Porosity in Aluminum Die Casting: Causes and Solutions

TL;DR

Porosity in aluminum die casting refers to small voids or cavities that form within the metal as it solidifies. This common manufacturing defect is primarily categorized into two types: gas porosity, caused by trapped gases, and shrinkage porosity, resulting from volume reduction during cooling. Porosity compromises a part's structural integrity, pressure tightness, and surface quality, potentially leading to component failure. However, it can be effectively managed and minimized through precise control over material quality, die design, and the casting process. Understanding its causes is the first step to prevention.

Defining Porosity in Aluminum Die Casting

In the world of high-pressure die casting, achieving a flawless, solid component is the ultimate goal. However, a common challenge that manufacturers face is porosity. Simply put, porosity is the presence of small, unwanted voids, holes, or pockets of air within a finished casting. According to manufacturing experts, this defect is a primary concern because it directly undermines the mechanical properties and performance of the final product. These voids can significantly reduce the part's strength, durability, and resistance to fatigue.

Porosity isn't a single type of flaw; it manifests in several ways that impact a component's utility. These forms are generally classified based on their location and connectivity:

- Blind Porosity: These are voids that are open to the surface of the casting but do not extend completely through the part. While they may not weaken the component structurally, they can trap liquids or cleaning chemicals from post-processing treatments like anodizing, leading to surface blemishes and corrosion over time.

- Through Porosity: This type creates a continuous leak path from one surface of the casting to another. For components that must be pressure-tight, such as fluid reservoirs or pneumatic housings, through porosity is a critical failure point that renders the part unusable.

- Fully Enclosed Porosity: These are internal voids completely sealed within the casting's walls. They are invisible from the outside and may not be an issue unless they are exposed during subsequent machining operations, at which point they become blind or through pores.

The consequences of porosity are severe, especially in critical applications like automotive and aerospace components. A porous part may fail under stress, leak fluids or gases, or have a poor surface finish after machining. Therefore, understanding its origins is essential for any high-quality manufacturing operation.

The Primary Types: Gas vs. Shrinkage Porosity

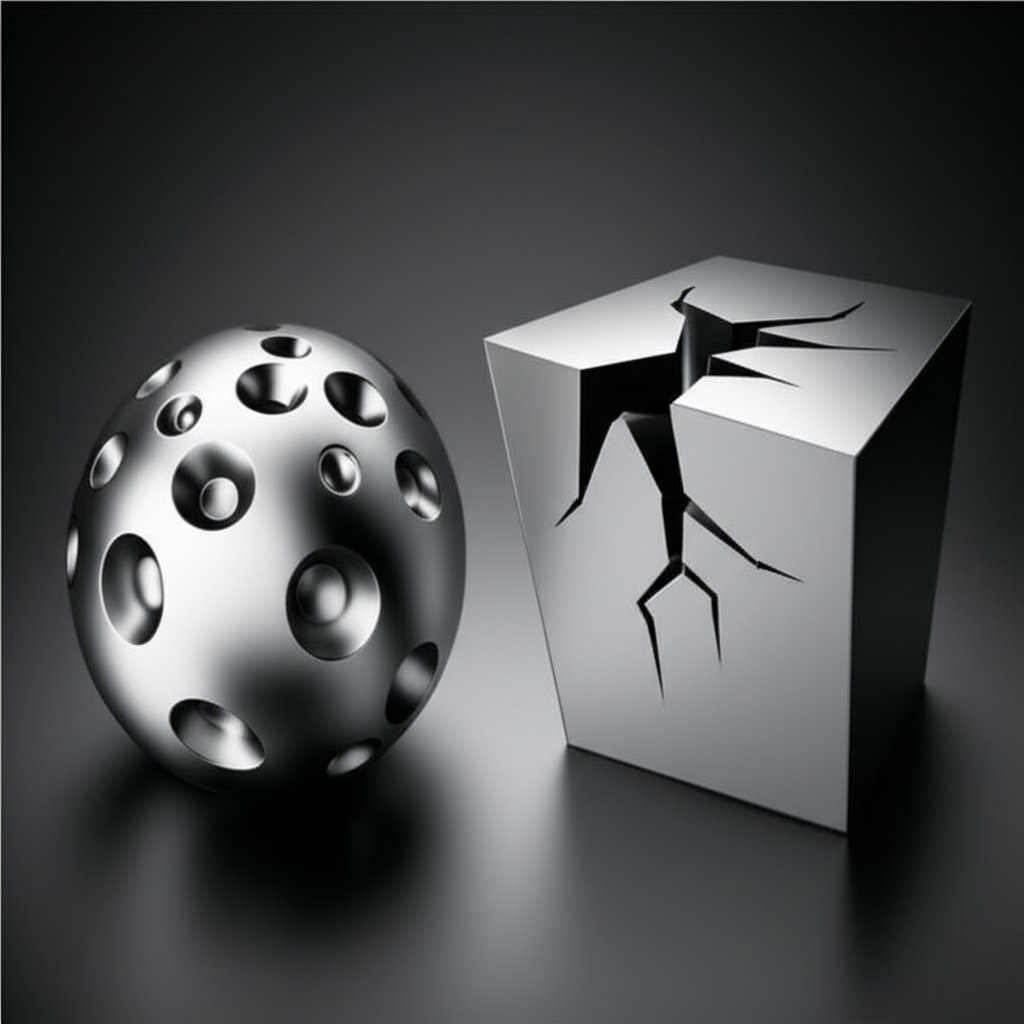

While various factors can lead to porosity, the defects are almost always traced back to one of two fundamental causes: trapped gas or metal shrinkage. Distinguishing between these two is crucial for effective troubleshooting and prevention, as their appearances and root causes are distinct. Each type presents unique challenges and requires different solutions.

Gas Porosity

Gas porosity is caused by the entrapment of gas within the molten aluminum during the injection and solidification process. The primary culprits are hydrogen, which is highly soluble in molten aluminum but not in its solid state, and air that gets trapped in the die cavity. As the metal cools, the dissolved gases are forced out of solution, forming bubbles. These bubbles become permanently trapped as the metal hardens around them. Gas pores are typically characterized by their smooth, spherical, or oval shape and are often found near the surface of the casting.

Shrinkage Porosity

Shrinkage porosity occurs because aluminum, like most metals, is denser in its solid state than in its liquid state. As the molten metal cools and solidifies, it shrinks in volume. If there isn't enough liquid metal available to fill the voids created by this shrinkage, cavities will form. This defect is most common in thicker sections of a casting, which are the last to solidify. Unlike the smooth bubbles of gas porosity, shrinkage porosity appears as jagged, angular, or linear cracks. It is a direct result of inadequate feeding of molten metal during the final stages of solidification.

To clarify the differences, here is a comparison of the two main types of porosity:

| Feature | Gas Porosity | Shrinkage Porosity |

|---|---|---|

| Primary Cause | Trapped gas (hydrogen, air, steam) released during solidification. | Volume deficit as molten metal shrinks during cooling. |

| Appearance | Smooth, round, or oval-shaped bubbles. Often shiny internally. | Jagged, angular, or linear voids with a dendritic (fern-like) texture. |

| Common Location | Typically found in the upper sections of the casting or near the surface. | Occurs in thick sections, junctions, or areas that are last to solidify (hot spots). |

| Key Prevention Strategy | Proper venting, melt degassing, controlled lubricant application, and optimized shot speed. | Optimized die temperature, sufficient metal pressure, and part design that ensures directional solidification. |

Root Causes and Proactive Prevention Strategies

Preventing porosity is far more effective and economical than dealing with defective parts after production. A successful prevention strategy requires a holistic approach that addresses the die design, the material, and the casting process itself. By controlling key variables, manufacturers can significantly reduce the occurrence of both gas and shrinkage defects.

Addressing Gas-Related Causes

Gas porosity stems from introducing gas into the metal or trapping it in the die. Prevention focuses on keeping gas out.

- Control Melt Quality: Use clean, dry raw materials to avoid introducing moisture, which creates hydrogen gas in molten aluminum. Degassing the melt with nitrogen or argon before casting is a highly effective method.

- Optimize Lubricant Application: While necessary, excessive or improperly applied die lubricant can vaporize during injection, creating gas that gets trapped. Use a minimal amount of high-quality lubricant and apply it evenly.

- Ensure Proper Venting: The die must have adequate vents and overflow channels to allow air in the cavity to escape as the molten metal is injected. Blocked or poorly designed vents are a primary cause of trapped air.

- Regulate Injection Process: A turbulent fill process can entrain air into the metal. Optimizing the shot speed and pressure profile ensures a smooth, progressive fill that pushes air out ahead of the metal flow.

Controlling Shrinkage-Related Causes

Shrinkage porosity is a battle against physics, managed by controlling how the casting cools. The key is to ensure thick sections have a steady supply of molten metal until they are fully solid.

- Maintain High Metal Pressure: The high-pressure phase of die casting is critical for combating shrinkage. As explained by industry experts, an intensifier system applies immense pressure during solidification to force molten metal into developing shrinkage voids. Maintaining adequate static and intensified pressure is essential.

- Optimize Die Temperature: Uneven cooling causes hot spots that are prone to shrinkage. By using strategically placed cooling and heating channels in the die, manufacturers can promote directional solidification, where the casting freezes progressively towards the gate, allowing it to be continuously fed with molten metal.

- Improve Part and Die Design: Designing parts with uniform wall thickness is the best way to avoid shrinkage. Where thick sections are unavoidable, they should be located near a gate. Generous fillets and rounded corners should be used instead of sharp angles, which can create isolated hot spots.

Ultimately, preventing porosity starts with a robust design and manufacturing process. Partnering with a supplier that demonstrates deep expertise in process control is crucial. For instance, suppliers holding IATF16949 certification for automotive parts emphasize rigorous quality control and in-house die design, directly addressing the root causes of defects like porosity from the project's inception.

Inspection Methods for Detecting Porosity

Since not all porosity is visible on the surface, manufacturers rely on a range of inspection methods to ensure parts meet quality standards. These techniques, often referred to as Non-Destructive Testing (NDT), allow for the detection of internal flaws without damaging the component. Selecting the right method depends on the part's criticality, the type of porosity suspected, and budget constraints.

Common inspection techniques include:

- Visual Inspection: The simplest method, used to identify surface-level porosity like blisters or open holes. While easy to perform, it cannot detect internal defects.

- X-ray Inspection (Radiography): This is one of the most reliable methods for detecting internal porosity. The part is exposed to X-rays, and the resulting image reveals density variations. Voids appear as darker spots on the radiograph, allowing inspectors to see their size, shape, and location.

- Computed Tomography (CT) Scanning: An advanced form of X-ray, CT scanning creates a full 3D model of the part, providing a comprehensive view of all internal and external features. It is highly accurate for identifying the precise volume and distribution of porosity but is also the most expensive method.

- Pressure Testing: This method is specifically used to detect through porosity in parts designed to be pressure-tight. The casting is sealed and pressurized with air or liquid. A drop in pressure or the appearance of bubbles when submerged in water indicates a leak path.

In many cases, acceptance standards, such as those from ASTM International, define the allowable amount and size of porosity for a given application. As noted by casting specialists, these NDT methods are crucial for verifying that components meet the required quality and safety standards before they are put into service. This verification is a critical part of the manufacturing process.

Frequently Asked Questions

1. What causes porosity in aluminum casting?

Porosity in aluminum casting is primarily caused by two factors: the dissolution and subsequent release of hydrogen gas during solidification (gas porosity), and the volume reduction or shrinkage of the metal as it cools from a liquid to a solid state (shrinkage porosity). Other contributing factors include trapped air from poor venting, excessive die lubricant, and inconsistent metal pressure.

2. What is the porosity of die casting?

In die casting, porosity refers to the presence of small holes, voids, or air pockets within the metal structure of a cast part. It is considered a defect because it reduces the density and mechanical strength of the component, and can create leak paths in parts that need to be pressure-tight.

3. How to check porosity in aluminium casting?

Porosity in aluminum castings can be checked using several non-destructive testing (NDT) methods. Visual inspection can identify surface defects, while pressure testing is used to find leaks. For internal voids, X-ray inspection (radiography) and industrial CT scanning are the most effective methods, as they can reveal the size, shape, and location of porosity inside the part without damaging it.

4. How to avoid porosity in casting?

Avoiding porosity involves controlling the entire casting process. Key strategies include using clean, dry, and properly degassed molten metal, designing the die with adequate vents and overflows, optimizing the injection speed and pressure, maintaining consistent die temperatures to ensure uniform cooling, and designing the part with consistent wall thickness to minimize shrinkage.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —