Stamping Catalytic Converter Shells: Manufacturing & Anti-Theft Guide

TL;DR

Stamping catalytic converter shells primarily refers to the industrial metal forming process where stainless steel sheets are pressed into the protective housing halves, known as "clam-shells," that encase the ceramic substrate. This manufacturing stage involves hydraulic presses, blanking dies, and automated seam welding to create a hermetic seal. Secondarily, the term describes the post-production practice of engraving identification numbers—such as VINs or CARB Executive Order codes—onto the finished shell for regulatory compliance and theft deterrence.

The Manufacturing Process: From Coil to Shell

The fabrication of a catalytic converter shell is a precision engineering workflow that transforms raw stainless steel coil into a finished automotive component capable of withstanding extreme thermal cycling. The process begins with coil processing and blanking. Stainless steel coils are fed into automated blanking systems that cut the metal into precise flat sheets, or "blanks," optimized to minimize scrap waste. These blanks serve as the foundational material for the subsequent forming stages.

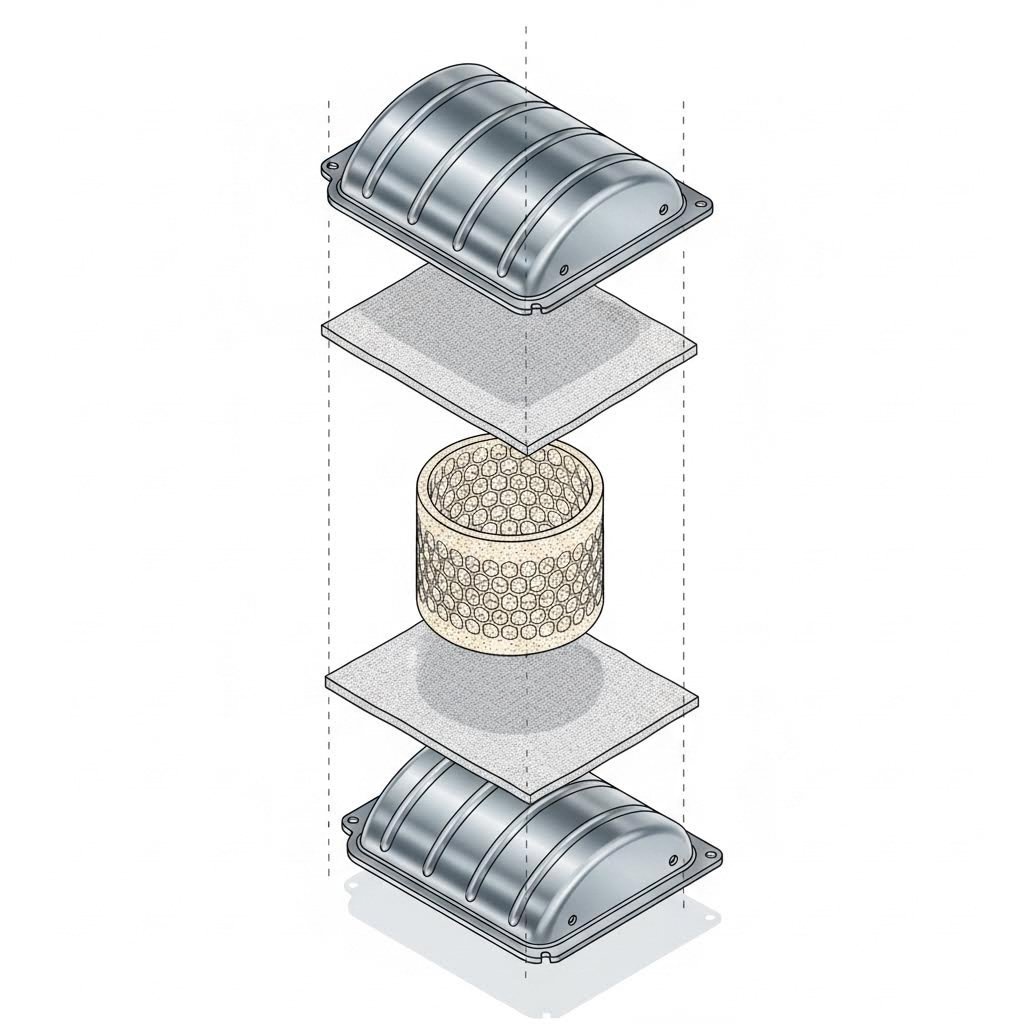

In the deep draw stamping phase, the metal blanks are fed into high-tonnage hydraulic or mechanical presses. Using custom tool-and-die sets, the press forces the flat sheet into a cavity to form the "clam-shell" shape—typically one half of the full converter body. This method allows for complex geometries that can fit into tight vehicle undercarriages, a significant advantage over cylindrical "spun" converter designs. The stamping process must maintain strict wall thickness tolerances to ensure the shell can protect the fragile ceramic substrate inside without adding unnecessary weight.

For automotive OEMs and Tier 1 suppliers, scalability and precision are non-negotiable. Manufacturers often require partners who can handle the entire lifecycle from rapid prototyping to mass production. Companies like Shaoyi Metal Technology specialize in these comprehensive stamping solutions, utilizing press capabilities up to 600 tons and IATF 16949-certified quality systems to deliver critical components like converter shells with micron-level accuracy.

The final stage is seam welding. Once the substrate and insulation mats are inserted between two stamped shell halves, robotic welding cells seal the edges. Racing Industries notes that seam welding (welding the top and bottom shells together) creates an air-tight, cost-effective bond that is superior to older manual methods. This hermetic seal is critical for preventing exhaust leaks and ensuring the converter operates at the correct internal pressure.

Materials & Engineering Specifications

Selecting the correct grade of stainless steel for stamped shells is a balance of cost, durability, and thermal management. The industry standard is 409 Stainless Steel (SS409). This ferritic grade offers sufficient corrosion resistance against road salts and moisture while maintaining good weldability and thermal fatigue resistance. It is the material of choice for most aftermarket and standard OEM converter bodies because it expands and contracts at rates compatible with the internal ceramic substrates, reducing the risk of crushing the core during heat cycles.

For high-performance or heavy-duty applications, manufacturers may upgrade to 304 Stainless Steel (SS304). This austenitic grade contains higher nickel content, providing superior resistance to rust and high-temperature oxidation. E&E Manufacturing highlights the importance of using these specialized materials to stamp components that can survive the harsh environment of an exhaust system, where temperatures frequently exceed 800°C (1472°F).

Engineers must also account for "wash coat" interactions and heat dissipation. The stamped shell acts as a heat shield; if the material is too thin, it may warp or burn through. If it is too thick, it adds parasitic weight to the vehicle. The ideal stamped shell balances these factors, providing a rigid, durable exoskeleton for the catalyst.

Compliance & Anti-Theft Marking

Beyond the forming process, "stamping" is the standard method for applying permanent identification to the converter shell. This serves two distinct purposes: regulatory compliance and theft prevention. In regulated markets like California, the California Air Resources Board (CARB) mandates that all aftermarket converters have specific data stamped or embossed on the shell. This includes the "EO Number" (Executive Order), the part number, and the date of manufacture. These markings verify that the part meets emissions standards and allows inspectors to distinguish legal parts from non-compliant alternatives.

For anti-theft purposes, Dot Peen marking has emerged as the superior technology. Unlike surface-level acid etching or stickers, Dot Peen machines use a carbide stylus to physically indent the metal with a series of deep dots. Rocklin Manufacturing explains that this method creates a permanent, tamper-resistant mark—often the Vehicle Identification Number (VIN)—that remains legible even after years of exposure to road debris and rust. This traceability makes stolen converters harder to sell to scrap yards, which are increasingly required to log the ID numbers of purchased units.

Quality Control & Identification

Validating the quality of a stamped shell involves rigorous testing before it ever reaches a vehicle. Leak testing is the primary QC measure, where the welded shell is pressurized to ensure the seam welds are free of pinholes. Any breach in the shell would allow untreated exhaust gas to escape, failing emissions tests. Dimensional accuracy is also verified using coordinate measuring machines (CMM) to ensure the stamped mounting points align perfectly with the vehicle's exhaust manifold.

For recyclers and buyers, reading the stamped numbers is the key to valuation. BR Metals advises that the serial numbers stamped on the shell are the most reliable way to identify the precious metal content inside. OEM converters typically feature the car manufacturer's logo (e.g., Ford, Toyota) and a specific alphanumeric code, whereas aftermarket units often start with an "N" series number. Recognizing these stamped codes distinguishes high-value OEM scrap from lower-value aftermarket replacements.

Securing and identifying Your Converter

Whether you are an engineer sourcing stamped shells for production or a vehicle owner concerned about theft, understanding the dual nature of "stamping" is essential. For manufacturers, the focus remains on precision forming and material selection to ensure durability. For end-users, the priority is verifying that the shell carries the necessary compliance stamps and adding anti-theft markings to protect the investment. As regulations tighten and theft remains a risk, the markings on the shell have become just as valuable as the metal itself.

Frequently Asked Questions

1. Can I stamp my own catalytic converter for theft prevention?

Yes, vehicle owners can mark their own converters, but using the correct tool is vital. Handheld engravers or chemical etching kits are available, but they may not be deep enough to last. Professional Dot Peen marking is recommended because it indents the metal deeply, making it difficult for thieves to grind off without damaging the converter shell itself.

2. What information should be stamped on a replacement converter?

A legal aftermarket catalytic converter must be stamped with the manufacturer's code, the part number, and the date of manufacture. In California, it must also display the CARB Executive Order (EO) number (e.g., D-123-45) to pass a smog check. If these stamps are missing or illegible, the vehicle may fail inspection.

3. Does stamping a VIN number actually stop theft?

Stamping a VIN does not physically prevent removal, but it acts as a strong deterrent. Reputable scrap dealers are trained to reject converters with visible VIN markings that do not match the seller's identification. It also creates a chain of evidence that aids law enforcement in tracing stolen parts back to criminal operations.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —