Cam Unit Selection For Stamping: Match Tonnage, Avoid Costly Mistakes

Understanding Cam Units and Their Role in Stamping Operations

When you're working with progressive or transfer dies, there's one component that quietly determines whether your stamping operation runs smoothly or grinds to a costly halt: the cam unit. But what exactly does this cam device do, and why does selecting the right one matter so much?

What Cam Units Actually Do in Stamping Dies

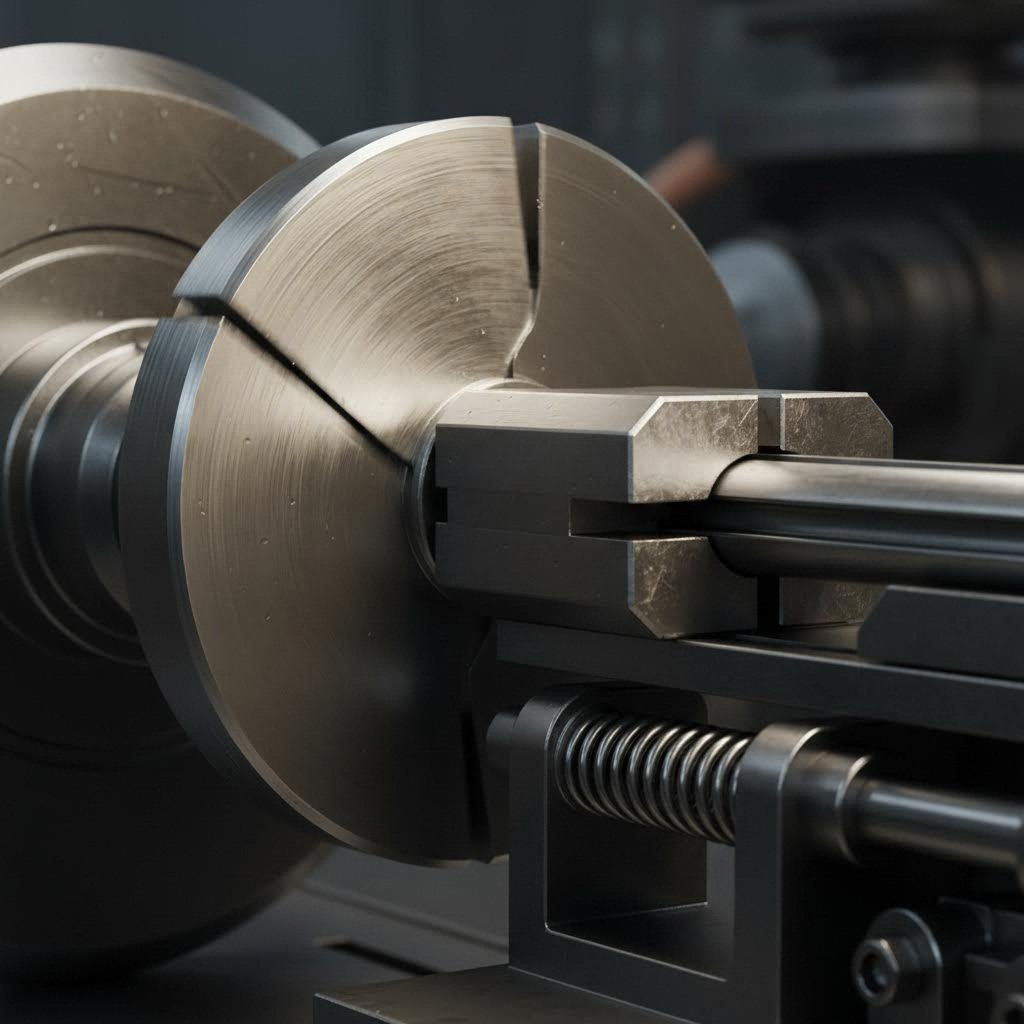

Picture your stamping press in action. The ram moves straight up and down, delivering tremendous vertical force. But here's the challenge—many part features require forming, piercing, or trimming at angles that vertical motion simply can't reach. That's where cam units come in.

A cam unit is essentially a mechanical motion converter. It takes the vertical energy from your press and redirects it horizontally or at specific angles, allowing you to perform operations that would otherwise be impossible. Understanding how cams work reveals their elegance: as the press ram descends, it engages a driver that activates the cam slider, translating that downward motion into precisely controlled lateral movement.

Different cam types serve distinct purposes within your die. Some handle simple side-piercing operations, while others manage complex angular forming sequences. The variety exists because stamping challenges vary dramatically—from punching holes in door panels to forming intricate bracket features.

Cam units transform what a stamping press can accomplish by converting vertical force into horizontal or angular work, effectively multiplying the geometric possibilities of every die design.

Why Selection Decisions Matter More Than You Think

Here's what product catalogs won't tell you: choosing the wrong cam unit doesn't just cause inconvenience—it creates a cascade of problems that affect everything from part quality to your bottom line.

When cam unit selection goes wrong, you'll notice:

- Premature wear patterns that force unexpected die maintenance shutdowns

- Inconsistent part dimensions that spike your scrap rates

- Reduced die longevity as components operate beyond their intended capacity

- Production inefficiencies from slower cycle times or frequent adjustments

The knowledge gap between reading a specification sheet and making the right selection decision is significant. Manufacturers provide tonnage ratings and stroke lengths, but they rarely explain how to match these specifications to your actual stamping challenges.

This guide takes a different approach. Instead of walking through product categories, we'll organize the selection process around real stamping problems you're trying to solve. You'll learn to calculate the forces your operation demands, match those requirements to appropriate cam types, and avoid the costly specification errors that plague even experienced die engineers.

Whether you're designing a new progressive die or troubleshooting performance issues in an existing setup, understanding proper cam unit selection gives you the foundation to make decisions that protect both part quality and production efficiency.

Cam Unit Types and When to Use Each One

Now that you understand what cam units accomplish, the next question becomes: which type fits your application? The answer depends on your specific stamping challenges—available space, required force, stroke distance, and mounting orientation all influence the decision. Let's break down the different types of cams and clarify when each one makes sense.

Standard vs Heavy-Duty Cam Units Explained

Think of standard cam units as your workhorses for everyday stamping operations. They handle moderate forces and strokes within typical progressive die applications. When your piercing cam needs fall within conventional parameters—say, punching holes in sheet metal panels or trimming standard features—a standard unit delivers reliable performance without overengineering your die.

Heavy-duty cams, on the other hand, step in when standard units reach their limits. Imagine you're piercing through thicker gauge materials or executing operations that demand significantly higher working forces. These units feature reinforced construction, larger bearing surfaces, and enhanced rigidity to handle punishing loads cycle after cycle. The trade-off? They require more die space and typically cost more upfront.

How do you know which category you need? Start with your force calculations (we'll cover this in detail later), then add appropriate safety margins. If your required working force approaches or exceeds 70-80% of a standard unit's capacity, moving to heavy-duty territory often proves wise.

Specialized Cams for Unique Stamping Challenges

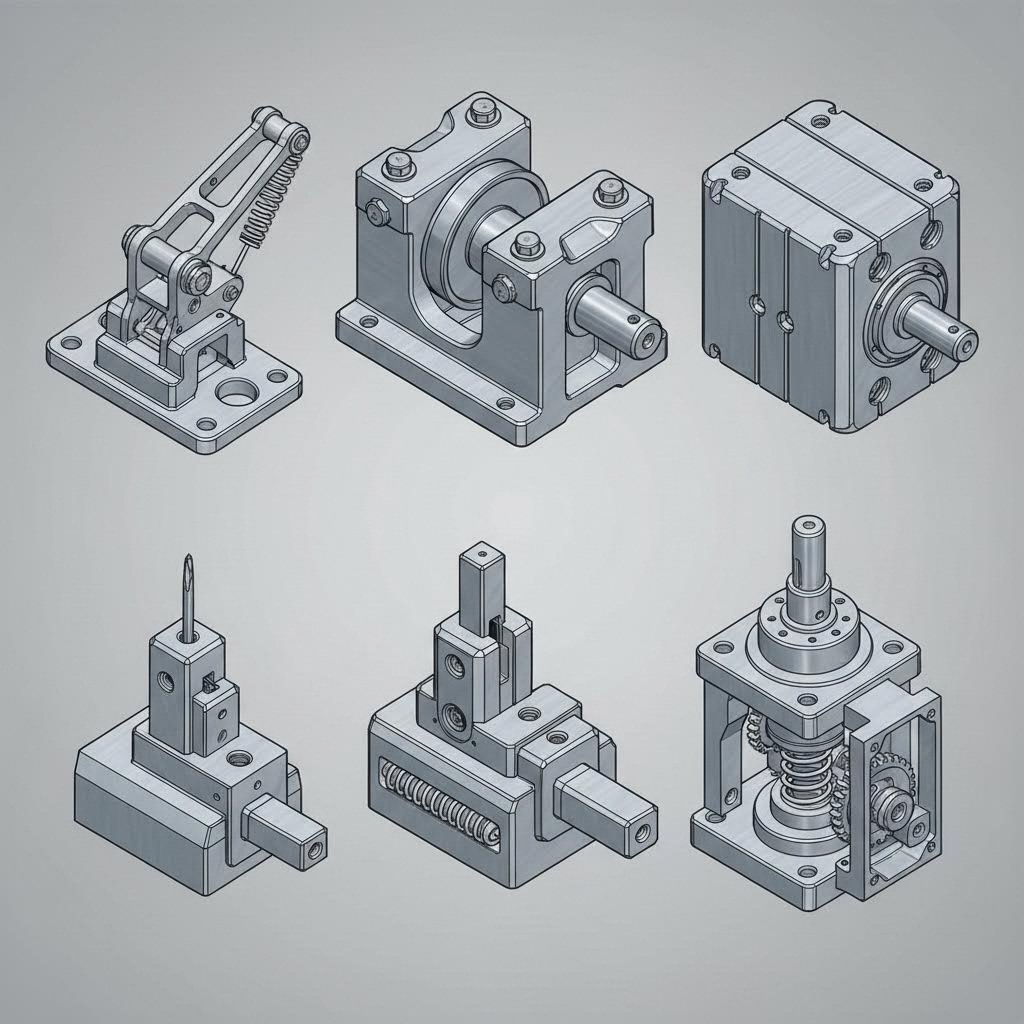

Beyond the standard and heavy-duty classifications, several specialized cam types address specific operational demands:

Aerial Cams: When die space is at a premium, aerial cams offer a compact solution. They mount above the die surface rather than within the die shoe, freeing valuable real estate for other components. You'll find these particularly useful in crowded progressive dies where every square inch matters.

Box Cams: These self-contained units integrate the driver and cam slider within a single housing. Box cams simplify installation and provide excellent rigidity, making them ideal for applications requiring precise, repeatable motion with minimal setup complexity.

Bump Cams: Designed for operations needing a quick, short-stroke action, bump cams excel at ejecting parts or activating secondary mechanisms. Their rapid cycling capability makes them suitable for high-speed production environments.

Piercing Cams: Purpose-built for punching and piercing operations at angles, these units optimize the force transmission path for cutting actions. When your primary cam function involves making holes or trimming at non-vertical angles, a dedicated piercing cam often outperforms general-purpose alternatives.

Comparing Cam Types: A Practical Reference

Selecting the right different cam type requires weighing multiple factors simultaneously. The following comparison helps clarify which unit suits specific scenarios:

| Cam Type | Typical Applications | Working Force Range | Stroke Capability | Mounting Considerations | Ideal Use Cases |

|---|---|---|---|---|---|

| Standard Cam | General piercing, trimming, forming | Low to moderate (up to ~50 kN) | Short to medium strokes | Horizontal to 15° mounting angle | Everyday operations in progressive dies with adequate space |

| Heavy-Duty Cam | Thick material piercing, high-force forming | High (50 kN and above) | Medium to long strokes | Requires robust mounting; 0° to 15° typical | Demanding applications where standard units are undersized |

| Aerial Cam | Space-constrained operations | Low to moderate | Short to medium strokes | Mounts above die surface; flexible orientation | Crowded dies needing compact lateral motion solutions |

| Box Cam | Precision forming, consistent cycling | Moderate | Medium strokes | Self-contained; simplified installation | Applications prioritizing setup ease and rigidity |

| Bump Cam | Part ejection, quick actuation | Low to moderate | Short, rapid strokes | Compact footprint; high-speed compatible | High-speed production requiring fast cycling |

| Piercing Cam | Angular hole punching, side trimming | Moderate to high | Variable based on design | Optimized for 15° to 60° mounting angles | Dedicated cutting operations at non-vertical angles |

Mounting Angle Considerations: Horizontal vs Angular Applications

One detail that often trips up engineers involves mounting angle requirements. Industry documentation distinguishes between two primary ranges:

- Horizontal to 15° mounting: Most standard and heavy-duty cams operate optimally within this range. The force transmission remains efficient, and driver engagement stays predictable.

- 15° to 60° mounting: Angular applications require cam units specifically designed for steeper orientations. The geometry changes how forces transfer through the system, demanding specialized driver configurations and often different cam slider profiles.

Attempting to use a horizontal-optimized cam at steep angles creates problems—accelerated wear, inconsistent stroke completion, and potential binding. Always verify that your selected unit matches your actual mounting orientation before finalizing specifications.

With a clear picture of available cam types and their strengths, the next step involves translating your operational requirements into specific tonnage calculations that guide your final selection.

Tonnage Calculation and Capacity Matching Fundamentals

You've identified the cam type that fits your application—but how do you know if it can actually handle the forces your operation demands? This is where many engineers stumble. Manufacturer data sheets provide working force specifications, yet they rarely explain how to interpret those numbers or match them to real-world requirements. Let's bridge that gap.

Breaking Down Working Force Specifications

Open any cam equipment catalog, and you'll encounter specifications listed in kilonewtons (kN) or tons-force (tonf). Understanding what these numbers actually mean—and how they relate to your press cam application—separates successful selections from costly mistakes.

First, the unit conversion basics: 1 tonf equals approximately 9.81 kN. When comparing specifications across different manufacturers or standards (ISO, NAAMS, JIS), always convert to a common unit before making decisions. A standard cam rated at 50 kN delivers roughly 5.1 tonf of working force—numbers that matter when your calculations are tight.

But here's what catalogs often bury in footnotes: those headline force ratings come with conditions attached. The maximum allowable force typically assumes:

- Optimal mounting orientation (usually horizontal)

- Proper driver engagement and timing

- Adequate lubrication and maintenance

- Operating within specified temperature ranges

Deviate from these conditions, and your actual allowable force drops. A cam rated for 80 kN under ideal circumstances might safely handle only 60-65 kN in your specific setup. Always review the fine print and derate accordingly.

Understanding Stroke Life Ratings: The Hidden Selection Factor

Here's a specification detail that catches even experienced engineers off guard: most manufacturers publish two different allowable force values tied to stroke life expectations.

Imagine you're reviewing a cam unit specification showing 100 kN allowable force at 1,000,000 strokes and 130 kN at 300,000 strokes. What does this mean for your selection?

The relationship is straightforward but critical. Higher forces accelerate wear on bearing surfaces, guide rails, and sliding components. Running at 130 kN delivers more capability per stroke but significantly shortens the interval before maintenance or replacement becomes necessary. Running at 100 kN extends service life but limits your per-stroke capacity.

Your production volume dictates which rating matters most:

- High-volume automotive production: Prioritize the 1,000,000-stroke rating. You'll run millions of cycles annually, making longevity essential for minimizing downtime and replacement costs.

- Low-volume or prototype runs: The higher force rating at 300,000 strokes might prove acceptable, letting you use a smaller, less expensive cam unit for limited production quantities.

- Moderate production with heavy loads: Consider oversizing—selecting a unit where your required force falls well below even the conservative rating ensures both capacity and durability.

Matching Cam Capacity to Your Operation

Calculating the actual tonnage your stamping operation requires involves several variables working together. Before matching any cam unit to your needs, you must determine the forces your specific operation generates.

The key factors influencing your tonnage calculations include:

- Material thickness: Thicker stock requires proportionally more force to shear or form. Doubling material thickness roughly doubles the required cutting force.

- Material type and tensile strength: Mild steel, high-strength steel, aluminum, and stainless steel each demand different force levels. A piercing operation through 304 stainless requires significantly more tonnage than the same geometry in mild steel.

- Cut length or perimeter: For piercing and blanking operations, total cut length directly multiplies with material properties. A complex hole pattern with 200mm of total cut perimeter demands twice the force of a 100mm perimeter.

- Operation type: Piercing, trimming, forming, and flanging each have different force characteristics. Forming operations often require sustained force through the stroke, while piercing peaks at breakthrough.

- Safety factors: Industry practice typically adds 20-30% above calculated requirements to account for material variations, tool wear, and unexpected conditions.

Practical Force Calculation Approach

For piercing and blanking operations, a simplified formula provides your starting point:

Required Force = Cut Perimeter × Material Thickness × Material Shear Strength

Suppose you're piercing a rectangular slot (30mm × 10mm) through 2mm mild steel with a shear strength of 350 N/mm². Your calculation looks like this:

- Cut perimeter: (30 + 10) × 2 = 80mm

- Required force: 80mm × 2mm × 350 N/mm² = 56,000 N = 56 kN

- With 25% safety factor: 56 kN × 1.25 = 70 kN minimum cam capacity

Now you can confidently evaluate cam equipment specifications. A unit rated at 80 kN for 1,000,000 strokes provides adequate capacity with reasonable margin. A unit rated at 60 kN—even if technically close—leaves no room for material variations or tool wear.

When your calculations land between standard unit sizes, always round up. The cost difference between a 70 kN and 100 kN rated cam unit pales against the expense of premature failure, production stoppages, or scrapped parts from an undersized selection.

With tonnage requirements clearly defined, the next critical decision involves selecting the right cam driver and ensuring system-wide compatibility—a topic where mounting angles and industry standards intersect in ways that demand careful attention.

Cam Driver Selection and System Compatibility

You've calculated your tonnage requirements and identified the right cam type—but there's another piece of the puzzle that determines whether your system performs as expected: the cam driver. Think of the driver as the translator between your press ram's vertical motion and the cam unit's lateral action. Get this relationship wrong, and even a perfectly sized cam unit underperforms.

Cam Driver Selection Principles

Understanding how to use a cam effectively starts with recognizing that the driver and cam unit function as an integrated system. The driver—sometimes called a trigger—engages with the cam slider during the press stroke, initiating and controlling the lateral movement that performs your stamping operation.

Several factors govern driver selection:

- Force transmission angle: The geometry between driver and cam slider affects how efficiently vertical force converts to horizontal motion. Steeper angles reduce efficiency and increase component stress.

- Engagement timing: Drivers must engage at the correct point in the press stroke. Early engagement can cause binding; late engagement reduces available working stroke.

- Return mechanism compatibility: The driver must work harmoniously with the cam's return system—whether spring-loaded, nitrogen cylinder, or mechanically actuated.

- Wear characteristics: Driver contact surfaces experience significant sliding friction. Material selection and hardness must match the cam unit's design specifications.

A special cam application might require custom driver geometry to accommodate unusual mounting orientations or force requirements. Standard drivers work well for conventional setups, but don't assume one-size-fits-all when your application pushes boundaries.

Trigger Types and Mounting Angle Relationships

Here's where mounting angle becomes critical. The relationship between your cam unit's orientation and the required driver configuration follows predictable patterns—but ignoring these patterns leads to premature wear and inconsistent performance.

Horizontal mounting (0° to 15°): This range represents the sweet spot for most stamping applications. Force transmission remains highly efficient, and standard driver configurations handle the load effectively. When your die design allows horizontal or near-horizontal cam orientation, you'll benefit from:

- Maximum force transfer efficiency

- Reduced wear on contact surfaces

- Predictable stroke characteristics

- Wider driver compatibility across manufacturers

Angled mounting (15° to 60°): Steeper orientations demand specialized consideration. As mounting angle increases, the force vector changes—requiring drivers specifically engineered for angular applications. You'll notice that angular drivers typically feature:

- Modified contact surface geometries

- Adjusted engagement profiles to maintain smooth actuation

- Enhanced wear resistance for increased sliding friction

- Specific pairing requirements with compatible cam units

Attempting to use a horizontal driver with a steeply mounted cam unit creates binding, accelerated wear, and potential safety hazards. Always verify that your driver selection matches your actual mounting configuration.

Step-by-Step Driver Matching Process

Matching cam drivers to specific applications follows a logical sequence. Whether you're designing a new die or troubleshooting an existing setup, this process ensures compatibility:

- Document your mounting angle: Measure or specify the exact orientation of your cam unit within the die. Even a few degrees can shift you from one driver category to another.

- Verify force requirements: Confirm that your calculated working force falls within both the cam unit's and the driver's rated capacity. Drivers have force limits too.

- Check stroke compatibility: Ensure the driver's engagement length accommodates your required cam stroke. Insufficient engagement causes incomplete actuation.

- Match industry standards: Identify which standard your die follows—ISO, NAAMS, JIS, or specific automotive OEM specifications—and select drivers designed for that standard.

- Confirm return mechanism coordination: Verify that driver disengagement timing aligns with your cam unit's return stroke to prevent interference.

- Review manufacturer pairing recommendations: Many cam unit suppliers specify approved driver combinations. Deviating from these pairings may void warranties or compromise performance.

Industry Standards and Cross-Compatibility Considerations

Cam unit selection for stamping rarely happens in isolation. Your die likely needs to meet specific industry standards, and these standards influence driver compatibility significantly.

ISO standards: Provide internationally recognized specifications for cam unit dimensions, mounting patterns, and driver interfaces. Useful when working with global suppliers or multi-region production.

NAAMS (North American Automotive Metric Standards): Common in automotive stamping, NAAMS specifications define precise tolerances and interchangeability requirements. If your customer mandates NAAMS compliance, your cam drivers must match these specifications exactly.

JIS (Japanese Industrial Standards): Prevalent in Japanese automotive OEM tooling, JIS specifications often differ from NAAMS in subtle but important ways. A cam unit or other secondary equipment designed for JIS tooling may require JIS-compliant drivers.

Automotive OEM-specific standards: Major automakers sometimes impose proprietary specifications beyond industry standards. Ford, GM, Toyota, and others may require specific driver configurations for dies running in their facilities.

Cross-compatibility between standards isn't guaranteed. A NAAMS-compliant cam unit might accept an ISO driver in some configurations but not others. When mixing standards—intentionally or through supplier availability—always verify physical fit and performance compatibility before production.

Understanding the complete cam system—unit, driver, and mounting configuration working together—positions you to make selections that perform reliably. Next, we'll examine how to match these system components to the specific stamping challenges you're trying to solve.

Matching Cam Units to Specific Stamping Challenges

You've learned about cam types, calculated your tonnage requirements, and understand driver compatibility. But here's the question that matters most: which configuration actually solves your specific problem? Rather than forcing you to translate generic specifications into practical decisions, let's flip the approach. We'll start with the stamping challenges you're facing and work backward to the right cam unit applications.

Solving Tight Space Constraints with Aerial Cams

Imagine you're designing a progressive die for a complex automotive bracket. The part geometry demands side-piercing at three separate stations, but your die shoe real estate is already packed with forming stations, pilots, and lifters. Where do you fit the cam units?

This is where aerial cam systems prove invaluable. Unlike conventional cams that mount within the die shoe, aerial configurations position above the die surface—effectively borrowing vertical space instead of consuming precious horizontal area.

When evaluating whether aerial cams fit your application, consider these factors:

- Available vertical clearance: Aerial units require headroom above your strip line. Verify your press daylight accommodates the added height.

- Force requirements: Aerial cams typically handle low to moderate forces. If your side-piercing operation demands heavy tonnage, you may need to reconsider die layout to accommodate conventional heavy duty cam units.

- Access for maintenance: Positioning above the die surface often improves maintenance access compared to units buried within the die structure.

- Strip feeding considerations: Ensure the aerial mounting doesn't interfere with strip progression or automatic feeding systems.

For crowded dies where standard mounting isn't feasible, aerial configurations often represent the difference between a workable design and starting over with a larger die shoe.

High-Force Applications and Heavy-Duty Solutions

Now consider the opposite challenge. You're piercing through 4mm high-strength steel, and your force calculations exceed 150 kN. Standard cam units simply won't survive the demands. This scenario calls for heavy duty cam units engineered specifically for punishing applications.

Heavy-duty configurations address high-force challenges through:

- Reinforced slider construction: Thicker cross-sections and premium materials resist deflection under extreme loads.

- Enlarged bearing surfaces: Greater contact area distributes force, reducing localized stress and extending service life.

- Enhanced guide systems: Precision-ground guides maintain alignment even when forces try to deflect the slider.

- Robust return mechanisms: Heavy-duty nitrogen cylinders or mechanical returns ensure positive retraction against higher friction loads.

The trade-off with heavy-duty units involves size and cost. They consume more die space and carry higher price tags than standard alternatives. But when your application genuinely demands the capacity, undersizing to save money or space creates far more expensive problems down the line.

Complex Angular Forming Requirements

Some stamping operations don't fit neatly into horizontal or simple angular categories. Imagine forming a feature that requires lateral motion at 45° while simultaneously applying downward pressure. Standard stamping die cam selection approaches struggle with these compound movements.

Complex angular applications often benefit from:

- Compound cam configurations: Multiple cam actions staged in sequence to achieve complex motion paths.

- Custom driver geometries: When standard drivers can't achieve the required engagement angle, custom solutions bridge the gap.

- Guided forming systems: Combining cam-driven lateral motion with guided vertical components creates controlled compound movements.

Before assuming you need a special configuration, verify that your angular requirements truly exceed standard capabilities. Many operations initially perceived as complex actually fall within the 15° to 60° range that standard angular cams handle effectively.

High-Speed Production Demands

Speed changes everything. A cam unit performing flawlessly at 30 strokes per minute might develop problems at 60 SPM and fail outright at 100 SPM. High-speed stamping demands cam configurations specifically designed for rapid cycling.

Key considerations for high-speed applications include:

- Mass and inertia: Lighter sliders accelerate and decelerate faster, enabling higher cycling rates without excessive stress.

- Return spring or cylinder sizing: The return mechanism must overcome inertia and friction quickly enough to reset before the next stroke begins.

- Lubrication systems: High-speed operation generates more heat and accelerates lubricant breakdown. Automatic lubrication or enhanced retention features become essential.

- Driver engagement dynamics: At high speeds, engagement and disengagement timing becomes critical. Even slight misalignment creates impact loading that accelerates wear.

Decision Matrix: Matching Problems to Solutions

When facing a stamping challenge, use this decision matrix to identify the most appropriate cam configuration:

| Stamping Challenge | Recommended Cam Type | Key Configuration Considerations | When Standard Solutions Work | When Special Configurations Are Needed |

|---|---|---|---|---|

| Limited die space | Aerial cam systems | Vertical clearance, moderate force capacity | Forces under 50 kN, adequate press daylight | Extreme space constraints requiring custom mounting |

| High-tonnage piercing | Heavy duty cam units | Reinforced construction, robust return mechanisms | Forces within published heavy-duty ratings | Forces exceeding 200 kN or unusual stroke lengths |

| Angular forming (15°-60°) | Angular piercing cams | Matched angular drivers, proper force derating | Single-angle operations within standard ranges | Compound angles or simultaneous multi-axis motion |

| High-speed production (60+ SPM) | Lightweight or bump cams | Low mass, rapid return systems, enhanced lubrication | Moderate forces with proven high-speed ratings | Extreme speeds combined with high forces |

| Part ejection/quick actuation | Bump cams | Short stroke, rapid cycling capability | Simple ejection with standard force requirements | Timed ejection sequences or unusual actuation paths |

| Precision forming | Box cams | Self-contained rigidity, consistent stroke repeatability | Moderate forces with standard stroke lengths | Ultra-tight tolerances requiring custom guidance |

Evaluating Standard vs Special Configurations

How do you know when a standard solution works versus when you need something special? Start by honestly assessing whether your application falls within published specifications—not at the edge, but comfortably within rated parameters.

Standard solutions typically work when:

- Your calculated force falls below 70% of the rated capacity

- Your mounting angle matches standard ranges (0°-15° or 15°-60°)

- Your stroke length appears in standard product offerings

- Your production speed stays within proven cycling rates

- Available die space accommodates standard unit dimensions

Consider special configurations when:

- Multiple parameters simultaneously push boundaries

- Compound motion paths exceed single-axis capabilities

- Unusual mounting orientations prevent standard driver engagement

- Production volumes justify custom optimization for specific performance gains

- Integration with existing proprietary tooling requires non-standard interfaces

When special configurations become necessary, engage with experienced cam unit suppliers early in the design process. Custom solutions require longer lead times and collaboration to ensure the final product meets your actual requirements.

With the right cam configuration matched to your specific challenge, the next critical step involves avoiding the selection mistakes that undermine even well-intentioned engineering decisions.

Selection Mistakes That Compromise Stamping Performance

You've done the calculations, reviewed the specifications, and selected what seems like the perfect cam unit. But here's the uncomfortable truth: even experienced die engineers make selection errors that don't reveal themselves until production begins—and by then, the costs multiply rapidly. Understanding these cam selection mistakes before you finalize specifications saves far more than the time it takes to double-check your decisions.

Costly Errors in Cam Unit Specification

What separates a trouble-free cam installation from one that causes ongoing headaches? Often, it comes down to overlooking details that product catalogs don't emphasize. These cam unit specification errors appear repeatedly across stamping operations—and they're almost always preventable.

- Underestimating working force requirements: This remains the most common and damaging mistake. Engineers calculate theoretical force needs but forget to add adequate safety margins for material variation, tool wear, or off-center loading. A cam rated at exactly your calculated requirement operates at its limit from day one—leaving zero margin for the real-world variables that inevitably occur.

- Ignoring stroke life ratings: Remember those dual force specifications—one for 1,000,000 strokes, another for 300,000? Selecting based on the higher force rating without considering your actual production volumes creates premature wear. A cam running at 300,000-stroke capacity in a high-volume automotive application won't last through a single model year.

- Mismatching mounting angles with driver types: A horizontal driver paired with a 30° mounted cam unit creates binding, inconsistent stroke completion, and accelerated wear on contact surfaces. This mismatch often happens when engineers reuse drivers from previous projects without verifying compatibility with new mounting orientations.

- Overlooking maintenance access requirements: That perfect cam position within your die layout becomes a nightmare when technicians can't reach the unit for lubrication, adjustment, or replacement. Inaccessible cams lead to deferred maintenance, which leads to unexpected failures.

- Failing to account for thermal expansion: Dies heat up during production. Components expand at different rates. A cam unit selected with tight clearances at room temperature may bind when the die reaches operating temperature—or conversely, develop excessive play that affects part quality.

- Selecting based solely on initial cost: The cheapest cam unit that technically meets specifications often costs more over its service life. Inferior materials, looser tolerances, or reduced bearing capacity translate into shorter replacement intervals and more frequent production interruptions.

- Neglecting return mechanism capacity: The cam must return completely before the next press stroke. Undersized springs or nitrogen cylinders struggle against friction and inertia, especially as wear increases. Incomplete return causes driver collision and catastrophic damage.

Red Flags That Signal Wrong Selection

Sometimes stamping cam problems don't emerge during the selection process—they appear after installation. Recognizing these warning signs early helps you address issues before they cascade into major failures or quality escapes.

Watch for these indicators that your cam unit may be incorrectly specified:

- Excessive heat generation: A properly sized cam unit warms slightly during operation. If the slider or housing becomes too hot to touch comfortably, the unit is likely working harder than intended—either from undersizing, inadequate lubrication, or binding from misalignment.

- Inconsistent stroke completion: When parts show variation in cam-formed features—some fully formed, others incomplete—the unit may lack sufficient force or return capacity. This inconsistency often worsens as production continues.

- Unusual noise patterns: Listen to your cam units. Grinding, clicking, or impact sounds during cycling indicate problems. Metal-on-metal contact where smooth sliding should occur signals wear, misalignment, or inadequate lubrication.

- Rapid lubricant consumption: If you're adding lubricant far more frequently than maintenance schedules suggest, something is wrong. Excessive consumption often indicates high friction from improper loading or contamination from wear particles.

- Visible wear progression: Inspect contact surfaces regularly. Scoring, galling, or material transfer between driver and slider surfaces indicates loads or engagement geometry beyond design intent.

- Return timing drift: A cam that initially returned crisply but now hesitates or fails to reach full retraction points to degrading return mechanisms—often from undersized springs or cylinders fighting greater-than-expected friction.

Verification Steps Before Finalizing Selection

Die cam troubleshooting is far more expensive than upfront verification. Before committing to any cam unit specification, work through these confirmation steps:

- Recalculate forces with worst-case material properties: Use the high end of material strength specifications, not nominal values. Add at least 25% safety factor beyond this conservative calculation.

- Verify mounting angle compatibility: Confirm that your selected driver explicitly supports your cam unit's mounting orientation. When in doubt, consult the manufacturer's compatibility charts.

- Model thermal conditions: Consider how die temperature affects clearances. If running high volumes or with heated dies, verify that cam specifications account for expansion.

- Simulate maintenance access: Before finalizing die layout, physically verify—or model in CAD—that technicians can access the cam unit for routine service without disassembling surrounding components.

- Check stroke life against production plans: Calculate expected annual strokes based on your production schedule. Ensure your selected force rating corresponds to a stroke life that exceeds at least two years of planned production.

- Review return mechanism sizing: Confirm that return springs or nitrogen cylinders provide adequate force for positive retraction at your operating speed—with margin for friction increase as wear develops.

- Validate against industry standards: If your customer requires NAAMS, ISO, JIS, or OEM-specific compliance, verify that every component in your cam system meets those specifications.

These verification steps take time—but far less time than troubleshooting failed cam units during production trials or rebuilding dies to correct selection errors. The wisdom that product catalogs cannot provide comes from understanding that specifications represent starting points, not guarantees.

With selection mistakes identified and prevention strategies in place, the final consideration involves maintaining your cam units properly throughout their service life—a topic that directly impacts whether your careful selection translates into reliable long-term performance.

Maintenance Requirements and Lifecycle Planning

You've selected the right cam unit, verified compatibility, and avoided the common specification mistakes. But here's what determines whether that careful selection pays off over the long term: how well you maintain the unit throughout its die cam service life. Surprisingly, this critical topic gets almost no attention in product catalogs or competitor content—yet maintenance practices directly influence whether your cam units deliver years of reliable performance or become recurring headaches.

Maintenance Schedules by Cam Unit Type

Not all cam units demand the same maintenance attention. Understanding how different configurations vary in their service requirements helps you plan resources effectively—and should actually factor into your initial selection decisions.

Standard cam units typically require moderate maintenance. Their conventional construction provides good access to wear surfaces and lubrication points. Expect routine attention at regular intervals with straightforward procedures.

Heavy-duty cam units handle greater forces but generate more heat and friction as a result. Stamping cam lubrication intervals shorten compared to standard units, and inspection for wear indicators becomes more critical. The robust construction means components last longer under proper care—but neglect accelerates failure dramatically.

Aerial cams often benefit from better maintenance access due to their above-die positioning. However, their exposure to environmental contaminants may require more frequent cleaning. The lighter construction means wear progresses faster if lubrication lapses.

Box cams present a trade-off. Their self-contained design protects internal components but can complicate inspection of wear surfaces. Follow manufacturer guidance carefully, as some box cam designs require disassembly for thorough maintenance.

High-speed bump cams demand the most frequent attention. Rapid cycling accelerates lubricant breakdown and wear progression. If your production runs high-speed cam operations, budget for proportionally more maintenance time.

Comprehensive Maintenance Checklist by Frequency

Organizing cam unit maintenance around consistent schedules prevents the reactive approach that leads to unexpected failures. Use this frequency-based checklist as your foundation:

-

Daily maintenance tasks:

- Visual inspection for obvious damage, debris accumulation, or lubricant leakage

- Listen for unusual noise during operation—grinding, clicking, or impact sounds

- Verify complete stroke and return with no hesitation or binding

- Check that automatic lubrication systems (if equipped) are functioning

- Wipe external surfaces to remove metal particles and contamination

-

Weekly maintenance tasks:

- Apply fresh lubricant to all accessible grease points and sliding surfaces

- Inspect driver engagement surfaces for scoring, galling, or material transfer

- Check return spring tension or nitrogen cylinder pressure

- Verify mounting bolt torque remains within specification

- Measure stroke consistency across multiple cycles

-

Monthly maintenance tasks:

- Perform detailed inspection of all cam wear indicators—guide rails, slider surfaces, bearing areas

- Clean and re-lubricate internal components according to manufacturer procedures

- Check for thermal damage or discoloration indicating overheating

- Inspect seals and wipers for degradation that allows contamination ingress

- Review stroke counter readings against expected production volumes

- Document any wear measurements for trend tracking

-

Annual maintenance tasks:

- Complete disassembly and inspection per manufacturer guidelines

- Replace wear components (springs, seals, wipers, bushings) regardless of apparent condition

- Verify dimensional accuracy of slider and guide surfaces against original specifications

- Rebuild or replace nitrogen cylinders approaching end of service life

- Recalibrate any integrated sensors or monitoring equipment

- Evaluate overall condition against remaining production requirements and plan replacements

Extending Service Life Through Proper Care

Beyond scheduled maintenance, several practices significantly extend cam unit longevity:

Lubrication quality matters: Use only manufacturer-recommended lubricants. Stamping cam lubrication requirements vary—some units need high-pressure grease, others require specific oil viscosities. Substituting incompatible products accelerates wear even when applied correctly.

Control operating temperature: Excessive heat degrades lubricants and accelerates wear. If your cam units consistently run hot, investigate root causes—undersizing, inadequate lubrication, or binding from misalignment—rather than simply accepting elevated temperatures as normal.

Maintain cleanliness: Metal particles, die lubricant overspray, and environmental contamination work into sliding surfaces and act as abrasives. Regular cleaning and functional wipers prevent this contamination from shortening service life.

Address problems immediately: Small issues become big failures. A slight hesitation in return stroke, an occasional unusual noise, or marginally increased lubricant consumption all signal developing problems. Investigating early often reveals simple fixes; ignoring warnings leads to catastrophic failures.

Troubleshooting Common Cam Unit Problems

When cam units develop issues despite proper maintenance, systematic troubleshooting identifies root causes:

Excessive wear: If wear progresses faster than expected, evaluate whether the unit is actually sized correctly for your application. Accelerated wear often indicates undersizing—the unit works harder than designed, generating more friction and heat. Also verify lubrication adequacy and contamination control.

Binding during stroke: Binding typically stems from misalignment, thermal expansion issues, or contamination in guide surfaces. Check mounting bolt torque, verify driver engagement geometry, and inspect for debris or galling on sliding surfaces. Thermal binding worsens as the die heats—if problems appear mid-run but not at startup, temperature is likely involved.

Inconsistent stroke: When stroke length varies between cycles, investigate return mechanism condition first. Weak springs or low nitrogen pressure prevents complete retraction. Also check for mechanical interference from adjacent die components or strip material.

Noise issues: Grinding sounds indicate metal-to-metal contact—typically from inadequate lubrication or worn guide surfaces. Clicking or impact noises suggest timing problems with driver engagement or return mechanism issues. Squealing often points to lubricant breakdown or contamination.

Documenting problems and corrective actions builds institutional knowledge that improves future cam unit selection and maintenance practices. What you learn from troubleshooting one application informs better decisions on the next.

With maintenance practices established and troubleshooting approaches understood, the final step involves synthesizing everything into a unified selection framework that guides you from initial requirements through validated specification.

Building Your Cam Unit Selection Framework

You've explored cam types, calculated tonnage requirements, navigated driver compatibility, matched configurations to specific challenges, learned to avoid costly mistakes, and established maintenance practices. Now it's time to bring everything together into a systematic framework that transforms these individual insights into a repeatable selection process. Whether you're specifying cams for a new progressive die or evaluating replacements for existing tooling, this cam unit selection guide provides the structure to make confident, validated decisions.

Your Complete Selection Checklist

Before diving into specifications, gather the information that drives every downstream decision. Think of this checklist as your foundation—skip any element, and you risk building your selection on incomplete data.

Application requirements documentation:

- What stamping operation does the cam perform? (piercing, trimming, forming, ejection)

- What material are you processing? (type, thickness, tensile strength)

- What are the part feature dimensions affected by cam action?

- What mounting orientation does your die design require?

- What production volume and cycle rate do you anticipate?

- What industry standards must the die meet? (NAAMS, ISO, JIS, OEM-specific)

Physical constraints inventory:

- Available die shoe space for cam unit mounting

- Vertical clearance for aerial configurations if conventional mounting isn't feasible

- Maintenance access paths for lubrication and inspection

- Adjacent component interference zones

- Thermal considerations based on die operating temperature

Performance expectations:

- Required stroke length for complete operation

- Acceptable stroke life before maintenance or replacement

- Tolerance requirements for cam-produced features

- Cycling speed compatibility with press specifications

From Requirements to Final Specification

With your requirements documented, follow this step-by-step die engineering process to transform information into validated specifications:

- Define operation requirements precisely: Start by clearly articulating what the cam must accomplish. Document the specific operation type, direction of motion required, and how the cam action integrates with other die stations. Vague requirements lead to specification errors—take time to be specific.

- Calculate force needs with appropriate margins: Apply the tonnage calculation methodology covered earlier. Use worst-case material properties, add 25-30% safety factor, and determine which stroke life rating (1,000,000 vs 300,000 strokes) matches your production volume. Your calculated force requirement becomes your minimum cam capacity threshold.

- Identify space constraints and mounting options: Map the physical envelope available for cam installation. Determine whether conventional in-die mounting works or if aerial configurations become necessary. Document the mounting angle—horizontal (0°-15°) or angular (15°-60°)—as this directly influences both cam unit and driver selection.

- Select the appropriate cam type: Based on your force requirements, space constraints, and operation characteristics, choose from standard, heavy-duty, aerial, box, bump, or piercing cam configurations. Reference the comparison tables and decision matrix from earlier sections to match your specific challenge to the right cam category.

- Choose a compatible driver configuration: With your cam type and mounting angle defined, select a driver that matches both parameters. Verify that the driver's force rating accommodates your requirements and that engagement geometry works with your mounting orientation. Don't assume compatibility—confirm it explicitly.

- Verify against applicable standards: Cross-reference your selections against the industry standards your die must meet. If NAAMS compliance is required, verify every component meets those specifications. For automotive OEM tooling, confirm that cam system requirements align with customer-specific standards.

- Validate with your supplier or engineering partner: Before finalizing specifications, review your selections with an experienced source. Whether that's the cam unit manufacturer's application engineering team or your die engineering partner, external validation catches oversights that internal review might miss.

The Value of Experienced Die Engineering Partners

Here's a reality that specification sheets can't capture: cam unit selection happens within the context of complete die design. The best cam selection for an isolated operation might create problems when integrated with forming stations, pilots, strip handling, or other die elements. This interdependency is why working with experienced die engineering partners—teams who understand both cam unit specifications and overall stamping die design—often proves more valuable than independent specification work.

Experienced partners bring several advantages to your cam system requirements decisions:

- Holistic design perspective: They evaluate cam selection within the context of complete die function, identifying potential conflicts before they become problems.

- Simulation capabilities: Advanced CAE simulation validates cam performance within the dynamic die environment, predicting issues that static calculations might miss.

- Standards expertise: Partners working across multiple OEM programs understand the nuances of various industry standards and can navigate compliance requirements efficiently.

- Practical experience: Real-world stamping experience informs selections in ways that catalog specifications cannot—they've seen what works and what fails across thousands of applications.

For automotive stamping applications where precision and reliability are non-negotiable, partnering with IATF 16949 certified organizations ensures that quality management systems support every aspect of die design and fabrication. Companies like Shaoyi combine advanced CAE simulation capabilities with deep stamping die expertise, providing validation for cam unit integration within comprehensive die solutions. Their engineering teams understand how proper cam selection contributes to the defect-free results that automotive OEMs demand.

Bringing It All Together

Cam unit selection for stamping isn't a single decision—it's a series of interconnected choices that build upon each other. The framework presented throughout this guide transforms what might seem like an overwhelming specification challenge into a manageable, systematic process:

- Understand what cam units do and why selection matters

- Know the different cam types and when each applies

- Calculate tonnage requirements accurately with appropriate margins

- Select compatible drivers based on mounting orientation and force requirements

- Match configurations to your specific stamping challenges

- Avoid the selection mistakes that compromise performance

- Plan for maintenance requirements throughout the cam unit's lifecycle

- Follow the structured stamping die specification process from requirements to validation

Each step builds on the previous ones. Skip the tonnage calculations, and you can't confidently select between standard and heavy-duty units. Ignore mounting angle considerations, and your driver selection may cause binding. Overlook maintenance planning, and your careful selection degrades into premature failure.

The difference between a cam installation that performs reliably for years and one that causes ongoing problems often comes down to the diligence applied during selection. Product catalogs provide specifications—but the judgment to interpret those specifications within your specific application context comes from understanding the complete picture.

Armed with this cam unit selection guide, you're equipped to make decisions that protect part quality, extend die longevity, and maintain the production efficiency your stamping operations demand.

Frequently Asked Questions About Cam Unit Selection for Stamping

1. What are cam units and how do they work in stamping dies?

Cam units are mechanical motion converters that redirect the vertical force from a stamping press into horizontal or angular motion. When the press ram descends, it engages a driver that activates the cam slider, enabling operations like side-piercing, angular forming, and trimming that vertical motion alone cannot accomplish. This makes them essential components in progressive and transfer dies for producing complex part geometries.

2. What are the 7 steps in the stamping method?

The seven most popular metal stamping processes include blanking (cutting the initial shape), piercing (creating holes), drawing (forming depth), bending (creating angles), air bending (flexible angle forming), bottoming and coining (precision bending), and pinch trimming (removing excess material). Each process may utilize different cam unit configurations depending on the required motion direction and force levels.

3. What are the different types of cam systems used in stamping?

Stamping operations utilize several cam types: standard cams for everyday piercing and trimming, heavy-duty cams for high-force applications exceeding 50 kN, aerial cams for space-constrained dies, box cams offering self-contained rigidity, bump cams for quick ejection actions, and piercing cams optimized for angular cutting operations. Selection depends on force requirements, available space, and mounting orientation.

4. How do you calculate the required tonnage for cam unit selection?

Calculate required force using the formula: Cut Perimeter × Material Thickness × Material Shear Strength. Add a 25-30% safety factor to account for material variations and tool wear. Consider stroke life ratings—manufacturers typically provide force values for both 1,000,000 and 300,000 stroke lifespans. Match your production volume to the appropriate rating for optimal cam sizing.

5. What are the most common mistakes when selecting cam units for stamping dies?

Critical selection errors include underestimating working force requirements without adequate safety margins, ignoring stroke life ratings relative to production volumes, mismatching mounting angles with driver types, overlooking maintenance access in die layout, and failing to account for thermal expansion during operation. These mistakes lead to premature wear, inconsistent part quality, and unexpected production stoppages.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —