The Essential Forging Process for Universal Joints

TL;DR

The forging process for universal joints is a sophisticated manufacturing method that shapes high-grade steel alloys under extreme pressure to create robust, durable components. Key techniques include hot forging, where metal is heated above its recrystallization temperature for easier shaping, and cold forging for enhanced precision. This process uses high-tonnage presses and specialized dies to form the primary parts, such as yokes and crosses, ensuring superior strength and a continuous grain structure essential for high-stress applications.

Understanding Universal Joints and the Forging Advantage

A universal joint, often called a U-joint, is a critical mechanical coupling that connects rotating shafts, allowing them to transmit torque and motion even when they are at an angle to each other. This flexibility is essential in countless applications, from automotive driveshafts and steering systems to industrial and agricultural machinery. The joint typically consists of two yokes connected by a cross-shaped component, or spider, which houses bearings to facilitate smooth rotation.

Forging is the preferred manufacturing method for these components due to the immense strength it imparts. Unlike casting or machining from solid stock, forging shapes the metal through controlled deformation, aligning the material's internal grain structure with the part's final shape. This creates a continuous grain flow that follows the contours of the yoke and cross, resulting in exceptional tensile strength, fatigue resistance, and impact durability. This structural integrity is paramount for a component that must withstand constant, complex, and alternating loads throughout its service life.

The material selection for universal joints is dictated by these demanding conditions. High-quality alloy steels are the standard choice because of their excellent strength, toughness, and wear resistance. For instance, medium-carbon steels like 45 steel are commonly used for components such as the universal joint fork. In some specialized applications, particularly those requiring high corrosion resistance, stainless steel alloys may be employed, and surfaces can be coated to reduce friction and prevent galling.

Core Forging Techniques: Hot vs. Cold Forging

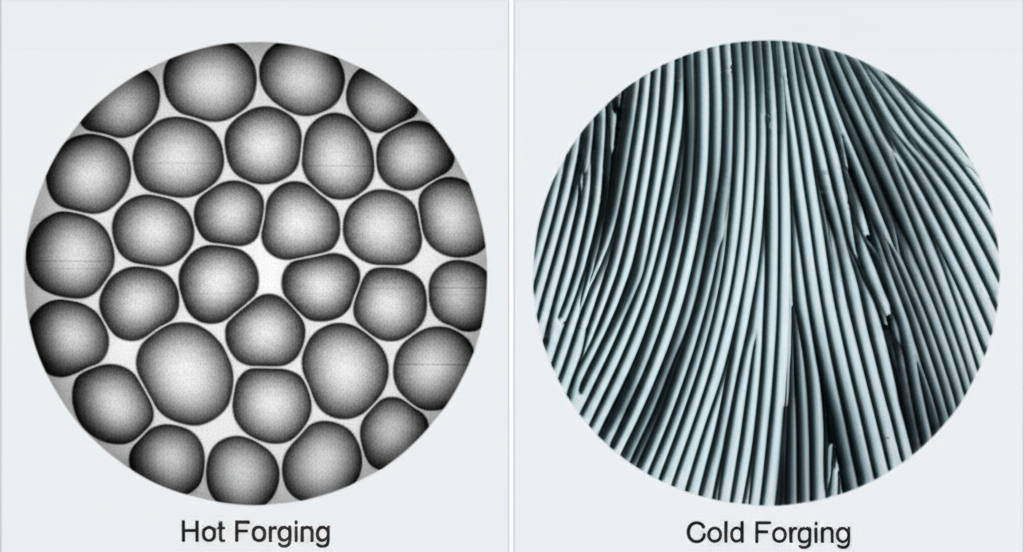

The manufacturing of universal joints primarily relies on two main forging techniques: hot forging and cold forging. The choice between them depends on the specific component, required material properties, and production volume. Each method offers a distinct set of advantages and disadvantages in terms of precision, strength, and cost.

Hot Forging is the most common method for producing universal joint components like the cross. In this process, the steel billet is heated to a temperature above its recrystallization point. This extreme heat makes the metal malleable and plastic, allowing it to be shaped with less pressure from a forging press or hammer. The primary benefit of hot forging is its ability to create complex 3D geometries and large deformations with relative ease, making it ideal for the intricate shape of a U-joint cross. It also refines the grain structure of the metal, eliminating porosity and enhancing its toughness.

Cold Forging, by contrast, is performed at or near room temperature. This process requires significantly more pressure to shape the metal but offers superior dimensional accuracy, a better surface finish, and enhanced strength through a phenomenon known as work hardening. While less common for the initial shaping of complex parts like the cross, cold forging can be used for certain components or as a secondary finishing process to achieve tight tolerances without the need for extensive machining.

Here is a comparison of the two primary methods:

| Feature | Hot Forging | Cold Forging |

|---|---|---|

| Temperature | Above recrystallization temperature (e.g., up to 1150°C for steel) | Room temperature or slightly above |

| Pressure Required | Lower | Significantly higher |

| Dimensional Accuracy | Lower (due to thermal contraction) | Higher |

| Surface Finish | Rougher (oxide scale forms) | Smoother |

| Material Strength | Good toughness and ductility | Increased hardness and tensile strength (work hardening) |

| Common Application | Initial shaping of complex parts (yokes, crosses) | High-precision parts, finishing processes |

The Step-by-Step Manufacturing Process

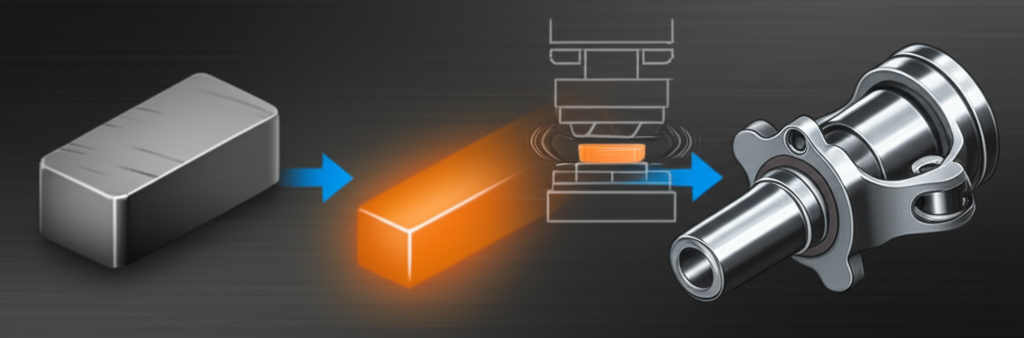

The creation of a universal joint through forging is a multi-stage process that transforms a simple steel bar into a high-performance mechanical component. Each step is meticulously controlled to ensure the final product meets stringent quality and durability standards. While specific details can vary, the general workflow follows a clear, sequential path.

- Material Preparation and Cutting: The process begins with the selection of high-grade steel alloy bars. These bars are inspected for quality and then cut into precise lengths, known as billets or slugs. The weight and volume of each billet are calculated to ensure there is just enough material to fill the die cavity, minimizing waste (known as flash).

- Heating (for Hot Forging): The cut billets are transported to a furnace, often an induction furnace, where they are heated to the optimal forging temperature. For steel, this is typically between 1100°C and 1250°C. This step is critical for making the metal malleable enough to be shaped under pressure.

- Forging and Forming: The heated billet is quickly placed into the lower half of a custom-engineered die set within a high-tonnage forging press. The press then applies immense pressure, forcing the plastic metal to flow and fill the die's cavity, which is shaped like the desired component (e.g., a yoke or cross). This is often a multi-step process, involving a pre-forging stage to roughly form the part and a final forging stage to achieve the net shape and fine details.

- Trimming: After forging, the part has a thin line of excess material around its edges where the two halves of the die met. This excess, called flash, is removed in a trimming press. The flash is later recycled.

- Heat Treatment: To achieve the final desired mechanical properties, the forged components undergo heat treatment. As detailed by HYB Universal Joint, this involves processes like quenching (rapid cooling) to harden the steel and tempering (reheating to a lower temperature) to increase toughness and reduce brittleness. Some parts may also be carburized to create a hard, wear-resistant surface.

- Finishing and Machining: While forging creates a near-net shape, precision machining is required to achieve the final, tight tolerances for bearing surfaces and connection points. Operations like drilling, grinding, and lathing are performed using CNC machinery to ensure perfect fit and smooth operation.

- Assembly and Quality Control: Finally, the individual components—yokes, cross, and bearings—are assembled. Throughout the entire process, rigorous quality control checks are performed, including dimensional inspections and durability testing, to ensure every universal joint meets performance specifications.

Forging Specific Components: Yokes and Crosses

The universal joint's primary components, the yoke and the cross, have distinct geometries that require specialized forging die designs and process considerations. Optimizing these processes is key to improving material utilization, extending die life, and ensuring the structural integrity of the final part.

Forging the Universal Joint Yoke

The universal joint fork, or yoke, is a typical fork-shaped forging with significant variations in its metal distribution. Its complex shape, featuring narrow, high ribs, makes it challenging to forge efficiently. Traditional methods can lead to poor material flow, creating excessive flash in some areas and incomplete filling in others. This not only wastes material but also causes accelerated die wear and requires higher forging pressures.

To overcome these challenges, advanced techniques like a semi-enclosed pre-forging process have been developed. As explained in an analysis by Xinlong Machinery, this involves redesigning the die structure to better control metal flow, forcing it into the necessary cavities rather than out into the flash gutter. By optimizing the pre-forging shape and die layout, manufacturers can increase material utilization from around 61.5% to 75% or more, significantly reduce the final forging load, and more than double the service life of the dies.

For companies seeking robust and reliable automotive components, specialized forging services are essential. For instance, for robust and reliable automotive components, check out the custom forging services from Shaoyi Metal Technology. They specialize in high-quality, IATF16949 certified hot forging for the automotive industry, offering everything from rapid prototyping for small batches to full-scale mass production. Their expertise in in-house die manufacturing ensures precision and efficiency for complex parts like universal joint yokes.

Forging the Cross Shaft

The cross shaft, also known as the spider, is the central component that connects the two yokes. Its four-pronged geometry is a classic example of a complex 3D part that is ideally suited for closed-die hot forging. The process must ensure that the grain flow is continuous from the center out through each of the four trunnions (or journal pegs). This is critical for withstanding the torsional and bending forces it experiences during operation.

The forging process for a U-joint cross involves pressing a heated steel billet in a die that forces the material to flow outwards into the four arms of the cross shape. The design of the preform and the die is crucial to ensure the mold fills completely without defects. After forging, the cross undergoes heat treatment, such as carburizing, to create a very hard, wear-resistant surface on the trunnions where the needle bearings will sit, while maintaining a tougher, more ductile core to absorb shock loads.

Frequently Asked Questions

-

What are the 4 types of forging processes?

There are four main types of forging processes used to shape metal. These include impression die forging (or closed-die forging), where metal is pressed between two dies that contain a precise shape; open-die forging, where the metal is shaped between flat dies without enclosing it; cold forging, which is done at room temperature for precision; and seamless rolled ring forging, used to create ring-shaped components.

-

What are universal joints made of?

Universal joints are typically made from high-strength, heat-treatable steel alloys to withstand high torque and wear. Common materials include carbon steels like 45 steel and various alloy steels. For applications requiring high corrosion resistance, such as in marine or offshore environments, components may be made from stainless steel, like 316L grade. Coatings like PTFE can also be applied to reduce friction.

-

What is the cross forging process?

Cross forging is the preliminary working of forging stock in alternate planes to develop mechanical properties. For a universal joint cross, a closed-die process is used where a heated billet is compressed, forcing the metal to flow outwards into the four cavities of the die. For a universal joint cross, this involves using a closed-die process where a heated billet is compressed, forcing the metal to flow outwards into the four cavities of the die that form the arms of the cross. The process is designed to ensure the die cavity is completely filled while minimizing waste material (flash).

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —