The Growing Demand for Aluminum in Automotive Manufacturing

In the fast - paced world of automotive manufacturing, aluminum has emerged as a star material, and its demand is surging for many compelling reasons.

Unique Properties of Aluminum

Aluminum possesses a remarkable strength - to - weight ratio. Its density is merely one - third that of steel. When two vehicles of identical stiffness and load - carrying capacity are compared - one aluminum - based and the other steel - based - the aluminum vehicle body can be up to 45% lighter. This weight advantage translates into significant benefits, such as improved fuel efficiency and enhanced vehicle performance, making aluminum - intensive vehicles more attractive in the market. Aluminum’s low density, approximately 2.7 grams per cubic centimeter, makes it one of the lightest commercial metals, second only to magnesium. Its lightweight nature is ideal for industries like aerospace and automotive manufacturing, where reducing weight is crucial.

Moreover, aluminum exhibits excellent corrosion resistance and malleability. It can be alloyed with various elements to optimize specific mechanical properties like electrical conductivity, formability, and impact resistance. These attributes make aluminum a versatile and reliable material for automotive applications. Aluminum naturally forms a protective oxide layer on its surface, providing excellent corrosion resistance in various environments. This property can be enhanced through anodizing, making aluminum suitable for use in harsh environments like marine and aerospace applications.

Environmental and Market Drivers

As environmental concerns grow, governments and consumers are demanding more fuel - efficient and low - emission vehicles. Aluminum - intensive vehicles meet these demands by offering better mileage for internal combustion engine vehicles and extended range for battery electric vehicles. This aligns with the global shift toward sustainable and eco - friendly transportation.

The rise of electric vehicles (EVs) has further fueled the demand for aluminum. The heavy weight of EV batteries necessitates the use of lightweight yet strong materials like aluminum to improve vehicle range and performance. Aluminum allows EVs to achieve comparable or even better acceleration and driving range while maintaining safety standards.

Applications in Automotive Manufacturing

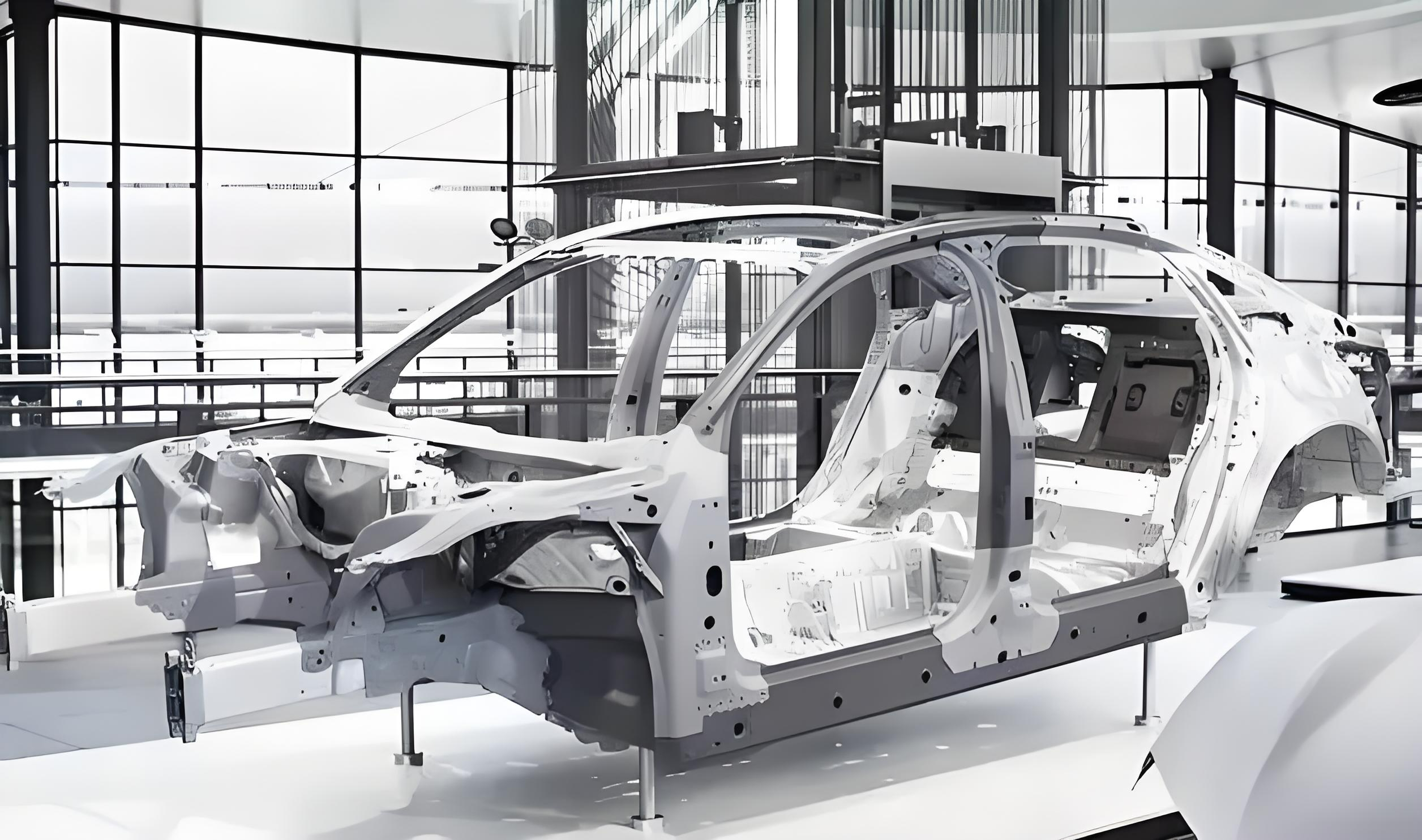

Aluminum is widely used in various automotive components. In body structures, aluminum - intensive designs reduce vehicle weight without compromising strength and safety. For engine components, aluminum - alloy engine blocks and cylinder heads contribute to improved fuel efficiency and reduced emissions. In suspension systems, aluminum parts enhance vehicle handling and ride comfort. Additionally, aluminum is used in wheels, brake components, and interior parts like air conditioner components and tachometer magnets.

Shaoyi's Role in Aluminum Automotive Parts Manufacturing

At Shaoyi, we recognize the immense potential of aluminum in automotive manufacturing. In recent years, aluminum - based metal components have accounted for as much as 70% of our production. With our advanced production equipment and rigorous quality control systems, we produce high - quality aluminum automotive parts that meet the stringent requirements of the industry. Our expertise in automotive metal stamping and CNC machining enables us to create precision aluminum parts for various applications. We are committed to driving innovation and contributing to the sustainable development of the automotive industry through our aluminum - based solutions.

The growing demand for aluminum in automotive manufacturing is a trend driven by technological advancements, environmental considerations, and market demands. As the automotive industry continues to evolve, aluminum will play an increasingly important role in shaping the future of vehicle design and performance.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —