-T6 | Excellent corrosion resistance, good machinability, high weldability, medium strength. The T6 temper indicates it has been solution heat-treated and artificially aged for maximum strength. | General-purpose structural components, suspension parts, and applications where a balance of strength and corrosion resistance is needed. |

| 7075-T6 | Very high strength-to-weight ratio, comparable to many steels. Excellent fatigue strength. Lower corrosion resistance and weldability compared to 6061. | High-stress, critical performance applications such as steering knuckles, control arms, and other chassis components where maximum strength and minimal weight are essential. |

| 6082-T6 | Often called a "structural alloy," it has slightly higher mechanical properties than 6061 and excellent corrosion resistance. It is highly resistant to stress corrosion cracking. | Highly stressed structural applications, including subframes and load-bearing chassis components that require superior durability in harsh environments. |

| 5052 | Excellent resistance to saltwater corrosion, good workability. Not heat-treatable, so it has lower strength compared to 6xxx and 7xxx series alloys. | Applications in marine or coastal environments, or non-structural parts where corrosion resistance is the primary concern over high strength. |

Ultimately, consulting with our engineering team is the best way to determine the ideal alloy for your project. We can help you navigate these options to ensure your custom bushings meet and exceed your performance expectations.

How to Get a Quote for Your Custom Bushings

Initiating the process for your custom extruded aluminum bushings is straightforward. To provide you with an accurate and timely quote, we require a clear understanding of your project's technical specifications. Preparing this information in advance will ensure a smooth and efficient process, moving your project from concept to production without delay.

Follow these simple steps to get started:

- Prepare Your Technical Drawings: The most important piece of information is a detailed technical drawing or a 3D CAD model of the bushing. Please include all dimensions, tolerances, and specific features. Common file formats like DWG, DXF, STEP, or PDF are acceptable.

-

Specify Your Requirements: Along with the drawing, please provide the following details:

- Material Alloy: Specify the desired aluminum alloy (e.g., 6061-T6, 7075-T6) or describe the performance needs so we can recommend one.

- Quantity: Let us know the required volume, whether for a prototype run or full-scale production.

- Application Details: Briefly describe where and how the bushing will be used. This context helps our engineers ensure the design and material are perfectly suited for the job.

- Finishing Requirements: Indicate if any surface treatments like anodizing or powder coating are needed.

- Submit Your Request: Send all the information via our online quote request form or directly to our engineering team's email. We will review your submission and typically respond with a detailed quote within 24-48 hours.

Our team is ready to assist you at every step. If you have any questions or need guidance on your design, don't hesitate to contact us directly. We are committed to providing you with high-quality, precision-engineered solutions for your automotive needs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —