Stamped Steel Control Arm Noise: A Complete Diagnostic Guide

TL;DR

A stamped steel control arm making noise is a clear warning of a serious issue. You'll typically hear clunking, clicking, or knocking sounds, especially over bumps or during turns. These noises are almost always caused by worn-out bushings or failed ball joints. Ignoring them can lead to dangerous steering instability, rapid tire wear, and potentially a complete suspension failure, so a prompt diagnosis is critical for your safety.

Decoding Control Arm Noises: From Clicks to Clunks

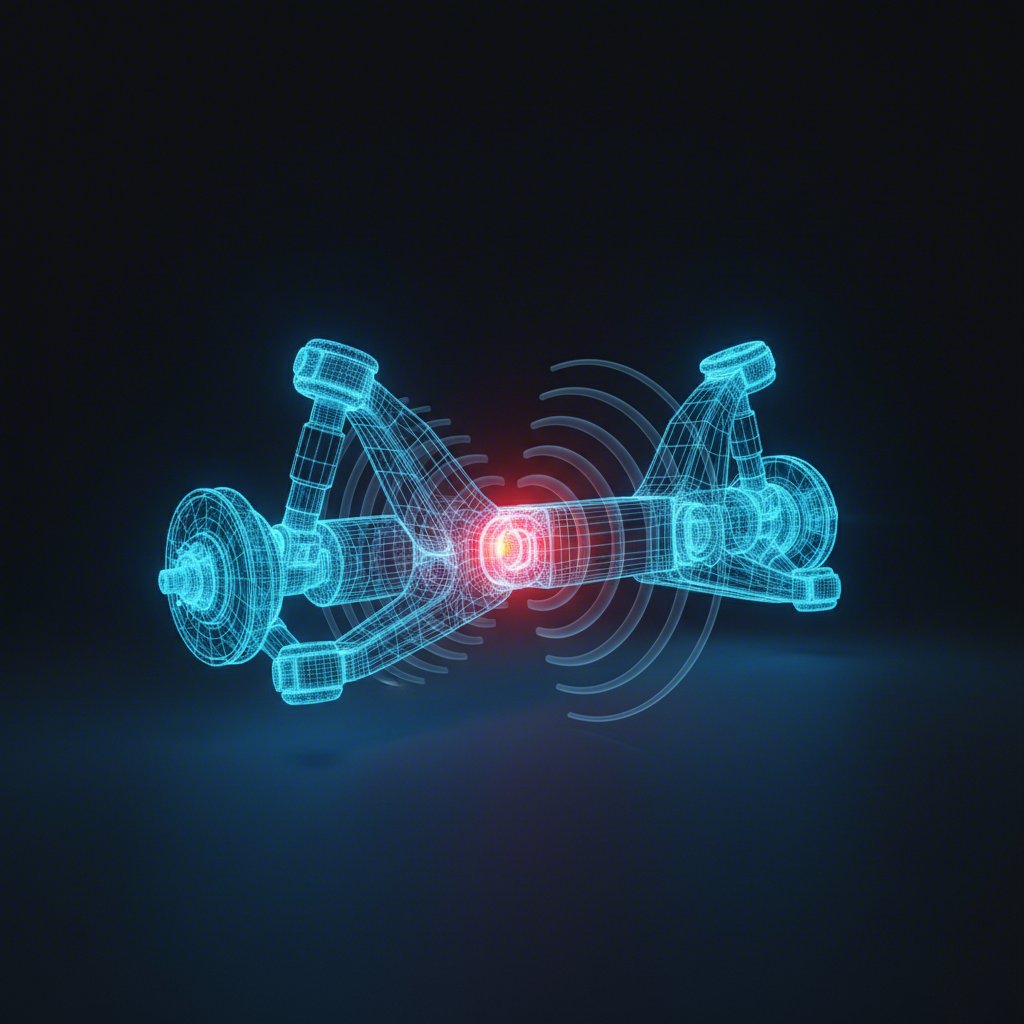

Before diagnosing the sounds, it's essential to understand what a control arm does. This crucial suspension component is a hinged link that connects your vehicle's frame to the steering knuckle, which holds the wheel. It allows the wheel to move up and down over bumps while keeping it stable and aligned. In stamped steel control arms, the most common points of failure are the rubber bushings that connect to the frame and the ball joint that connects to the wheel assembly.

When these parts wear out, they produce distinct sounds that can help you pinpoint the problem. A worn or damaged bushing often leads to a dull clunking or knocking noise. As the rubber deteriorates, the metal of the control arm can make direct contact with the subframe, especially when braking, accelerating, or hitting a bump. A failing ball joint, on the other hand, typically produces a sharper clicking or popping sound. This happens when wear creates excessive play, allowing the metal ball stud to shift suddenly within its socket during low-speed turns or as the suspension unloads after a bump.

Other noises can also indicate a problem. Some drivers report a crunching sound, particularly when turning at low speeds or braking, which points to a severely worn bushing. Listening carefully to not just the type of sound but also when it occurs is key to an accurate diagnosis. For example, a rhythmic clicking that gets faster as you accelerate in a turn is more likely a CV joint, whereas a single, sharp click when initiating a turn points toward a ball joint.

| Noise Type | Likely Cause | When It Occurs | Urgency Level |

|---|---|---|---|

| Clunking or Knocking | Worn Bushings | Over bumps, braking, or accelerating | High |

| Clicking or Popping | Worn Ball Joint | Low-speed turns, going over small bumps | High |

| Crunching | Severely Torn Bushing | Braking or turning at low speeds | Immediate |

| Rattling | Worn Stabilizer Bar Link (related component) | Over rough pavement at low speeds | Medium |

A Step-by-Step Guide to Diagnosing a Bad Control Arm

Once you've identified the suspicious noises, a physical inspection can confirm the diagnosis. This process involves both visual checks and physical tests to identify excessive movement in the control arm assembly. Before you begin, always prioritize safety. Never work under a vehicle supported only by a jack; use certified jack stands on a level, solid surface and chock the wheels that remain on the ground.

Here is a safe, step-by-step process to inspect your control arms:

- Visual Inspection: With the vehicle safely raised, use a good light source to get a clear view of the control arms. Look closely at the rubber bushings where the arm connects to the frame. Healthy bushings should be solid and centered. Look for cracks, tearing, or signs that the rubber has separated from its metal sleeve. Next, inspect the ball joint's protective rubber boot at the other end of the arm. A torn or ripped boot that is leaking grease is a clear sign of impending failure, as it allows contaminants to destroy the joint from the inside.

- The Wheel Shake Test: This is a classic test for ball joint wear. Firmly grasp the front tire at the top and bottom (12 and 6 o'clock positions). Try to rock the wheel in and out. There should be no movement or play. If you feel a clunk or see movement, it's a strong indicator of a worn ball joint. Any looseness here is a serious safety concern as this joint is a critical pivot point for your steering.

- The Pry Bar Test: To check the bushings, you'll need a long pry bar. Carefully place the bar between the vehicle's subframe and the control arm, near a bushing. Gently apply leverage to see if you can move the arm forward or backward in its mount. The rubber should flex slightly, but the entire arm should not shift. If you can easily move the arm or hear a clunk while prying, the bushing has failed.

- The Diagnostic Test Drive: If you're still unsure, a focused test drive can provide final clues. In a safe area like an empty parking lot, perform slow, tight turns in both directions. Drive over a speed bump at a low speed. Apply the brakes firmly from about 15 mph. Pay close attention to exactly when the noise occurs during these maneuvers to confirm your suspicions from the physical inspection.

Beyond the Noise: Other Telltale Symptoms of Control Arm Failure

While noise is often the first and most obvious symptom, a failing control arm will manifest in other ways that affect your vehicle's handling and safety. Recognizing these additional signs can help you build a complete diagnostic picture and confirm that the control arm is indeed the culprit. These symptoms often become more pronounced as the bushings or ball joint wear worsens.

Steering Wheel Vibration or Wander

A primary symptom of a bad control arm is a change in steering feel. You might notice excessive vibration through the steering wheel, especially at higher speeds. More concerning is a phenomenon known as steering wander, where the vehicle feels loose and drifts from side to side, requiring constant small corrections to keep it driving in a straight line. This happens because the worn components can no longer hold the wheel in its proper alignment, allowing it to shift and change direction slightly on its own.

Uneven Tire Wear

Proper wheel alignment is critical for tire longevity, and control arms play a vital role in maintaining it. When a control arm fails, it can no longer hold the wheel at the correct angle relative to the road. This causes the tire to lean in or out, leading to rapid and uneven tire wear. Typically, you will see the inside or outside edge of the tire's tread wearing down much faster than the center. If you notice this wear pattern, it's a strong visual confirmation that a key suspension component has failed.

Poor Steering Response

A healthy suspension provides a crisp and predictable steering response. When a control arm is bad, the vehicle can feel sloppy and unresponsive. The looseness in the worn parts creates a delay between your input at the steering wheel and the vehicle's reaction. In an emergency maneuver, this lack of precision can be dangerous, compromising your ability to control the vehicle effectively. If your car feels less stable or bouncy, especially when cornering or on uneven roads, a failing control arm is a likely cause.

Risks, Costs, and Solutions: What to Do Next

Diagnosing a bad control arm is the first step; taking prompt action is the next. Continuing to drive with a faulty control arm is not just risky, it's dangerous. A severely worn ball joint can separate completely, causing the wheel to detach from the suspension and leading to a total loss of steering control. Therefore, the answer to "how long can you drive on it?" is simple: you shouldn't. The vehicle should be repaired as soon as possible.

The cost of replacement can vary significantly based on your vehicle's make and model and local labor rates. Generally, you can expect the part itself to cost between $50 and $400. Professional labor will add another $100 to $400 per arm. A wheel alignment is a mandatory final step after replacement, which typically adds another $80 to $150 to the total bill. While some experienced DIYers can tackle this job, it is a safety-critical repair that requires proper tools and knowledge.

Stamped steel control arms are common due to their strength and cost-effectiveness in mass production. For automotive manufacturers seeking precision and reliability in such components, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. deliver comprehensive solutions from prototyping to large-scale production, ensuring high-quality parts that meet stringent industry standards. When replacing parts, it is almost always recommended to replace the entire control arm assembly, which comes with new bushings and a ball joint pre-installed. This is far more efficient and reliable than trying to press out individual worn components.

Your clear next steps should be:

- Stop driving the vehicle if the symptoms are severe.

- Get a quote from a qualified mechanic for the repair.

- Do not delay the replacement to ensure your safety and prevent further damage to other suspension parts and your tires.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —