Automotive Stamping Safety Standards: Compliance, PPE & Quality Protocols

TL;DR

Automotive stamping safety standards rely on three critical pillars: regulatory compliance, operational safeguarding, and product quality assurance. In the United States, OSHA 29 CFR 1910.217 mandates the legal requirements for mechanical power presses, while ANSI B11.1 provides consensus best practices for machine guarding and design. For worker protection, ANSI/ISEA 105 dictates cut resistance levels, with automotive applications typically requiring Level A7–A9 gloves due to sharp, high-strength steel edges.

Beyond worker safety, product safety is governed by IATF 16949, a quality management standard that ensures safety-critical components—like airbag housings and brake pedals—are manufactured with zero defects. Mastering these standards requires a holistic approach: rigorous machine guarding (light curtains, physical barriers), disciplined die design (efficient scrap shedding), and documented training programs for all operators and die setters.

The Regulatory Core: OSHA & ANSI Standards

The foundation of a safe stamping floor in the automotive sector is built upon two distinct but related bodies of standards: the mandatory federal regulations from OSHA and the voluntary consensus standards from ANSI. Understanding the distinction and the interplay between them is essential for plant managers and safety engineers.

OSHA 29 CFR 1910.217: The Legal Baseline

OSHA’s standard for Mechanical Power Presses (29 CFR 1910.217) is not a suggestion; it is the law. This regulation focuses heavily on preventing amputation hazards at the point of operation. Key requirements include the installation of guards or devices that prevent the operator’s hands or other body parts from entering the danger zone during the die-closing cycle. It mandates specific protocols for regular inspections, requiring that presses be examined at least weekly to ensure clutches, brakes, and control mechanisms are functioning correctly.

A critical component of 1910.217 is the requirement for control reliability in systems using presence-sensing devices (like light curtains). If a safety component fails, the system must be designed to stop the press and prevent a successive stroke. Failure to adhere to these specific guarding and inspection mandates is a frequent cause of severe citations and, more importantly, life-altering injuries.

ANSI B11.1: Best Practice & Risk Assessment

While OSHA provides the regulatory floor, the ANSI B11.1 standard establishes the ceiling of safety excellence. As a consensus standard, it often reflects more current technology and methodologies than federal regulations. ANSI B11.1 emphasizes a risk assessment approach, encouraging manufacturers to analyze every task associated with the press—from operation to maintenance and die setting—and apply appropriate risk reduction measures.

Compliance with ANSI B11.1 involves rigorous brake monitoring systems that track the stopping time of the press. If the stopping time deteriorates beyond a set limit, the monitor prevents the press from cycling, ensuring that safety devices like light curtains have sufficient time to halt the slide before an operator can reach the hazard. Adhering to ANSI standards is often cited as a defense in liability cases, demonstrating that a facility went beyond the bare minimum to ensure worker safety.

Operational Safety: Machine Guarding & Die Design

Effective safety measures are not just about adding guards to a machine; they must be integrated into the tooling and operational workflow itself. In automotive stamping, where complex progressive dies run at high speeds, the design of the die plays a pivotal role in preventing accidents.

Safeguarding Technologies

Modern automotive press lines utilize a mix of barrier guards and presence-sensing devices. Light curtains are the industry standard for point-of-operation guarding, creating an invisible infrared field that stops the machine immediately if broken. However, for these to be effective, the safety distance must be calculated precisely based on the press's stopping time. If the press takes too long to stop, a worker’s hand could technically reach the die before the motion ceases, rendering the curtain useless.

Physical barrier guards are equally critical, particularly for the sides and rear of the press where operator interaction is less frequent but hazards still exist. These interlocked barriers must ensure that the machine cannot operate if a gate is open. For automated lines, awareness barriers and perimeter guarding prevent unauthorized entry into the robot work cells where sheet metal is transferred.

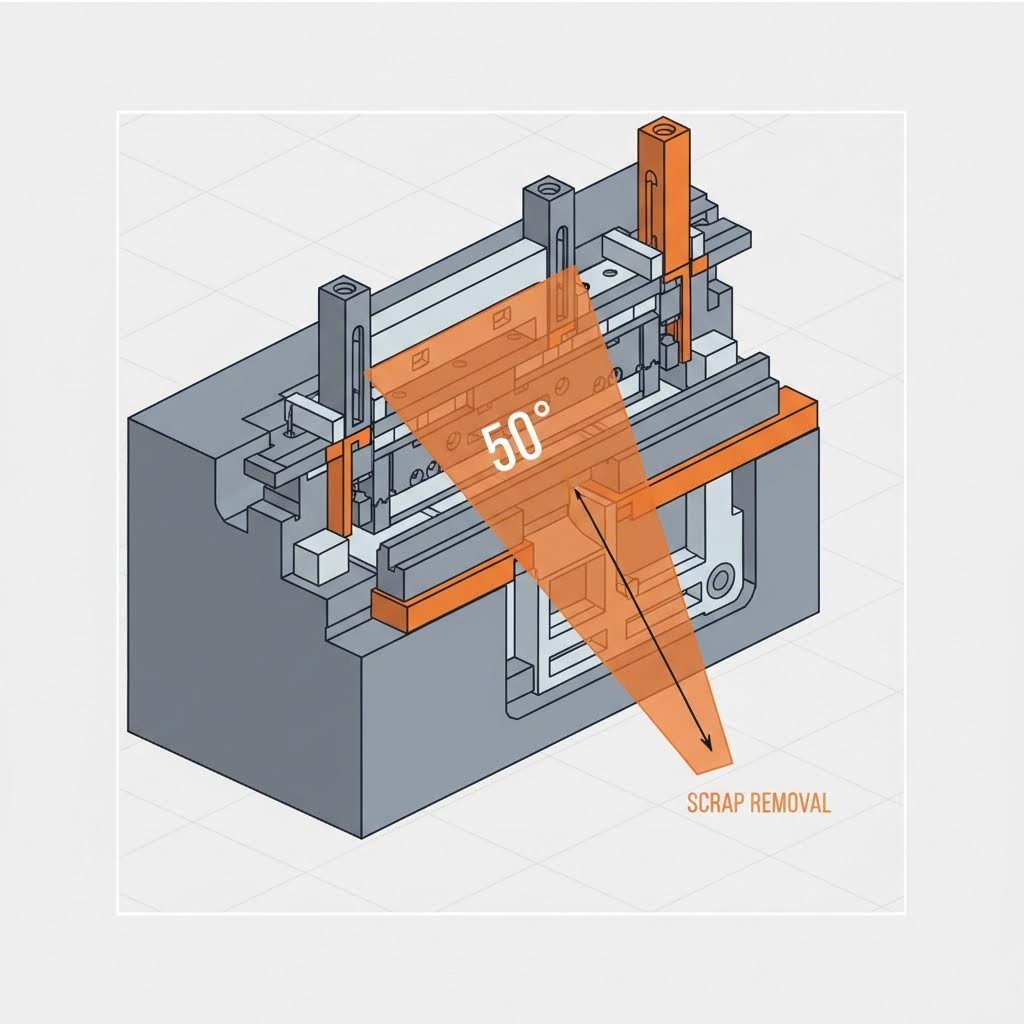

Safety-Centric Die Design

A surprising number of stamping injuries occur not during normal operation, but when clearing scrap jams or adjusting the die. Intelligent die design mitigates these risks. According to industry experts, waste chutes and scrap funnels should be designed with inclination angles greater than 30 degrees—ideally 50 degrees for smaller scrap—to ensure gravity effectively clears the debris. If scrap accumulates, operators are tempted to reach in to clear it, bypassing safety protocols.

Designers must also account for scrap deformation. Ensuring that punches have appropriate back clearance and that scrap cutters are positioned to allow free fall prevents the "nesting" of scrap that leads to jams. By engineering the die to shed waste reliably, manufacturers remove the primary incentive for unsafe interventions.

Personal Protection: PPE & Cut Resistance

Automotive stamping involves handling some of the sharpest, highest-strength materials in manufacturing. As lightweighting trends push the industry toward advanced high-strength steels (AHSS), the risk of severe lacerations increases. The first line of defense for the individual worker is Personal Protective Equipment (PPE), specifically cut-resistant hand protection.

ANSI/ISEA 105 Standards

The ANSI/ISEA 105 standard creates a consistent scale for rating the cut resistance of gloves, ranging from A1 (low) to A9 (extreme). For general assembly, lower levels may suffice, but automotive stamping environments typically demand Level A7 to A9 protection. A glove rated A9 can withstand over 6,000 grams of cutting load, a necessary threshold when handling raw stamped edges that act like serrated razors.

Materials engineering has advanced significantly in this area. Modern high-performance gloves often use composite shells blending steel fibers with para-aramid (like Kevlar®) or HPPE (high-performance polyethylene). These "salt and pepper" or steel-reinforced shells provide the necessary cut protection without sacrificing the dexterity needed to handle small precision parts. Managers should enforce a strict PPE matrix that matches the glove rating to the specific task—die setters handling raw coil stock require different protection than forklift drivers moving finished pallets.

Product Safety: Quality Standards (IATF 16949)

In the automotive sector, "safety" has a dual meaning: protecting the worker making the part, and protecting the driver using the vehicle. A defect in a stamped component—such as a micro-crack in a brake pedal or a burr on an airbag housing—can lead to catastrophic failure on the road.

The Role of IATF 16949

IATF 16949 is the global technical specification for quality management in the automotive supply chain. Unlike general ISO 9001 certification, IATF 16949 focuses specifically on defect prevention, reduction of variation, and waste reduction. For stamping suppliers, this means maintaining strict traceability of raw materials and process parameters. Every coil of steel must be traceable to the specific batch of stamped parts, ensuring that if a material defect is found, the affected lot can be immediately contained.

Safety-critical parts (often designated with special symbols on engineering drawings) require even higher levels of scrutiny. Manufacturers must prove their process capability (Cpk) ensures that 100% of these parts meet specifications. This often involves automated vision systems that inspect every single stamped part for dimensions and surface defects before it leaves the press.

For automotive OEMs and Tier 1 suppliers, selecting a partner who embodies these rigorous standards is non-negotiable. Shaoyi Metal Technology provides comprehensive stamping solutions that bridge the gap from rapid prototyping to high-volume manufacturing. With IATF 16949 certification and press capabilities up to 600 tons, they specialize in producing safety-critical components like control arms and subframes that strictly adhere to global OEM standards.

Safety Culture & Training Requirements

Equipment and certifications are useless without a competent workforce. OSHA regulations and industry best practices mandate comprehensive training programs that differentiate between general operators and specialized personnel like die setters and maintenance staff.

Operators must be trained specifically on the safe operation of the press they are running, including how to verify that safeguards are functional before every shift. Die setters face different hazards, often working with the guards removed or bypassed under specific "inch mode" protocols. Their training must focus on energy control procedures (Lockout/Tagout) and the proper use of safety blocks to prevent the slide from falling during die maintenance.

A robust safety culture is reinforced by regular audits. Weekly inspections of press mechanics (clutch/brake mechanisms) should be complemented by behavioral safety observations. Are operators wearing their A9 gloves? Are light curtains being tested at every shift change? Documenting these audits creates a feedback loop that continually improves safety performance and ensures the facility remains audit-ready for both OSHA inspectors and automotive clients.

Summary of Compliance Protocols

Achieving excellence in automotive stamping safety requires integrating legal mandates with operational discipline. By aligning facility protocols with OSHA 1910.217 for machinery, adopting ANSI B11.1 for risk management, and enforcing strict PPE standards, manufacturers protect their most valuable asset—their people. Simultaneously, adherence to IATF 16949 ensures that the components leaving the dock contribute to safer vehicles on the road.

Success in this high-stakes industry is not accidental; it is the result of deliberate planning, rigorous training, and the selection of certified partners who understand the critical nature of automotive manufacturing. Prioritize these standards to build a production environment that is resilient, compliant, and world-class.

Frequently Asked Questions

1. What is the difference between ISO 9001 and IATF 16949?

ISO 9001 is a general quality management standard applicable to any industry. IATF 16949 is a technical specification built upon ISO 9001 but explicitly tailored for the automotive sector. It includes additional, more stringent requirements for defect prevention, supply chain management, and safety-critical parts documentation.

2. What are the main steps in the automotive stamping process?

The stamping process typically involves feeding a metal strip or blank into a press where a die forms it. Key steps include blanking (cutting the initial shape), piercing (punching holes), drawing (stretching metal into 3D shapes), and bending. Progressive dies may perform all these steps sequentially in a single pass.

3. What PPE cut level is required for stamping automotive parts?

Due to the prevalence of sharp edges and high-strength steel, the automotive stamping industry generally recommends ANSI Level A7 to A9 cut-resistant gloves. Lower levels (A1–A4) are typically insufficient for handling raw stamped metal and can lead to severe laceration injuries.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —