Why Forged Wheels Are Expensive: The Hidden Costs Nobody Reveals

Understanding What Makes Forged Wheels Different

You've done the research, found the perfect wheel design, and then—bam—the price tag hits you like a freight train. Four figures per wheel? Sometimes even five? If you've ever wondered why forged wheels command such premium prices, you're not alone. This sticker shock sends countless enthusiasts scrambling for answers, questioning whether these wheels are genuinely worth the investment or simply overpriced automotive jewelry.

The $5,000 Question Every Enthusiast Asks

Here's the thing: when you're comparing a set of cast wheels at $1,500 against fully forged wheels pushing $8,000 or more, you naturally want to understand what justifies that massive price gap. The answer isn't hidden marketing magic or arbitrary markup—it's rooted in fundamental differences in how these wheels come into existence.

So, what is a forged wheel exactly? Unlike cast wheels where molten aluminum is simply poured into molds and cooled, forged wheels begin their life as a solid block of aerospace-grade aluminum. This isn't just any aluminum either. Manufacturers typically use 6061-T6 aluminum—the same material trusted in military applications, aerospace engineering, and Formula 1 racing. The "T6" designation refers to a specific heat treatment process involving solution heat treatment and controlled aging that dramatically enhances the alloy's yield strength and hardness.

From Raw Aluminum to Rolling Art

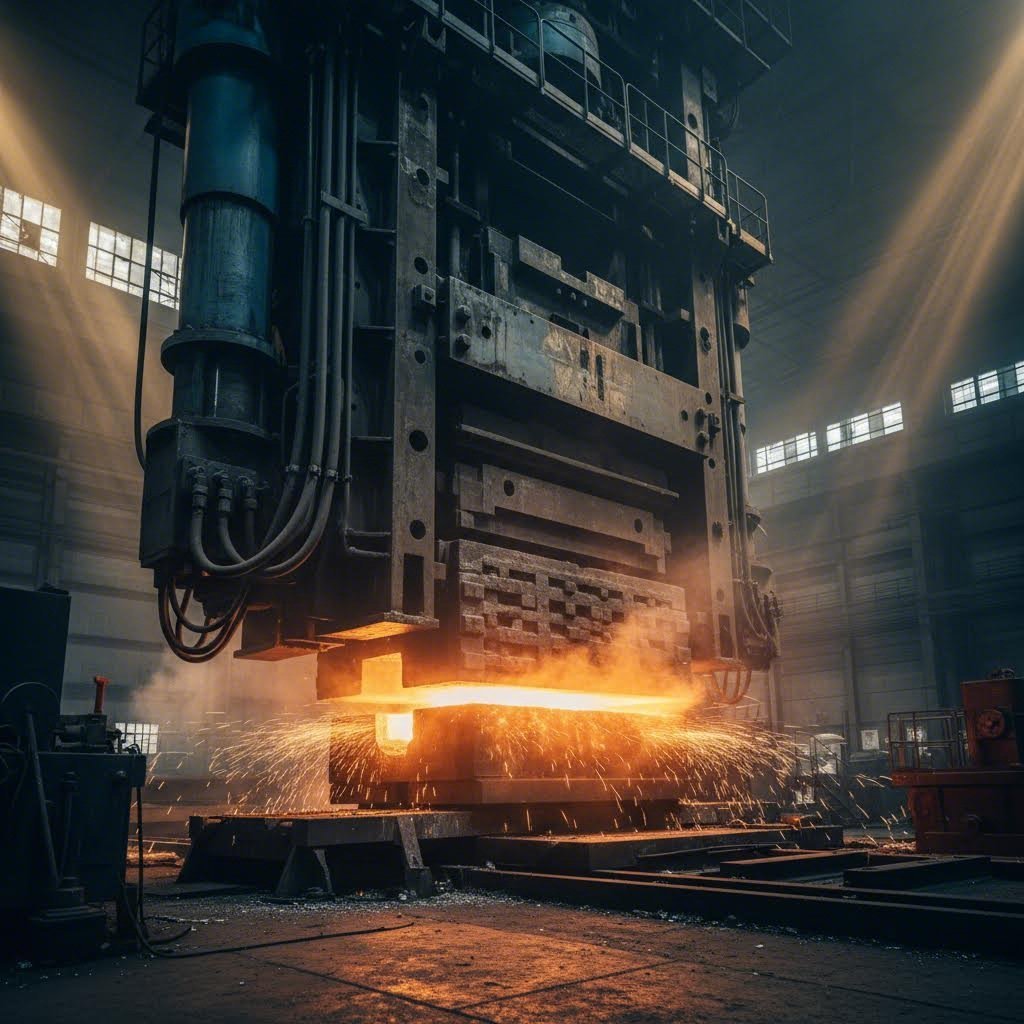

Understanding what are forged rims requires grasping the fundamental transformation that occurs during manufacturing. That solid aluminum billet gets heated to extreme temperatures—approaching but not reaching its melting point—and then subjected to enormous hydraulic pressure. We're talking 8,000 to 10,000 tons of force compressing and shaping that metal into wheel form.

At a molecular level, the forging process keeps the continuity of the metal's grain structure intact, resulting in a dramatically stronger finished product. Cast wheels, by contrast, have their original molecular structure disrupted when the aluminum is melted and reformed.

This distinction matters enormously. When you ask what does forged wheels mean in practical terms, the answer lies in that grain structure. Forging aligns the aluminum's internal grain pattern, eliminating the microscopic air pockets (porosity) that plague cast wheels. The result? Forged wheels are approximately three times stronger than cast alternatives while being roughly 25% lighter.

What are forged wheels capable of that cast wheels aren't? Superior impact resistance, better load capacity, and the ability to be repaired after damage that would destroy lesser wheels. These aren't minor performance tweaks—they're fundamental structural advantages that directly impact how your vehicle handles, accelerates, and stops.

Throughout this guide, we'll pull back the curtain on every cost factor that contributes to forged wheel pricing. From the multi-million dollar forging presses and skilled CNC operators to the raw material costs and certification requirements, you'll discover that the price of the most expensive rims on the market reflects genuine manufacturing complexity rather than inflated profit margins. By the end, you'll understand exactly where your money goes—and whether that investment makes sense for your specific driving needs.

The Manufacturing Process That Justifies Premium Pricing

Ever wondered what actually happens behind the scenes to transform a chunk of raw aluminum into a precision forged wheel? The manufacturing journey is far more complex than most enthusiasts realize—and understanding this process reveals exactly why these wheels carry their premium price tags.

The forged rims meaning extends far beyond a simple label. It represents a multi-stage manufacturing odyssey that demands specialized equipment, skilled labor, and meticulous quality control at every step. Let's walk through exactly what happens when forging rims from start to finish.

The 10,000-Ton Press Behind Every Wheel

The journey begins with billet selection—choosing the right block of aerospace-grade 6061-T6 aluminum. This isn't a random grab from inventory. Engineers evaluate each billet's chemical composition, ensuring it meets strict specifications for magnesium and silicon content that determine final strength characteristics.

Next comes the heating phase. The aluminum billet is brought to temperatures between 750°F and 900°F—hot enough to become malleable but still solid. This precise temperature window is critical. Too cold, and the metal won't flow properly under pressure. Too hot, and you risk compromising the aluminum's structural integrity.

Here's where things get intense. That heated billet enters a hydraulic forging press capable of applying 8,000 to 10,000 tons of pressure. Imagine the weight of roughly 5,000 cars concentrated on a single point. This immense force compresses the aluminum into a rough wheel shape called a forging blank, fundamentally reorganizing its internal structure in the process.

But the forging blank is far from finished. Precision forged wheels require extensive CNC machining to achieve their final dimensions. Computer-controlled cutting tools carve out spoke designs, drill bolt patterns, and machine the barrel to exact specifications—often within tolerances of just 0.001 inches. This machining phase alone can take several hours per wheel.

The final stages involve surface treatments: heat treatment to optimize hardness, shot peening to improve fatigue resistance, and finishing processes like powder coating, polishing, or anodizing. Each step adds time, labor, and cost to the finished product.

Why Grain Structure Determines Everything

The real magic of fully forged wheels happens at the molecular level. When that massive press compresses the aluminum billet, it aligns the metal's grain structure in a continuous, unbroken pattern. Think of it like wood grain—aligned fibers are dramatically stronger than randomly oriented ones.

This grain alignment eliminates porosity—those microscopic air pockets and voids that inevitably form when casting molten metal into molds. According to India Forging's metallurgical analysis, cast aluminum parts commonly contain inclusions and defects that weaken the structure, while forged parts maintain consistent grain structure throughout.

The practical result? A one piece forged wheel can be 25-30% lighter than a comparable cast wheel while maintaining equal or greater strength. This isn't marketing fluff—it's basic metallurgical science. The compressed, aligned grain structure of a forged rim creates superior molecular density that resists cracking, bending, and fatigue failure.

Additionally, ASM Tuning reports that compression forged wheels can save up to 4-5kg per corner compared to cast alternatives. This weight reduction compounds across every aspect of driving dynamics, from acceleration and braking to cornering response.

| Manufacturing Aspect | Forged Wheels | Cast Wheels |

|---|---|---|

| Raw Material Form | Solid aluminum billet | Molten aluminum |

| Primary Process | 8,000-10,000 tons hydraulic pressure | Poured into mold and cooled |

| Secondary Processing | Extensive CNC machining (2-4 hours) | Trimming and basic machining |

| Equipment Investment | Multi-million dollar forging presses | Standard foundry equipment |

| Production Time per Wheel | 4-8 hours minimum | 30 minutes to 2 hours |

| Grain Structure | Aligned and continuous | Random with potential porosity |

| Typical Weight Comparison | 25-30% lighter | Baseline weight |

| Strength Characteristics | Superior fatigue resistance and toughness | Prone to cracking under stress |

When you examine this manufacturing comparison, the price differential starts making sense. Every forged wheel represents hours of machine time on equipment costing millions of dollars, operated by skilled technicians who command premium wages. Cast wheels, by contrast, can be mass-produced quickly using relatively inexpensive foundry equipment.

But equipment and time only tell part of the story. The real cost drivers extend into raw materials, quality control, research and development, and certification requirements—factors we'll break down in detail next.

Breaking Down the Real Cost Components

You've seen the manufacturing complexity. You understand the metallurgical advantages. But where exactly does your money go when you purchase forged aluminium wheels? The pricing puzzle has more pieces than most buyers realize—and understanding each component reveals why even the cheapest options from reputable forged wheels brands still carry significant price tags.

Let's pull back the curtain on every dollar that goes into creating these precision components.

Where Your Money Actually Goes

The cost structure of forged alloy wheels differs fundamentally from mass-produced alternatives. While cast wheel manufacturers spread their expenses across hundreds of thousands of units, forged wheel producers work with dramatically lower volumes—forcing fixed costs to be absorbed by fewer products.

Here's a comprehensive breakdown of the cost categories that determine final pricing:

- Raw Material Costs: Aerospace-grade 6061-T6 aluminum commands a significant premium over standard casting alloys like A356. According to IMARC Group's manufacturing analysis, producing a single 12kg alloy wheel requires approximately 12.6kg of aluminum—accounting for material loss during machining. For forged truck wheels and performance applications requiring larger diameters, material consumption increases proportionally. Market volatility adds another layer of complexity; global aluminum markets have experienced significant volatility, and aluminum markets experience similar fluctuations that directly impact production costs.

- Equipment Investment: Hydraulic forging presses capable of delivering 8,000-10,000 tons of pressure represent multi-million dollar capital expenditures. Unlike casting equipment that can be purchased relatively affordably, forging infrastructure requires massive upfront investment. CNC machining centers, heat treatment furnaces, and finishing equipment add millions more to facility costs. These capital expenses must be amortized across production runs—and with lower volumes, each wheel carries a heavier burden of that equipment cost.

- Labor Hours: Skilled CNC operators, quality inspectors, and finishing technicians command premium wages. Frigate's forging cost analysis identifies labor as a significant cost driver, noting that specialized forging operations require trained personnel for machine operation, process supervision, and quality verification. In regions with higher costs of living, these labor expenses climb even higher. Unlike automated casting lines that require minimal human intervention, forging operations demand constant skilled oversight.

- R&D and Engineering Costs: Every new wheel design requires extensive engineering work before production begins. CAD modeling, stress analysis, prototype development, and design validation all consume engineering hours. Advanced CAD/CAM systems and sophisticated simulations help predict tooling wear and optimize designs, but this technology requires ongoing investment and specialized expertise.

- Tooling and Setup: Custom dies and molds are manufactured specifically for each wheel design. According to Frigate's analysis, tooling costs can represent a significant portion of total pricing, especially for smaller production runs. Complex spoke patterns and intricate designs require more advanced tooling that takes longer to develop and costs more to produce. If tooling wears out or becomes damaged during production, replacement costs add to the final price.

- Certification and Testing Fees: Meeting safety standards like JWL (Japan Light Alloy Wheel), VIA (Vehicle Inspection Association), or TÜV certification requires rigorous testing protocols. Radial fatigue testing, impact resistance verification, wheel balancing, and air leak inspections must be performed—often on every single wheel. This quality control infrastructure requires specialized equipment, trained personnel, and ongoing operational costs.

The Hidden Costs Behind Every Spoke

Beyond the obvious production expenses, several hidden factors quietly inflate forged wheel pricing that buyers rarely consider.

Material waste represents a significant hidden cost. When CNC machines carve intricate spoke designs from forging blanks, substantial aluminum gets removed—and while scrap can be recycled, it still adds to overall production expenses. Industry analysis confirms that scrap rates can exceed initial expectations depending on design complexity, leading to inaccurate cost projections if not properly accounted for.

Production volume economics create another pricing pressure. When you're curious about how much are Forgiato wheels or wonder how much do Forgiato rims cost, remember that premium brands produce far fewer units than mass-market manufacturers. A cast wheel factory might produce 200,000 pieces annually, spreading fixed costs thin across massive volumes. Forged wheel specialists often produce a fraction of that quantity, meaning each wheel must absorb proportionally more overhead.

Consider Corleone forged wheels price points or similar boutique manufacturers—their low-volume, high-customization approach means every fixed cost gets divided among fewer units. Tooling that might cost $50,000 to develop gets spread across perhaps 500 wheels instead of 50,000, adding $100 per wheel instead of $1.

Quality control adds another layer. While some manufacturers cut corners, reputable forged wheels brands perform X-ray inspection, dimensional verification, and load testing on every single wheel leaving their facility. This level of scrutiny prevents defective parts from reaching customers but adds significant per-unit costs that mass-produced wheels simply don't bear.

Understanding these cost components helps explain why forged wheel pricing isn't arbitrary—it reflects genuine manufacturing complexity and quality investment. But construction method and customization level also play crucial roles in final pricing, factors we'll examine next.

Construction Methods and Customization Factors

Now that you understand the raw cost components, here's where things get interesting. Not all forged wheels are created equal—and the construction method you choose dramatically impacts both pricing and performance characteristics. Whether you're shopping for forged rims for trucks or lightweight track wheels, understanding these three distinct construction approaches helps you make smarter purchasing decisions.

One Piece, Two Piece, Three Piece Explained

When browsing forged wheels for trucks or performance applications, you'll encounter three fundamental construction types. Each offers unique advantages—and each carries different cost implications.

Monoblock (One-Piece) Forged Wheels: These true forged rims represent the pinnacle of strength-to-weight ratio. Manufacturers mill the entire wheel from a single block of forged aluminum, creating an uninterrupted structure with no joints, welds, or bolts. According to FlexiForge's engineering analysis, monoblock forged wheels deliver the highest structural integrity because the grain structure flows continuously throughout the entire wheel.

Why does this construction method command the highest prices? Material waste. When CNC machines carve intricate spoke designs from that solid billet, substantial aluminum gets removed and discarded. Complex designs with deep concave profiles or elaborate spoke patterns can waste 40-50% of the original billet weight. That discarded aluminum represents real cost that gets factored into your final price.

Two-Piece Forged Wheels: This construction separates the center (face and spokes) from the outer barrel. The two components are either welded together or connected using high-strength bolts. Vivid Racing notes that forged 2 piece wheels offer a compelling middle ground—providing more design flexibility at moderate cost compared to monoblock options.

The beauty of two-piece construction lies in customization potential. Manufacturers can combine different barrel widths with the same center design, offering varied offset and backspacing options without engineering entirely new wheels. If you damage the barrel on a pothole, you can potentially replace just that component rather than the entire wheel—a significant advantage for daily drivers.

Three-Piece Forged Wheels: Maximum customization meets complex assembly. Three-piece wheels separate the inner barrel, outer barrel, and center into distinct components connected by precisely torqued hardware. This construction allows manufacturers to create nearly any width and offset combination imaginable, making them popular for show cars and custom builds requiring unusual fitments.

However, complexity adds cost. Assembly requires precision hardware, careful torque specifications, and additional quality control steps. Industry analysis confirms that three-piece wheels typically cost two to three times more than comparable one-piece options—and they're slightly heavier due to the additional hardware connecting the components.

For off-road and 4x4 applications, monoblock construction typically dominates due to its superior impact resistance and structural integrity. Off-road environments subject wheels to extreme stress—and the continuous grain structure of one-piece forging handles those demands better than multi-piece alternatives.

| Characteristic | Monoblock (One-Piece) | Two-Piece | Three-Piece |

|---|---|---|---|

| Construction | Single forged billet | Forged center + separate barrel | Center + inner barrel + outer barrel |

| Strength | Highest—continuous grain flow | High—welded or bolted joints | Good—multiple connection points |

| Weight | Lightest option | Slightly heavier than monoblock | Heaviest due to hardware |

| Customization | Limited offset/width options | Moderate flexibility | Maximum—virtually any width/offset |

| Repairability | Entire wheel replacement if damaged | Barrel can be replaced separately | Individual components replaceable |

| Relative Price | $$$ (highest material waste) | $$ (moderate) | $$$$ (complex assembly labor) |

| Best Use Cases | Track, performance, off-road | Street performance, daily drivers | Show cars, custom builds |

How Customization Multiplies Costs

Beyond construction method, customization options add layers of expense that many buyers underestimate. When you're designing your perfect set of wheels, each personal touch carries a price tag.

Custom Colors and Finishes: Standard powder coating adds reasonable cost, but specialty finishes escalate quickly. Brushed surfaces, hand-polished lips, multi-tone color combinations, and custom color matching to your vehicle's paint code all require additional labor hours and specialized materials. Splux Wheels offers over 100 powder coated finishes—and each option beyond basic colors adds to production complexity.

Engraving and Personalization: Laser engraving your name, logo, or custom graphics onto the wheel face requires additional machine time and setup. While the per-unit cost seems modest, it adds processing steps that extend lead times and create opportunities for quality control issues.

Center Caps and Hardware: Custom center caps with your vehicle's logo, colored lug hardware, or specialty valve stems might seem like minor additions. But each custom component requires sourcing, inventory management, and assembly coordination—all of which add overhead costs.

Unique Specifications: Requesting non-standard sizes, unusual bolt patterns, or custom offsets often requires new tooling development. If your specifications don't match existing production runs, manufacturers must either create dedicated tooling or modify existing dies—expenses that get passed directly to you.

Lead times extend proportionally with customization complexity. A standard monoblock wheel from existing inventory might ship within days. Fully customized three-piece wheels with specialty finishes and engravings? Expect 8-12 weeks or longer as manufacturers schedule your unique specifications into production queues.

Understanding these construction and customization factors helps explain price variations between seemingly similar wheels. But geography plays an equally important role in determining what you'll ultimately pay—a factor we'll examine next.

Manufacturing Location and Quality Standards

You've seen the cost components and construction methods—but here's a factor that dramatically shifts pricing yet rarely gets discussed openly: where your forged wheels are actually made. The manufacturing location impacts everything from labor costs and quality control rigor to shipping timelines and final retail price. Understanding this geographic dimension helps you evaluate whether premium pricing reflects genuine quality differences or simply inflated overhead.

Geography's Impact on Your Wheel Price

The global forged wheel industry concentrates primarily in three regions: North America (predominantly the USA), Europe (Germany leading), and Asia (China and Japan). Each region brings distinct cost structures and manufacturing philosophies that directly influence what you'll pay at checkout.

American Forged Wheels: USA-made forged wheels command premium pricing for several interconnected reasons. According to Forgelite's industry analysis, skilled operators and machine shops in the US charge $100-$200 per hour—compared to roughly $15-$20 per hour in China. When creating a set of forged wheels takes anywhere from half a day to multiple days, that labor differential alone creates massive pricing gaps. Brands like American Force forged wheels leverage this "Made in USA" positioning to justify premium price points, often reaching $15,000-$20,000+ for a complete set.

Japanese and German Manufacturing: Rays Engineering forged wheels and German manufacturers like BBS represent another tier of premium pricing. These regions combine high labor costs with decades of motorsport heritage and engineering excellence. JDM forged wheels from companies like Rays, Enkei, and Work Wheels carry price premiums built on proven track records—literally. When Formula 1 teams and professional racing series choose your wheels, that validation commands market premium.

Chinese Manufacturing: China forged wheels typically sell at 40-70% of comparable USA-made alternatives. Industry data confirms this price differential stems primarily from labor cost differences rather than inherently inferior quality. However, the Chinese forged wheels market spans an enormous quality spectrum—from questionable budget options to world-class production facilities meeting the strictest international standards.

The critical insight here isn't that one region automatically produces superior products. Rather, manufacturing location creates baseline cost structures that affect minimum viable pricing. A Chinese manufacturer operating premium equipment with rigorous quality control will still undercut American prices—but not by as much as a corner-cutting operation using outdated equipment and minimal inspection protocols.

Certifications That Separate Premium from Pretenders

How do you distinguish legitimate quality from marketing claims when evaluating forged wheels from different regions? Certifications provide objective verification that manufacturers meet internationally recognized standards.

According to FlexiForge's certification guide, reputable forged wheel manufacturers should hold multiple relevant certifications:

- ISO 9001: The foundational quality management standard demonstrating consistent processes from design through final inspection. This certification proves a company follows structured quality control rather than ad-hoc procedures.

- JWL and JWL-T: Japanese Light Alloy Wheel standards confirming wheels meet safety and quality requirements. Despite originating in Japan, these standards are widely accepted globally as baseline quality indicators.

- VIA Certification: Vehicle Inspection Association testing provides independent third-party verification that wheels meet JWL standards—adding extra assurance beyond manufacturer self-reporting.

- TÜV Certification: Particularly important for European markets, TÜV certification indicates products passed rigorous German safety and quality testing protocols.

- IATF 16949:2016: This automotive industry-specific certification covers the entire production process and is vital for manufacturers supplying major automakers. It focuses on continuous improvement and defect prevention—exactly what you want in safety-critical components like wheels.

The IATF 16949 certification deserves particular attention. This isn't a simple checkbox—it requires comprehensive quality management systems, documented processes, and regular third-party audits. Manufacturers holding this certification have invested significantly in quality infrastructure that directly benefits end customers.

Select Asian manufacturers have achieved quality parity with Western counterparts through precisely this certification approach. Companies like Shaoyi (Ningbo) Metal Technology demonstrate how precision hot forging operations can meet global automotive standards through IATF 16949 certification and rigorous quality control protocols. Their example shows that geographic location matters less than manufacturing discipline and quality investment.

Quality Control Differences You Can't See: Premium manufacturers distinguish themselves through testing protocols that budget operations skip entirely. X-ray inspection technology allows manufacturers to detect internal defects—porosity, inclusions, and structural weaknesses—invisible to visual inspection. After X-ray screening, wheels undergo heat treatment and mechanical processing before facing dynamic balance inspection, airtightness testing, and dimensional verification.

According to Forgelite's quality standards, their wheels must meet runout specifications of 0.02"/0.5mm or less—stricter than the North American industry standard of 0.03"/0.75mm. Wheels failing to meet spec get remade entirely rather than shipped with known defects. This level of scrutiny adds cost but prevents the vibration issues, safety risks, and customer headaches that plague budget alternatives.

Premium manufacturers also perform independent quality verification rather than relying solely on factory QC. Some companies maintain their own personnel at manufacturing facilities specifically to conduct final QC checks before shipment. This redundancy catches issues that might otherwise reach customers—but the additional labor and infrastructure adds to final pricing.

Logistics and Port Proximity: Where wheels get manufactured affects not just production cost but delivery timeline and shipping expense. Manufacturers located near major shipping ports enjoy significant logistics advantages. Shaoyi's proximity to Ningbo Port, for example, reduces inland transportation costs and enables faster container loading for international shipments. These efficiencies translate to shorter lead times and reduced per-unit shipping costs compared to facilities located far from port infrastructure.

For buyers importing forged wheels china produces, port proximity matters considerably. Ningbo ranks among the world's busiest container ports, offering frequent sailings to virtually every major market. This connectivity means shorter transit times and more predictable delivery schedules—factors that matter when customers are waiting weeks for custom wheel orders.

The geographic equation ultimately comes down to this: location establishes baseline costs, but certification and quality control investment determine actual value. A certified Chinese manufacturer with rigorous inspection protocols may deliver equal or superior quality to an uncertified domestic producer—at significantly lower cost. The smart buyer evaluates certifications, testing procedures, and manufacturer reputation rather than making assumptions based purely on country of origin.

Understanding these manufacturing and quality factors sets the stage for the most practical question: how do forged wheels actually compare against cast and flow-formed alternatives in real-world performance and value?

Forged Versus Cast and Flow-Formed Alternatives

You understand the manufacturing complexity and cost structure behind forged wheels. But here's the question that ultimately matters: are forged wheels actually worth it compared to cast and flow-formed alternatives? The answer depends on what you value—and understanding the real-world performance differences helps you make that call with confidence.

When comparing alloy vs forged wheels, the distinction extends far beyond marketing claims. So what is the difference between forged wheels and alloy wheels in practical terms? Cast alloy wheels represent the entry point—affordable, widely available, but limited in performance potential. Flow-formed wheels occupy the middle ground, offering some forging benefits at moderate prices. Fully forged wheels sit at the apex, delivering measurable advantages that serious drivers actually feel behind the wheel.

Performance Gains You Can Actually Feel

Are forged wheels lighter? Absolutely—and that weight difference translates directly into tangible performance improvements. According to Velgen Wheels' performance analysis, reducing unsprung weight creates a cascade of benefits that touch nearly every aspect of vehicle dynamics.

Here's what that weight reduction actually delivers:

- Faster Acceleration: Lighter wheels reduce rotational mass, meaning your engine uses less energy to get the wheels spinning. This translates to quicker response times and more effective use of available horsepower—especially noticeable when launching from a standstill or making highway passes.

- Improved Braking: Your brakes don't have to work as hard to slow down lighter rotating mass. Industry research confirms that reduced rotational inertia allows vehicles to stop more quickly with greater precision. Less heat buildup in the braking system also extends brake component lifespan.

- Sharper Handling: With less mass at each corner, your suspension responds more effectively to road imperfections and steering inputs. The vehicle feels more nimble, more connected to the road surface. This improvement becomes especially apparent on winding roads or during spirited driving.

- Enhanced Suspension Response: Reducing unsprung weight allows shock absorbers and springs to control wheel movement more precisely. The result is improved tire contact with the road surface, better traction, and a more compliant ride quality over rough pavement.

- Better Fuel Efficiency: When your engine works less hard to rotate the wheels, fuel consumption decreases proportionally. While savings per tank may seem modest, they compound over time—especially for high-mileage drivers.

These aren't theoretical benefits—forged performance advantages show up on lap timers, acceleration tests, and brake distance measurements. That's precisely why motorsport teams exclusively run forged wheels despite their premium cost. In competitive environments where every fraction of a second matters, the performance edge justifies the investment without question.

| Metric | Forged Wheels | Flow-Formed Wheels | Cast Wheels |

|---|---|---|---|

| Typical Weight (18" wheel) | 17-20 lbs | 20-24 lbs | 24-30 lbs |

| Relative Strength | Highest | Moderate-High | Baseline |

| Impact Resistance | Excellent—bends before cracking | Good | Poor—prone to cracking |

| Price Range per Wheel | $900-$2,000+ | $300-$600 | $100-$300 |

| Repairability | Often repairable after damage | Limited repair options | Usually unrepairable |

| Motorsport Suitability | Preferred choice | Acceptable for amateur events | Not recommended |

When asking what is better alloy or forged wheels, consider your actual use case. According to Modern Muscle Wheels, cast wheels remain the most affordable upgrade path—prices starting around $100-$300 per wheel make them accessible for budget-conscious enthusiasts. Flow-formed wheels bridge the gap, using a hybrid manufacturing process that stretches and compresses aluminum to achieve strength approaching forged levels at roughly $300-$600 per wheel. Forged wheels command $900-$2,000+ per wheel, with premium brands like RAYS Engineering reaching $232-$782 and Vossen ranging from $1,996 to $4,996 for a set.

The Resale Value Advantage Nobody Mentions

Here's a factor competitors rarely discuss: forged wheels retain their value remarkably well on the secondary market. This resale advantage stems from two interconnected factors—durability and desirability.

Durability first. When a cast wheel hits a pothole hard enough to cause damage, it typically cracks. Game over—the wheel goes in the trash. Forged wheels handle the same impact differently. Their aligned grain structure and superior ductility mean they're more likely to bend than crack. A bent forged wheel can often be straightened by a skilled repair shop, returning it to service rather than the landfill.

Industry analysis confirms that forged wheels from premium brands like RAYS maintain excellent resale value due to their high demand and quality reputation. Buyers in the secondary market understand they're purchasing wheels with remaining service life—something far less certain with used cast alternatives that may harbor invisible stress fractures from previous impacts.

Desirability compounds this effect. Forged wheels from established manufacturers carry brand cachet that transcends mere functionality. A set of used RAYS TE37s or BBS LMs commands strong resale prices precisely because buyers recognize these products as proven performers. The brand reputation, motorsport heritage, and consistent quality create demand that persists years after initial purchase.

This resale value fundamentally changes the cost equation. When comparing forged wheels vs alloy wheels on pure purchase price, forged options look expensive. But factor in the resale value you'll recover when selling, and the effective cost of ownership narrows considerably. You might spend $4,000 more upfront on forged wheels—but recover $2,500 more when selling years later. That $1,500 net difference buys genuine performance improvements and superior durability throughout your ownership period.

Understanding the performance advantages, durability benefits, and resale value dynamics helps frame forged wheel pricing in proper context. But brand reputation and market positioning add yet another layer to the pricing equation—factors we'll examine next.

Brand Premium and Market Positioning

You've seen the manufacturing costs, construction methods, and geographic factors that drive forged wheel pricing. But here's another layer that significantly impacts what you'll pay at checkout: brand reputation and the marketing infrastructure behind it. When you're wondering how much are Forgiatos or comparing Forgiatos price against lesser-known alternatives, you're not just paying for aluminum and machining—you're paying for decades of brand building, celebrity associations, and customer service infrastructure.

The Brand Tax Explained

Premium wheel brands like Forgiato, Vossen, and BBS didn't achieve their status overnight. Their current market positioning reflects years of strategic investment that gets baked into every wheel they sell.

According to Wheels Doctor's industry analysis, Vossen has cultivated a strong reputation among car enthusiasts, tuners, and luxury vehicle owners through deliberate brand positioning. This reputation contributes directly to pricing—but it also required substantial investment to create and maintain.

Consider what goes into building a premium wheel brand:

- Motorsport Involvement: BBS wheels appear on Formula 1 cars, NASCAR vehicles, and professional racing series worldwide. This visibility doesn't come free—sponsorship deals, technical partnerships, and racing development programs require significant ongoing investment. When racing teams choose your wheels and win championships, that validation commands market premium. But earning that position costs millions in development, testing, and partnership fees.

- Celebrity Endorsements and Social Media: Brands like Rucci Forged gain visibility through celebrity vehicle builds featured on social media platforms. Brands like Forgiato appear regularly on high-profile builds for musicians, athletes, and influencers. These associations don't happen organically—they require relationship building, product gifting, and sometimes direct compensation. The marketing value translates to brand recognition, but the costs get distributed across retail pricing.

- Show Car Programs: Premium manufacturers invest heavily in building show vehicles that tour car events, generating buzz and demonstrating design possibilities. These builds showcase what's possible with their wheels but represent pure marketing expense—vehicles that never generate direct revenue but create aspirational imagery that drives sales.

- Content Production: Professional photography, video production, website development, and social media management require dedicated teams and ongoing budgets. When Vellano wheels or Amani wheels appear in stunning lifestyle imagery, that content cost money to create. Brands maintaining consistent visual presence invest heavily in content that supports their premium positioning.

These marketing investments create genuine value—brand recognition, quality assurance through reputation, and aspirational appeal that enhances ownership experience. But they add costs that get reflected in final pricing. When comparing a set of Forgiato wheels against lesser-known alternatives, part of that price differential represents marketing infrastructure rather than manufacturing differences.

What You Pay For Beyond the Metal

Beyond marketing and brand building, premium wheel manufacturers maintain costly infrastructure that supports their market position. These operational expenses rarely get discussed but significantly impact retail pricing.

- Dealer Networks and Distribution: Established brands sell through authorized dealer networks rather than directly to consumers. Each dealer in the chain requires margin—typically 20-40% markup between wholesale and retail pricing. A wheel that costs $600 to manufacture might wholesale at $900 and retail at $1,200 or more. This distribution structure provides local expertise and installation support but adds significant cost between factory and consumer.

- Warranty Programs: Premium brands typically offer comprehensive warranties covering manufacturing defects, finish durability, and sometimes even road hazard protection. According to industry analysis, Vossen and similar manufacturers maintain warranty infrastructure that includes claims processing, replacement inventory, and customer service staff. These programs provide genuine value—but the costs get distributed across all wheel sales rather than charged only to customers who file claims.

- Customer Service Infrastructure: When you call a premium wheel manufacturer with questions about fitment, finish options, or order status, you reach trained staff in professional facilities. Maintaining customer service teams, technical support specialists, and sales representatives requires ongoing payroll expense. Budget brands often minimize these costs through automated systems or overseas call centers—but premium brands invest in service quality that matches their product positioning.

- Quality Assurance and Testing: As noted in Vossen's quality documentation, premium manufacturers perform rigorous testing exceeding industry standards—impact resistance verification, fatigue testing, and finish durability assessment. Maintaining testing facilities, equipment calibration, and quality control personnel adds overhead that budget manufacturers avoid. You're paying for the assurance that every wheel meets consistent standards, not just the manufacturing cost of your specific set.

- Research and Design Investment: Premium brands release new designs regularly, keeping their catalogs fresh and maintaining design leadership. Each new wheel design requires engineering time, prototype development, testing validation, and tooling investment. According to industry sources, Vossen invests heavily in state-of-the-art technologies and advanced CAD/CAM systems to maintain design leadership. These R&D costs get amortized across production runs—adding to per-wheel pricing.

Here's the reality check: lesser-known brands can sometimes offer comparable manufacturing quality at significantly lower prices precisely because they avoid these overhead categories. A wheel manufactured to identical specifications on similar equipment costs less when it doesn't carry marketing expense, dealer margins, and extensive customer service infrastructure.

This doesn't mean premium brands overcharge or that budget alternatives match their quality. Rather, the pricing difference reflects genuinely different business models. Premium brands invest in reputation, service, and customer experience—all of which have real value. Budget brands minimize overhead to compete on price—potentially sacrificing consistency, support, and peace of mind.

Understanding this dynamic helps you evaluate what you're actually paying for. If brand recognition, dealer support, and comprehensive warranty matter to your purchase decision, premium pricing delivers genuine value. If you're comfortable researching independently, buying direct, and accepting limited warranty coverage, lesser-known manufacturers may offer equivalent wheels at meaningful savings.

The question isn't whether brand premium is justified—it's whether that premium delivers value that matters to you specifically. Which brings us to the final consideration: determining whether forged wheels make financial sense for your particular situation and driving needs.

Making the Right Investment Decision

You've absorbed the manufacturing complexity, cost breakdowns, and performance data. Now comes the question that actually matters: should you buy forged wheels? The honest answer isn't a simple yes or no—it depends entirely on how you'll use them, what you drive, and what you genuinely value. Let's cut through the marketing noise and evaluate when forged wheels deliver real value versus when cheaper alternatives make more financial sense.

When Forged Wheels Make Financial Sense

Certain driving scenarios and ownership situations make the premium pricing of forged wheels genuinely worthwhile. If any of these descriptions match your situation, the investment likely pays dividends.

Track Enthusiasts and Performance Drivers: If you regularly push your vehicle on circuit days, autocross events, or spirited canyon runs, forged wheels deliver measurable advantages you'll actually feel. According to Performance Plus Tire's analysis, competitive racing demands the safety, strength, and weight savings that only forged wheels can offer. The reduced unsprung mass translates directly to faster lap times, shorter braking distances, and sharper handling response. Racing teams choose forged wheels almost exclusively—not because they're wealthy, but because performance matters more than cost savings at the track.

High-Performance Vehicle Owners: When you're driving something valued over $70,000—a Porsche, BMW M-car, or similar performance machine—forged wheels become proportionally sensible. As ThreePiece.us notes, a reasonable guideline suggests wheels should represent about 10% of your vehicle's purchase price. Spending $5,000-$8,000 on wheels for a six-figure sports car maintains appropriate proportionality. Plus, these vehicles often come with decent OEM wheels—opting for cast alternatives might actually represent a downgrade from factory equipment.

Long-Term Ownership Plans: If you're building a keeper—a vehicle you'll own for a decade or more—the total cost of ownership equation shifts favorably toward forged. Their superior durability means they'll likely outlast multiple sets of cheaper alternatives. The repairability advantage compounds this benefit; when you inevitably hit that pothole, a bent forged wheel can often be straightened rather than replaced. Over a ten-year ownership period, one set of quality forged wheels may cost less than cycling through two or three sets of cast alternatives that crack under stress.

Weight-Sensitive Builds: Building a lightweight track car, autocross weapon, or hill climb special? Every pound matters. Forged wheels offer the best forged rims performance-to-weight ratio available. When your build philosophy prioritizes minimal mass, the 25-30% weight savings over cast alternatives represents exactly the kind of upgrade that aligns with your goals.

Honest Assessment for Different Driver Types

Not every driver needs forged wheels—and understanding when cheaper alternatives make more practical sense helps you avoid overspending on capabilities you'll never utilize.

Daily Commuters and Street Drivers: Here's the uncomfortable truth: if your vehicle primarily sees stop-and-go traffic, grocery runs, and highway commuting, you probably won't notice the performance benefits of forged wheels. According to industry analysis, the vast majority of drivers won't experience sufficient performance gains to warrant the premium. Cast or flow-formed wheels deliver adequate performance for everyday driving at a fraction of the cost. The money you save could fund more impactful upgrades—quality tires, brake improvements, or suspension tuning that you'd actually feel during normal driving.

Pothole-Prone Environments: Live somewhere with crater-filled roads? Ultra-lightweight forged wheels—particularly aggressive designs with thin inner barrels—can actually be more vulnerable to damage than beefier cast alternatives. ThreePiece.us specifically warns that wheels like TE37s have super thin inner barrels prone to cracking when combined with stretched tires or pothole-riddled roads. In harsh road conditions, a slightly heavier but more robust wheel might actually serve you better.

Budget-Constrained Builds: If your project car cost $10,000, spending $5,000 on wheels creates problematic proportionality. That money could fund an entire suspension overhaul, quality brake upgrade, engine modifications, and still leave change for decent flow-formed wheels. Prioritize modifications that deliver the most noticeable improvements relative to your vehicle's baseline performance. For budget builds, cheap forged wheels from questionable sources aren't the answer either—quality cast or flow-formed options from reputable manufacturers provide better value.

Short Ownership Periods: Planning to flip the vehicle in a year or two? The resale value advantage of forged wheels requires time to materialize. If you're looking for affordable forged wheels purely for temporary use, consider that cast wheels lose less total value over short ownership periods simply because less was invested initially. The break-even calculation favors forged wheels only when you're holding long enough for durability and resale advantages to accumulate.

The Total Cost of Ownership Calculation:

Smart buyers evaluate wheels on total ownership cost rather than purchase price alone. Here's the framework:

- Initial Investment: Forged wheels cost 3-5x more than cast alternatives upfront. This gap is real and significant—no getting around it.

- Longevity: Quality forged wheels can last 10+ years of hard use. Cast wheels may crack from impacts that forged wheels shrug off. How many sets of cheaper wheels would you cycle through over the same timeframe?

- Repairability: When damage occurs, forged wheels can often be straightened and returned to service. Cast wheels typically get replaced entirely. Factor in potential repair savings versus guaranteed replacement costs.

- Resale Value: Premium forged wheels from recognized brands retain substantial value. Used RAYS, BBS, or Vossen wheels command strong secondary market prices. Cast wheels depreciate heavily and sell for fractions of original cost.

When you understand the manufacturing supply chain, identifying quality options becomes easier. Manufacturers like Shaoyi demonstrate that precision hot forging with proper certifications can deliver quality components—whether wheels, suspension arms, or drive shafts. Exploring certified forging partners helps buyers understand what quality manufacturing actually looks like, enabling more informed purchasing decisions.

Decision Framework Questions:

Before committing to forged wheels—or dismissing them—ask yourself these clarifying questions:

- Do I regularly drive in ways that would utilize reduced unsprung weight? (Track days, spirited driving, competitive events)

- What's my vehicle worth, and does a 10% wheel investment make proportional sense?

- How long do I plan to own this vehicle? (Longer ownership favors forged; short flips favor cast)

- What are my local road conditions? (Smooth roads favor lightweight; rough roads may favor robust construction)

- Could the money I'd save on cast wheels fund other modifications that would deliver more noticeable improvements?

- Am I buying for genuine performance benefits or primarily aesthetic reasons? (If aesthetics drive the decision, cheaper alternatives may deliver equal visual impact)

The cheapest forged wheels from reputable manufacturers start around $900-$1,000 per wheel—still significantly more than quality cast alternatives at $150-$300. When hunting for cheap forged rims, remember that suspiciously low pricing often signals quality compromises you'll regret. Better to buy quality cast wheels than sketchy budget-forged options from unknown manufacturers without proper certifications.

Ultimately, forged wheels represent an investment that pays returns only when your driving actually demands what they deliver. For track enthusiasts, performance car owners, and long-term keepers, the premium pricing reflects genuine value. For daily drivers, short-term owners, and budget-conscious builders, that money often works harder elsewhere. Your answer depends entirely on your specific situation—and now you have the framework to decide with confidence.

Frequently Asked Questions About Forged Wheel Pricing

1. Why are forgeline wheels so expensive?

Forged wheels like Forgeline command premium prices due to their complex manufacturing process involving multi-million dollar hydraulic presses applying 8,000-10,000 tons of pressure, aerospace-grade 6061-T6 aluminum that costs significantly more than casting alloys, and extensive CNC machining taking 2-4 hours per wheel. Additionally, skilled US-based operators charge $100-$200 per hour, rigorous quality control including X-ray inspection and load testing adds overhead, and low production volumes mean fixed costs spread across fewer units—all factors that justify premium pricing.

2. Can you feel a difference with forged wheels?

Yes, the performance difference is tangible. Forged wheels weigh 25-30% less than cast alternatives, reducing unsprung mass at each corner. This translates to faster acceleration response, shorter braking distances, sharper handling, and improved suspension performance. Professional racing teams exclusively use forged wheels because these advantages show up measurably on lap timers. However, daily commuters in stop-and-go traffic may not notice these benefits during normal driving conditions.

3. What is the difference between forged wheels and cast wheels?

The fundamental difference lies in manufacturing. Cast wheels are made by pouring molten aluminum into molds where it cools with random grain structure and potential porosity. Forged wheels start as solid aluminum billets compressed under extreme pressure, aligning the grain structure and eliminating air pockets. This results in forged wheels being approximately three times stronger while weighing 25% less. Forged wheels also bend rather than crack under impact, making them repairable, and they retain significantly better resale value.

4. Are forged wheels worth it for daily driving?

For most daily drivers, forged wheels represent more investment than necessary. The performance benefits—reduced rotational mass, improved handling, faster acceleration—are most noticeable during spirited driving or track use. If your vehicle primarily sees commuting and errands, quality cast or flow-formed wheels at $150-$600 per wheel deliver adequate performance. However, forged wheels make sense for daily drivers planning long-term ownership, as their durability, repairability, and strong resale value can offset the initial premium over 10+ years.

5. How much do quality forged wheels typically cost?

Quality forged wheels from reputable manufacturers start around $900-$1,000 per wheel, with premium brands ranging from $1,500 to $2,500+ per wheel. Complete sets from established brands like RAYS Engineering range from $928 to $3,128, while Vossen sets run $1,996 to $4,996. Custom three-piece forged wheels with specialty finishes can exceed $5,000 per wheel. The price varies based on construction method (monoblock vs. multi-piece), manufacturing location, customization level, and brand positioning.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —