Automotive Stamping Cost Reduction Strategies: Maximizing ROI

TL;DR

Effective automotive stamping cost reduction strategies rely on a three-pillared approach: rigorous Design for Manufacturability (DFM), strategic material utilization, and volume-appropriate process selection. By engaging engineers early to simplify part geometry and relax non-critical tolerances, manufacturers can significantly lower tooling costs and scrap rates. Furthermore, choosing between progressive, transfer, or hybrid stamping based on precise production volumes ensures that capital investment aligns with long-term ROI, minimizing the total cost of ownership (TCO) for stamped assemblies.

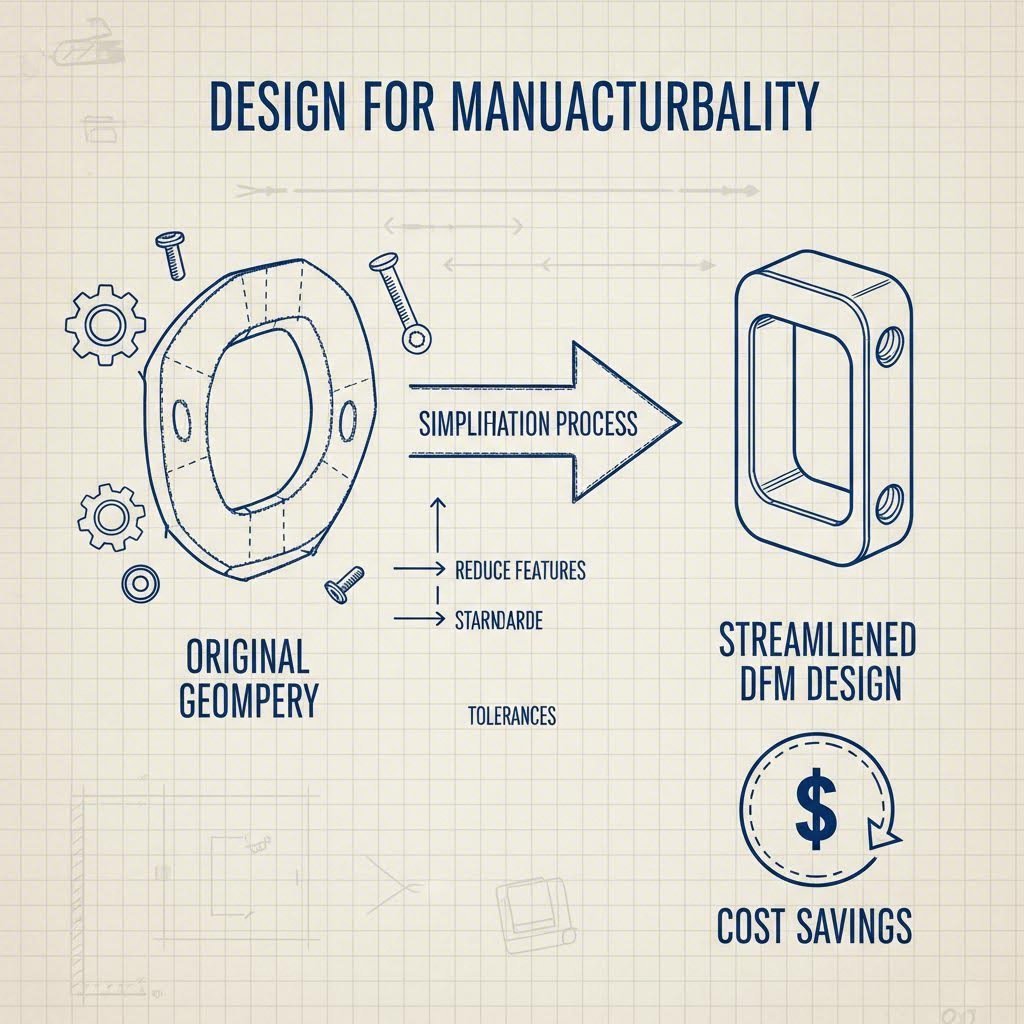

Design for Manufacturability (DFM): The First Line of Defense

The most substantial cost savings in automotive stamping occur long before the first sheet of metal touches a press. Design for Manufacturability (DFM) is the engineering discipline of optimizing a part's design to simplify its production, serving as the primary lever for controlling costs. In the context of stamping, this means analyzing geometry to reduce tooling complexity and material waste without compromising part performance.

A critical DFM tactic involves incorporating symmetry into part design. As noted by industry experts, symmetrical parts often allow for balanced forces within the die, which reduces wear and extends tooling life. Additionally, standardizing hole sizes and bend radii across a vehicle assembly allows manufacturers to use standard, off-the-shelf tooling components rather than custom punches, drastically reducing initial setup costs. Engineers should also scrutinize tolerances; requesting tight tolerances (e.g., ±0.001”) on non-mating surfaces unnecessarily drives up costs by requiring precision grinding or secondary operations.

To implement this effectively, automotive OEMs must conduct DFM reviews prior to finalizing CAD models. This review process involves simulating the forming process to predict failure points such as tearing or wrinkling. By identifying these issues digitally, engineers can adjust radii or wall angles to suit the material’s formability, avoiding expensive physical die modifications during the trial phase.

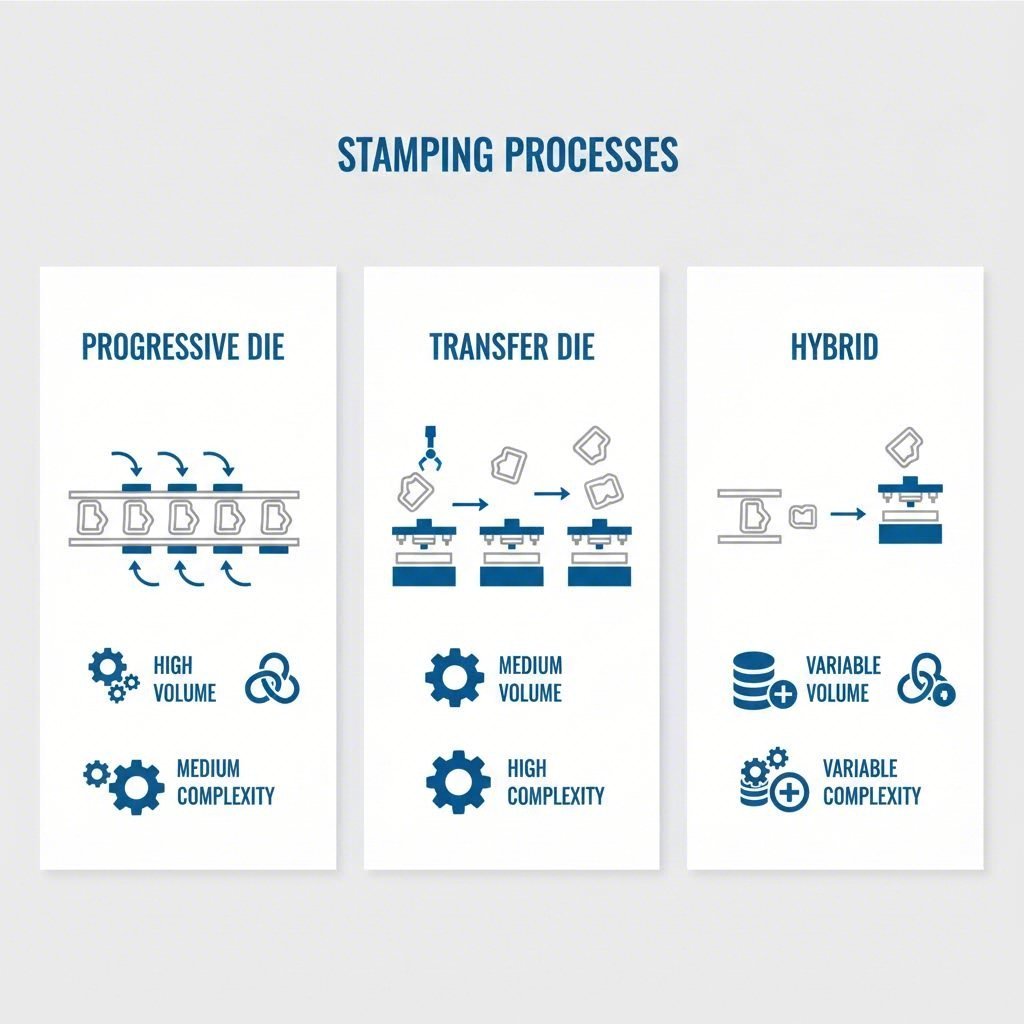

Process Selection Strategy: Matching Technique to Volume

Selecting the correct stamping methodology—Progressive, Transfer, or Hybrid—is a purely economic decision driven by production volume and part complexity. Using a high-speed progressive die for a low-volume run results in unrecoverable tooling amortization costs, whereas using a manual transfer process for high volumes kills margins through excessive labor.

Progressive Die Stamping is the gold standard for high-volume, small-to-medium parts. It feeds a metal strip through multiple stations automatically, producing a finished part with every stroke. While the upfront tooling cost is high, the piece price is minimized due to speed. Conversely, Transfer Die Stamping is necessary for large automotive components like subframes or door panels that require movement between separate die stations. While slower, it accommodates complex geometries that progressive dies cannot handle.

For manufacturers navigating the transition from development to mass production, selecting a partner with versatile capabilities is essential. Suppliers capable of scaling operations, such as Shaoyi Metal Technology, leverage press capabilities up to 600 tons to manage the critical shift from rapid prototyping (50 parts) to high-volume manufacturing (millions of parts), ensuring that the process evolves efficiently as demand scales.

| Method | Ideal Volume | Tooling Cost | Piece Price | Best For |

|---|---|---|---|---|

| Progressive Die | High (250k+/year) | High | Low | Brackets, clips, connectors |

| Transfer Die | Medium-High | Medium | Medium | Large body panels, frames |

| Hybrid / Stage Tooling | Low-Medium | Low | High | Prototyping, niche vehicles |

Material Utilization & Scrap Reduction

Raw material often constitutes the single largest variable cost in automotive stamping, frequently exceeding 50-60% of the total part cost. Therefore, strategies focused on scrap reduction and material optimization yield immediate financial returns. The primary method for achieving this is "nesting optimization," where part layout on the strip is engineered to minimize the web width (the unused metal between parts).

Advanced nesting software can rotate and interlock parts to maximize the number of units per coil. For example, trapezoidal or L-shaped parts can often be nested back-to-back to share a common cut line, effectively reducing scrap by double-digit percentages. Furthermore, engineers should evaluate the potential of using "offal"—the scrap metal generated from stamping large windows in door panels or sunroofs—to stamp smaller brackets or washers. This practice essentially provides free material for secondary parts.

Another avenue is material substitution. By collaborating with metallurgists, engineers can switch to thinner, High-Strength Low-Alloy (HSLA) steels that maintain structural integrity while reducing weight. Although HSLA materials may have a higher cost per pound, the reduction in total tonnage required often results in a net savings, aligning with lightweighting goals for fuel efficiency.

Tooling Strategy & Lifecycle Management

Viewing tooling solely as an upfront expense is a strategic error; it must be viewed through the lens of Total Cost of Ownership (TCO). Investing in premium tool steels and specialized coatings (like Titanium Carbonitride) for high-wear areas can significantly reduce downtime for maintenance. Lifecycle management strategies suggest that spending 15-20% more on a durable die build can save 50% in long-term maintenance and quality rejection costs.

Modular tooling designs offer another layer of efficiency. By designing dies with interchangeable inserts for variable features (such as different hole patterns for different car models), manufacturers can use a single master die base for multiple SKUs. This drastically cuts storage requirements and tooling investment. Furthermore, implementing a preventative maintenance schedule—based on stroke count rather than failure—ensures that cutting edges remain sharp, reducing the energy required for the press and preventing burrs that lead to scrap.

Advanced Efficiency: Automation & Secondary Operations

To further compress costs, modern stamping lines are increasingly integrating secondary operations directly into the primary die. Technologies like in-die tapping, hardware insertion, and even in-die sensing allow for the completion of finished assemblies without the need for manual post-processing. This elimination of secondary touches reduces labor costs and work-in-progress (WIP) inventory.

In-die protection sensors are particularly valuable for preventing catastrophic tool damage. By detecting misfeeds or slug pulling in real-time, these sensors stop the press before a crash occurs, saving tens of thousands of dollars in repairs and weeks of production downtime. As highlighted in research by MIT, streamlining these production flows is essential for OEMs to remain competitive against global cost pressures.

Conclusion: maximizing Engineering ROI

Achieving sustainable cost reduction in automotive stamping is not about cutting corners, but about engineering precision. By prioritizing Design for Manufacturability, optimizing material usage through advanced nesting, and selecting the appropriate process for the volume, manufacturers can protect their margins. The integration of high-quality tooling and automation further secures long-term efficiency, transforming the stamping press from a cost center into a competitive asset.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —