Near-Net Shape Forging Benefits for the Automotive Sector

TL;DR

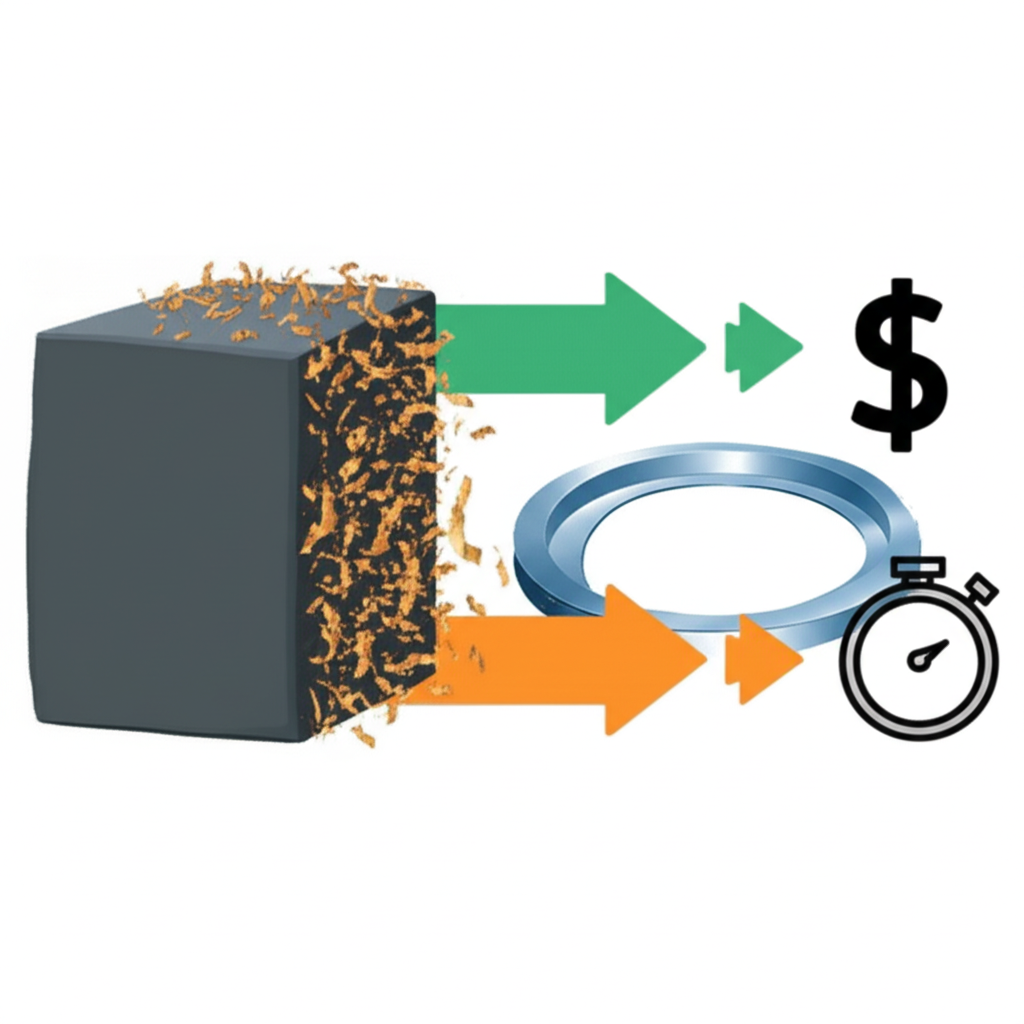

Near-net shape forging is a manufacturing process that creates automotive parts extremely close to their final, or 'net,' dimensions. This technique significantly minimizes the need for secondary machining, leading to substantial benefits such as reduced material waste, lower production costs, and faster manufacturing cycles. Ultimately, it delivers stronger, more reliable components with superior structural integrity for the automotive industry.

What Is Near-Net Shape Forging?

Near-net shape forging is an advanced manufacturing process designed to produce a metal component that is as close as possible to its final, finished dimensions. Unlike traditional forging methods that create a rough approximation of the part (often called an 'as-forged' component), near-net shape forging delivers a product that requires minimal subsequent machining, grinding, or finishing. This precision is key to its value, especially in a demanding sector like the automotive industry.

The core principle is efficiency. Traditional forging often leaves a significant amount of excess material that must be painstakingly removed. This removal process consumes time, energy, and labor, while also generating considerable scrap material. According to AST Forged Wheels, a major drawback of conventional methods is starting with too much metal, a practice that is not ideal for the manufacturer or the customer in terms of cost. Near-net shape forging directly addresses this inefficiency by shaping the metal intelligently from the start.

The process itself involves hammering or pressing a metal billet into a die that mirrors the final part's geometry with high precision. This is fundamentally different from casting, where molten metal is poured into a mold. As explained in a blog by Cybernet Manufacturing, the hammering action in forging provides a distinct metallurgical advantage by creating a specific grain flow that follows the contours of the part, which enhances its strength and resilience—a critical factor for high-performance automotive components.

The Core Economic Advantages: Slashing Costs and Waste

One of the most compelling arguments for adopting near-net shape forging in the automotive sector is its significant economic impact. By creating parts that are almost complete from the outset, manufacturers can achieve considerable savings across multiple areas of production. These financial benefits make the process a cornerstone of modern lean manufacturing.

The primary cost-saving benefit comes from a drastic reduction in material waste. Because the initial forging is so close to the final geometry, far less metal needs to be machined away. This minimizes the amount of scrap generated, which is a direct financial loss; as AST Forged Wheels notes, selling scrap metal typically recoups only about half of the initial material cost. By using raw materials more effectively, companies can lower their input costs substantially.

Furthermore, the reduction in required machining translates directly to lower operational expenses. Less machine time means reduced energy consumption, less wear and tear on cutting tools and equipment, and fewer labor hours dedicated to finishing each part. Double Eagle Alloys highlights that lower production costs are a key benefit, as the streamlined process eliminates many of the costly steps associated with traditional manufacturing. This efficiency gain not only saves money but also frees up valuable machine capacity for other tasks.

Boosting Operational Efficiency in Automotive Production

In the fast-paced automotive industry, production speed and efficiency are just as critical as cost. Near-net shape forging provides a powerful advantage by accelerating manufacturing timelines and improving overall workflow. By minimizing the extensive post-forging machining, the entire production cycle becomes shorter and more predictable.

This reduction in processing time leads to significantly faster lead times for finished components. For automotive manufacturers operating on tight schedules and just-in-time supply chains, this speed is invaluable. It allows for greater agility in responding to market demands and reduces the risk of production bottlenecks caused by lengthy finishing processes. The ability to move a part from raw material to a near-finished state in fewer steps streamlines the entire operational flow.

Achieving these efficiency gains often relies on partnering with specialized providers who have mastered the near-net shape process. For instance, companies looking for robust and reliable automotive components can explore the custom forging services from Shaoyi Metal Technology. They specialize in high-quality, IATF16949 certified hot forging for the automotive industry, offering everything from rapid prototyping to mass production. Their expertise and in-house capabilities help ensure the precision and efficiency that near-net shape forging promises, facilitating timely delivery for global supply chains.

Ultimately, the operational benefits extend beyond just speed. A more efficient, streamlined process is also a more reliable one. With fewer steps and less manual intervention required for finishing, there are fewer opportunities for error, leading to more consistent quality and higher production yields.

Enhancing Part Quality and Structural Integrity

Beyond the economic and operational benefits, near-net shape forging delivers a superior product in terms of mechanical performance and reliability. The inherent nature of the forging process imparts metallurgical properties that are highly desirable for critical automotive applications, such as engine components, suspension parts, and driveline systems.

The primary advantage lies in the grain flow of the metal. During the forging process, the repeated hammering and pressing forces the metal's internal grain structure to align with the shape of the component. This continuous, unbroken grain flow enhances the part's strength, ductility, and resistance to impact and fatigue. In contrast, machining a part from a solid block of metal (bar stock) cuts through these grain flows, creating potential weak points. As noted by Leanwerks, this process results in increased metallurgical strength with more effective grain flow.

This enhanced structural integrity means that forged parts can be made lighter without sacrificing strength—a critical goal in the automotive industry for improving fuel efficiency and performance. The process also helps to consolidate and close any internal voids or porosity that might be present in the raw metal, resulting in a denser and more uniform material. This leads to components that are not only stronger but also more reliable and durable over their service life, meeting the stringent safety and performance standards of the automotive sector.

Frequently Asked Questions

1. What are the major advantages of the forging process?

Forging offers several key advantages over other manufacturing methods like casting or machining. It produces parts with superior mechanical properties, including improved strength, ductility, and fatigue resistance, due to the refined grain structure. This process also eliminates internal porosity, leading to higher structural integrity and reliability, which is crucial for safety-critical components.

2. Why is net shape manufacturing an important consideration?

Net shape and near-net shape manufacturing are important because they are highly efficient. By producing parts that are very close to their final dimensions, these methods drastically reduce material waste, minimize the need for costly and time-consuming secondary machining, and shorten overall production lead times. This leads to significant cost savings and a more sustainable manufacturing process.

3. What is forging in the automotive industry?

In the automotive industry, forging is a manufacturing process used to create strong, durable metal components by shaping metal with compressive forces. It is essential for producing critical parts that must withstand high stress and fatigue, such as connecting rods, crankshafts, gears, and wheel hubs. Forged components are integral to modern vehicle design for their strength and reliability.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —