Preventing Common Hot Forging Defects: A Practical Guide

TL;DR

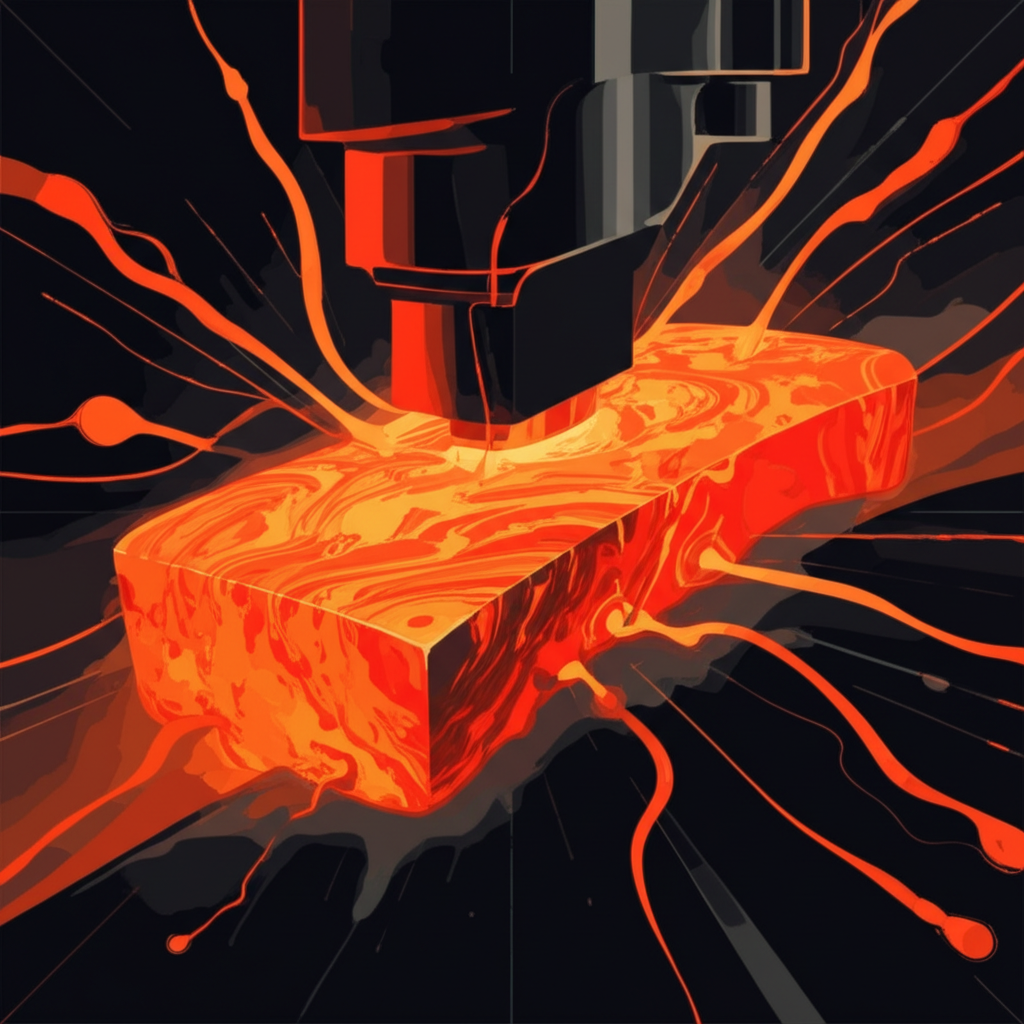

Common hot forging defects include surface cracks, folds, scale pits, and incomplete fills. These issues typically stem from improper temperature control, poor die design, or inadequate material preparation. Preventing them requires precise process monitoring, correct material selection, and meticulous quality control throughout the forging cycle. Ultimately, a well-managed process ensures the final component meets strength and durability specifications.

Understanding the Root Causes of Hot Forging Defects

Hot forging is a superior manufacturing process for creating strong, durable metal components, but it is not without challenges. Defects can arise from a complex interplay of thermal, material, and mechanical factors. Understanding these root causes is the first step toward prevention and quality assurance. Most forging defects can be traced back to three primary categories: thermal inaccuracies, material imperfections, and flaws in equipment or design.

Thermal control is arguably the most critical factor in hot forging. If the workpiece is not heated to the optimal temperature, or if it cools too quickly, defects are almost inevitable. Forging at too low a temperature increases the material's resistance to deformation, which can lead to surface cracking. Conversely, overheating can degrade the material's grain structure, reducing its final strength. As detailed in multiple expert sources, rapid or uneven cooling is a primary cause of internal cracks (flakes) and residual stress, which can warp or weaken the component long after it has been formed. Maintaining a consistent, appropriate temperature throughout the process is essential.

The quality of the raw material is another fundamental pillar of successful forging. Defects can be inherent in the billet before it even enters the forge. Impurities, gas porosity, or internal voids in the raw stock will likely be exacerbated during the forging process. According to industry guides like those from Tedmetal, selecting high-quality, clean material free from inclusions is a crucial preventative measure. Furthermore, an insufficient volume of raw material can lead to unfilled sections, where the die cavity is not completely filled, resulting in a useless part.

Finally, the mechanical aspects of the process—namely die design and equipment alignment—play a significant role. A poorly designed die can restrict metal flow, causing the material to fold over on itself (a defect known as a cold shut or lap) or fail to fill sharp corners. Sharp radii in the die are a common cause of these issues. Additionally, misalignment between the upper and lower dies, known as a die shift, results in a mismatched part with incorrect dimensions. Proper die engineering and regular equipment maintenance are non-negotiable for producing defect-free forgings.

A Detailed Guide to Common Hot Forging Defects

Identifying specific defects is crucial for diagnosing and solving underlying process issues. While many imperfections can occur, several types are consistently cited as the most common challenges in hot forging operations. Each has distinct characteristics, causes, and consequences for the final product's integrity.

1. Surface Cracks and Flakes

Cracks are among the most severe forging defects. Surface cracks often occur when the workpiece is worked at too low a temperature or when excessive stress is applied. Internal cracks, often called flakes, are typically caused by improper cooling. When a forged part cools too rapidly, hydrogen gas dissolved in the metal can precipitate and create immense internal pressure, leading to micro-cracks that severely compromise the component's strength. Both types of cracks render a part unusable for high-stress applications.

2. Folds, Laps, and Cold Shuts

These defects occur when metal folds over on itself during the forging process but the two surfaces do not fuse together, creating a weak spot that often looks like a crack. This is frequently caused by poor die design, particularly dies with sharp corners or insufficient fillet radii that impede smooth metal flow. A cold shut specifically refers to small cracks appearing at the corners. According to GS Forgings, increasing the fillet radius of the die is a direct and effective way to prevent this issue. Folds can be difficult to detect during the forging process itself and require skilled operators who understand material flow to prevent them.

3. Unfilled Sections and Misruns

An unfilled section, or misrun, is a defect where the metal fails to completely fill the die cavity. This results in a component that is incomplete and dimensionally inaccurate. The most common causes are an insufficient amount of raw material, improper heating that makes the metal less plastic, or a poor forging technique that doesn't apply enough pressure to force the metal into every part of the die. Proper die design and ensuring adequate material volume are key to prevention.

4. Scale Pits

When hot metal is exposed to the atmosphere, it forms an oxide layer on its surface known as scale. If this scale is not removed before or during forging, it can be pressed into the surface of the component, creating depressions called scale pits. This defect is primarily an aesthetic issue but can also act as a stress concentration point, potentially leading to fatigue failure. Thorough cleaning of the workpiece surface before forging is the primary method of prevention.

5. Die Shift or Mismatch

A die shift defect is purely mechanical, caused by the misalignment of the top and bottom dies. This results in a forging where the two halves of the part do not line up correctly, creating a horizontal displacement. The solution is straightforward: ensure proper alignment of the dies before starting the forging operation. Modern forging presses often incorporate features to ensure precise alignment and prevent this common dimensional error.

Proactive Strategies for Defect Prevention

Preventing forging defects is far more effective and economical than trying to correct them after the fact. A proactive approach focused on meticulous preparation, precise process control, and post-forging care can virtually eliminate most common issues. This requires a systematic quality control mindset at every stage of production.

The process begins with material preparation. As highlighted by forging experts, selecting the right material, free from impurities and internal flaws, is the first line of defense. Before heating, the surface of the raw material must be thoroughly cleaned to remove any scale, dirt, or lubricants that could be pressed into the final part, causing defects like scale pits. Ensuring the correct volume of material is used for each part is also critical to prevent unfilled sections.

During the forging itself, precision is key. This means maintaining the optimal temperature for the specific alloy being worked. Both the heating of the billet and the temperature of the dies must be carefully controlled to prevent surface cracking or improper grain growth. The force and speed of the press or hammer blows must be calibrated to ensure complete die fill without stressing the material to its breaking point. For industries with exacting standards, such as automotive manufacturing, partnering with a specialized provider is often essential. For instance, companies like Shaoyi Metal Technology offer custom hot forging services with IATF16949 certification, demonstrating a commitment to the rigorous process controls needed to produce defect-free components for high-performance applications.

Post-forging handling is the final critical step. As noted by multiple sources, cooling the part too quickly is a primary cause of internal cracks and residual stress. A controlled, slow cooling process allows the material's internal structure to stabilize, preventing the formation of these hidden but dangerous flaws. Implementing a comprehensive quality control program, including non-destructive testing methods like ultrasonic or magnetic particle inspection, ensures that any potential defects are caught before the component is shipped.

Frequently Asked Questions

1. What are the 4 types of forging processes?

The four main types of forging processes are impression die forging (or closed-die forging), open-die forging, cold forging, and seamless rolled ring forging. Each method is chosen based on the part's complexity, size, material, and required mechanical properties.

2. What are the defects of open die forging?

Common defects in open-die forging include surface cracks from improper temperature control, internal voids if the material is not worked thoroughly, and dimensional inconsistencies. Because the workpiece is not fully enclosed, achieving tight tolerances can be more challenging than in closed-die forging.

3. What are the disadvantages of hot forging?

While hot forging produces strong parts, its disadvantages include lower dimensional accuracy compared to cold forging due to thermal expansion and contraction. The high temperatures can also cause surface oxidation (scaling), which may require additional cleaning or machining. Finally, it is a more energy-intensive process.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —