Deep Drawing for Automotive Parts: Process & Advantages

TL;DR

The deep drawing process is a cold-forming metal manufacturing technique used to shape flat sheet metal into seamless, hollow components where the depth is greater than the radius. This method is fundamental to the automotive industry, as it efficiently produces strong, dimensionally accurate, and leak-proof parts. Key applications include critical components like airbag inflators, fuel pump housings, and ABS brake modules, where structural integrity is paramount.

Understanding the Deep Drawing Process: Fundamentals and Mechanics

Deep drawing is a specialized metal forming process, technically defined as a tensile-compression forming process, that transforms a flat sheet of metal, known as a blank, into a three-dimensional hollow shape without seams or joints. Unlike general metal stamping, which may involve bending or punching, deep drawing forces the material to flow into a die cavity, creating parts with a depth greater than their radius. This distinction is crucial for manufacturing components that require a monolithic, leak-proof structure, a common requirement for automotive parts. The process is valued for its ability to maintain a relatively uniform material thickness from the initial blank to the final product.

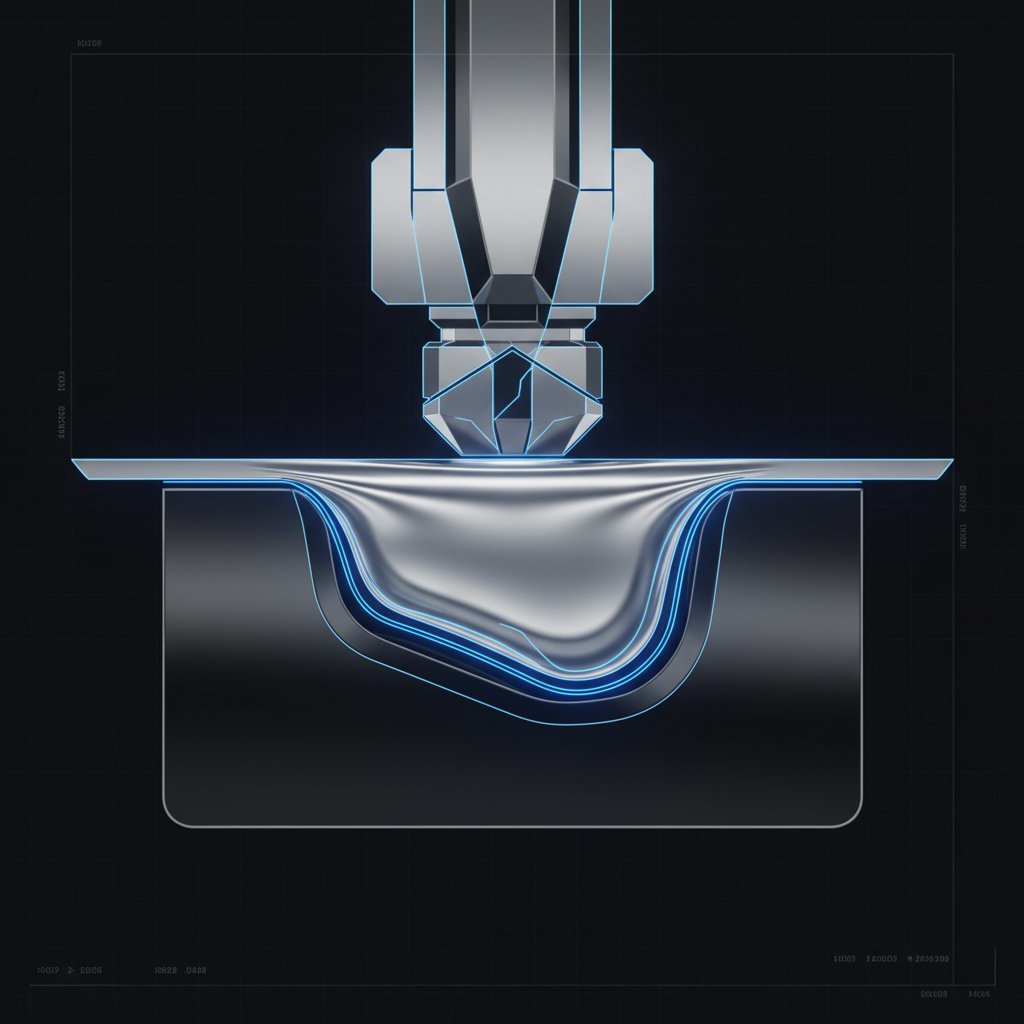

The mechanics of the deep drawing process revolve around three primary components: the punch, the die, and the blank holder. The operation begins by placing the sheet metal blank onto the die. The blank holder then descends to apply controlled pressure on the edges of the blank, securing it against the die face. This pressure is critical for managing material flow and preventing defects like wrinkling. Following this, the punch, which has the shape of the desired internal part geometry, moves downward, pushing the blank into the die cavity. The metal is drawn over the radiused edge of the die, causing it to deform and take the shape of the punch and die.

A successful deep drawing operation depends on the precise calibration of several factors. The clearance between the punch and the die must be carefully managed—too little clearance can cause the material to tear, while too much can lead to wrinkling. According to a detailed guide from Macrodyne, proper lubrication is also essential to reduce friction, which facilitates smooth material flow, minimizes tool wear, and improves the surface finish of the final part. The entire sequence is a carefully orchestrated plastic deformation that results in a strong, seamless component.

The step-by-step procedure can be summarized as follows:

- Blank Placement: A flat sheet metal blank is positioned on the die ring.

- Clamping: The blank holder applies pressure to the perimeter of the blank to control material flow.

- Drawing: The punch descends, forcing the metal blank into the die cavity to form the desired shape.

- Retraction: The punch retracts, and the finished part is ejected from the die.

For complex or very deep parts, this process may need to be performed in multiple stages, with each stage progressively reducing the diameter and increasing the length of the component. This multi-stage approach prevents the material from exceeding its formability limits in a single operation.

Key Advantages and Automotive Applications

The deep drawing process offers significant advantages that make it indispensable in the automotive industry. One of the most critical benefits is the creation of seamless parts. As detailed by Trans-Matic, this monolithic structure eliminates weak points associated with welds or joints, making components inherently leak-proof, waterproof, and airtight. This is vital for safety-critical systems like fuel pumps and brake modules. Furthermore, the process induces work hardening (or strain hardening), a form of cold working that increases the material's strength and hardness without requiring heat treatment, resulting in more durable and rugged components.

From a manufacturing perspective, deep drawing is highly efficient and cost-effective for high-volume production runs. The ability to perform multiple forming operations in a single press cycle, combined with rapid cycle times, significantly reduces production costs and lead times. This efficiency is a key reason why deep drawing is preferred over more expensive methods like casting or multi-part machining and assembly. It minimizes material waste and can be highly automated, further reducing labor costs and ensuring consistent quality across thousands of parts.

The applications of deep drawing in the automotive sector are extensive and diverse, covering a wide range of critical components. Some prominent examples include:

- Safety Systems: Inflators and diffusers for airbags, and housings for ABS brake modules.

- Fuel and Engine Systems: Fuel pump components, injector cups, and various sensor housings.

- Structural and Body Components: Fuel tanks, engine parts, and complex body panels.

- Other Components: Thermostat connections, bayonet sockets, and connectors for various systems.

Materials like aluminum are particularly well-suited for deep drawing in automotive applications. As Hudson Technologies explains, aluminum offers an exceptional strength-to-weight ratio, natural corrosion resistance, and high dent resistance. These properties make deep-drawn aluminum parts ideal for reducing vehicle weight to improve fuel efficiency while maintaining structural integrity and safety.

Critical Process Considerations: Materials, Design, and Defects

Achieving a successful deep drawing outcome requires meticulous attention to material properties, tooling design, and process parameters. The choice of material is paramount; metals must possess high ductility to stretch and form without failing. Suitable materials include aluminum alloys, cold-rolled low-carbon steel, certain stainless steels, brass, and copper. The material's plastic strain ratio and strain hardening characteristics influence how it behaves under the tensile and compressive stresses of the process.

Proper tooling design and precise process control are essential to avoid common manufacturing defects. As manufacturing experts at Neway Precision note, challenges like wrinkling, tearing, and springback must be anticipated and mitigated. For instance, advanced simulation software is often used to predict material flow and optimize tooling before production begins. This proactive approach saves significant costs by avoiding trial-and-error adjustments. For manufacturers seeking robust solutions, some firms specialize in this area. For example, Shaoyi (Ningbo) Metal Technology Co., Ltd. provides expertise in creating custom automotive stamping dies, leveraging advanced simulations to ensure precision and efficiency for complex components.

Several common defects can arise if the process is not carefully controlled. Understanding their causes and solutions is key to maintaining quality. While deep drawing involves pushing a blank through a die, stretch forming is a different process that involves stretching the material over a die without significant flange draw-in, resulting in material thinning.

| Defect | Common Cause | Solution |

|---|---|---|

| Wrinkling | Insufficient blank holder force, allowing compressive stresses to buckle the material in the flange area. | Increase blank holder pressure, use draw beads to control material flow, or modify die radii. |

| Tearing / Cracking | Excessive blank holder force, sharp die/punch radii, poor lubrication, or exceeding the material's limiting draw ratio. | Reduce blank holder force, increase radii, improve lubrication, or add intermediate drawing stages. |

| Earing | Anisotropy in the sheet metal, where material properties are not uniform in all directions, causing uneven flow. | Use higher-grade material with less anisotropy or design the blank to leave extra material for trimming. |

| Uneven Thickness | Improper clearance between the punch and die or inconsistent material flow. | Adjust tooling clearance and optimize blank holder pressure for uniform flow. |

Quality Assurance in Deep Drawing for Automotive Parts

In the automotive industry, where precision and reliability are non-negotiable, quality assurance is a critical final stage of the deep drawing process. The intense stresses and material displacement inherent in forming can lead to dimensional inaccuracies or compromise material integrity if not properly managed. Ensuring that every component meets tight tolerances is essential for its function, especially for safety-critical parts like airbag diffusers or brake system housings, where failure is not an option.

Modern quality assurance extends beyond simple post-production inspection. According to metrology leader ZEISS, a proactive approach involves verifying the forming tools *before* production begins. By using advanced optical 3D measuring systems, manufacturers can scan the entire surface of the punch and die with high precision. This digital twin of the tooling allows for the detection of any deviations from the CAD model, ensuring the tools themselves are perfect before the first part is ever drawn. This pre-verification step helps prevent systemic errors and saves significant time and resources.

In-process monitoring is another cornerstone of contemporary quality control. Robot-guided sensors can be integrated directly into the production line to measure critical dimensions of parts as they are manufactured. This real-time feedback allows for immediate adjustments to process parameters, such as blank holder pressure or lubrication, to correct any deviations before they lead to a large batch of defective parts. This contrasts sharply with traditional methods that rely solely on inspecting a sample of finished components, where errors might only be discovered after significant waste has occurred. By combining tool verification with in-process monitoring, automotive manufacturers can ensure that deep-drawn parts are produced with the highest level of accuracy, safety, and reliability.

Frequently Asked Questions

1. How is deep drawing done?

The deep drawing process is performed using a punch and a die. A flat sheet metal blank is placed over the die cavity. A blank holder applies pressure to the edges of the blank, and a punch then presses the metal into the die cavity, causing it to deform and take the desired hollow shape. The process relies on the controlled flow of material rather than stretching it thin.

2. What is the formula for deep drawing force?

A common formula to approximate the maximum punch force (F) required for deep drawing is F = S * p * t, where S is the tensile strength of the material, p is the perimeter of the drawn part, and t is the thickness of the material blank. This calculation provides an estimate, but actual forces can be influenced by factors like friction, lubrication, and tool geometry.

3. What is the difference between deep drawing and stretch forming?

In deep drawing, the material is encouraged to flow from the flange area into the die cavity, resulting in a cup-shaped part with a relatively unchanged wall thickness. In contrast, stretch forming clamps the edges of the blank tightly and stretches the material over a punch or die, which intentionally thins the material to create the desired shape.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —