Expert Forged Gear Blanks Manufacturer for Critical Applications

TL;DR

As a leading forged gear blanks manufacturer, we specialize in producing high-strength, custom-forged components for critical industrial applications. Our precision forging processes, extensive material selection—including carbon, alloy, and stainless steels—and rigorous quality control ensure superior durability and performance. We deliver near-net shape blanks that reduce machining time and material waste, providing a reliable foundation for your gear systems.

The Critical Role of High-Quality Forged Gear Blanks

A forged gear blank is the foundational workpiece from which a finished gear is machined. Unlike parts machined from standard bar stock or created through casting, a forged blank undergoes a process of intense heat and pressure that fundamentally improves its mechanical properties. This manufacturing method is crucial for gears used in demanding environments where failure is not an option, such as in aerospace, automotive, and heavy industrial equipment.

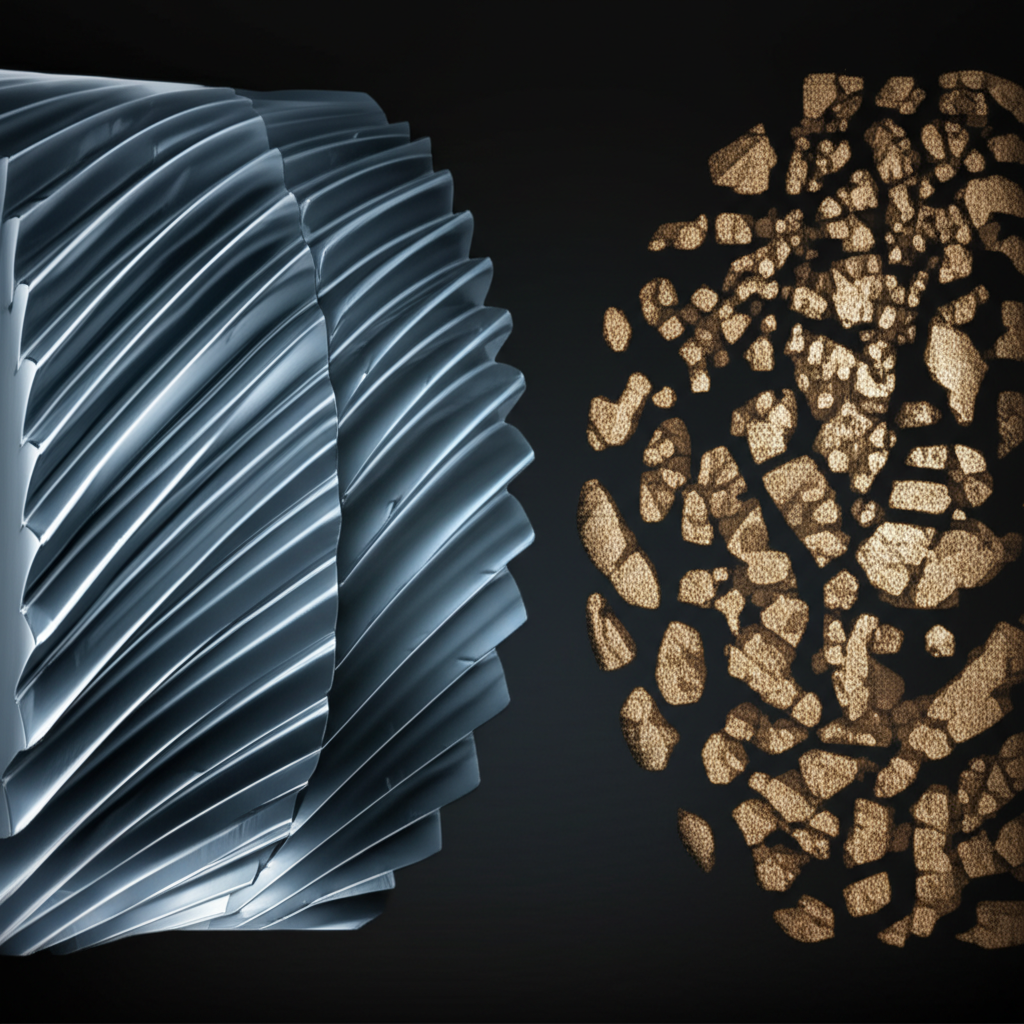

The primary advantage of forging lies in the refinement of the metal's grain structure. The forging process forces the internal grains of the metal to align with the shape of the part, creating a continuous and directional grain flow. This is a key differentiator from casting, where the grain structure is typically random and non-directional. According to experts at Scot Forge, this refined microstructure results in significantly higher strength, ductility, and resistance to impact and fatigue. A forged gear blank can withstand greater stress and wear, leading to a longer service life and increased reliability of the final gear.

Furthermore, the forging process eliminates internal defects common in other methods. Casting can introduce porosity, voids, or shrinkage issues that create weak points within the material. Forging, however, consolidates the material, closing any potential voids and ensuring a dense, structurally sound component. This metallurgical soundness, as highlighted by manufacturers like Solmet Technologies, is essential for gears that must perform under extreme torque and repetitive stress, ensuring consistent and predictable performance throughout their operational life.

Our Forging Processes: Precision, Flexibility, and Scale

To meet diverse client specifications, we employ several advanced forging techniques, each offering unique benefits in terms of shape, size, and production volume. Our capabilities are designed to produce near-net shapes, which closely resemble the final product, minimizing the need for extensive and costly machining. This approach not only saves time but also reduces material waste, delivering a more cost-effective component.

Our primary forging processes include:

- Open-Die Forging: This method offers exceptional flexibility and is ideal for producing large, custom gear blanks or handling low-volume production runs. We can forge parts weighing up to 3,500 lbs, making it suitable for heavy-duty applications. This process allows for a wide range of sizes and shapes, including single and double hub configurations, providing a versatile solution for unique engineering challenges.

- Closed-Die Forging: For higher volume production runs requiring precise, repeatable dimensions, closed-die forging is the optimal choice. This process uses custom dies to shape the metal, resulting in excellent dimensional accuracy and a superior surface finish. It is a highly efficient method for manufacturing standardized gear blanks with complex geometries.

- Seamless Rolled Ring Forging: As detailed by industry leaders like All Metals & Forge Group, the seamless rolled ring process is perfect for creating ring-shaped gear blanks with superior tangential strength and a refined grain structure. This technique is highly efficient for producing blanks for large ring gears, bearings, and couplings, with capabilities to produce diameters ranging from a few inches up to 102 inches.

These varied processes allow us to serve a broad spectrum of industries, from automotive to mining. By matching the right forging technique to the specific application, we ensure that every gear blank we produce meets the exact mechanical and dimensional requirements of our clients.

Material Selection for Demanding Applications

The performance of a gear is intrinsically linked to the material from which it is made. We offer an extensive inventory of high-quality metals to ensure your forged gear blanks can withstand their intended operational stresses, temperatures, and environmental conditions. Our metallurgical expertise allows us to guide you in selecting the ideal material for your specific application, balancing factors like strength, wear resistance, and cost.

Our most commonly forged materials include:

- Carbon Steels: Valued for their strength and cost-effectiveness, carbon steels are a popular choice for a wide range of general-purpose gear applications.

- Alloy Steels: By adding elements like chromium, nickel, and molybdenum, alloy steels offer enhanced properties such as superior hardness, toughness, and fatigue strength, making them ideal for high-stress and heavy-load applications.

- Stainless Steels: For applications requiring high corrosion resistance, such as in the marine or food processing industries, stainless steel provides excellent durability and longevity.

- Non-Ferrous Metals: We also work with materials like aluminum, titanium, and copper alloys for applications where specific properties like light weight or conductivity are required.

For highly specialized sectors, material selection and manufacturing processes must meet stringent certification standards. For instance, in the automotive industry, components often require IATF 16949 certification to ensure quality and reliability. For robust and reliable automotive components, companies like Shaoyi Metal Technology specialize in certified hot forging, providing everything from rapid prototyping to mass production for the automotive sector.

Why Partner With Us for Your Forged Gear Blanks

Choosing the right manufacturer is a critical decision that impacts your product's performance and your operational efficiency. We are dedicated to being more than just a supplier; we are a strategic partner committed to your success. Our focus on quality, customization, and customer service sets us apart in the industry.

Uncompromising Quality and Metallurgical Integrity

Quality is at the core of everything we do. From initial material inspection to final dimensional verification, our rigorous quality assurance processes ensure that every forged gear blank meets the highest standards. We employ non-destructive testing methods to guarantee metallurgical soundness, ensuring our products are free from defects and built to last in the most demanding environments.

Custom Solutions for Complex Needs

We understand that one size does not fit all. Our engineering team works closely with you to understand your specific requirements, from material selection to final geometry. Whether you need a one-off prototype or a large production run, we have the flexibility and expertise to deliver custom forged gear blanks tailored to your application. Our capability to produce near-net shapes saves you valuable machining time and material costs.

A Commitment to Partnership and Reliability

As a U.S.-based manufacturer, we are committed to providing reliable service and on-time delivery. We pride ourselves on clear communication and a collaborative approach, ensuring your project stays on track. Our goal is to build long-term relationships based on trust and mutual success. When you partner with us, you gain access to decades of forging expertise and a team dedicated to helping you achieve your goals. Contact our engineering team today to request a quote and discuss your project needs.

Frequently Asked Questions About Forged Gear Blanks

1. What is the main difference between a forged and a cast gear blank?

The primary difference lies in the grain structure and resulting strength. Forging aligns the metal's grain flow with the part's shape, creating superior strength, ductility, and fatigue resistance. Casting results in a random, non-directional grain structure, which can contain defects like porosity, making it less durable for high-stress applications.

2. What information is needed to get a quote for custom forged gear blanks?

To provide an accurate quote, we typically need a drawing or sketch with dimensions and tolerances, the desired material grade (e.g., carbon, alloy, or stainless steel), the required quantity, and any specific testing or certification requirements. The more detail you can provide about the end-use application, the better we can tailor the solution to your needs.

3. Can forging save money compared to machining from bar stock?

Yes, especially for complex shapes or larger parts. Forging to a near-net shape significantly reduces the amount of material that needs to be machined away, saving on both material costs and machining time. While there is an initial tooling investment for closed-die forging, the per-part cost savings can be substantial on higher volume runs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —