Powder Coating Stamped Automotive Parts: Technical Guide & Standards

TL;DR

Powder coating stamped automotive parts provides a superior protective barrier against corrosion, chipping, and road salts compared to traditional liquid paints. By utilizing electrostatic application, this process creates a dense, uniform finish that wraps around the sharp edges and complex geometries typical of stamped components like brackets, chassis frames, and trim.

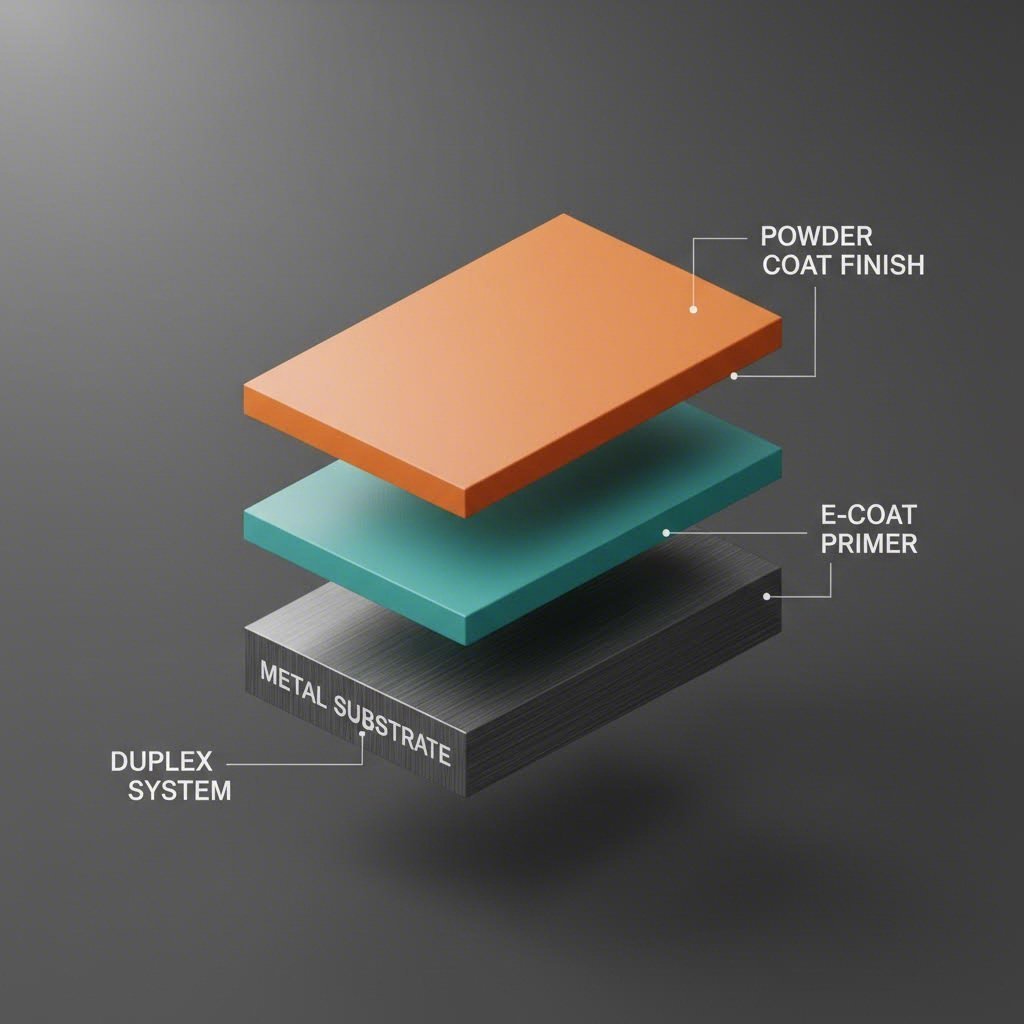

For maximum durability in harsh automotive environments, engineers often specify a duplex system—pairing an E-coat primer for total immersion coverage with a powder topcoat for UV stability and aesthetic resilience. This combination frequently exceeds 1,000 hours in ASTM B117 salt spray tests, making it the industry standard for high-performance automotive stamping applications.

The Critical Challenges: Sharp Edges and Complex Geometries

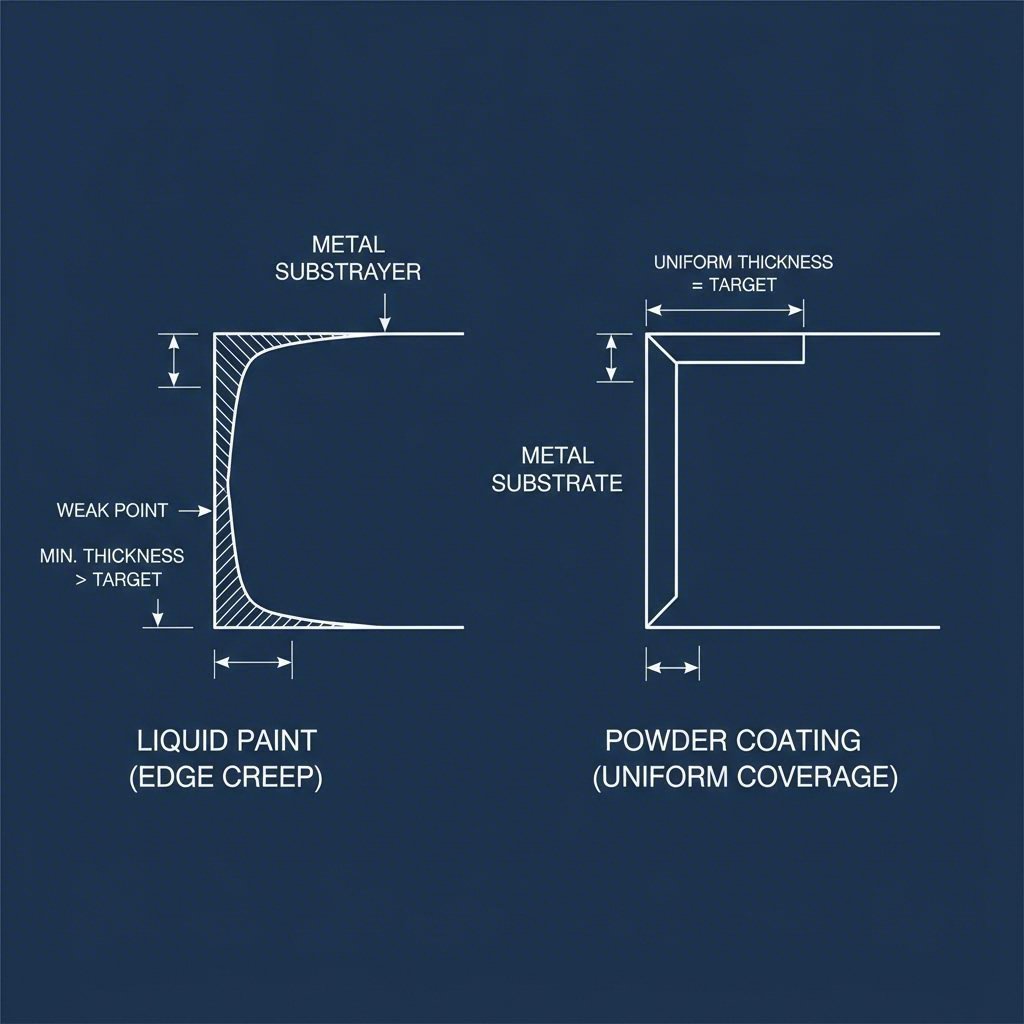

Stamped metal parts present unique engineering hurdles that standard painting processes often fail to address. The primary issue stems from the stamping process itself: shearing metal creates sharp edges and burrs. On a microscopic level, liquid paints tend to pull away from these sharp peaks during curing—a phenomenon known as "edge creep"—leaving the most vulnerable areas of the part with the thinnest protection.

Powder coating mitigates this risk through its rheology. As the powder melts and flows during the cure cycle, it builds a thicker film (typically 2–4 mils) that encapsulates sharp stamped edges more effectively than wet paint. However, for deep-drawn stampings with recessed areas, the Faraday Cage Effect can prevent powder from reaching internal corners. The electrostatic charge accumulates at the opening of the recess, repelling powder from the deep pocket.

To solve this, automotive engineers often rely on duplex coating systems or specify high-edge-coverage powders. Additionally, the quality of the substrate is paramount. Sourcing components from precision stamping partners who manage burr height and edge condition is the first line of defense against premature coating failure.

Comparison: E-Coat, Powder Coat, and Duplex Systems

Choosing the right finishing specification is critical for the Bill of Materials (BOM). While powder coating offers excellent durability, it is not always the standalone solution for every automotive application. The table below breaks down the technical differences between Electro-coating (E-Coat), Powder Coating, and the Duplex System.

| Feature | E-Coat (Electro-Deposition) | Powder Coat | Duplex System (E-Coat + Powder) |

|---|---|---|---|

| Application Method | Immersion (Dipping) | Electrostatic Spray | Immersion Primer + Spray Topcoat |

| Edge Coverage | Excellent (Uniform thickness) | Good (Thicker build) | Superior (Double layer) |

| Recess Penetration | 100% (Liquid flows everywhere) | Limited (Faraday Cage issues) | 100% (E-coat protects recesses) |

| UV Resistance | Poor (Chalks in sunlight) | Excellent (Polyester/Urethane) | Excellent |

| Corrosion Resistance | High (500-1,000 hrs salt spray) | High (500-1,500 hrs) | Extreme (1,500-4,000+ hrs) |

| Best For | Underbody, hidden brackets | Wheels, trim, exterior parts | Critical chassis & exterior trim |

The Duplex Advantage: For automotive OEMs and Tier 1 suppliers, the duplex system is considered the "gold standard." The E-coat acts as a primer, ensuring that every micron of the stamped part—including inside welds and deep draws—is sealed against moisture. The powder topcoat then provides the requisite color, gloss, and UV shield. This synergy is essential for parts like control arms, subframes, and wiper assemblies that face both road debris and sunlight.

Essential Pre-Treatment: The Foundation of Adhesion

No amount of high-quality powder can save a stamped part that wasn't properly prepped. Stamping operations rely on heavy-duty lubricants and oils to protect die tooling and facilitate metal flow. If these hydrocarbon-based fluids are not completely removed, they will outgas during the powder curing oven cycle, causing defects like pinholes, blisters, or "fisheyes."

A robust automotive pre-treatment line typically involves a multi-stage process, often ranging from 5 to 8 stages:

- Alkaline Cleaning: Removes organic soils, stamping oils, and shop dirt.

- Rinsing: Prevents cross-contamination between stages.

- Surface Conditioning: Activates the metal surface for coating reception.

- Zinc or Iron Phosphating: Creates a conversion coating that chemically bonds to the metal, significantly boosting adhesion and corrosion resistance.

- Sealing: Passivates the phosphate layer.

- RO/DI Rinse: A final rinse with Reverse Osmosis or Deionized water to leave a mineral-free surface.

Material Considerations: The pre-treatment chemistry must ideally match the substrate. Aluminum stampings may require a dedicated line or specific chromate-free chemistries to prevent oxidation, while galvanized steel requires careful handling to avoid damaging the zinc layer.

Strategic Sourcing: From Prototype to Production

The success of the finishing process is inextricably linked to the quality of the raw stamping. Surface defects, excessive burrs, or inconsistent material properties can compromise even the most advanced coating lines. To ensure a flawless finish, it is crucial to partner with manufacturers who understand the interplay between fabrication and finishing.

Leading providers like Shaoyi Metal Technology bridge this gap by offering comprehensive stamping solutions that scale from rapid prototyping to high-volume manufacturing. With IATF 16949 certification and press capabilities up to 600 tons, they deliver precision components—such as control arms and subframes—that meet strict OEM standards. Starting with a high-precision substrate minimizes downstream finishing risks and ensures that the final powder-coated part meets rigorous durability expectations.

Automotive Standards and Durability Testing

Validation is the final step in the manufacturing workflow. Automotive powder coatings must pass a battery of standardized tests to be approved for OEM use. Engineers should verify supplier capabilities against these key standards:

- ASTM B117 (Salt Spray): The baseline for corrosion resistance. Standard automotive powder coatings typically target 500 to 1,000 hours, while duplex systems aim for 1,500+ hours without red rust creeping more than a few millimeters from a scribe line.

- ASTM D3359 (Adhesion): Often called the "cross-hatch" test. A pattern is cut into the coating and tape is applied and pulled off. A rating of 5B means 0% coating loss, a non-negotiable metric for car parts.

- Gravelometer (Chip Resistance): Critical for underbody parts like suspension arms and springs. This test simulates flying road gravel impacting the part to ensure the coating doesn't shatter or delaminate upon impact.

Specifying these tests on the print ensures that the finishing partner maintains process controls that guarantee longevity in real-world driving conditions.

Conclusion

Powder coating stamped automotive parts is more than an aesthetic choice; it is a vital engineering decision that impacts the vehicle's longevity and safety. By understanding the physics of edge coverage, leveraging duplex systems for critical components, and insisting on rigorous pre-treatment protocols, manufacturers can deliver parts that withstand the harshest road environments.

Whether you are engineering a new chassis component or sourcing brackets for an assembly, the integration of precision stamping with advanced finishing specifications creates a product that meets the high standards of the modern automotive industry.

Frequently Asked Questions

1. What are the downsides of powder coating for stamped parts?

The main limitation is the difficulty in touching up the finish if it gets damaged, as powder cannot simply be painted over without specific preparation. Additionally, the Faraday Cage Effect can make it challenging to coat deep recesses in complex stamped geometries without specialized equipment or manual reinforcement.

2. Which automotive parts are best suited for powder coating?

Powder coating is ideal for metal parts exposed to the elements or road debris. Common applications include wheels, chassis frames, suspension components (control arms, springs), brake calipers, bumpers, and under-hood brackets. It is generally not used for internal engine components that exceed the thermal limits of the powder (typically ~400°F).

3. What is the difference between aesthetic and functional powder coating?

Aesthetic powder coating focuses on color match, gloss levels, and surface smoothness, often used for visible trim or wheels. Functional powder coating prioritizes protection, such as electrical insulation, extreme corrosion resistance, or high heat tolerance, often used for underbody or engine bay components where looks are secondary to performance.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —