Stamped Steel Control Arms: Your OEM vs Aftermarket ID Guide

TL;DR

Identifying your vehicle's control arms is simpler than you think. Stamped steel arms are characterized by their smooth, often glossy black surface and a visible welded seam where two pieces of metal are joined. When comparing OEM vs. aftermarket stamped steel control arms, look for key differences: OEM parts are designed to meet factory specifications at a low cost and are often unmarked. Aftermarket parts, however, frequently feature manufacturer logos, part numbers, or design improvements like grease fittings and more durable bushings, as they are engineered to enhance longevity and performance.

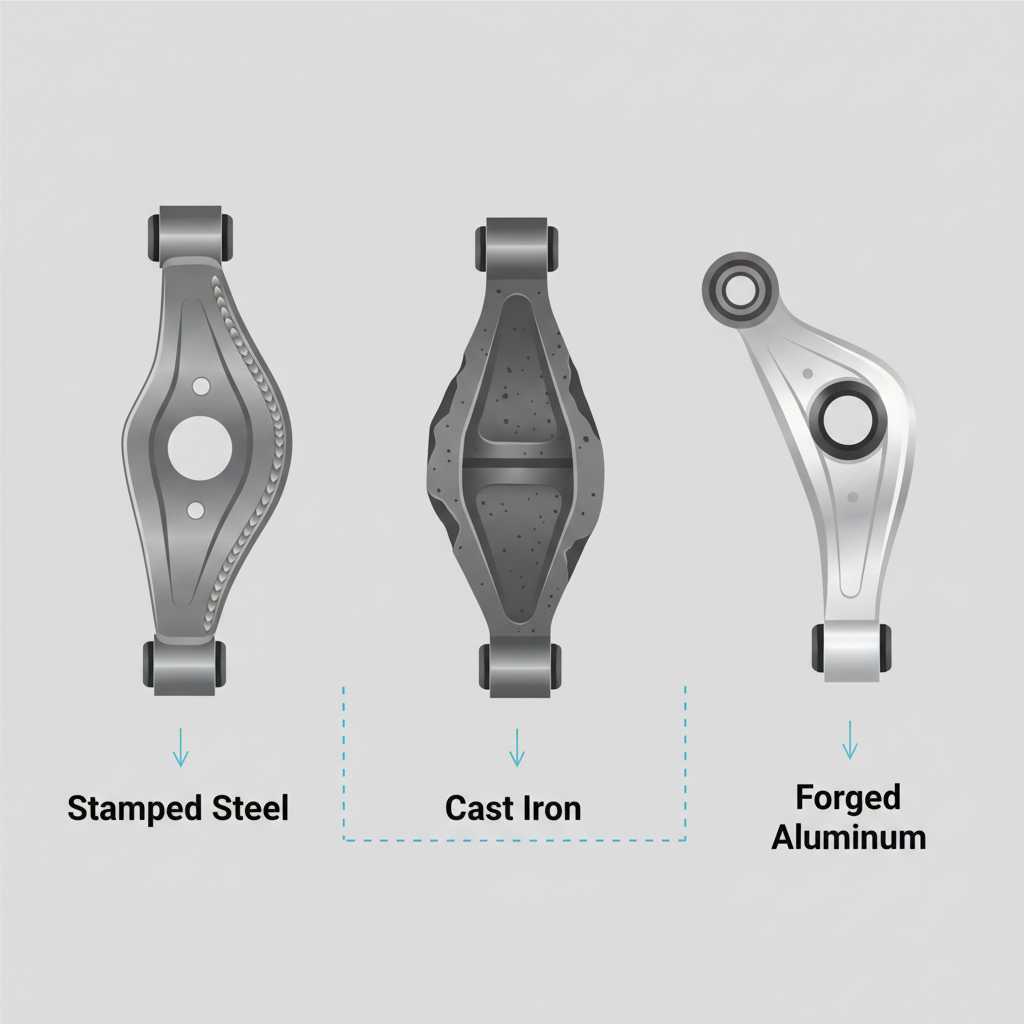

A Visual Guide: Stamped Steel vs. Cast and Forged Arms

Before you can distinguish between an OEM and an aftermarket part, you first need to identify the type of control arm your vehicle uses. The manufacturing process gives each type distinct visual characteristics. Understanding these differences is the first step in making an informed decision about your suspension.

The three most common types of control arms are stamped steel, cast steel (or iron), and forged aluminum. Stamped steel arms are made by pressing sheets of steel into a desired shape and then welding them together. Cast arms are created by pouring molten metal into a mold. Forged arms are shaped from a solid piece of metal under extreme pressure. These different methods result in unique textures, finishes, and markings that are easy to spot with a quick inspection.

Here are the key identifiers for each type:

- Stamped Steel: These are typically finished with glossy black paint. Their most telling feature is a smooth surface and a clear welded seam running along the edges where the stamped pieces were joined.

- Cast Steel/Iron: Look for a rough, textured finish, similar to cast iron cookware. They often have a distinct ridge or line where the two halves of the mold came together.

- Aluminum (Cast or Forged): These usually have a raw silver or light gray appearance. A simple magnet test is the most definitive way to identify them; a magnet will not stick to aluminum but will stick firmly to both stamped and cast steel arms.

To make identification easier, here is a simple comparison:

| Characteristic | Stamped Steel | Cast Steel/Iron | Aluminum |

|---|---|---|---|

| Finish | Smooth, glossy black paint | Rough, textured black or gray | Textured silver/gray |

| Key Feature | Visible welded seam | Casting ridge/line | Lightweight feel |

| Magnet Test | Sticks | Sticks | Does not stick |

To check your own vehicle, follow these simple steps:

- Safely access your vehicle's front suspension. You may need to turn the wheel to get a clear view of the upper and lower control arms.

- Clean a small area of the control arm to reveal its true surface and finish.

- Look for a welded seam (stamped steel) or a casting ridge (cast steel).

- Use a magnet to confirm if the material is steel or aluminum.

The Great Debate: OEM vs. Aftermarket Control Arms

Once you've identified your control arm type, the next question is whether to stick with Original Equipment Manufacturer (OEM) parts or choose an aftermarket solution. This decision comes down to a fundamental difference in design philosophy. As explained in an article by automotive parts manufacturer Mevotech, the OEM is primarily concerned with initial quality, weight, and production cost, ensuring the part meets the vehicle's original specifications. In contrast, the aftermarket's goal is often to engineer a more robust solution that increases the longevity of the repair and addresses known failure points in the original design.

Factory control arms are typically made from stamped steel and fitted with soft rubber bushings designed to minimize noise and vibration for a comfortable ride. However, these components can lead to deflection under load, hindering performance. Aftermarket manufacturers often address these shortcomings by using higher-grade materials, stronger welds, and more durable bushings, such as polyurethane, which offer a significant improvement in handling and traction. This focus on durability is why many enthusiasts and repair professionals lean toward aftermarket options for older vehicles or those used in demanding conditions.

The precision required in creating these components, whether for OEM or aftermarket, is significant. For automotive manufacturers seeking reliable metal stamping, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. specialize in providing comprehensive solutions from prototyping to mass production, ensuring parts meet stringent quality standards like IATF 16949.

To help you decide, here’s a breakdown of the pros and cons:

| Factor | OEM Control Arms | Aftermarket Control Arms |

|---|---|---|

| Cost | Often higher for the part itself, but can be a direct replacement. | Generally more affordable with a wide range of price points. |

| Durability | Designed to meet original service life; may have known weak points. | Often engineered to be stronger than original, with improved materials and serviceable joints. |

| Performance | Prioritizes ride comfort and quietness over handling. | Can significantly improve handling, steering response, and traction. May increase road noise. |

| Fitment | Guaranteed to be an exact match for the original part. | High-quality brands offer direct-fit replacements, but some may require modifications. |

| Warranty | Typically comes with a limited warranty from the vehicle manufacturer. | Varies by brand, with many premium options offering lifetime warranties. |

Choosing OEM is a safe bet if you want to maintain the vehicle's original feel, especially if it's new or under warranty. However, for a vehicle that has seen some miles or for owners looking to enhance performance and durability, a high-quality aftermarket control arm is often the superior choice.

Spotting the Difference: Is That an Aftermarket Part?

If you're looking at a vehicle and trying to determine if the control arms are original or have been replaced, there are several clear indicators. While some aftermarket parts are designed to be exact visual copies of OEM components, many performance-oriented brands add features that make them easy to identify.

The most reliable identifiers are branding, part numbers, and unique design features not found on the stock component. OEM parts are often left unmarked or may have a subtle stamp from the vehicle manufacturer. Aftermarket companies, on the other hand, are proud of their products and usually display their brand name or logo prominently.

Here are the key things to look for when inspecting a control arm:

- Brand Names or Logos: Look for names like Mevotech, Moog, ReadyLIFT, or other well-known aftermarket brands stamped, cast, or stickered onto the arm.

- Part Numbers: Aftermarket parts will have a specific part number on them. A quick search for this number online will usually reveal the manufacturer and product details.

- Unique Features: Many aftermarket arms include enhancements. The presence of a grease fitting (Zerk fitting) for serviceable ball joints is a common aftermarket upgrade. Brightly colored polyurethane bushings (often red or black) are another giveaway, as OEM bushings are almost always plain black rubber.

- Construction and Finish: While OEM stamped steel arms have a simple black finish, some aftermarket arms might be powder-coated in different colors or have a more robust, tubular construction instead of a stamped design. As detailed by FordMuscle, these design changes are made to increase strength and performance.

If you're still unsure, follow this simple diagnostic process:

- Thoroughly clean the control arm to make any markings visible. Dirt and grease can easily hide logos and part numbers.

- Use a good light source and take clear photos of any stamps, markings, or numbers you find.

- Search the numbers online to identify the manufacturer.

- Compare the physical features of the arm—such as the bushings, ball joint design, and welds—to pictures of known OEM parts for your specific vehicle model. The differences will often become obvious.

Frequently Asked Questions

1. How do I know if my control arms are stamped steel?

Stamped steel control arms have a distinct look. They are typically painted with a smooth, glossy black finish. The most definitive feature is a welded seam that runs along the front and back where two pieces of pressed steel were joined together. You can also use a magnet; if it sticks, the part is made of steel (either stamped or cast).

2. How can you tell if an aftermarket is an OEM?

The easiest way to tell the difference is by looking for branding. OEM parts are made by or for your vehicle's manufacturer and will often have the car company's logo or no branding at all. Aftermarket parts are made by third-party companies and will typically feature their own brand name, logo, or a unique part number stamped or stickered onto the component.

3. How do I tell what kind of control arms I have?

You can identify the type of control arm by its appearance. Stamped steel arms are smooth and have welded seams. Cast steel arms have a rough, textured finish and often a visible line from the casting mold. Aluminum arms are silver or gray in color and a magnet will not stick to them. A quick visual inspection and a magnet test are usually all you need.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —