Aluminum Sheet Metal Forming: 8 Essential Points From Alloy Selection To Launch

Understanding Aluminum Sheet Metal Forming Fundamentals

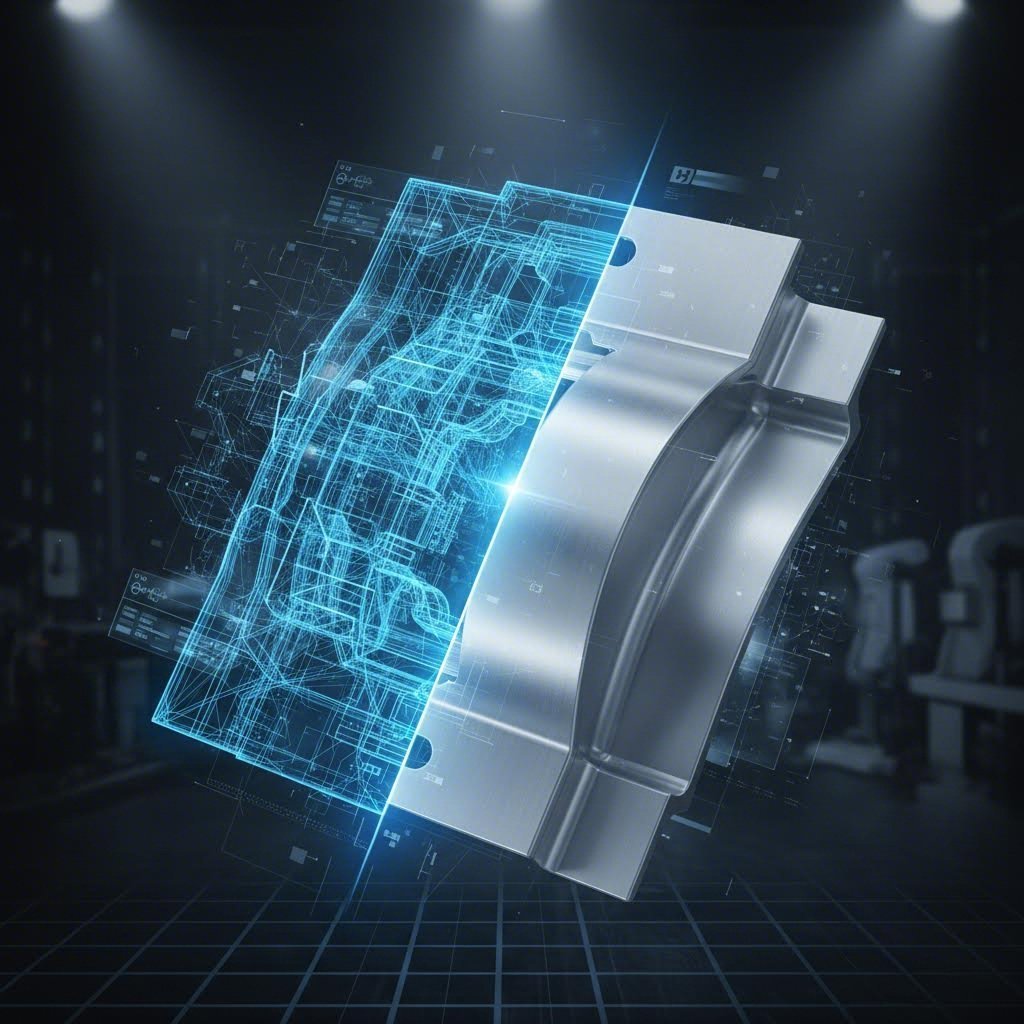

Imagine taking a flat, rigid sheet of aluminum and transforming it into a sleek automotive panel, an aircraft fuselage component, or a precision electronic enclosure. That's exactly what aluminum sheet metal forming accomplishes - it's the controlled process of shaping flat aluminum sheets metal into complex three-dimensional geometries through mechanical deformation, all without removing material or compromising structural integrity.

So, what is sheet metal in the context of aluminum? It refers to aluminum that has been rolled into thin, flat pieces - typically ranging from 0.5mm to 6mm thick - ready to be bent, stretched, drawn, or stamped into functional parts. This sheet metal forming process has revolutionized manufacturing across industries, enabling engineers to create lightweight yet remarkably strong components that would be impossible to achieve with traditional casting or machining alone.

Why Aluminum Dominates Modern Metal Forming

You might wonder why aluminum has become the go-to material for high-performance applications. The answer lies in its exceptional combination of properties that make forming and shaping both practical and advantageous.

First, consider the weight factor. According to Industrial Metal Service, steel is approximately 2.5 times denser than aluminum. This means aluminum structural components weigh significantly less while still providing adequate tensile strength for demanding applications. The aerospace industry has embraced this advantage so thoroughly that aircraft and spacecraft can consist of up to 90% aluminum alloys.

Then there's corrosion resistance. Unlike steel, aluminum doesn't rust. When exposed to oxygen, it forms a protective aluminum oxide layer that actually shields the metal from further corrosion - a natural passivation that makes it ideal for marine vessels and outdoor applications.

The automotive industry is increasingly turning to aluminum to minimize vehicle weight and improve fuel efficiency. When you understand how metal was made and processed over centuries, you'll appreciate how modern aluminum production has revolutionized what's possible in lightweight engineering.

The Science Behind Aluminum Deformation

What is the forming process that makes aluminum so workable? It comes down to the metal's crystalline structure and its behavior under stress.

Aluminum is significantly more malleable than steel, allowing it to be formed into more delicate geometries - including very thin walls that would crack in harder materials. Its relative softness makes cutting and shaping faster and more economical. Understanding aluminum - how is it made and processed - reveals why it responds so favorably to forming operations.

Aluminum's elastic deformation under load is three times greater than steel, allowing it to absorb impact energy without permanent damage - a structural advantage that translates directly into forming success.

This lower coefficient of elasticity means aluminum can flex and return to shape during forming operations, though it also introduces springback challenges that fabricators must account for. The mechanical properties of aluminum alloys vary significantly depending on composition - yield strength for high-strength alloys reaches about 85% of breaking strength, providing predictable behavior during deformation.

As you continue through this guide, you'll discover how alloy selection directly impacts formability, which processes work best for specific geometries, and how to overcome common challenges like springback and surface protection. From choosing between 5052 and 6061 alloys to optimizing your production workflow, each section builds on these fundamentals to help you achieve forming success.

Aluminum Alloys and Tempers for Forming Success

Selecting the right aluminum alloy sheet metal is like choosing the right tool for a job - get it wrong, and you'll fight the material every step of the way. Get it right, and forming becomes predictable, efficient, and cost-effective. The secret lies in understanding how different alloy compositions and temper conditions affect formability, springback behavior, and ultimately, your process selection.

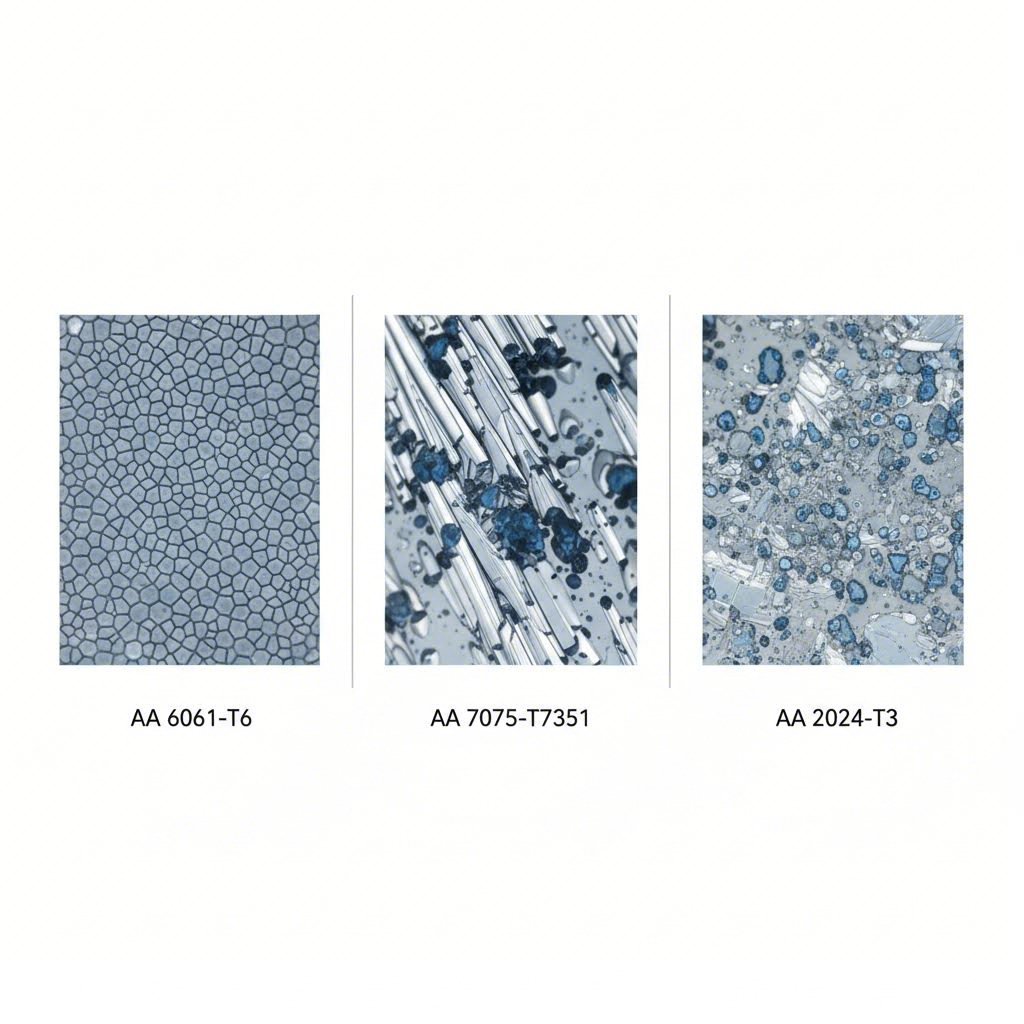

Alloy Series and Their Forming Personalities

Each aluminum alloy series has a distinct "personality" when it comes to aluminum fabrication. Understanding these characteristics helps you match the material to your forming requirements.

The 1xxx series (99%+ pure aluminum) offers exceptional formability and corrosion resistance but limited strength. According to ESAB, these alloys have ultimate tensile strength ranging from only 10 to 27 ksi, making them suitable for specialized chemical tanks and electrical bus bars rather than structural forming applications.

The 3xxx series (aluminum-manganese alloys) provides moderate strength with excellent formability and elevated temperature performance. You'll find these alloys in heat exchangers and cookware - applications requiring good forming characteristics without high structural demands. Their ultimate tensile strength ranges from 16 to 41 ksi.

The 5xxx series (aluminum-magnesium alloys) represents the sweet spot for many forming operations. With ultimate tensile strength from 18 to 51 ksi, 5052 aluminium delivers the highest strength among non-heat-treatable alloys while maintaining excellent weldability and corrosion resistance. This makes thin aluminum sheet metal in 5052 particularly popular for marine applications, aircraft fuel tanks, and general fabrication work.

The 6xxx series (aluminum-magnesium-silicon alloys) offers heat-treatable strength ranging from 18 to 58 ksi. However, these alloys present a critical forming consideration: they're naturally prone to solidification cracking. This means you should never weld or form them autogenously without proper filler material and technique adjustments.

Temper Selection for Optimal Formability

Here's something many engineers overlook: temper selection is just as critical as alloy choice for forming success. The temper designation tells you exactly how the material will behave under stress.

For non-heat-treatable alloys (1xxx, 3xxx, 5xxx), the "H" temper system indicates strain hardening levels:

- O temper - Fully annealed, maximum formability, lowest strength

- H32 - Strain hardened and stabilized to quarter-hard condition, balancing formability with moderate strength

- H34 - Half-hard condition, reduced formability but higher strength

- H38 - Full-hard condition, limited forming capability

For heat-treatable alloys (2xxx, 6xxx, 7xxx), the "T" temper system indicates thermal treatment:

- T4 - Solution heat-treated and naturally aged, good formability

- T6 - Solution heat-treated and artificially aged, maximum strength but reduced formability

- O temper - Annealed condition for maximum formability before subsequent heat treatment

When comparing 5052-H32 vs 6061-T6 for forming operations, the differences are dramatic. The alum 5052 H32 temper provides excellent cold workability - you can bend it without cracking at standard sheet metal thickness aluminum specifications. In contrast, 6061-T6's heat treatment maximizes hardness, delivering 32% higher ultimate strength than 5052 but significantly reducing bend radius flexibility.

Alloy Comparison for Forming Applications

| Alloy | Formability Rating | Typical Applications | Min Bend Radius (×thickness) | Springback Tendency |

|---|---|---|---|---|

| 1100-O | Excellent | Chemical equipment, decorative trim | 0-1t | Low |

| 3003-H14 | Very Good | Heat exchangers, storage tanks | 1t | Low-Moderate |

| 5052-H32 | Good | Marine, aircraft, general fabrication | 1-2t | Moderate |

| 6061-T6 | Fair | Structural components, frames | 3-4t | High |

Notice how the minimum bend radius increases dramatically as you move from soft, pure aluminum to heat-treated structural alloys. For 5052 aluminum sheet metal at 0.063" thickness, you can typically achieve a 1t bend radius. The same operation with 6061-T6 might require 3-4t to prevent cracking at the bend line.

Thickness Selection for Forming Processes

The relationship between aluminum sheet material thickness and forming process selection directly impacts your project success. Thinner gauges (0.020" to 0.063") work well for stamping and deep drawing operations where complex geometries require material flow. Medium gauges (0.063" to 0.125") suit most general forming and bending applications. Heavier gauges (0.125" to 0.500") typically require more robust equipment and may benefit from warm forming techniques to prevent cracking.

As you select your alloy and temper combination, keep in mind that these decisions cascade through every subsequent forming operation - from tooling design to springback compensation. The next section explores exactly which forming processes work best for different part geometries and production volumes.

Core Forming Processes for Aluminum Sheet

Now that you understand how alloy and temper selection sets the foundation, let's explore the metal forming processes that transform flat aluminum sheets into finished components. Each forming process has distinct mechanical principles, production advantages, and application sweet spots. Choosing the right one depends on your part geometry, tolerance requirements, and production volume.

Stamping and Deep Drawing Aluminum Components

Stamping and deep drawing represent the workhorses of high-volume aluminum forming. But how do these sheet metal fabrication processes actually work?

In stamping, a press forces a punch through the aluminum sheet against a die cavity, creating features like holes, embossments, or bent flanges in a single stroke. The forming process happens rapidly - often in fractions of a second - making it ideal for automotive panels, electronic enclosures, and appliance components.

Deep drawing takes this further by pulling the aluminum blank into a die cavity to create cup-shaped or cylindrical parts. According to Toledo Metal Spinning, deep draw metal stamping is a cold-forming process where the material's grain structure undergoes changes at room temperature as the blank forms and stretches into its final shape. Here's the benefit: this cold working actually increases the aluminum's strength and durability during the forming operation.

However, drawing metal sheet in aluminum requires a more controlled approach than steel. Unlike stainless steel, which can flow and redistribute thickness under force, aluminum cannot be overstretched or excessively deformed. The blank must be positioned precisely - if placed too far off, the material will stretch and fracture. A successful aluminum draw depends on maintaining the correct draw ratio: the relationship between the punch diameter and the metal blank diameter.

Roll Forming for Continuous Aluminum Profiles

When you need long, consistent profiles - think structural channels, trim pieces, or complex cross-sections - sheet metal roll forming delivers unmatched efficiency. This metal forming process passes aluminum strip through a series of contoured roller stations, progressively bending the material into the final shape.

Roll forming excels at producing forming metal sheet into consistent geometries at high speeds. Unlike stamping's single-stroke approach, roll forming is continuous - the aluminum feeds through and emerges as a finished profile ready for cutting to length. This makes it cost-effective for high-volume applications like building cladding, automotive trim, and industrial racking systems.

The process also handles varying sheet metal thickness aluminum with relative ease by adjusting roller gaps and forming sequences.

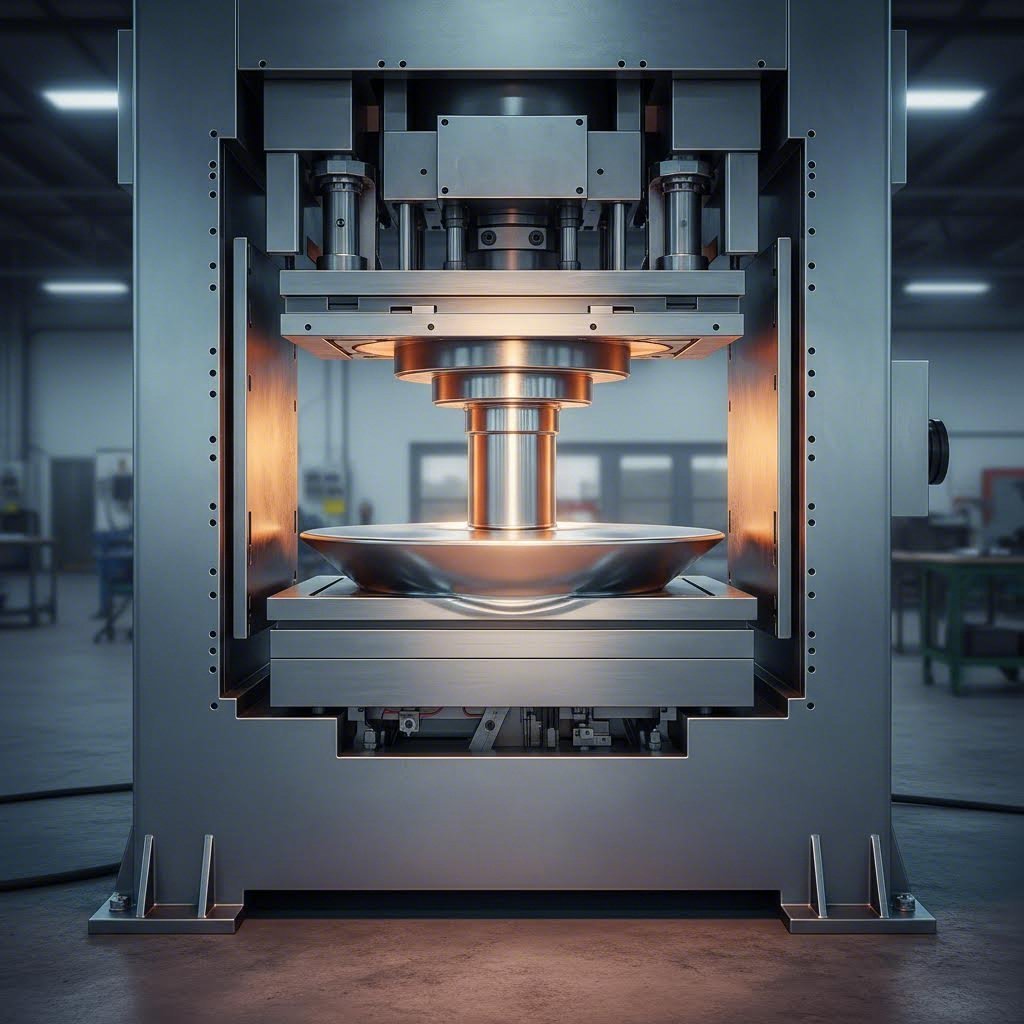

Stretch Forming and Hydroforming for Complex Geometries

What about complex curves and compound shapes that stamping can't achieve? That's where stretch forming and hydroforming enter the picture.

Stretch forming grips the aluminum sheet at both ends and stretches it over a form die while applying tension. This process excels at producing large, curved panels for aerospace fuselages, architectural facades, and transportation applications. The stretching action minimizes springback - a significant advantage when dimensional accuracy matters.

Hydroforming uses pressurized fluid (typically water-based at up to 10,000 PSI) to force aluminum against a die surface. According to Toledo Metal Spinning, hydroforming allows various materials to become complex and structurally sound parts with tight tolerances. It enables asymmetrical or irregular shaped geometries, while conventional deep drawn parts are typically symmetrical throughout the entire shape. This makes hydroforming ideal for sheet metal pressings requiring intricate contours.

Key Process Selection Criteria

How do you decide which forming process fits your application? Consider these factors:

- Part geometry - Simple bends suit stamping; cylindrical shapes favor deep drawing; continuous profiles need roll forming; complex curves require stretch forming or hydroforming

- Production volume - High volumes justify stamping die investment; lower volumes may suit hydroforming or stretch forming

- Tolerance requirements - Hydroforming and stretch forming typically achieve tighter tolerances on complex shapes

- Material thickness - Thin gauges work well for deep drawing; heavier gauges may require progressive stamping or warm forming

- Surface finish requirements - Hydroforming's fluid pressure produces excellent surface quality without die marks

- Tooling budget - Stamping dies require significant investment; hydroforming tooling costs less for complex geometries

Cold Forming vs Warm Forming: The Temperature Advantage

Most aluminum forming operations occur at room temperature - this is cold forming. The metal forming process works by permanently deforming the grain structure without adding heat. Cold forming provides excellent dimensional control and surface finish while work-hardening the aluminum for added strength.

However, certain difficult geometries and high-strength alloys benefit from elevated temperature forming. Research from MDPI Applied Sciences confirms that when aluminum alloys are formed within the 200-350°C temperature range, formability parameters such as drawability and elongation can improve by approximately 200-300%.

Warm forming offers specific advantages:

- Reduced springback - at 400°C, springback angle can decrease from 9° at room temperature to just 0.5°

- Lower forming forces - bending loads can reduce by up to 87% at elevated temperatures

- Tighter bend radii possible without cracking

- Complex geometries achievable in single operations

The trade-off? Warm forming requires temperature-controlled tooling, longer cycle times, and careful process control to prevent overheating that degrades mechanical properties.

Tooling Considerations for Aluminum Forming

Aluminum's unique properties demand specific tooling strategies that differ from steel forming operations.

Die materials: Tooling for aluminum often uses hardened tool steel or carbide inserts to resist the galling tendency aluminum exhibits. Polished die surfaces minimize pickup and extend tool life.

Lubrication requirements: Proper lubrication is critical for aluminum. Each material requires different lubricants depending on their properties, and aluminum-specific formulations reduce friction while preventing the metal-to-metal adhesion that causes surface defects. Lubrication not only reduces friction and promotes metal flow but also mitigates temperature differences during forming.

Surface finish protection: Aluminum's soft surface scratches easily. Protective films, specialized die coatings, and careful material handling preserve the cosmetic appearance required for visible components.

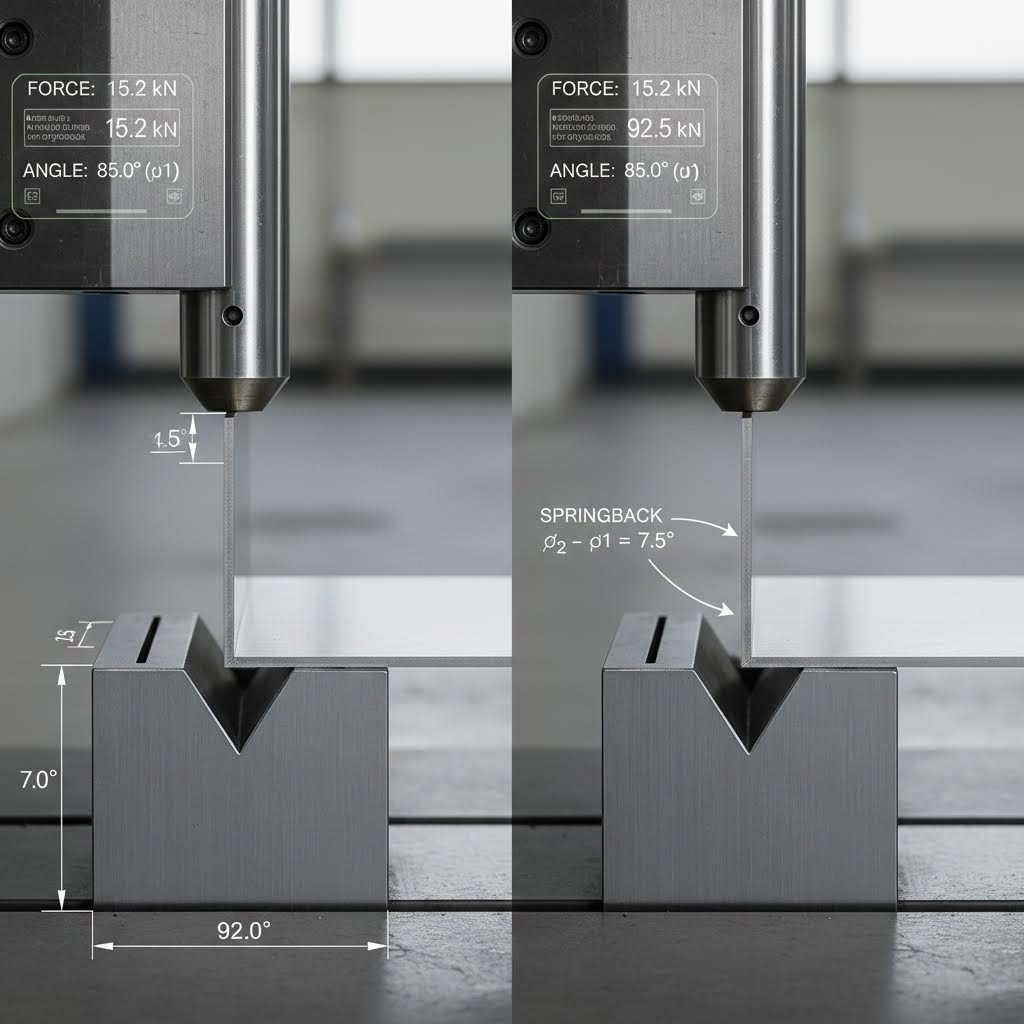

Springback Compensation Techniques

Every aluminum forming operation must account for springback - the elastic recovery that occurs when forming pressure releases. Research published in PMC shows that springback increases with the tangential stress gradient and is significantly influenced by mold parameters.

Practical compensation strategies include:

- Overbending - Design tooling to bend past the target angle, anticipating elastic recovery

- Bottoming - Apply additional force at the end of the stroke to set the bend permanently

- Coining - Use high pressure to plastically deform the bend area beyond its yield point

- Warm forming - Elevate temperature to reduce elastic recovery (springback angle decreases significantly at temperatures above 200°C)

- Die clearance optimization - Smaller die clearances enhance heat transfer and improve dimensional control

Understanding these forming fundamentals prepares you to tackle the specific challenges that arise when working with aluminum - from conquering excessive springback to protecting those critical surface finishes.

Overcoming Aluminum Forming Challenges

Working with sheet metal in aluminum presents a fundamentally different experience than forming sheet metal in steel. Attempting to bend aluminum with the same approach used for steel is, quite frankly, a recipe for failure. Although both are metals, their mechanical responses differ profoundly - and mastering aluminum demands respect for its unique behavior. Let's tackle the specific challenges you'll encounter and the proven techniques to overcome them.

Conquering Springback in Aluminum Forming

Springback is the elusive adversary in precision sheet metal forming - a hidden force that subtly reverses your work the moment pressure releases. Think of it as aluminum's elastic memory: its intrinsic tendency to revert toward its original, unbent state. According to Jeelix, controlling this phenomenon requires both accurate prediction and well-designed compensation strategies.

Why does aluminum spring back more aggressively than steel? The answer lies in its lower modulus of elasticity. Aluminum's elastic deformation under load is approximately three times greater than steel, meaning more energy gets stored during bending - energy that releases when you remove the forming pressure.

For sheet metal working operations, here's what you need to know about predicting springback behavior:

- Material hardness matters - Heat-treated tempers (T6, H38) exhibit significantly more springback than annealed conditions (O temper)

- Bend radius influences recovery - Tighter radii relative to thickness produce greater springback angles

- Thickness affects behavior - Thinner gauges typically show proportionally more elastic recovery

Practical compensation techniques for working with sheet metal in aluminum include:

- Overbending - Design tooling to bend 2-5° past target angle, anticipating elastic recovery

- Bottoming and coining - Apply additional force at stroke end to plastically set the bend

- Thermo-mechanical compensation - Use heated lower dies with room-temperature punches to create controlled stress differentials that can reduce springback by up to 20%

- Warm forming - At 400°C, springback angle can decrease from 9° at room temperature to just 0.5°

Understanding Minimum Bend Radius and Crack Prevention

The Minimum Bend Radius (MBR) isn't a guideline you can ignore - it's a physical boundary defined by the material's internal structure. When forming sheet metal, the outer surface stretches in tension. The MBR marks the smallest radius achievable before tensile strain exceeds the material's elongation capacity, causing microscopic fractures that propagate into visible cracks.

Three factors govern your minimum bend radius in the shaping of metals:

Material ductility (elongation) forms the foundation. Soft, annealed alloys like 3003-O exhibit high elongation and handle extremely sharp bends approaching a 0T inside radius. Conversely, 5052 aluminum bending in H32 temper requires 1-2T radius, while 6061-T6 demands 3-4T or greater to prevent cracking.

Material thickness creates a direct correlation. As thickness increases, outer fibers must stretch more to wrap around the same radius. That's why MBR is expressed as a multiple of sheet thickness - a 2mm sheet with a 3T requirement needs a 6mm inside bend radius.

Grain direction represents the hidden fault line that catches many fabricators off guard. During rolling, malleable sheet metal develops pronounced grain structure as crystals align in one direction. Bends made perpendicular to the grain (across it) can tolerate significantly tighter radii than bends parallel to the grain. When possible, orient your bend lines to cross the rolling direction.

Always bend before anodizing. The anodizing process forms a hard, brittle aluminum oxide layer - essentially a ceramic coating with negligible ductility. If bent afterward, this layer will craze and crack even if the underlying metal remains intact.

Surface Quality Preservation Techniques

A flawless bend goes beyond dimensional precision - it must be visually perfect and mechanically robust. Surface defects aren't random occurrences; they stem from predictable mismatches in processing parameters. Here's how to prevent the most common issues:

Galling and scratching occur when intense friction between aluminum and steel tooling causes surface damage. Rough tooling or debris acts like abrasive grit against the soft aluminum surface.

Prevention strategies include:

- Surface isolation - Apply removable polyurethane protective film to sheets before bending

- Tooling selection - Use hardened, precisely ground, and highly polished die surfaces

- Non-marring solutions - Install urethane die inserts or Teflon-coated tooling for cosmetic applications

- Process control - Opt for air bending over bottoming to minimize contact pressure

Wrinkling develops when the inner surface of a bend experiences compression beyond the material's buckling threshold. This is particularly problematic with thin sheets or when forming tight radii. Adequate blank holder pressure during deep drawing and proper die clearances help control this issue.

Troubleshooting Common Forming Defects

When problems arise during forming operations, follow this systematic approach:

- Identify the defect type - Is it cracking, springback deviation, surface damage, or dimensional inaccuracy?

- Check material specifications - Verify alloy, temper, thickness, and grain orientation match your process requirements

- Evaluate tooling condition - Inspect dies for wear, scratches, debris, or improper clearances

- Review process parameters - Confirm forming speed, lubrication application, and blank positioning

- Adjust one variable at a time - Modify bend radius, overbend angle, or forming temperature systematically

- Document results - Record successful parameter combinations for future reference

Tolerance Expectations: Aluminum vs Steel

Realistic tolerance expectations differ significantly between aluminum and steel forming. Aluminum's greater springback variability and surface sensitivity mean you should typically expect:

- Angular tolerances - ±0.5° to ±1° for aluminum versus ±0.25° to ±0.5° for steel

- Dimensional tolerances - Generally 1.5-2× wider than comparable steel operations

- Surface finish requirements - More protective measures needed to maintain cosmetic standards

These challenges aren't obstacles - they're simply parameters that require proper planning. With the right alloy selection, tooling design, and process controls, aluminum forming delivers consistent, high-quality results that justify its position as the material of choice for lightweight, high-performance applications.

Understanding these forming fundamentals prepares you to apply aluminum effectively across different industries - each with their own specific requirements, quality standards, and production workflows.

Industry Applications and Production Workflows

Different industries don't just use aluminum sheet metal forming - they demand fundamentally different approaches to alloy selection, quality validation, and production scaling. What works perfectly for a consumer electronics enclosure might fail catastrophically in an aerospace structural component. Understanding these industry-specific requirements transforms aluminum manufacturing from trial-and-error into predictable, certifiable results.

Automotive Aluminum Forming Requirements

The automotive sector represents one of the most demanding environments for sheet metal manufacturing. Weight reduction drives everything - every kilogram saved translates to improved fuel efficiency and reduced emissions. But automotive aluminum parts manufacturing operates under constraints that consumer products never encounter.

Quality standards like IATF 16949 govern every aspect of automotive sheet metal production. This certification framework demands documented process controls, statistical process capability studies, and complete material traceability from raw stock through finished assembly. You can't simply produce good parts - you must prove your sheet metal process consistently produces good parts within defined statistical limits.

For automotive body panels and structural components, alloy selection typically centers on:

- 5xxx series alloys (5052, 5182, 5754) - Excellent formability for complex body panels, good corrosion resistance, no heat treatment required

- 6xxx series alloys (6016, 6022, 6111) - Heat-treatable for enhanced strength in structural applications, excellent surface quality for visible components

- 7xxx series alloys - High-strength options for crash management structures requiring maximum energy absorption

Automotive forming operations also face stringent surface finish requirements. Class A surfaces on visible body panels demand flawless forming without scratches, galling marks, or orange peel texture. This drives investment in specialized tooling coatings, protective films, and controlled lubrication systems throughout the sheet metal processing workflow.

Aerospace and Consumer Products Considerations

Aerospace sheet metal manufacturing operates under even more rigorous certification requirements. AS9100 and NADCAP certifications establish quality frameworks that trace every material lot, document every process parameter, and require periodic capability demonstrations.

The alloy preferences differ significantly from automotive applications. Aerospace typically relies on:

- 2024 aluminum - High strength-to-weight ratio for fuselage skins and structural members

- 7075 aluminum - Maximum strength for critical load-bearing components

- 6061 aluminum - Good all-around performance for brackets, fittings, and secondary structures

Consumer products face different pressures entirely. Cost sensitivity often outweighs strength requirements, and visual aesthetics matter as much as mechanical performance. Here, the sheet metal manufacturing industry typically gravitates toward:

- 1100 and 3003 aluminum - Lowest cost, excellent formability for simple enclosures and decorative trim

- 5052 aluminum - Best balance of formability, corrosion resistance, and cost for appliances and electronics housings

Industry-to-Alloy Mapping

| Industry | Recommended Alloys | Typical Forming Processes | Critical Quality Considerations |

|---|---|---|---|

| Automotive Body Panels | 5182, 6016, 6111 | Stamping, deep drawing | Class A surface finish, IATF 16949 compliance, dimensional stability |

| Automotive Structural | 6061-T6, 7075 | Stamping, hydroforming | Crash performance validation, weld compatibility, fatigue resistance |

| Aerospace Structural | 2024-T3, 7075-T6 | Stretch forming, hydroforming | AS9100 certification, material traceability, NDT inspection |

| Aerospace Secondary | 6061-T6, 5052-H32 | Stamping, roll forming | Corrosion protection, fastener compatibility, weight optimization |

| Consumer Electronics | 5052-H32, 6061-T6 | Stamping, progressive die | Cosmetic finish, anodizing compatibility, tight tolerances |

| Appliances | 3003-H14, 5052-H32 | Stamping, deep drawing | Cost efficiency, surface uniformity, finishing adhesion |

From Prototype to Production Volume

The journey from concept to full-scale sheet metal production involves distinct phases, each with aluminum-specific considerations that can derail projects if overlooked.

Design validation begins with material selection based on your application requirements. During this phase, you're confirming that your chosen alloy and temper combination achieves the required formability, strength, and surface quality. Prototype parts using production-intent materials reveal issues that CAD simulations miss - actual springback behavior, grain direction sensitivity, and surface quality under real forming conditions.

Tooling development represents the critical bridge between prototype success and production readiness. For aluminum sheet metal processing, tooling considerations include die material selection (hardened tool steel resists galling), surface finish requirements (polished surfaces minimize pickup), and clearance optimization for your specific alloy and thickness combination. According to Approved Sheet Metal, advanced forming techniques like hydroforming and deep drawing allow creation of complex shapes and contours particularly effective for aluminum's malleable nature.

Production ramp-up validates that your process scales reliably. Statistical process control monitoring confirms dimensional stability across production runs. First article inspection (FAI) documents that production parts match design specifications before full-rate production begins.

Post-Forming Considerations

What happens after forming significantly impacts your final part performance. Heat treatment effects on formed aluminum components require careful planning.

For heat-treatable alloys (6xxx, 7xxx series), post-forming heat treatment can restore or enhance mechanical properties. However, this introduces potential distortion concerns - parts must be fixtured during heat treatment to maintain dimensional accuracy.

Finishing compatibility varies by alloy. According to Approved Sheet Metal, aluminum has the most finishing options of any common sheet metal material - unlike stainless steel, it can be anodized and chromated. Anodizing provides durable corrosion protection with aesthetic appeal, while chromating offers corrosion resistance frequently specified for aerospace applications. Powder coating adds both protection and color customization for industrial and consumer products.

Remember: always complete forming operations before anodizing. The anodized layer is essentially ceramic - attempting to bend afterward causes cracking and coating failure regardless of how carefully you control the forming operation.

With your industry requirements defined and production workflow mapped, the next critical step involves optimizing your part designs specifically for aluminum formability - ensuring your geometry, tolerances, and feature placement enable efficient, cost-effective manufacturing from the start.

Design Optimization for Aluminum Formability

You've selected the perfect alloy, understood the forming processes, and learned to overcome springback challenges. But here's the reality check: even the best material and process choices can't rescue a poorly designed part. Design for Manufacturability (DFM) is where aluminum forming projects succeed or fail - long before metal ever touches tooling. Getting geometry, feature placement, and tolerances right from the start eliminates costly iterations and accelerates your path to production.

DFM Principles for Formed Aluminum Parts

What is sheet metal fabrication success really about? It starts with designing parts that respect the physical realities of how aluminum behaves under stress. According to Five Flute, sheet metal design for manufacturability is based entirely on the design engineer's understanding of how desired features and feature tolerances are impacted by the range of anticipated forming operations.

Think of DFM as a conversation between your design intent and the metal's willingness to cooperate. Every bend, hole, slot, and edge interacts with aluminum's properties in predictable ways - if you know what to look for.

Here are the essential DFM best practices specific to aluminum forming:

- Respect minimum bend radii - Design bends at 1-4× material thickness depending on alloy and temper; 6061-T6 requires larger radii than 5052-H32

- Include bend relief - Add material removal at bend edges where curved sections meet flat material to prevent crack propagation; aim for relief width ≥ half material thickness

- Position holes strategically - Place holes at least 2.5× thickness plus one bend radius away from bend lines to avoid distortion

- Consider grain direction - Orient bend lines perpendicular to rolling direction whenever possible; failure to do so can result in cracking, especially with heat-treated alloys like 6061-T6

- Optimize nesting efficiency - Design part profiles that nest efficiently on sheet stock to reduce material waste and lower costs

- Specify appropriate tolerances - Avoid over-tolerancing; tighter tolerances require closer punch-to-die fits, increasing wear and cost

- Plan for springback - Account for 2-5° of elastic recovery in your tolerance stack-ups for bends

Holes, slots, and tabs follow specific spacing rules that prevent deformation during sheet metal fabrication processes. Holes should be located approximately 1.5× material thickness from edges and 2× material thickness apart from each other. Slot widths should exceed material thickness to prevent punching issues, and tab widths should maintain at least 2× material thickness for structural integrity.

How Geometry Impacts Forming Feasibility and Cost

Every geometric decision carries cost implications. Sharp internal corners require specialized tooling or EDM operations. Extremely tight bend radii risk cracking and may require warm forming or alloy substitution. Deep draws beyond standard ratios demand progressive operations or alternative processes entirely.

Consider how modern metal forming machines have expanded what's geometrically possible. CNC forming enables programmable bend sequences that would be impractical with manual setups. CNC sheet metal forming machines can execute complex multi-bend parts with consistent accuracy across production runs, reducing the tolerance penalties you'd accept with manual operations.

Even more revolutionary, digital sheet metal forming technology eliminates traditional tooling barriers entirely. This process uses a single-point tool to create intricate contours without dies - perfect for prototyping and low-volume production where tooling investment doesn't make economic sense. According to Evology Manufacturing, digital sheet metal forming offers advantages including shorter lead times, elimination of expensive tooling and die manufacturing, and virtually no minimum order quantity.

Integrating Forming with Assembly Requirements

Here's what many engineers miss: forming decisions made in isolation can create downstream nightmares during welding and assembly. Your beautifully formed part still needs to join with other components - and how you designed it determines whether that joining operation succeeds or struggles.

Welding compatibility starts with alloy selection but extends to geometry. Formed features need adequate access for welding equipment. Tight corners and enclosed sections may be impossible to weld properly. Additionally, heat-affected zones from welding can distort formed features if bend lines sit too close to weld locations.

Fastener accessibility requires planning during the design phase. Can assembly tools reach the fastener locations? Do formed flanges provide adequate edge distance for rivets or bolts? PEM inserts and self-clinching fasteners often provide faster, more cost-effective assembly than welding - but they require specific material thickness and hole sizing to function properly.

According to Five Flute, good DFM at the part level considers assembly simplicity. Where possible, design parts to be self-locating, minimizing the need for jigs and fixtures during assembly. With sheet metal engineering in particular, using PEM inserts or rivets instead of welding can save significant time and money if functionality permits.

Digital Technologies Enabling Complex Geometries

Traditional forming has physical limitations - die clearances, springback compensation, and accessible tooling angles all constrain what's achievable. Modern sheet metal engineering technologies are pushing these boundaries.

CNC forming brings programmable precision to brake press operations. Complex bend sequences execute automatically, eliminating operator variability and enabling tighter tolerances on multi-bend parts. For production volumes that justify the programming investment, CNC forming delivers repeatability that manual operations simply cannot match.

Digital sheet metal forming represents an even more dramatic departure from traditional methods. As Evology Manufacturing explains, this technology shapes sheet metal efficiently without traditional tooling by using a single-point tool to create intricate contours. The Figur G15 machine can form parts up to 1,450mm × 1,000mm in aluminum up to 3.175mm thick.

The general accuracy of digital sheet metal forming technology falls between 0.5%-2% of the largest part dimension - suitable for many prototyping and production applications. For parts requiring smooth surfaces with less than 60 degrees of draft angle, this technology delivers excellent results without any tooling investment.

Early DFM Engagement Accelerates Production

When should DFM analysis happen? The short answer: as early as possible. The longer answer involves understanding why delayed DFM creates cascading problems.

Tooling iterations represent one of the largest cost drivers in sheet metal programs. Each design change after tooling fabrication begins triggers modifications, re-machining, or complete tool rebuilds. A bend radius that seemed reasonable in CAD might prove unmakeable in your chosen alloy - discovering this after tool steel is cut means expensive corrections.

Early DFM engagement catches these issues when changes cost nothing but design time. Experienced forming partners can review your geometry and flag potential problems before you've committed to tooling. They'll identify where tolerances need relaxation, where feature placement conflicts with forming physics, and where alternative geometries achieve the same function with better manufacturability.

The payoff extends beyond cost savings. Accelerated time-to-production results when designs don't require multiple tooling iterations. First articles that pass inspection on the first attempt keep programs on schedule. Statistical process capability that's built into the design - rather than forced through process adjustments - delivers sustainable quality throughout production runs.

With your design optimized for aluminum formability, the final piece of the puzzle involves selecting a forming partner with the technical capabilities, quality systems, and responsiveness to bring your project from concept to production efficiently.

Selecting the Right Aluminum Forming Partner

You've mastered alloy selection, understood forming processes, and optimized your design for manufacturability. Now comes the decision that determines whether all that preparation translates into production success: choosing the right aluminum fabricator. This isn't simply about finding someone who can bend metal - it's about identifying a partner whose capabilities, quality systems, and responsiveness align with your project requirements.

Think of your forming partner as an extension of your engineering team. According to TMCO, the success of your project often depends on the expertise and precision of your manufacturing partner. Choosing the right aluminium fabricator can make the difference between a smooth production run and costly setbacks.

Evaluating Aluminum Forming Capabilities

What separates a capable aluminum fabrication services provider from one that will struggle with your project? Start by evaluating these critical capability areas:

- Technical equipment and processes - Look for CNC press brakes for consistent bending, high-precision laser cutting systems, TIG and MIG welding stations, and in-house machining centers. These metal forming technology investments directly impact accuracy and repeatability.

- Material expertise - A qualified aluminum fabricator understands which alloy grades suit your application, whether you need weldability, formability, or high strength. They should readily discuss 5052 versus 6061 trade-offs without hesitation.

- Quality certifications - Look for ISO 9001 certification as a baseline. For automotive applications, IATF 16949 certification demonstrates the rigorous process controls required for chassis, suspension, and structural components. Aerospace projects demand AS9100 compliance.

- Engineering and DFM support - The right fabricator doesn't just follow drawings - they help improve them. In-house engineers should assist with CAD/CAM modeling and Design for Manufacturability reviews before fabricating aluminum begins.

- Scalability - Can they handle both prototype quantities and high-volume production runs under one roof? This flexibility prevents production bottlenecks as your program grows.

- Communication transparency - The best partners provide progress updates, timeline reviews, and engineering feedback throughout the project lifecycle.

For example, manufacturers like Shaoyi (Ningbo) Metal Technology exemplify what comprehensive capabilities look like in practice. Their IATF 16949 certification validates automotive-grade quality systems, while their integrated approach combines custom metal stamping with precision assemblies - exactly the technical depth you should seek when evaluating potential partners.

Accelerating Your Supply Chain

Speed matters in today's competitive landscape - but not at the expense of quality. The key is finding partners who have built speed into their processes through investment and optimization rather than shortcuts.

Rapid prototyping capabilities can dramatically compress your product development timeline. According to Advantage Metal Products, rapid prototyping expedites the overall manufacturing process from initial concept to market readiness. Techniques such as CNC machining allow for rapid fabrication of metal components directly from CAD models, eliminating traditional tooling setup delays.

What does "rapid" actually mean in practice? Look for partners offering 5-day turnaround on prototype parts. This capability enables multiple design iterations within weeks rather than months - critical when you're validating formability assumptions or testing fit with mating components. Shaoyi's 5-day rapid prototyping service, for instance, allows automotive developers to validate designs quickly before committing to production tooling investments.

Quote turnaround time reveals more than you might think about a fabricator's operational efficiency. A partner who delivers quotes within 12 hours demonstrates streamlined internal processes and genuine responsiveness to customer needs. Compare this to industry norms of days or weeks for quotes, and you'll understand why quick turnaround accelerates decision-making across your supply chain.

DFM support speed compounds these advantages. When your aluminum fab partner reviews designs proactively and identifies manufacturability issues before quoting, you avoid the costly iteration cycles that plague poorly planned projects. Comprehensive DFM support - like the engineering collaboration Shaoyi provides - catches tolerance conflicts, grain direction issues, and tooling constraints while changes still cost nothing but design time.

As Karkhana emphasizes, collaborating with your fabricator during the design phase ensures manufacturability and cost efficiency. Their input can help you make tweaks that reduce production complexity without compromising functionality.

The Prototype-to-Production Transition

The real test of an aluminium fabrication partnership comes during the transition from validated prototypes to full-rate production. Seamless scaling requires:

- Automated production capabilities - Manual processes that work for prototypes often can't sustain production volumes economically. Look for partners with automated stamping lines and robotic handling systems.

- Statistical process control - Production consistency requires documented monitoring of critical dimensions throughout runs, not just first-article and final inspection.

- Capacity flexibility - Your volumes may fluctuate. Partners with scalable capacity can ramp up for launch surges and adjust to steady-state demand without quality compromises.

- Integrated finishing - Having forming, machining, and finishing under one roof eliminates handoff delays and quality variations that multi-vendor approaches introduce.

According to TMCO, partnering with a full-service aluminum fabricator eliminates coordination challenges. Their vertically integrated setup combines metal fabrication, CNC machining, finishing, and assembly - reducing lead times and ensuring consistent quality protocols across every process stage.

Making Your Selection Decision

When comparing potential partners, weight your evaluation criteria based on your specific project requirements. High-volume automotive programs demand IATF 16949 certification and proven production scalability. Prototype-heavy development projects prioritize turnaround speed and DFM collaboration. Aerospace applications require AS9100 compliance and rigorous material traceability.

Request case studies from similar applications. Ask about their experience with your specific alloy and temper combinations. Understand their approach to springback compensation and surface quality preservation - these aluminum-specific challenges separate experienced aluminum fab shops from general metal fabricators who struggle with the material's unique behavior.

The investment in thorough partner evaluation pays dividends throughout your program. The right aluminum forming partner becomes a competitive advantage - accelerating your development cycles, reducing quality issues, and providing the technical expertise that complements your internal capabilities.

With your forming partner selected, you're ready to launch your aluminum forming project with confidence. The final section synthesizes everything covered and provides your action plan for moving forward.

Launching Your Aluminum Forming Project

You've journeyed through alloy selection, forming processes, challenge mitigation, industry applications, DFM optimization, and partner evaluation. Now it's time to transform that knowledge into action. Whether you're developing automotive structural components, aerospace panels, or consumer electronics enclosures, the path forward follows predictable steps - steps that separate successful projects from costly learning experiences.

Understanding how is sheet metal made and processed reveals why aluminum dominates modern manufacturing. The combination of lightweight performance, corrosion resistance, and formability creates opportunities across industries - but only when you respect the material's unique behavior and plan accordingly.

Your Aluminum Forming Action Plan

Ready to move from planning to production? Follow this structured approach:

Step 1: Define your requirements clearly. Document the mechanical properties needed, surface finish expectations, production volumes anticipated, and quality certifications required. These specifications drive every subsequent decision.

Step 2: Select alloy and temper strategically. Match your formability needs with strength requirements. Remember - 5052-H32 offers excellent formability for complex geometries, while 6061-T6 delivers higher strength at the cost of tighter bend radius restrictions.

Step 3: Choose your forming process. Part geometry, tolerance requirements, and production volume dictate whether stamping, deep drawing, roll forming, or hydroforming best serves your application. High volumes justify stamping die investment; complex geometries may warrant hydroforming despite higher per-part costs.

Step 4: Engage DFM early. Before finalizing designs, review geometry against forming constraints. Verify bend radii, hole placement relative to bend lines, and grain direction orientation. Early DFM engagement prevents expensive tooling iterations.

Step 5: Qualify your forming partner. Evaluate technical capabilities, quality certifications, prototyping speed, and production scalability. Request references from similar applications and assess their experience with your specific alloy requirements.

The difference between forming steel sheet and forming aluminum extends beyond material substitution. Aluminum's greater springback, galling tendency, and surface sensitivity demand process adjustments throughout - from tooling design to lubrication selection to post-forming handling.

Key Takeaways for Project Success

Looking back across everything covered, certain principles emerge as non-negotiable for sheet metal work success with aluminum:

The single most critical success factor in aluminum forming is matching your alloy and temper selection to your specific formability requirements - get this wrong, and no amount of process optimization can compensate.

Beyond alloy selection, keep these essentials front of mind:

- Springback is predictable - Build compensation into your tooling design from the start rather than chasing corrections in production

- Grain direction matters - Orient bends perpendicular to rolling direction whenever geometry permits

- Surface protection is non-negotiable - Plan for protective films, polished tooling, and careful handling throughout metal processing operations

- Tolerances should reflect reality - Aluminum forming tolerances run 1.5-2× wider than comparable steel operations; over-tolerancing increases cost without adding value

- Quality certifications align with applications - IATF 16949 for automotive, AS9100 for aerospace, ISO 9001 as baseline for general fabrication

When you're ready to fabricate sheet metal in aluminum, the partner you choose becomes your competitive advantage. Look for manufacturers who combine rapid prototyping capabilities with production scalability - the ability to validate designs quickly through 5-day prototype turnaround, then scale seamlessly to automated mass production.

For automotive applications demanding IATF 16949-certified quality, partners like Shaoyi (Ningbo) Metal Technology offer the comprehensive capabilities discussed throughout this guide - from DFM support and 12-hour quote turnaround to precision assemblies for chassis, suspension, and structural components. Their integrated approach to metal for fabrication eliminates the coordination challenges that slow multi-vendor supply chains.

Your aluminum forming project success depends on decisions made before metal ever touches tooling. Armed with the knowledge from this guide, you're positioned to make those decisions with confidence - selecting the right alloy, the right process, and the right partner to bring your designs to production efficiently and reliably.

Frequently Asked Questions About Aluminum Sheet Metal Forming

1. What is the best aluminum for sheet metal forming?

5052 aluminum is widely considered the best choice for sheet metal forming due to its excellent balance of formability, weldability, and corrosion resistance. It offers the highest strength among non-heat-treatable alloys while maintaining workability for complex geometries. For applications requiring higher strength, 6061-T6 is preferred, though it requires larger bend radii (3-4× material thickness) compared to 5052-H32 (1-2× thickness). Your specific choice should balance formability needs with strength requirements and post-forming operations like welding or anodizing.

2. What is the process of forming aluminum?

Aluminum forming involves transforming flat sheets into three-dimensional shapes through controlled deformation. Common processes include stamping (pressing metal through dies for high-volume parts), deep drawing (pulling blanks into cup-shaped components), roll forming (passing strips through roller stations for continuous profiles), stretch forming (stretching sheets over form dies for curved panels), and hydroforming (using pressurized fluid for complex geometries). Process selection depends on part geometry, production volume, tolerance requirements, and budget constraints.

3. How to stiffen an aluminum sheet?

Aluminum sheets can be stiffened through several techniques. Work hardening through rolling increases strength and hardness by reducing thickness. Adding formed features like ribs, beads, or flanges dramatically improves rigidity without adding material. For heat-treatable alloys like 6061, artificial aging (T6 temper) maximizes hardness and strength. Strategic bend placement creates structural stiffness through geometry rather than material thickness. Combining thinner gauge material with formed stiffening features often proves more cost-effective than using thicker sheets.

4. Can you cold forge aluminium?

Yes, aluminum can be cold forged effectively. Cold forging is suitable for manufacturing low-cost, high-quality automotive components from high-strength aluminum alloys. This method excels for parts requiring narrow geometrical tolerances, good concentricity, smooth surface finishes, and near-net-shape products. However, most sheet metal forming operations use cold forming processes like stamping and deep drawing rather than forging. For difficult geometries, warm forming at 200-350°C can improve formability parameters by 200-300% while reducing springback significantly.

5. How do you compensate for springback in aluminum forming?

Springback compensation in aluminum forming requires multiple strategies. Overbending tooling 2-5° past target angles anticipates elastic recovery. Bottoming and coining apply additional force to plastically set bends permanently. Warm forming at elevated temperatures (200-400°C) can reduce springback angles from 9° to as little as 0.5°. Thermo-mechanical compensation using heated lower dies with room-temperature punches creates stress differentials reducing springback by up to 20%. Selecting softer tempers (O or H32) over fully hardened conditions also minimizes elastic recovery.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —