Stamped Steel Control Arm Lifespan: The Real Factors

TL;DR

A stamped steel control arm lifespan typically falls between 60,000 and 100,000 miles. However, this is not a guarantee. The actual service life is heavily influenced by driving conditions and environmental factors, with exposure to road salt and moisture being the primary cause of premature failure due to rust and corrosion.

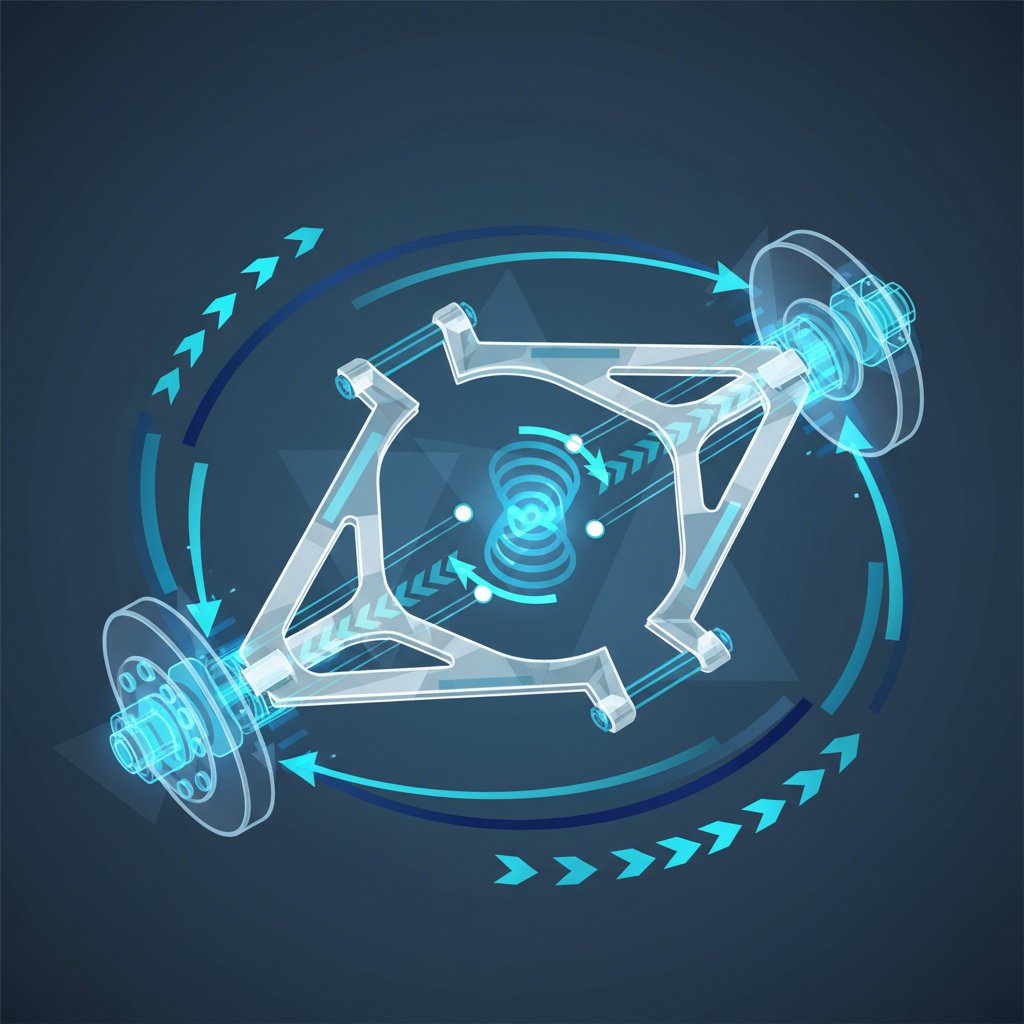

What Is the Typical Lifespan of Stamped Steel Control Arms?

When trying to determine the lifespan of stamped steel control arms, you'll find a wide range of estimates. This is because, more than many other car parts, their durability is directly tied to their environment and how the vehicle is used. While manufacturers design these components for longevity, their inherent material properties present specific challenges that can shorten their service life considerably.

Based on industry data and expert observations, the expected lifespan varies significantly:

- General Guideline: Most sources suggest a range of 60,000 to 100,000 miles under normal driving conditions. This is a common window for original equipment manufacturer (OEM) parts on many passenger vehicles, including popular trucks like the Chevy Silverado where this question often arises.

- Harsh Conditions Estimate: In areas with severe weather or poor road quality, the lower end of 60,000 to 80,000 miles is a more realistic expectation.

- Ideal Conditions: In dry climates with well-maintained roads, it's not unheard of for control arms to last 150,000 miles or more, though this is the exception rather than the rule.

The primary reason for this wide variance is the nature of stamped steel itself. It is created by pressing a sheet of steel into the desired shape. While this is a cost-effective manufacturing method, the resulting part is highly susceptible to rust and corrosion, especially in regions that use road salt during winter. Unlike solid forged or cast parts, stamped arms can have seams and crevices where moisture and salt can collect, accelerating deterioration from the inside out.

Ultimately, mileage should be treated as a guideline, not a strict replacement interval. Regular visual inspection during routine maintenance, such as oil changes or tire rotations, is the most reliable way to assess the health of your control arms. A technician can spot early signs of rust, worn bushings, or failing ball joints long before they become a critical safety issue.

Key Factors That Reduce Control Arm Lifespan

While mileage provides a rough estimate, several specific factors actively work to shorten the life of stamped steel control arms. Understanding these elements can help you anticipate potential issues and take preventative measures. The most significant threats are environmental exposure, road conditions, and the failure of integrated components like bushings and ball joints.

Environmental Corrosion: This is the number one enemy of stamped steel. Exposure to moisture, and particularly road salt, initiates an aggressive corrosion process. The salt creates an electrochemical reaction that rapidly eats away at the steel, weakening its structural integrity. A control arm that appears solid on the surface could be severely compromised by internal rust. This is why vehicles in the "Salt Belt" often require suspension component replacement far sooner than those in drier, warmer climates.

Harsh Driving Conditions: Your driving habits and environment play a huge role. Frequent driving on poorly maintained, unpaved, or pothole-ridden roads places immense stress on the entire suspension system. Every hard impact sends a shockwave through the control arm, stressing the metal and, more critically, the bushings and ball joints that allow it to pivot. Over time, these repeated impacts can cause the metal to fatigue or lead to the premature failure of its connecting parts.

Component Failure: Often, the steel arm itself doesn't break, but its integrated components wear out. Rubber bushings, which absorb vibration and allow movement, can dry rot, crack, or become compressed, leading to a loose or noisy suspension. The ball joint, which is the critical pivot point connecting the arm to the steering knuckle, is another common failure point. On some stamped steel arms, particularly on certain truck models, the design for retaining the ball joint can be a weak point, potentially leading to a catastrophic failure where the ball joint separates from the arm.

The manufacturing process is key to durability. While stamping is cost-effective, it requires high precision to ensure strength. For automotive manufacturers, sourcing high-quality components is critical. Companies specializing in automotive metal stamping, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., utilize advanced, IATF 16949 certified processes to produce reliable parts that meet stringent industry standards, from prototyping to mass production.

To maximize the life of your control arms, consider these preventative tips:

- Regularly wash your vehicle's undercarriage, especially during winter months, to remove salt and grime.

- Drive cautiously and try to avoid hitting potholes and large bumps on the road.

- Have your suspension inspected annually by a qualified technician to catch any signs of wear or corrosion early.

Stamped Steel vs. Alternative Materials

When it's time to replace a control arm, you may find you have options beyond the standard stamped steel part. Understanding the differences between materials can help you make an informed decision based on your vehicle, driving style, and climate. Each material offers a unique balance of cost, strength, weight, and durability.

Stamped steel is the most common OEM choice primarily because it is inexpensive to produce. However, its susceptibility to rust and lower rigidity lead many owners to consider upgrades. Forged steel, cast aluminum, and tubular steel are the most common alternatives, each with distinct advantages and disadvantages that make them suitable for different applications.

Here is a comparison of the most common control arm materials:

| Material | Primary Advantage | Primary Disadvantage | Best For |

|---|---|---|---|

| Stamped Steel | Low manufacturing cost | Prone to rust and corrosion; less rigid | OEM replacement for daily drivers in dry climates |

| Forged Steel | Extremely strong and durable | Heavy and more expensive | Heavy-duty trucks and vehicles requiring maximum strength |

| Cast Aluminum | Lightweight and corrosion-resistant | Can crack on severe impact; higher cost | Performance/luxury cars and vehicles in wet/salty climates |

| Tubular Steel | High strength-to-weight ratio; customizable | Often the most expensive option | Custom, off-road, and high-performance applications |

Deciding whether to upgrade from stamped steel depends on your specific needs. If you live in an area with heavy road salt use, upgrading to cast aluminum can be a wise long-term investment due to its superior corrosion resistance. For those with heavy-duty trucks or who frequently tow, the added strength of a forged steel arm might provide extra peace of mind. For most daily drivers in moderate climates, a quality OEM-style stamped steel replacement is often sufficient and the most budget-friendly choice.

Frequently Asked Questions

1. What is the best material for control arms?

There is no single "best" material for all situations; the ideal choice depends on your vehicle, budget, and environment. Stamped steel is the best for cost-effective OEM replacement. Cast aluminum is excellent for corrosion resistance, making it ideal for vehicles in wet or snowy climates. Forged steel offers maximum strength and is best for heavy-duty applications. Tubular steel provides a high strength-to-weight ratio, favored in performance and custom builds.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —