Automotive Metal Stamping Process Overview: From Coil to Component

TL;DR

Automotive metal stamping process overview: This high-speed manufacturing technique converts flat sheet metal into precise vehicle components using hydraulic or mechanical presses and custom dies. The process relies on extreme pressure (often exceeding 1,600 tons) to cut, form, and shape materials like high-strength steel and aluminum into critical parts ranging from chassis brackets to body panels. For automotive engineers and procurement teams, metal stamping offers unmatched scalability, cost-efficiency, and repeatability, making it the backbone of modern mass production.

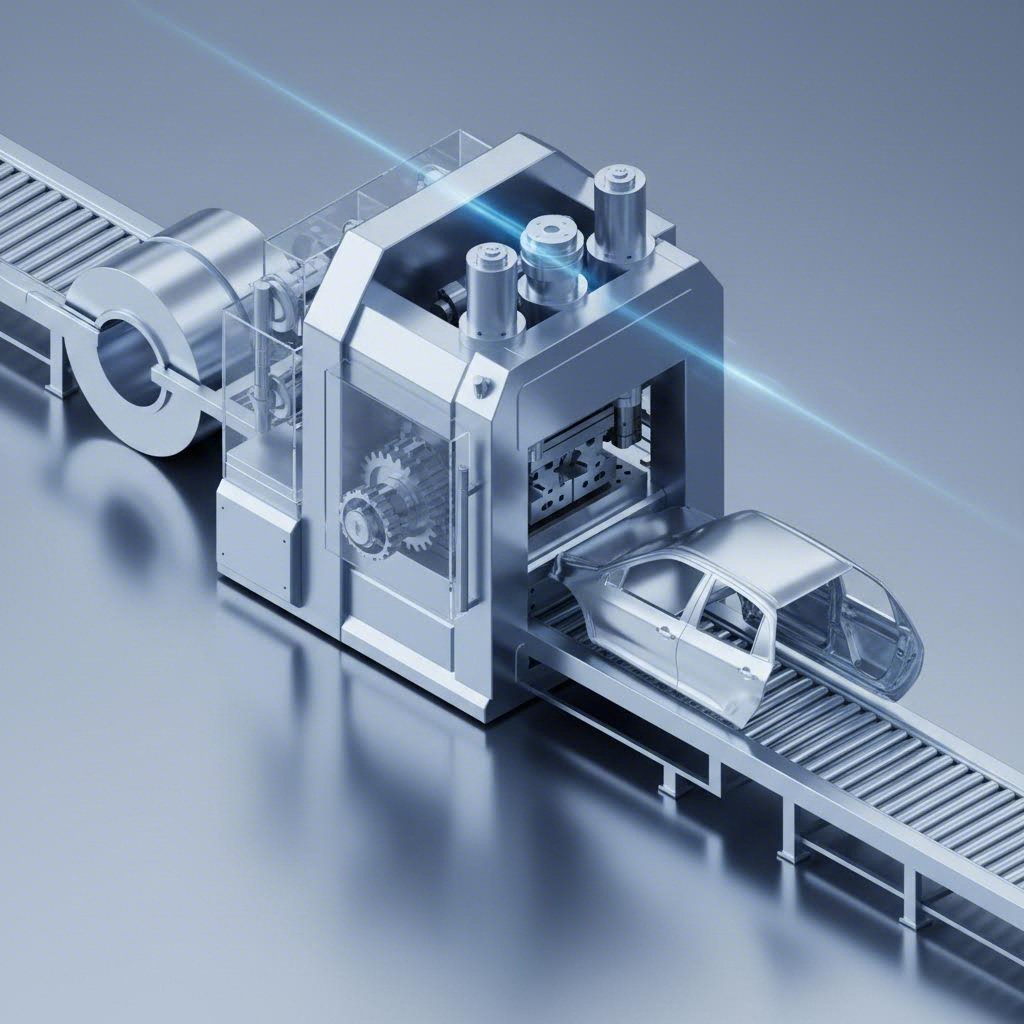

The Anatomy of the Process: From Coil to Component

Understanding the journey from a raw metal coil to a finished automotive part requires looking inside the press shop. The process is a chronological workflow where precision engineering meets brute force. According to major manufacturers like Toyota, a single stamping step can take as little as three seconds while applying vertical pressure equivalent to thousands of cars stacked on top of each other.

- Design and Die Creation: The process begins long before the metal touches the press. Engineers use CAD/CAM software to design the component and the corresponding "die" (the tool that shapes the metal). This stage determines the part's tolerances, often measuring within 1/1000th of a millimeter to ensure seamless assembly.

- Material Feeding: Huge coils of sheet metal are unraveled and fed into the press. This stage often involves straightening and leveling the metal to remove any curvature from the coil, ensuring the "blank" enters the die perfectly flat.

- Blanking and Piercing: As the metal enters the press, the first operation is typically "blanking," where the rough outline of the part is cut from the strip. Simultaneously, piercing operations may punch holes required for fasteners or assembly alignment.

- Forming and Drawing: This is where the magic happens. The press forces the flat blank into the die cavity, plastically deforming it into a 3D shape. This can involve bending, flanging, or drawing the metal to create depth.

- Finishing: The stamped part is ejected, but it isn't finished. Post-processing steps like deburring remove sharp edges, while surface treatments may be applied for corrosion resistance.

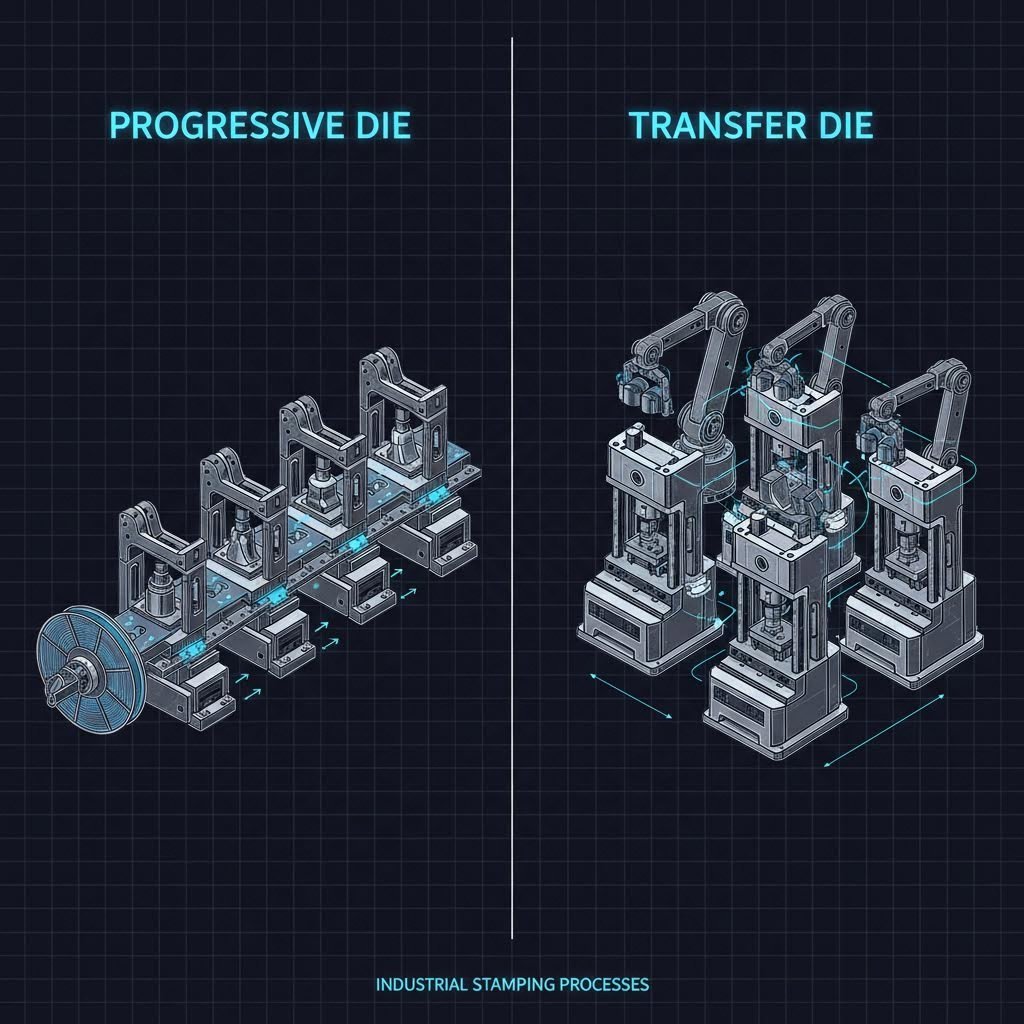

Core Stamping Techniques: Progressive vs. Transfer vs. Deep Draw

Not all automotive parts are created equal, and neither are the stamping methods used to produce them. Choosing the right technique depends on the part's complexity, volume, and size. Leaders in the field like ESI Engineering emphasize three dominant methods.

Progressive Die Stamping

Ideal for high-volume production of small-to-medium parts, progressive stamping uses a continuous strip of metal that feeds through a series of stations within a single die. Each station performs a different operation (cut, bend, punch) as the strip moves forward. It is the speed king of the industry, capable of producing hundreds of parts per minute with minimal waste.

Transfer Die Stamping

For larger components like door panels or engine frames, transfer stamping is the standard. Unlike progressive stamping where parts stay attached to the metal strip, here the part is cut free early in the process. Mechanical "fingers" or transfer systems move the individual part from one die station to the next. This allows for more complex geometries and larger sizes that a continuous strip cannot support.

Deep Draw Stamping

When a part's depth exceeds its diameter—think of an oil filter housing or a fuel tank—deep drawing is required. This technique uses a punch to radically stretch the metal into a die cavity. It requires specialized material flow control to prevent tearing or wrinkling during the extreme deformation process.

| Feature | Progressive Die | Transfer Die | Deep Draw |

|---|---|---|---|

| Primary Benefit | High speed & volume | Large & complex parts | Depth & cylindrical shapes |

| Typical Parts | Brackets, clips, terminals | Body pillars, suspension arms | Oil filters, sensor housings |

| Cost Driver | Lower per-piece cost | Higher tooling investment | Material formability limits |

Material Science: What Metals Build a Car?

The days of cars being made entirely of mild steel are long gone. Modern automotive stamping involves a complex mix of advanced alloys designed to balance safety, weight, and performance. American Industrial highlights the shift toward materials that support the industry's lightweighting mandates.

High-Strength Steel (HSS) remains the industry standard for safety-critical components like the chassis and passenger safety cage. It offers exceptional crash protection but requires significantly higher tonnage to stamp compared to traditional steel. Manufacturers must use hardened dies to withstand the abrasion and stress of forming HSS.

Aluminum is the material of choice for reducing vehicle weight and extending EV range. Used frequently for hoods, doors, and liftgates, aluminum is lighter than steel but more difficult to stamp due to its tendency to spring back after forming. It requires precise die engineering to compensate for this elasticity.

Copper and Brass play a smaller structural role but a massive functional one. With the rise of vehicle electrification, these metals are stamped into busbars, terminals, and connectors, valued for their superior electrical conductivity.

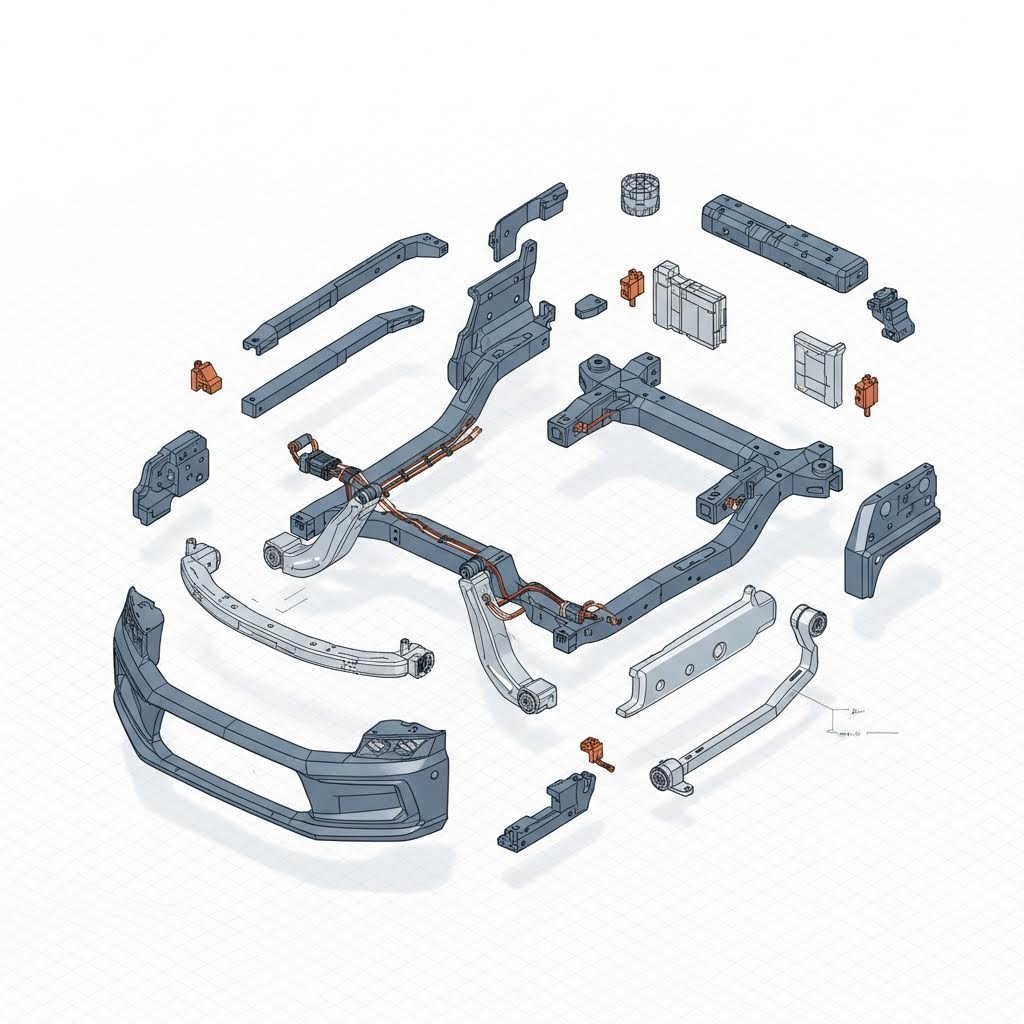

Automotive Applications: What Parts Are Actually Stamped?

The versatility of the stamping process means it touches nearly every system in a vehicle. From the shiny exterior to the hidden mechanical heart, stamped parts are ubiquitous.

- Body-in-White: This refers to the vehicle's skeletal frame. Stamped parts here include large panels like fenders, hoods, and roofs, as well as structural pillars (A, B, and C pillars) that protect occupants. Surface finish is critical here; "Class A" stamping ensures a flawless exterior appearance.

- Chassis and Suspension: These parts, such as control arms and cross-members, must endure constant road vibration and stress. Stamping provides the necessary durability and fatigue resistance.

- Powertrain and Engine: Precision is paramount for engine components like oil pans, valve covers, and transmission gears. These parts often require tight tolerances to prevent leaks and ensure mechanical efficiency.

For manufacturers navigating the complex landscape between initial design and full-scale assembly, finding a partner capable of handling the entire spectrum is crucial. Companies like Shaoyi Metal Technology offer comprehensive stamping solutions that bridge the gap from rapid prototyping to mass production, utilizing presses up to 600 tons to deliver IATF 16949-certified components for everything from chassis systems to intricate electrical terminals.

Industry Trends: The Future of Stamping

The automotive stamping sector is evolving rapidly, driven by the transition to electric vehicles (EVs) and smart manufacturing. National Material notes that the demand for battery enclosures and thermal management systems is creating new opportunities for stampers. These components often require large, deep-drawn geometries and specialized joining techniques.

Furthermore, automation is transforming the press floor. Modern lines integrate IoT sensors directly into the dies to monitor wear and tear in real-time, predicting maintenance needs before a breakdown occurs. This "smart stamping" approach maximizes uptime and ensures that the millionth part produced is just as precise as the first.

Frequently Asked Questions

1. What are the 7 steps in the stamping method?

While variations exist, the seven common steps in a comprehensive stamping process include: 1. Blanking (cutting the rough shape), 2. Piercing (punching holes), 3. Drawing (forming depth), 4. Bending (shaping angles), 5. Air Bending (forming without bottoming out), 6. Bottoming and Coining (imprinting details and setting the final shape), and 7. Pinch Trimming (removing excess material from drawn parts).

2. What are the four types of metal stamping?

The four primary categories are Progressive Die Stamping (continuous automated shaping), Transfer Die Stamping (for large parts moved mechanically), Deep Draw Stamping (for deep, hollow shapes), and Fourslide/Multi-slide Stamping (for intricate bending from four directions simultaneously).

3. What is the stamping process in automated manufacturing?

In automated manufacturing, stamping involves interconnected systems where robotic arms or mechanical feeders move metal through the press line with minimal human intervention. This includes automatic coil feeding, robotic transfer between die stations, and automated optical inspection systems that verify quality at high speeds.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —