Mold Flow Analysis for Automotive Die Casting Explained

TL;DR

Die casting simulation is a computer-aided engineering (CAE) simulation used in the design phase of automotive die casting. It virtually predicts how molten metal will flow, fill, and solidify within a mold. The primary purpose of this analysis is to identify and prevent critical manufacturing defects like porosity, air traps, and short shots before any steel is cut, thereby optimizing the mold design to ensure the production of high-quality, reliable automotive components while saving significant time and cost.

What is Die Casting Simulation and Why is it Crucial for Automotive Die Casting?

Die casting simulation is a sophisticated technique that provides a virtual window into the die casting process before a physical mold is ever created. Using powerful CAE software, engineers can model and visualize the complex physics of molten metal filling a die cavity. This numerical modeling predicts the flow, filling, and solidification stages of the process, offering data-driven insights that were once only achievable through costly and time-consuming trial and error.

The core function of this analysis is to move from a reactive to a proactive approach in mold design. Historically, die casting relied heavily on the experience of engineers, and initial production runs (known as T1 trials) often revealed flaws that required expensive and lengthy mold modifications. Die casting simulation fundamentally changes this dynamic by allowing designers to test various runner layouts, gate locations, and process parameters in a digital environment. This virtual testing identifies potential issues early in the design stage, enabling corrections before committing to manufacturing the physical tool.

In the demanding automotive sector, where parts are often complex and subject to stringent safety and performance standards, this proactive validation is indispensable. The simulation helps ensure that components, from intricate electronic housings to large structural parts, are produced consistently and economically. By optimizing the process digitally, manufacturers can achieve a much higher success rate on the first trial, drastically reducing development cycles and costs.

The key benefits of integrating die casting simulation into the automotive die casting workflow are substantial and directly impact the bottom line and product quality. These advantages include:

- Defect Prevention: By predicting issues like porosity, weld lines, and incomplete filling, the analysis allows engineers to redesign molds to eliminate these flaws from the outset.

- Cost Reduction: It minimizes the need for expensive mold rework and reduces material scrap rates. By validating the design upfront, it avoids the high costs associated with production line troubleshooting.

- Accelerated Development Cycle: Simulation significantly cuts down on the number of physical trials needed to produce a perfect part, shortening the time from design to market.

- Improved Part Quality and Performance: Optimized filling and cooling lead to parts with better structural integrity, superior surface finish, and enhanced mechanical properties, which are critical for automotive applications.

- Enhanced Tool Longevity: By analyzing thermal stresses on the mold itself, the simulation can help optimize cooling systems to prevent premature cracking or wear, extending the life of the expensive die.

Preventing Critical Defects: The Core Objective of Die Casting Simulation

The primary goal of die casting simulation is to serve as a powerful diagnostic tool that identifies and mitigates potential manufacturing defects before they materialize. These flaws can compromise a part's structural integrity, appearance, and performance, leading to costly scrap or, worse, in-field failures. The simulation provides a detailed preview of how the molten metal will behave, allowing engineers to pinpoint the root causes of common die casting defects.

One of the most critical defects addressed is porosity, which refers to voids or holes within the casting. As detailed by experts at Dura Mold, Inc., porosity is generally categorized into two types. Gas-related porosity occurs when air or gases from lubricants get trapped in the metal as it solidifies, typically appearing as smooth, round voids. Shrinkage porosity, on the other hand, is caused by volume reduction during solidification and often looks rough and jagged. Both types can severely weaken a component, and simulation helps identify areas of trapped gas or insufficient feeding that lead to these issues.

Another common issue is the formation of air traps. These occur when molten metal flows converge and trap a pocket of air within the cavity. If not properly vented, this trapped air can cause surface blemishes or internal voids. Similarly, weld lines form where two separate flow fronts meet but fail to fuse together completely, creating a potential weak point in the final part. Simulation clearly visualizes these meeting points, allowing for adjustments to gate locations or flow paths to ensure the fronts are hot enough to merge properly.

Other significant defects that simulation helps prevent include incomplete filling (short shots), where the metal solidifies before completely filling the mold cavity, and cold shuts, a related issue where premature cooling prevents proper fusion of the metal stream. By analyzing the flow front temperature and pressure throughout the filling process, engineers can ensure the metal reaches every corner of the mold at the right temperature and pressure to form a complete, solid part.

To effectively use simulation results, engineers map visual indicators from the software to specific potential defects, allowing for targeted design interventions.

| Potential Defect | Simulation Indicator | Common Design Solution |

|---|---|---|

| Porosity (Gas & Shrinkage) | High-pressure zones indicating trapped air; isolated hot spots during solidification. | Add or relocate overflows and vents; optimize runner and gate design. |

| Air Traps | Areas where flow fronts converge and encircle a region. | Improve venting at the trap location; adjust gate position to alter the filling pattern. |

| Weld Lines | Lines showing where two or more melt flow fronts meet. | Change gate locations to move weld lines to non-critical areas; increase melt temperature. |

| Short Shot / Incomplete Fill | Simulation shows the melt front stopping before the cavity is full. | Increase wall thickness; adjust gate size or injection speed; add air vents. |

The Die Casting Simulation Process: A Step-by-Step Guide

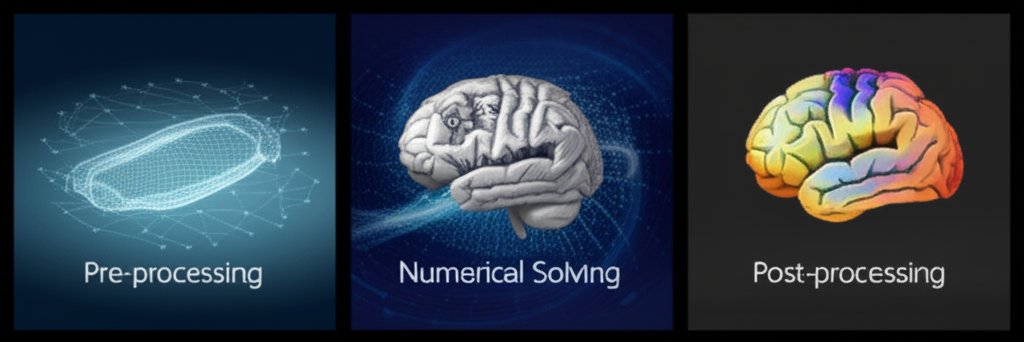

Conducting a die casting simulation is a systematic process that transforms a 3D digital model into actionable manufacturing insights. This workflow can be broken down into three primary stages: pre-processing, numerical solving, and post-processing. Each step is critical for ensuring the accuracy and utility of the final simulation report.

-

Pre-processing: Preparing the Digital Model

This initial stage is all about preparation. It begins with importing the 3D CAD model of the automotive part into the CAE software. The model is then simplified to remove features irrelevant to the flow analysis, such as small logos or threads, which can unnecessarily complicate calculations. The next crucial step is mesh generation, where the software divides the part's geometry into a network of small, interconnected elements (a mesh). The quality of this mesh is vital; it must be fine enough to capture important details without being so dense that it makes computation times excessively long. -

Material and Process Parameter Setup

Once the mesh is ready, the engineer defines the specific conditions of the die casting process. This involves selecting the exact metal alloy (e.g., A380 aluminum) from the software's extensive material database. Each material has unique properties like viscosity and thermal conductivity that the software uses in its calculations. Next, the process parameters are set to mimic the real-world production environment. This includes defining the melt temperature, mold temperature, filling time, and the pressure at which the machine will switch from velocity control to pressure control. -

Numerical Solving: The Computation Phase

This is the stage where the computer does the heavy lifting. The CAE software uses the prepared model and parameters to solve a series of complex mathematical equations governing fluid dynamics and heat transfer. It calculates how the molten metal will flow, how pressure and temperature will distribute throughout the mold, and how the part will cool and solidify. This is a computationally intensive phase that can take several hours, depending on the complexity of the part and the mesh density. -

Post-processing: Interpreting the Results

After the solver finishes its calculations, it generates a vast amount of raw data. The post-processing stage is where this data is translated into visual, interpretable formats like color-coded plots, graphs, and animations. An engineer analyzes these outputs to identify potential problems. For example, an animation of the filling pattern might reveal an air trap, or a temperature plot could highlight a hot spot that may lead to shrinkage porosity. The final output is typically a comprehensive report that summarizes these findings and provides clear recommendations for optimizing the mold design.

Interpreting the Results: Key Metrics in a Simulation Report

A die casting simulation report is a rich document filled with visual data that provides deep insights into the casting process. Understanding how to interpret these key metrics is what transforms the simulation from a theoretical exercise into a practical tool for creating a successful mold on the first try. The report typically visualizes several critical parameters that engineers scrutinize to refine the design.

One of the most fundamental outputs is the Filling Time analysis. This is often shown as an animation or a contour plot that illustrates how the molten metal progressively fills the cavity. A balanced filling process, where the metal reaches all extremities of the part at roughly the same time, is ideal. This plot immediately flags potential issues like short shots (where the flow stops prematurely) or hesitation (where the flow front slows down significantly), which can be seen as dense contour lines in a small area.

The Flow Front Temperature is another critical metric. It shows the temperature of the molten metal at its leading edge as it fills the mold. If the temperature drops too low before the cavity is full, it can lead to defects like cold shuts or poor-quality weld lines. Engineers analyze this to ensure the melt remains hot enough to properly fuse where flow fronts meet. Similarly, the Pressure at V/P Switchover plot shows the pressure distribution within the cavity at the moment the machine switches from the filling (velocity) stage to the packing (pressure) stage. This helps in identifying areas of high resistance and ensuring the injection pressure is sufficient to fill the part completely without causing flash.

Analysis reports also provide direct predictions of defects. Key metrics an engineer will look for include:

- Air Trap Locations: The software explicitly highlights spots where air is likely to be trapped by converging flow fronts. This allows designers to strategically add vents or overflows to the mold.

- Weld Line Formation: The report shows exactly where weld lines will appear. While sometimes unavoidable, their location can be moved to less structurally or aesthetically critical areas by adjusting gate positions.

- Volumetric Shrinkage: This metric predicts how much the material will shrink as it cools and solidifies. High shrinkage in thick sections can lead to sink marks or internal voids (porosity). Analyzing this helps in optimizing the packing pressure and cooling channel design to compensate for shrinkage.

- Deflection (Warpage): For parts with tight tolerances, the deflection analysis predicts how the part might warp or distort after ejection due to uneven cooling or internal stresses. This is crucial for ensuring the final part meets its dimensional specifications.

By carefully examining these interconnected metrics, an engineer can make informed decisions to modify the mold design—such as adjusting gate sizes, relocating runners, or refining the cooling layout—to mitigate risks and ensure a high-quality final product.

Application Spotlight: When is Die Casting Simulation Essential?

While die casting simulation is beneficial for nearly any die casting project, it becomes an indispensable, non-negotiable step for certain categories of automotive components where the cost of failure is high and the manufacturing complexity is significant. For these parts, simulation is a critical risk-mitigation strategy.

The first category includes thin-walled, complex parts. Components like electronic housings, transmission cases, or heat sinks often feature walls less than 1mm thick combined with intricate rib and boss structures. For these parts, the molten metal must travel long distances through narrow channels, increasing the risk of premature solidification, leading to short shots or cold shuts. As noted by Sunrise Metal, mold flow simulation is essential here to optimize the gating and runner system, ensuring the metal fills the entire cavity quickly and completely before it cools.

A second critical application is for large, integrated structural parts. The automotive industry's move towards 'gigacasting'—producing large sections of a vehicle's body or chassis as a single piece—presents immense challenges. These massive castings often require multiple gates to fill synchronously. Mold flow analysis is the only way to ensure a balanced flow from all gates, preventing weld lines in structurally critical areas and managing the immense thermal stresses across the die. Without simulation, achieving the required structural integrity for these components would be nearly impossible.

Finally, analysis is mandatory for high-performance parts with strict requirements. This includes components like hydraulic valve bodies that must be completely free of internal porosity to be leak-proof, or suspension and steering components subjected to high mechanical loads. For these parts, even minor internal defects can lead to catastrophic failure. Simulation is used to meticulously optimize the filling and solidification process to eliminate internal shrinkage and gas porosity, ensuring the final part is dense, strong, and meets rigorous safety standards.

While die casting is ideal for complex geometries, components demanding the absolute highest strength and fatigue resistance, such as critical suspension or powertrain parts, often rely on processes like hot forging. For instance, specialists like Shaoyi (Ningbo) Metal Technology focus on producing these robust automotive forging parts, demonstrating the importance of selecting the right manufacturing process for each specific application.

Frequently Asked Questions

1. What is die casting simulation?

Die casting simulation is a computer-aided engineering (CAE) simulation technique used during the design phase of a mold. It uses specialized software to predict how a molten material—such as metal for die casting or plastic for injection molding—will flow into, fill, and cool within the mold cavity. The primary goal is to identify and resolve potential manufacturing issues like incomplete filling, air traps, weld lines, and warpage before the physical mold is manufactured, thereby saving time and reducing costs.

2. What are the main outputs of a die casting simulation report?

A typical report provides a range of visual and data-driven outputs. Key results include analyses of the filling pattern (filling time), pressure and temperature distributions across the part, and predictions for the locations of potential defects like air traps and weld lines. It also includes assessments of volumetric shrinkage, which can cause sink marks, and a deflection analysis that predicts potential warpage of the final part after it cools.

3. How does die casting simulation save money in production?

The cost savings are significant and come from several areas. By identifying design flaws digitally, it drastically reduces the need for expensive and time-consuming physical modifications to hardened steel molds. It helps optimize the process parameters, leading to shorter cycle times and less material waste. Finally, by ensuring a higher quality part from the first production run, it minimizes scrap rates and avoids the high costs associated with troubleshooting problems on the factory floor.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —