Key Die Cast Parts for Modern Automotive Interiors

TL;DR

Automotive interior die cast parts are crucial components created by forcing molten non-ferrous metals like aluminum, zinc, and magnesium into reusable steel molds under high pressure. This highly efficient manufacturing process produces complex, durable, and precise parts—including steering columns, seat frames, and dashboard components—that are essential for modern vehicle safety, functionality, and overall quality.

Understanding Die Casting for Automotive Interiors

Die casting is a versatile and economical metalworking process used to manufacture large quantities of intricate metal parts with excellent dimensional accuracy. In the automotive sector, it is the backbone for producing a wide range of components. The process involves injecting molten metal into a hardened steel die (or mold), where it cools and solidifies into the final shape, often referred to as the casting. This method is prized for its ability to create parts with thin walls and complex geometries that would be difficult or costly to produce through other manufacturing techniques.

It's important to clarify the scope of this topic. While hobbyists and model car enthusiasts often search for miniature "die-cast" parts for scale models, this article focuses on the industrial manufacturing of functional, full-size components for production vehicles used by major Original Equipment Manufacturers (OEMs). The principles are similar, but the scale, materials, and quality standards are vastly different, serving the rigorous demands of companies like Ford, GM, and Honda.

The primary reason die casting is so prevalent in the automotive industry is its combination of speed, precision, and cost-effectiveness for high-volume production. As explained in a detailed guide to automotive die casting, this technique allows for the creation of lightweight yet strong parts, which is critical for improving fuel efficiency and vehicle performance. Components such as steering column housings, key lock mechanisms, and glove box doors are common examples of interior parts made through this process, delivering both structural integrity and a high-quality surface finish.

Core Materials in Automotive Interior Die Casting

The selection of material is critical in die casting and is determined by the part's required strength, weight, corrosion resistance, and thermal conductivity. For automotive interiors, the vast majority of die cast parts are made from non-ferrous metals, primarily aluminum, zinc, and magnesium alloys. Each metal offers a unique set of properties tailored to specific applications within the vehicle.

Aluminum alloys are the most common choice due to their excellent combination of light weight and high strength. They maintain their durability at high temperatures, making them suitable for components near the engine firewall or in other demanding environments. Aluminum also offers good corrosion resistance and finishing characteristics.

Zinc alloys are valued for their exceptional casting fluidity, allowing for the creation of parts with very thin walls and intricate details. Zinc provides a superior surface finish, making it ideal for components where aesthetics are important. It also offers high impact strength and is easily plated or finished, which is why it's often used for door handles, lock components, and decorative trim.

Magnesium alloys are the lightest of the common die casting metals, approximately 33% lighter than aluminum. This makes them a premium choice for manufacturers focused on maximizing vehicle weight reduction to improve fuel economy and handling. Parts like steering wheel frames and seat risers are often made from magnesium, as noted by manufacturers like Inox Cast, to achieve significant weight savings without compromising strength.

To better illustrate the differences, here is a comparison of these key materials:

| Material | Key Properties | Common Interior Applications |

|---|---|---|

| Aluminum | Excellent strength-to-weight ratio, high-temperature resistance, good corrosion resistance. | Dashboard support brackets, pedal brackets, electronic housings. |

| Zinc | High ductility, excellent for thin walls and fine details, superior surface finish, high impact strength. | Door lock housings, seat belt retractor gears, pulleys, decorative trim, handles. |

| Magnesium | Extremely lightweight (lightest structural metal), good strength-to-weight ratio, excellent EMI/RFI shielding. | Steering wheel frames, seat frames and risers, console brackets, instrument panel chassis. |

A Catalog of Common Interior Die Cast Parts

The versatility of die casting allows for the production of a vast array of components that make up a modern vehicle's interior. These parts are engineered for fit, function, and feel, contributing significantly to the driver and passenger experience. They can be grouped into several key functional areas within the cabin.

Steering & Dashboard Components

This area requires precision and strength for safety and operational integrity. Die casting is used to produce structurally critical yet complex parts.

- Steering Column Housings: These parts protect and align the steering shaft and often integrate mounting points for ignition switches and turn signal stalks.

- Instrument Panel Frames: Often made of magnesium for weight savings, these large, complex castings form the structural backbone of the entire dashboard assembly.

- Airbag Housings: Die cast components provide the necessary strength and precise dimensions to safely contain and deploy airbags during a collision.

- Key Lock Housings: Zinc die casting is frequently used for its durability and ability to hold tight tolerances for the locking mechanism.

Seating & Console Components

Parts in this category must be robust to handle daily use and meet stringent safety standards, while also being as lightweight as possible.

- Seat Frames and Risers: Magnesium and aluminum die castings provide a strong, lightweight structure for seats, contributing to overall vehicle weight reduction.

- Seat Belt Retractor Gears and Pulleys: Zinc is often the material of choice for these small, high-strength components that are critical for safety system performance.

- Console and Armrest Brackets: These structural parts must be durable and are often complex in shape to fit within the vehicle's interior design.

Door & Trim Components

These parts combine functional roles with aesthetic requirements, as they are frequently touched and seen by vehicle occupants.

- Interior Door Handles and Mechanisms: Zinc is commonly used for its excellent surface finish and perceived quality and durability.

- Glove Box Doors and Latches: Die casting provides the rigidity and precision needed for a smooth, reliable opening and closing mechanism.

- Mirror Brackets: These parts must securely hold the interior rearview mirror while absorbing vibrations.

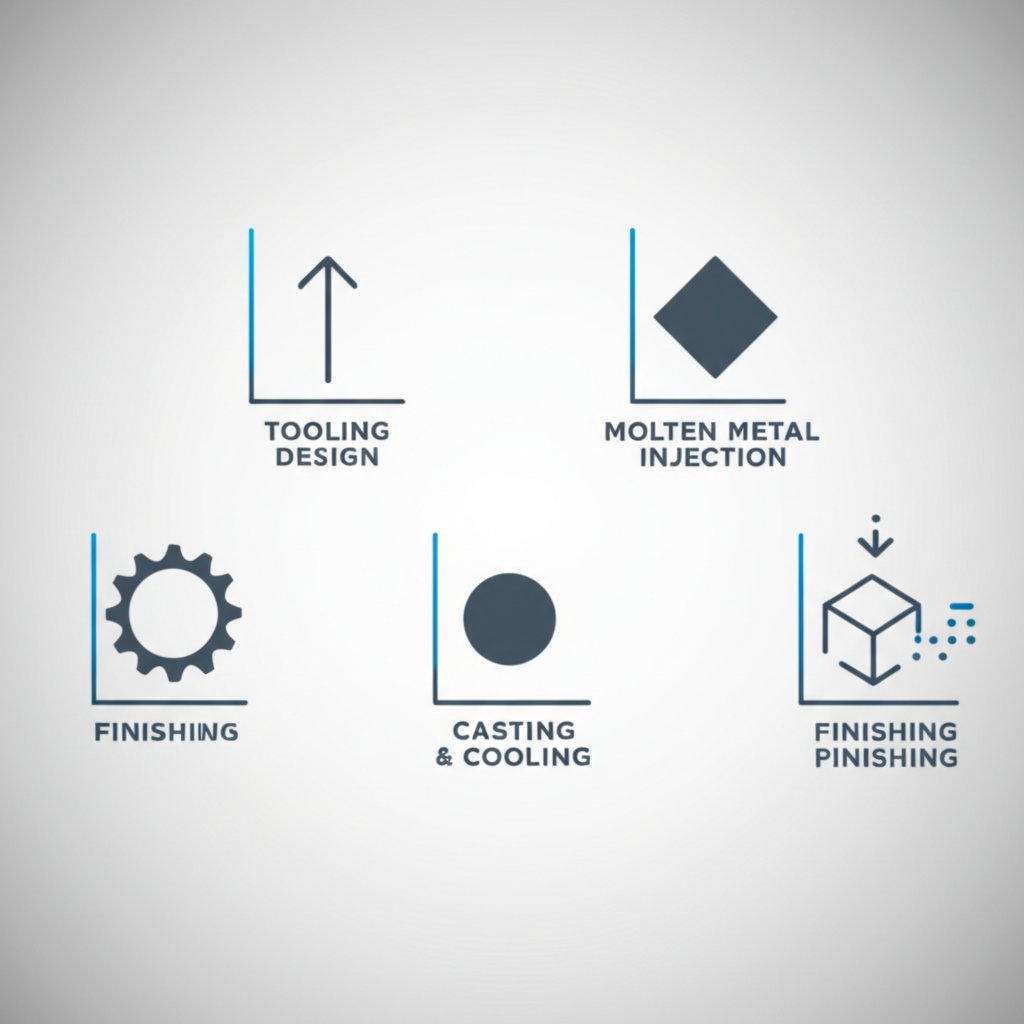

The Automotive Die Casting Process: From Tooling to Finish

Creating high-quality die cast parts is a multi-stage process that demands precision engineering from start to finish. Each step is critical to ensuring the final component meets the exacting standards of the automotive industry for strength, dimensional accuracy, and surface quality.

- Tooling and Die Design: The process begins with the creation of a reusable mold, known as a die. This is the most critical and capital-intensive stage. As specialists like Gemini Group explain, these dies are precision-engineered from hardened steel using advanced CAD/CAM software and CNC machining to create the two halves of the mold cavity that will form the part's shape.

- Alloy Preparation and Injection: The chosen metal alloy (aluminum, zinc, or magnesium) is melted in a furnace. It is then injected into the die cavity under extremely high pressure. The specific method varies; cold-chamber casting is typically used for high-melting-point metals like aluminum, while hot-chamber casting is faster and used for lower-melting-point alloys like zinc.

- Casting and Solidification: Once injected, the molten metal rapidly fills every detail of the mold. It is held under pressure as it cools and solidifies, which takes only a few seconds. This rapid cooling helps create a fine-grained microstructure, contributing to the part's strength.

- Ejection and Finishing: After solidification, the two halves of the die open, and ejector pins push the finished casting out. The raw part, which may have excess material called "flash" or runners, then moves to secondary operations. These can include trimming, sanding, CNC machining for critical features, and applying surface finishes like powder coating or painting.

While die casting excels for complex, net-shape parts, manufacturers choose from various metal forming processes based on component requirements. For example, processes like forging are selected for parts needing maximum strength and fatigue resistance, such as critical engine and chassis components. Companies specializing in these high-strength applications, such as Shaoyi (Ningbo) Metal Technology, utilize advanced hot forging processes to produce robust automotive parts, demonstrating the diverse manufacturing landscape within the industry.

Frequently Asked Questions

1. What are the components of die cast?

Most die castings are made from non-ferrous metals. The primary materials used in the automotive industry are alloys of aluminum, zinc, and magnesium. Other materials used in die casting for various industries include copper, lead, pewter, and tin-based alloys. The choice of metal depends on the specific requirements of the part, such as weight, strength, corrosion resistance, and thermal properties.

2. What automotive parts are made by casting?

Casting is used to produce a wide variety of automotive parts. Beyond the interior components discussed in this article (like steering column housings, seat frames, and instrument panel frames), casting is also essential for major powertrain and chassis components. Common examples include engine blocks, cylinder heads, transmission housings, pistons, wheels, and brake calipers. The process is fundamental to modern vehicle manufacturing due to its ability to create complex and structurally sound parts efficiently.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —