Automotive die stampings bending spring back “anti - human”? These 4 compensation programmes let the error be zero!

In the field of automotive die stamping die design, one of the most painful problems for engineers is "bending spring back".

Automotive stamping rebound

Whether it is automotive body parts(Automobile wings, automobile doors, automobile roofs. ..), body structural parts(side members/longitudinal members/cross members. ..), or engine mounts, seat bracket (seat bracket)and so on, as long as it involves the bending processing of metal sheets, spring back is like an invisible hand that always "wreaks havoc" at the last moment - the die design is precise, and the equipment is debugged in place, but the product size still deviates from the expectations after demolding. This phenomenon not only drags down production efficiency but may also directly lead to product scrapping, keeping countless engineers working overtime and even questioning life.

Don't panic! Spring back is not invincible. As long as the scientific compensation logic is mastered and combined with cutting - edge industry solutions, the error can be "zeroed". Shaoyi is a professional China automotive metal stamping dies parts factory. This time, it will deeply analyze the nature of bending spring back and unveil 4 efficient compensation solutions with its years of stamping die design experience, helping you "tame" spring back from the root and make die design more efficient!

1. Why is the bending spring back of automotive stamping parts so "troublesome"? Let's first explore its underlying logic.

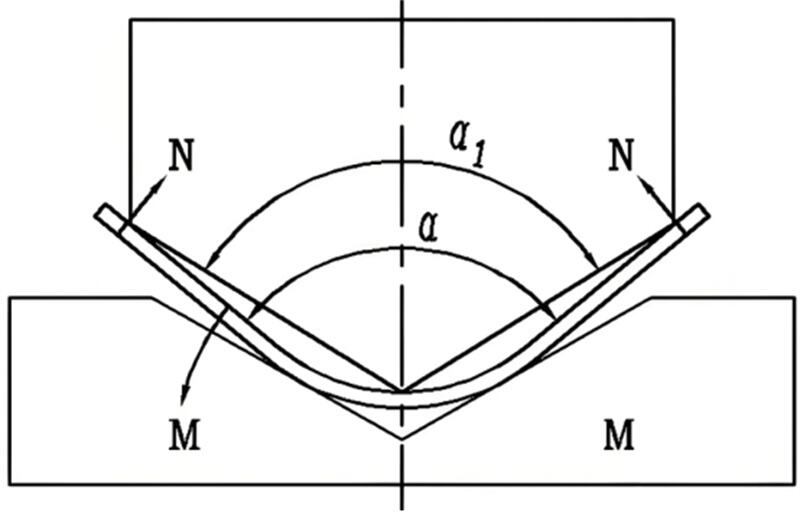

The essence of spring back is the elastic deformation recovery of metal materials. When sheet material undergoes plastic deformation under die pressure, elastic strain also occurs internally. Once external force is removed, elastic strain releases, causing the part's angle, radius, and even shape to deviate from die design values. The core influencing factors are:

Material properties: The higher the yield strength and the lower the elastic modulus (e. g. , Q235B and #10 steel commonly used by "automotive stamping suppliers"), the more pronounced the spring back.

Sheet thickness and bending radius: The smaller the ratio of sheet thickness (t) to inner bending radius (r) (r/t), the greater the spring back.

Die clearance and pressure: Insufficient pressure or excessive die clearance increases elastic deformation proportion.

Case Pain Point: A home appliance company produces stainless steel brackets. Design angle is 90°, but after demolding, it springs back to 95°, causing excessive assembly clearance. Traditional solutions involve repeated trial - mold adjustments, taking up to 2 weeks and increasing costs.

II. Four Compensation Programs Hit the Mark and Make Springback "Nowhere to Run"

Program 1: Over - Bending Compensation - Use "Proactive Prediction" to Counteract Springback

Principle: Predict the spring back angle of automotive stamping parts during production. In "automotive die stamping" design, deliberately make the bending angle smaller (or larger, depending on spring back direction) than the target. Use post - spring back recovery to hit the target.

Key formula:Δθ = θ spring back = K × (σ_s/E) × (r/t)

(K is the material coefficient, σ_s is the yield strength, E is the modulus of elasticity.)

Implementation steps:

1. Determine spring back Δθ via material testing or historical data.

2. Set die angle as θ die = θ target −Δθ.

3. Fine - tune the compensation coefficient after trial production.

Case: Shaoyi made a panel for a host plant. The panel required a 60° bend, but had a 4° spring back.

After adjusting the die angle to 56°, the part met precision standards. The pass rate rose from 70% to 99%.

Program 2: Local Strengthening - Use "Stress Traps" to Eliminate Elastic Deformation

Principle: In the non - functional areas of the bending zone, pre - set depressions, bulges, or ribs. The local plastic deformation from these consumes elastic strain energy, curbing spring back.

Design highlights:

- Control depression depth to 10% - 15% of sheet thickness.

- Angle ribs at 45° to the bending line to disperse stress.

- Optimize rib location with CAE simulation to retain strength.

Case: Shao Yi processed a host plant's sheet metal auto parts using laser engraving. It made micro - grooves 0. 5mm from the bending line, reducing spring back by 60% with no visible surface flaws.

Program 3: Dynamic Pressure Compensation – Let Dies "Intelligently Adjust"

Principle: Use a hydraulic or servo motor - driven adaptive die system. During bending, it real - time monitors pressure and displacement, dynamically adjusting clamping force to ensure full plastic deformation.

Technical highlights:

- Integrated force sensors and closed - loop control system.

- Supports multi - stage pressure loading (e. g. , pre - pressure, main pressure, holding pressure).

- Applicable to materials like high - strength steel and aluminum alloys.

Industry trend: A certain German - based automaker has introduced AI - driven adaptive bending machines. Through machine learning for spring back prediction, the compensation accuracy reaches ±0. 1°, and the debugging cycle is shortened by 80%.

Program 4: Thermal - Field Control Method - Reshape Material Characteristics with "Thermal Magic"

Principle: Locally heat or cool the bending area to alter the material's yield strength and elastic modulus, thereby controlling spring back.

Process Selection:

Laser heating: Precisely raise the temperature to 200 - 300°C (suitable for stainless steel).

Liquid nitrogen cooling: Rapidly cool to suppress elastic recovery (suitable for aluminum alloys).

Precautions: Balance thermal deformation and oxidation risks; use inert gas protection.

Advanced Application: An aerospace component uses induction - heating bending. Spring back error is within 0. 05mm, surpassing traditional cold - bending processes.

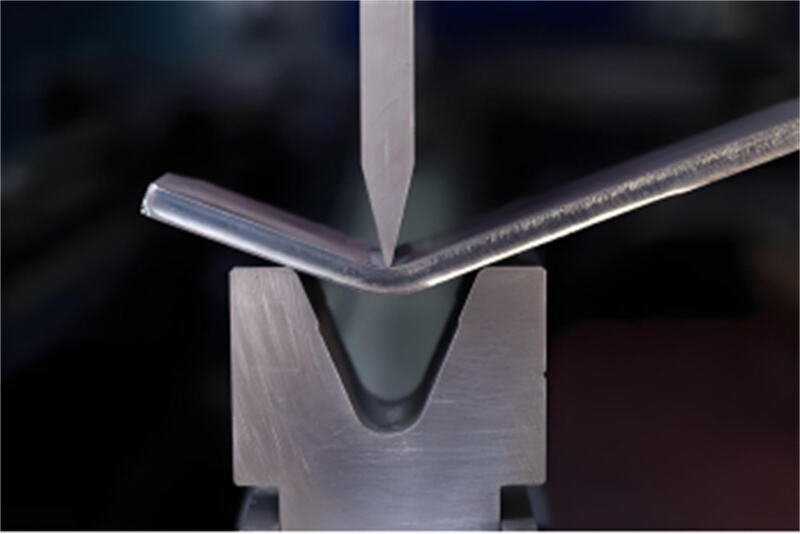

Rebound of the bending process

III. Practical Skills: How to Choose the Optimal Compensation Program?

1. Consider the material:

- Low - carbon steel, copper alloys → Over - bending compensation (low cost);

- High - strength steel, titanium alloys → Dynamic pressure compensation (high precision).

Consider the production volume:

- Small batches, multiple varieties → Over - bending compensation + CAE simulation;

- Large - scale production → Invest in adaptive die systems.

2. Tolerance - dependent selection:

- Civilian - grade (±0. 5°) → Local strengthening method.

- Military - grade (±0. 1°) → Combine thermal - field control with dynamic compensation.

IV. Conclusion: Coexist with Spring Back and Master the Power of "Certainty"

The bending spring back in automotive die stamping is tough but solvable. The auto parts manufacturing industry is shifting from experience - based trial and error to data - driven intelligent compensation, moving closer to the goal of zero spring back. Next time when faced with spring back issues in "automotive stamping parts", instead of head - on confrontation, use the four compensation programs to build a multi - layer defense. Remember, top - notch technicians use science to tame uncertainty.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —