Swap Aluminum Control Arms for Steel? Read This First

TL;DR

Yes, in many cases you can replace aluminum control arms with stamped steel ones, especially on newer trucks like the Chevrolet Silverado and GMC Sierra 1500. Both types often use the same larger-diameter ball joint and are designed to fit the same steering knuckle. However, this is not a universal rule. The critical step is to confirm your vehicle's specific configuration, as cast steel control arms use a different, smaller ball joint and are not interchangeable with aluminum or stamped steel parts.

Compatibility Check: Swapping Aluminum for Stamped Steel Control Arms

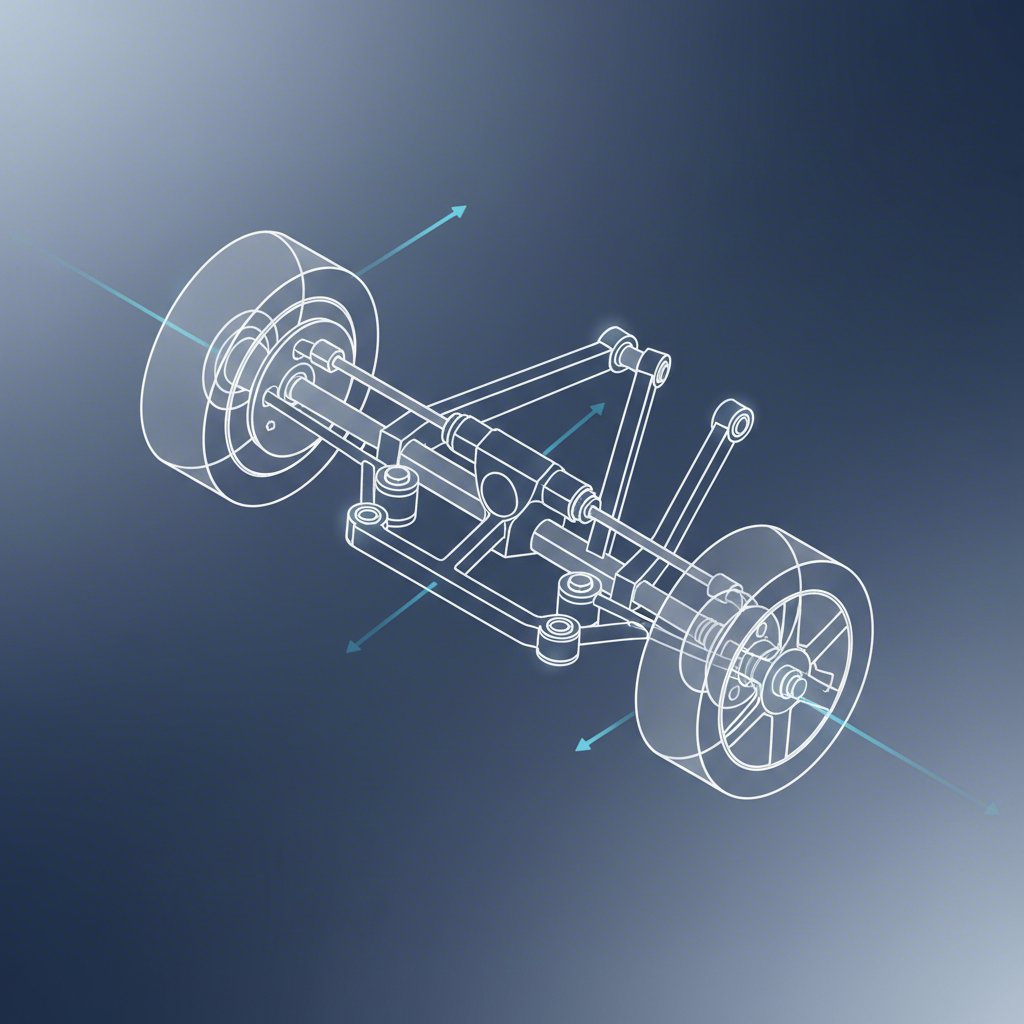

The idea of swapping control arm materials is a common consideration for truck owners during repairs or upgrades. For many modern trucks, particularly General Motors models from 2014 onwards, the vehicle frames are designed to accommodate different suspension components. This means that, physically, a stamped steel control arm will often bolt into the same mounting points as a factory-installed aluminum one. The success of the swap, however, depends less on the frame and more on the finer details of the suspension geometry.

The primary reason for this interchangeability is that manufacturers often standardize components to streamline production. As noted by suspension experts, many stamped steel and cast aluminum control arms were engineered to use the same size ball joint and mate with the same steering knuckle. This is particularly true for Chevy Silverado and GMC Sierra trucks built from mid-2016 to 2018. The main exception to this rule is the cast steel control arm, which was more common on earlier models (2014-early 2016) and typically uses a smaller, incompatible ball joint.

Before committing to a swap, it's essential to understand the trade-offs between the two materials. While they may be functionally interchangeable in some cases, their performance characteristics differ significantly. Your choice can impact your vehicle's handling, durability, and long-term maintenance needs. Below is a comparison to help you weigh the pros and cons of each material.

| Characteristic | Stamped Steel Control Arms | Aluminum Control Arms |

|---|---|---|

| Weight | Heavier, which can increase unsprung weight and slightly affect ride quality. | Lighter, reducing unsprung weight for potentially better handling and responsiveness. |

| Durability | Generally very strong and resistant to impacts and bending. Considered a robust choice for heavy-duty use. | High strength-to-weight ratio but can be more susceptible to cracking from sharp impacts compared to steel. |

| Corrosion Resistance | Prone to rust, especially if the protective coating is compromised. Requires more vigilance in wet or salty climates. | Naturally resistant to rust and corrosion, making it an excellent choice for regions with harsh weather. |

| Cost | Typically more affordable, both as an OEM part and in the aftermarket. | Generally more expensive due to higher material and manufacturing costs. |

The Critical Factor: Understanding Ball Joint and Knuckle Variations

The single most important element determining whether you can swap aluminum control arms for stamped steel is the compatibility of the ball joint and steering knuckle. While the arms themselves might look similar, manufacturers have used different combinations of these critical components across model years and even within the same year. Making a mistake here can lead to parts that simply won't fit, wasting time and money.

According to detailed technical guides from suspension specialists like Maxtrac Suspension, the key distinction lies between three main setups. For 2014+ GM 1500 trucks, both stamped steel and cast aluminum control arms were typically designed to use a larger diameter ball joint. These two types are often interchangeable because they fit the same corresponding steering knuckle. In contrast, cast steel control arms, a holdover from the previous generation of trucks, use a smaller diameter ball joint and are not compatible with the other two systems.

This is further confirmed by parts manufacturers like Kryptonite Products, who note that for 2014-2016 models, stamped steel and aluminum arms shared a larger ball joint, while forged/cast steel arms used a smaller one. To avoid any issues, you must positively identify what is currently on your vehicle before ordering new parts. Follow these simple steps:

- Visually Inspect the Material: Clean the control arm of any dirt and grime. A cast aluminum arm will typically have a raw, silver-colored finish and a slightly rough texture. A stamped steel arm usually has a smooth surface with a glossy black painted finish and a visible welded seam.

- Use the Magnet Test: This is the most reliable method. As advised by MOOG, a leading parts supplier, a magnet will not stick to an aluminum control arm. If the magnet sticks firmly, you have either a stamped steel or cast steel arm.

- Perform the Tap Test (If Steel): If the magnet sticks, you can differentiate between stamped and cast steel. Gently tap the arm with a small hammer. A stamped steel arm is hollow and will produce a higher-pitched sound. A cast steel arm is solid and will make a dull thud.

Control Arm Materials Explained: Stamped Steel vs. Aluminum vs. Cast Steel

Understanding the fundamental differences between control arm materials can help you make the best choice for your vehicle's needs and your budget. Each type is a product of its manufacturing process, which dictates its weight, strength, and cost. While stamped steel and aluminum are the focus of the swap, it's useful to understand cast steel as it's the primary source of incompatibility.

Stamped Steel control arms are made by pressing sheets of high-strength steel into a desired shape using a die. The pieces are then welded together to create a strong, hollow structure. This method is highly efficient and cost-effective for mass production, making it a popular choice for many factory vehicles. For automotive manufacturers, achieving this precision at scale is key. Companies that specialize in this field, like Shaoyi (Ningbo) Metal Technology Co., Ltd., provide comprehensive solutions from prototyping to mass production of complex stamped components.

Cast Aluminum arms are created by pouring molten aluminum into a mold. This process allows for more complex shapes and a high strength-to-weight ratio. The resulting part is lightweight and naturally corrosion-resistant, which is why it's often used on higher-trim or performance-oriented vehicles to reduce unsprung mass and improve suspension responsiveness.

Cast Steel (or Cast Iron) arms are made similarly to aluminum ones but with molten iron or steel. The final product is incredibly strong and durable but also very heavy. While extremely robust, its weight can be a disadvantage for ride quality. It is a common factory option on many modern heavy-duty and full-size trucks.

| Attribute | Stamped Steel | Cast Aluminum | Cast Steel |

|---|---|---|---|

| Manufacturing | Pressed and welded steel sheets | Molten aluminum poured into a mold | Molten iron/steel poured into a mold |

| Primary Benefit | Cost-effective and durable | Lightweight and corrosion-resistant | Maximum strength and rigidity |

| Main Drawback | Heavy, susceptible to rust | Higher cost, can be less ductile | Very heavy, increases unsprung weight |

| Ideal Use Case | Daily drivers, work trucks | Performance trucks, wet climates | Heavy-duty applications, older designs |

Frequently Asked Questions

1. What is the best material for control arms?

There is no single "best" material; the ideal choice depends on your priorities. For performance and handling in wet climates, aluminum is excellent due to its light weight and corrosion resistance. For a durable, budget-friendly option for a daily driver or work truck, stamped steel is a reliable choice. Cast steel offers maximum strength but is often too heavy for modern applications.

2. Can you upgrade control arms?

Absolutely. Upgrading to aftermarket control arms is a popular modification, especially for lifted trucks. Performance control arms can correct suspension geometry, improving alignment angles like camber and caster. This not only enhances vehicle stability but also helps prevent premature tire wear after installing a lift kit. Companies like Reklez Suspension Works offer kits designed to replace factory arms for better performance.

3. How to tell if control arms are steel or aluminum?

The easiest and most definitive way is the magnet test. According to a technical bulletin from MOOG Parts, you should clean the control arm and place a magnet on it. If the magnet does not stick, the arm is aluminum. If it sticks, it is made of steel (either stamped or cast).

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —