Aluminum Body Panel Stamping Dies: Design, Types, and Cost

TL;DR

Aluminum body panel stamping dies are high-precision, specialized tools essential to the automotive industry. They function within a metal forming process that uses high-pressure presses to shape flat aluminum sheets into the complex, three-dimensional components that form a vehicle's body, such as doors, fenders, and hoods. This process is critical for producing lightweight yet strong parts that improve fuel efficiency and performance, requiring a deep understanding of die types, materials, and design to achieve the required tolerances.

Understanding the Aluminum Stamping Process and Die Fundamentals

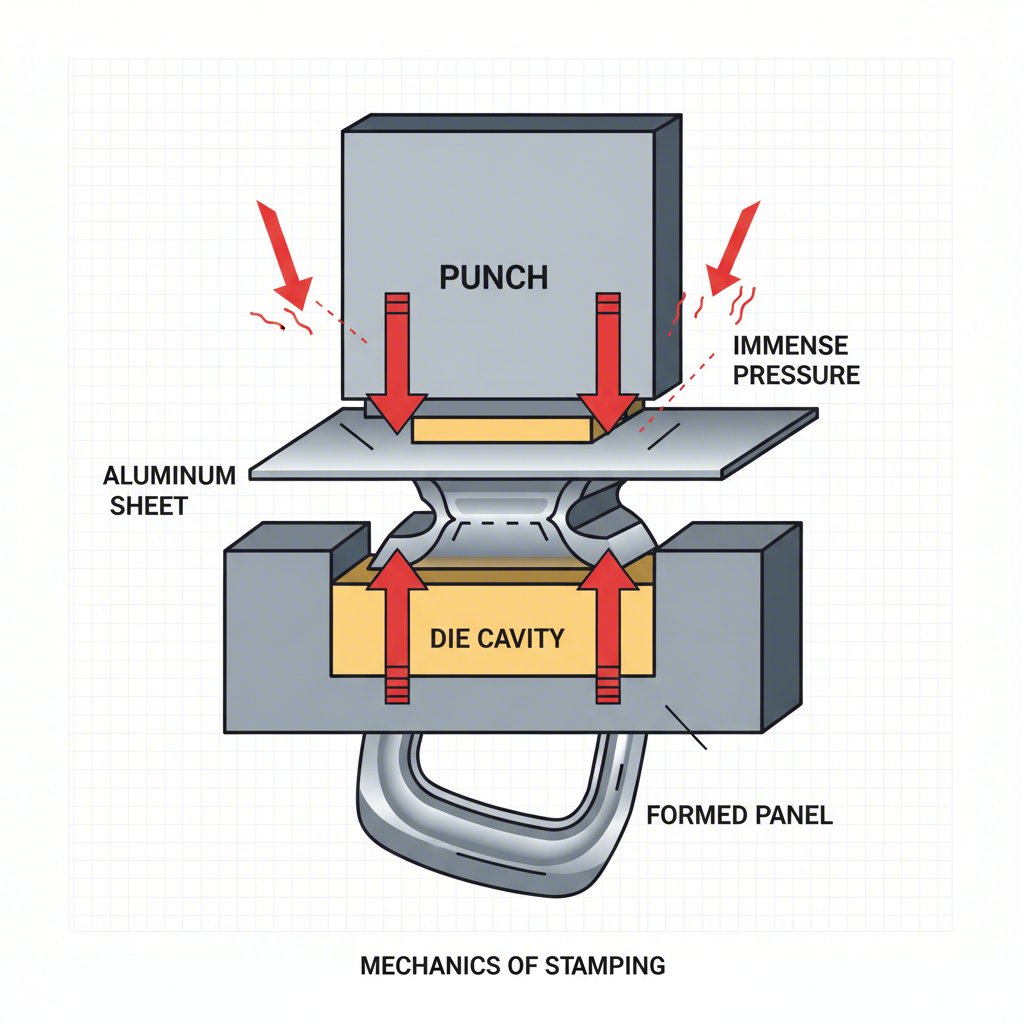

The aluminum stamping process is a cornerstone of modern automotive manufacturing, involving a series of sophisticated techniques to convert raw aluminum sheets into precisely formed components. At its core, the process uses a stamping press to apply immense force to a die set, which shapes or cuts the metal. A stamping die is a custom-engineered tool, typically consisting of two halves, that acts as a mold for the aluminum sheet. When the press closes, the die imparts its shape onto the metal, creating everything from a simple bracket to a complex fender with intricate curves. According to experts at Alsette, this method is particularly effective for deep drawing, where a metal sheet is pulled into a die cavity to create a three-dimensional part, a technique fundamental for body panels.

This process begins with blanking, where the initial flat shape is cut from a larger aluminum coil or sheet. Subsequent operations may include piercing, which punches necessary holes or slots, and forming or drawing, which creates the final 3D geometry. Aluminum is an ideal material for this application due to its excellent strength-to-weight ratio, ductility, and natural corrosion resistance. As noted by Sheetmetal Masion, aluminum requires less force to stamp than steel, which can influence press selection and energy consumption. The final parts, such as body side apertures and closure panels, are lightweight without compromising the structural integrity and crashworthiness of the vehicle.

While often discussed in similar contexts, metal stamping and die casting are fundamentally different processes. Stamping is a cold-working process that shapes solid sheet metal, whereas die casting involves injecting molten metal into a mold. This distinction leads to different applications, material choices, and outcomes. Stamping is highly efficient for high-volume production of parts from sheet materials like steel and aluminum, while die casting excels at creating highly complex, intricate shapes from metals like aluminum, zinc, and magnesium alloys.

| Criteria | Metal Stamping | Die Casting |

|---|---|---|

| Process | Shapes solid sheet metal using a press and die (cold working). | Injects molten metal into a mold cavity under high pressure. |

| Starting Material | Sheet metal coils or blanks (e.g., aluminum, steel). | Metal ingots or billets (e.g., aluminum, zinc, magnesium alloys). |

| Best For | High-volume production of parts with uniform wall thickness like body panels, brackets, and enclosures. | Creating complex, intricate parts with varying wall thicknesses, such as engine blocks or transmission housings. |

| Production Speed | Very high speed, suitable for mass production. | Slower than stamping, as each part must be cast and cooled individually. |

Key Types of Stamping Dies for Automotive Panels

The selection of a stamping die is critical and depends entirely on the part's complexity, size, and required production volume. In automotive manufacturing, several primary types of dies are employed to create body panels, each with distinct advantages. Understanding these types is crucial for engineers and procurement managers when planning a production line or commissioning custom tooling. The choice directly impacts production speed, cost, and the quality of the final component.

Progressive dies are highly efficient for producing smaller, complex parts at very high speeds. In this setup, a coil of aluminum is fed through the press, and a series of stations within a single die perform sequential operations—such as cutting, bending, and punching—at each stroke of the press. The part remains attached to the metal strip until the final station, where it is cut off. This method is ideal for high-volume components like brackets and connectors but is less suitable for large body panels like a hood or door.

For larger components, transfer dies are the preferred solution. Unlike progressive dies, a transfer die system uses a series of individual stations or separate presses. The part is first cut from the sheet (blanked) and then mechanically moved from one station to the next by robotic arms. Each station performs a specific forming operation. This method provides greater flexibility for producing large, deep-drawn parts such as fenders, doors, and body sides. While the production rate is slower than progressive stamping, it is the standard for manufacturing the main structural and cosmetic panels of a vehicle.

Deep drawing dies are a specialized category often used within a transfer die system. Their specific function is to pull a sheet metal blank into a die cavity to form a deep, three-dimensional shape without wrinkles or fractures. This is essential for parts with significant depth and complex curves. The design of these dies must carefully manage material flow to prevent thinning or tearing, making them one of the more complex and expensive types of tooling to engineer.

| Die Type | Mechanism | Best-Use Case | Pros | Cons |

|---|---|---|---|---|

| Progressive Die | A single die with multiple stations performs sequential operations on a continuous metal strip. | High-volume production of small to medium-sized, complex parts (e.g., brackets, connectors). | Extremely fast production rates; low labor cost per part. | High initial tooling cost; not suitable for very large parts. |

| Transfer Die | The part is separated from the blank and moved between multiple, separate die stations by a mechanical system. | Large, deep-drawn parts like doors, hoods, and fenders. | Versatile for complex geometries; can handle large parts. | Slower production speed than progressive dies; complex automation required. |

| Deep Drawing Die | A specialized die that pulls a sheet metal blank into a cavity to create deep, 3D shapes. | Parts requiring significant depth and complex curves, such as oil pans or body panels. | Creates seamless, strong, and lightweight hollow parts. | Requires precise control of material flow; high risk of defects like wrinkling or tearing. |

Die Materials, Quality, and Design Considerations

The performance, longevity, and precision of an aluminum stamping operation are directly tied to the quality of the die itself. The materials used in its construction and the engineering principles behind its design are critical factors that separate a high-performance tool from one that fails prematurely. For automotive applications, especially for exterior 'Class A' surfaces, the standards are exceptionally high. A 'Class A' die is engineered for high-volume production and must produce parts with a flawless surface finish and strict dimensional accuracy, making material choice and design paramount.

Die materials are typically chosen based on the expected production volume, the abrasiveness of the material being stamped, and the overall budget. High-carbon tool steels are a common choice for their hardness and wear resistance, ensuring a long service life. However, for some applications, cast steel or other alloys may be used as a more cost-effective alternative, though often at the expense of durability. OEM-grade stamping dies are often described as 'over-engineered,' built with superior materials to withstand millions of cycles, whereas cheaper aftermarket dies may use lower-quality materials that wear out faster.

Designing dies for aluminum presents unique challenges compared to steel. As detailed by simulation experts at AutoForm, aluminum exhibits greater springback—the tendency of the metal to return to its original shape after forming. Die designs must compensate for this by over-bending the part slightly so it springs back into the correct geometry. Furthermore, aluminum is more prone to galling (a form of wear caused by adhesion between sliding surfaces), making proper lubrication and die surface coatings essential. Providers of custom tooling, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., leverage advanced CAE simulations to predict and mitigate these issues, ensuring the final die produces parts that meet precise specifications from the first run.

When commissioning a custom stamping die for aluminum body panels, several key factors must be specified to ensure the tool meets quality and performance expectations. A clear checklist helps guarantee that the final product will be fit for purpose and deliver a strong return on investment.

- Material Specification: Clearly define the aluminum alloy and temper (e.g., 5182 or 6016) that will be stamped, as this affects springback and formability.

- Production Volume & Lifespan: Specify the total number of parts the die is expected to produce over its lifetime. This determines the required durability and material choice for the die itself.

- Part Tolerances: Provide detailed drawings with precise dimensional tolerances. Specify if the part is a 'Class A' surface requiring a perfect finish.

- Press Specifications: Inform the die maker of the press tonnage, stroke length, and bed size where the die will be used.

- Springback Compensation: Confirm that the design incorporates advanced springback compensation strategies, often validated through simulation software.

- Lubrication and Coating Requirements: Specify the type of lubrication to be used in production and any required die surface coatings (e.g., PVD, nitriding) to prevent galling and reduce friction.

Cost Analysis: Factors Influencing Stamping Die Price

The cost of an aluminum body panel stamping die is a significant capital investment, with prices varying dramatically based on a multitude of factors. There is no standard price; a die for a small, simple bracket might cost several thousand dollars, while a complex set of dies for a car door or fender can easily run into the hundreds of thousands or even millions. Understanding the key drivers behind this cost is essential for budgeting and for making informed decisions during the procurement process.

The primary cost driver is the size and complexity of the part. A larger part requires a physically larger die, which consumes more raw material (typically high-grade tool steel) and requires more machining time. Part complexity adds another layer of cost; a simple, flat part needs a relatively simple die, but a deep-drawn body panel with sharp character lines and negative angles requires a multi-stage die with sophisticated engineering to control material flow and springback. Each additional stage or complex feature adds significant design, machining, and tryout time, which directly increases the price.

Material quality and required precision are also major factors. A die built from premium tool steel designed for a lifespan of over a million strokes will be substantially more expensive than one made from cast steel for a low-volume run. Similarly, the tolerance requirements play a crucial role. A 'Class A' die for an exterior body panel demands near-perfect precision and surface finish, requiring extensive hand-finishing and rigorous validation, which adds considerable labor costs. In contrast, a die for an unseen structural component may have looser tolerances and a lower price tag.

To navigate this complex landscape and secure an accurate quote, it is vital to provide potential suppliers with a comprehensive technical package. Vague requirements will only lead to inaccurate estimates and potential cost overruns. A detailed specification package allows the die maker to understand the full scope of the project and provide a realistic and competitive bid.

- Part Size and Complexity: Larger and more intricate parts require more material and machining time, making this the single biggest cost factor.

- Die Material: High-quality tool steels for high-volume production are more expensive than lower-grade materials for prototyping or short runs.

- Required Precision (Tolerances): Tighter tolerances and 'Class A' surface finish requirements increase machining, polishing, and validation costs.

- Production Volume/Die Lifespan: Dies built for millions of cycles require more durable (and expensive) construction than those for a few thousand parts.

- Number of Die Stations: Complex parts requiring multiple forming, trimming, and piercing operations will need a more elaborate and costly multi-stage die set (e.g., in a transfer press).

- Tryout and Validation: The cost includes the time and materials needed to test the die, fine-tune it, and prove that it can produce parts that meet all specifications.

Conclusion: The Strategic Value of High-Quality Tooling

In the competitive landscape of automotive manufacturing, aluminum body panel stamping dies are more than just tools; they are strategic assets that directly influence production efficiency, part quality, and profitability. The initial investment in a well-designed, robustly constructed die pays dividends through reduced downtime, lower scrap rates, and consistent part quality over millions of cycles. Making the right choices in die type, materials, and design is fundamental to leveraging the benefits of lightweighting with aluminum.

Successfully navigating the complexities of die procurement requires a clear understanding of the interplay between part design, material properties, and the stamping process itself. From compensating for springback to selecting the appropriate die type for a given component, every decision has long-term consequences. By focusing on quality, partnering with experienced toolmakers, and providing detailed technical specifications, manufacturers can ensure their stamping operations are both reliable and cost-effective, ultimately delivering superior vehicles to the market.

Frequently Asked Questions

1. What is the difference between die cut and stamping?

While related, die cutting and stamping refer to different processes. Stamping is a broader term that encompasses forming, shaping, and bending metal in three dimensions, often a cold-working process. Die cutting, a subset of this, specifically refers to using a die to shear or cut a shape out of sheet material, similar to a cookie cutter. Die casting is a completely different method that involves injecting molten metal into a mold, not shaping solid sheet metal.

2. What aluminum material is used for die casting?

This question pertains to die casting, not stamping. For die casting, common aluminum alloys include A380, 383, and A360. These are chosen for their fluidity when molten, corrosion resistance, and pressure tightness. Stamping, on the other hand, uses different alloys that come in sheet form, such as 3003, 5052, and 6061, which are selected for their formability and strength in a solid state.

3. What are the different types of stamping die?

The primary types of stamping dies used in manufacturing include progressive dies, where multiple operations are performed sequentially on a single strip of metal; transfer dies, where a part is moved between different stations for various operations; and deep drawing dies, which are specialized for creating deep, 3D shapes. Other types include blanking dies for cutting initial shapes and piercing dies for creating holes.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —