7000 Series Aluminum: Unlocking Its Elite Strength-to-Weight Ratio

TL;DR

7000 series aluminum, particularly the 7075-T6 alloy, offers one of the highest strength-to-weight ratios among all aluminum alloys. This exceptional characteristic is defined by a typical ultimate tensile strength of around 572 MPa (83,000 psi) combined with a low density of approximately 2.81 g/cm³. This unique combination makes it an indispensable material for high-stress, weight-critical applications, primarily in the aerospace, defense, and high-performance sporting goods industries.

Understanding the Strength-to-Weight Ratio

In materials science and engineering, the strength-to-weight ratio is a critical metric for evaluating a material's efficiency. Also known as specific strength, it measures how much load a material can withstand relative to its mass. A higher ratio indicates a material that is both stronger and lighter, a highly desirable trait in countless applications where performance and efficiency are paramount.

The calculation for this ratio is straightforward: a material's strength (typically its ultimate tensile strength) is divided by its density. The resulting value allows engineers to compare different materials on a level playing field. For example, while some steel alloys may have a higher absolute strength than aluminum, their density is nearly three times greater, often resulting in a lower strength-to-weight ratio. This principle is why materials like 7000 series aluminum are essential for building faster aircraft, more fuel-efficient vehicles, and lighter high-performance equipment.

Technical Properties of 7000 Series Aluminum

The 7000 series aluminum alloys derive their superior strength primarily from zinc as the main alloying element, often combined with magnesium and copper. The 7075 alloy is the most prominent member of this series, especially in its T6 temper state (solution heat-treated and artificially aged), which significantly enhances its mechanical properties. This heat treatment process is crucial for achieving the high strength levels the series is known for.

Key mechanical properties define the performance of these alloys under stress. Ultimate Tensile Strength (UTS) is the maximum stress a material can withstand while being stretched or pulled before breaking. Tensile Yield Strength is the point at which the material begins to deform permanently. For a high-performance alloy like 7075-T6, these values are exceptionally high for a lightweight metal. The data below, sourced from leading material databases and industry suppliers, highlights the capabilities of key 7000 series alloys.

| Alloy & Temper | Ultimate Tensile Strength (UTS) | Tensile Yield Strength | Density |

|---|---|---|---|

| 7075-T6 | 572 MPa (83,000 psi) | 503 MPa (73,000 psi) | 2.81 g/cm³ |

| 7085 | Not specified; Yield is primary metric | 503 – 510 MPa (72,950 – 73,970 psi) | ~2.82 g/cm³ |

| 7050 | Not specified; Yield is primary metric | 390 – 500 MPa (57,000 – 72,500 psi) | ~2.83 g/cm³ |

Data synthesized from MatWeb and CEX Casting.

The impressive figures for 7075-T6, in particular, demonstrate why it is often compared to some grades of steel in terms of strength, but at only a third of the weight. This makes it the material of choice when performance cannot be compromised. However, it's important to note that this high strength can come with trade-offs, such as lower corrosion resistance compared to 6000 series alloys and reduced weldability.

Key Applications Driven by High Strength-to-Weight Ratio

The exceptional specific strength of 7000 series aluminum directly enables its use in some of the most demanding engineering fields. Its properties are not just beneficial; they are often a fundamental requirement for achieving modern performance standards.

In the aerospace and defense industries, 7000 series alloys are indispensable. Alloys like 7075 and 7050 are extensively used for critical structural components such as aircraft fuselage frames, wing spars, and landing gear parts. In these applications, every kilogram of weight saved translates directly into increased payload capacity, longer range, and better fuel efficiency. The material's ability to withstand high stress and fatigue from cyclical loading ensures the safety and reliability of the aircraft over its service life.

The automotive sector, especially in high-performance and electric vehicles, also leverages these alloys to reduce overall mass. Lighter vehicles accelerate faster, handle more nimbly, and, in the case of EVs, achieve a longer range per charge. For automotive projects demanding precision-engineered components, consider custom aluminum extrusions from a trusted partner. Shaoyi Metal Technology offers a comprehensive one-stop service, from rapid prototyping to full-scale production under a strict IATF 16949 certified quality system, specializing in strong, lightweight parts tailored to exact specifications.

Beyond transportation, 7000 series aluminum is also found in high-end sporting goods. Performance bicycle frames, rock climbing equipment, and ATV sprockets are often made from 7075 aluminum to provide maximum strength with minimal weight, giving athletes a competitive edge. In all these applications, the high strength-to-weight ratio is the enabling property that drives innovation and performance.

Comparative Analysis: 7000 Series vs. Other Materials

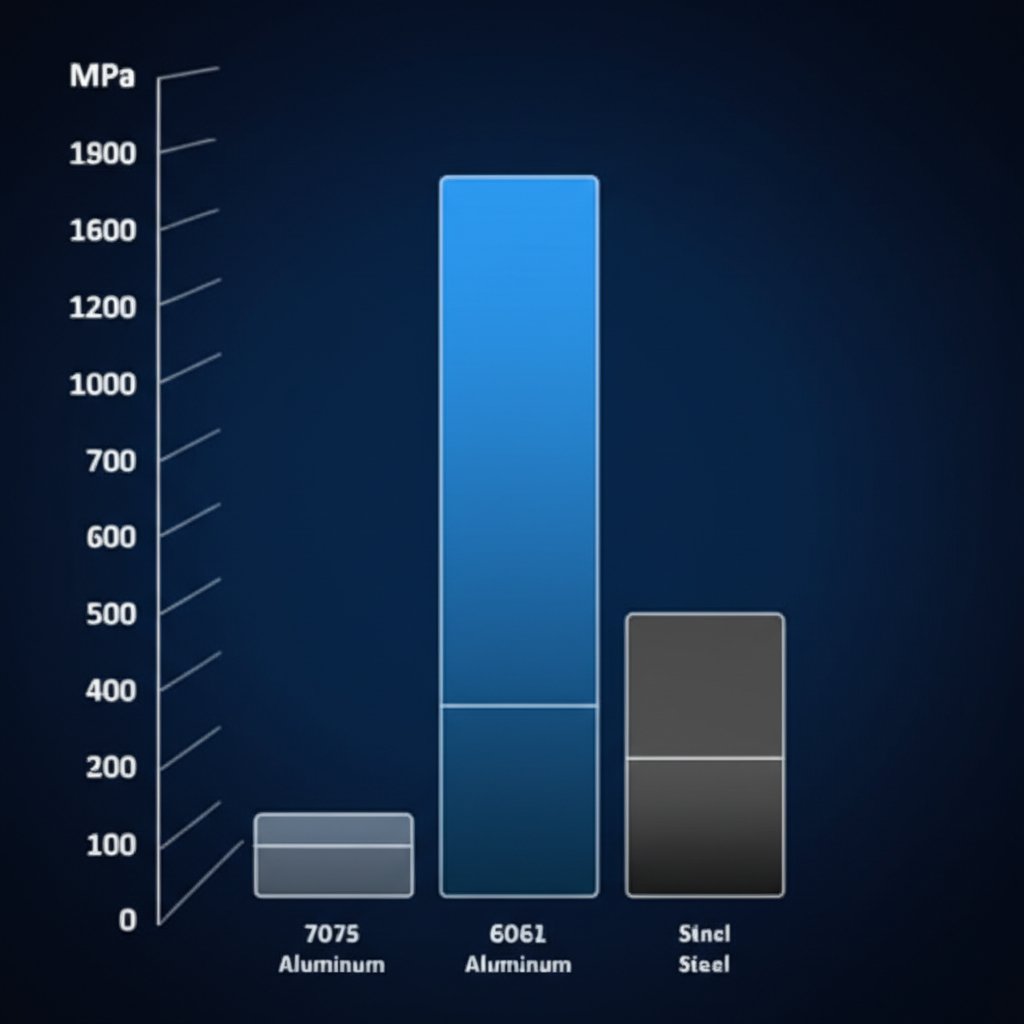

To fully appreciate the value of 7000 series aluminum, it's useful to compare its strength-to-weight ratio against other common engineering materials. While absolute strength is important, specific strength often provides a more relevant picture for applications where weight is a primary concern. The following table provides a clear comparison.

| Material | Typical Tensile Strength (MPa) | Density (g/cm³) | Strength-to-Weight Ratio (kNm/kg) |

|---|---|---|---|

| Aluminum 7075-T6 | 572 | 2.81 | ~203 |

| Aluminum 6061-T6 | 310 | 2.70 | ~115 |

| Mild Steel | 370 | 7.85 | ~47 |

| Titanium (Ti-6Al-4V) | 900+ | 4.43 | ~203+ |

Data synthesized from Yaji Aluminum and other industry sources.

As the table illustrates, 7075-T6 aluminum offers a specific strength that is nearly double that of the widely used 6061-T6 alloy and over four times that of mild steel. This highlights why simply substituting a stronger but heavier material like steel is often not a viable solution for lightweight design challenges. While certain titanium alloys can match or exceed the strength-to-weight ratio of 7075-T6, they come at a significantly higher material and processing cost, limiting their use to the most extreme performance applications. For a vast range of high-stress designs, 7000 series aluminum provides an optimal balance of performance, manufacturability, and cost.

Frequently Asked Questions

1. What is the strength of aluminum 7000 series?

The strength of 7000 series aluminum varies by alloy and temper, but it is known for being among the highest-strength aluminum alloys available. The most common high-performance alloy, 7075-T6, has a typical ultimate tensile strength of 572 MPa (83,000 psi) and a tensile yield strength of 503 MPa (73,000 psi). Other alloys in the series, like 7085, have minimum yield strengths in the range of 503-510 MPa.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —