In-House Die & Mold Manufacturing: Unlock Key Advantages

TL;DR

Bringing die and mold manufacturing in-house offers significant strategic advantages for businesses. This approach provides direct control over the entire production process, leading to substantial cost reductions, shorter product development cycles, and superior quality assurance. Furthermore, managing tooling internally mitigates risks associated with outsourcing, such as communication breakdowns and delays, while offering robust protection for valuable intellectual property.

Enhanced Quality Control and IP Protection

One of the most compelling advantages of in-house die and mold manufacturing is the unparalleled level of control it grants over product quality. When every stage of the tooling process happens under one roof, from initial design to final production, a company can enforce its quality standards with absolute precision. This integration ensures that the team of engineers, designers, and toolmakers work in unison, addressing potential issues before they escalate. According to insights from manufacturing experts, this cohesive oversight allows for practical injection molding constraints to be considered from the outset, rather than discovering problems after a mold has been built and shipped from an external supplier.

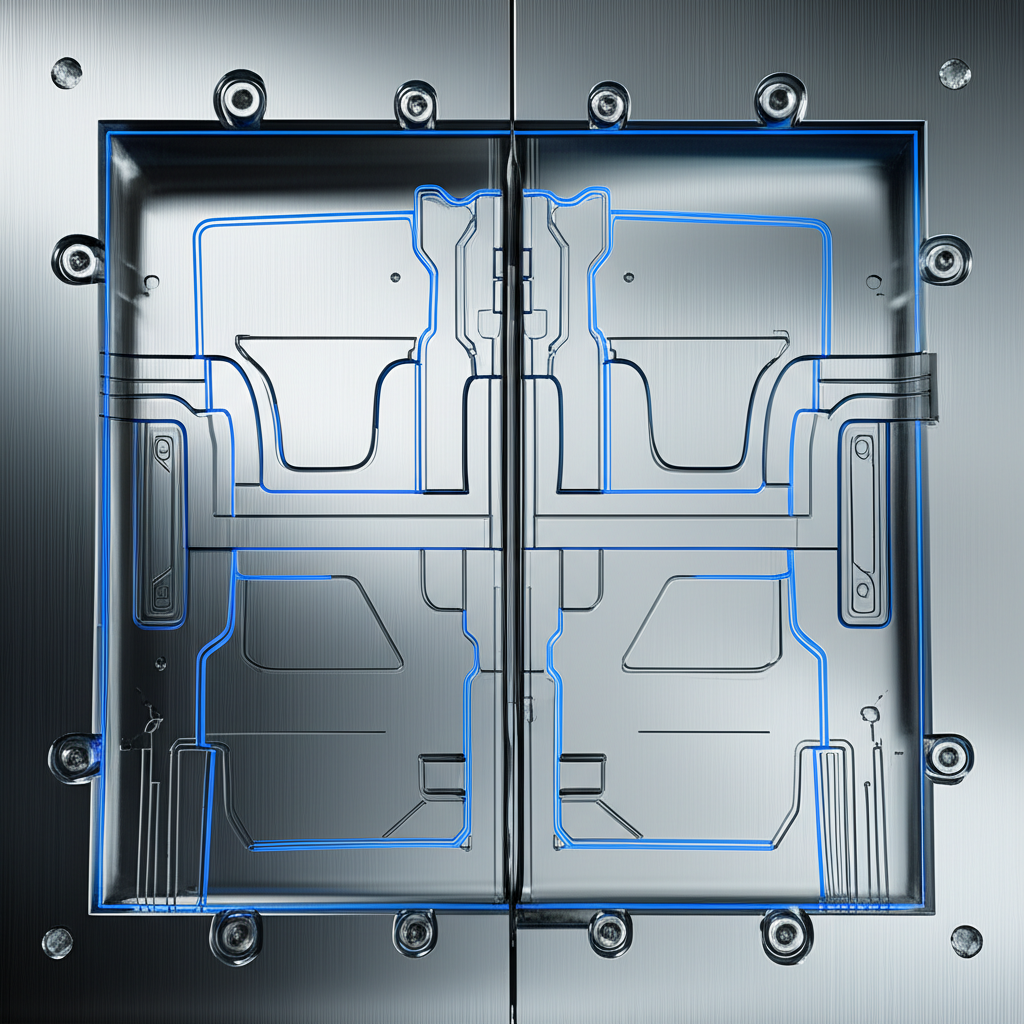

This direct control extends to material selection, machining tolerances, and finishing processes. In-house teams can perform in-depth inspections and evaluations throughout the creation of the mold, ensuring that every component—from the cavity and core to the runners and gates—is fabricated for reliable and consistent production. This meticulous approach significantly reduces the rate of defects and eliminates at-risk production runs, leading to a more dependable manufacturing output and higher customer satisfaction. This level of control is particularly critical in industries with stringent standards, such as automotive. For instance, specialized providers like Shaoyi Metal Technology leverage in-house die manufacturing to deliver IATF16949 certified components, ensuring precision from prototyping to mass production.

Beyond physical quality, in-house manufacturing provides a crucial safeguard for a company's most valuable asset: its intellectual property (IP). Outsourcing production, especially overseas, inherently carries the risk of IP theft or misuse. By keeping proprietary designs, trade secrets, and innovative processes internal, a company can better protect its competitive advantage. As noted by business strategists at NetSuite, maintaining production in-house keeps valuable IP "close to the vest," reducing the chances of sensitive information falling into the wrong hands. This security fosters a culture of innovation, as R&D teams can collaborate freely with manufacturing teams without fear of compromising sensitive data.

Significant Cost Reduction and Time Savings

While the initial capital investment for in-house tooling machinery can seem high, the long-term financial and operational benefits often provide a substantial return. By managing die and mold manufacturing internally, companies can achieve significant cost efficiencies and dramatically accelerate their production timelines.

How In-House Tooling Saves Money

Bringing tooling in-house directly impacts the bottom line by eliminating costs associated with third-party suppliers. This strategy circumvents several layers of expense that would otherwise be incurred. Key financial advantages include:

- Elimination of Supplier Markups: Outsourcing partners build their overhead and profit margins into their pricing. Handling tooling internally cuts out this middleman, leading to direct cost savings.

- Reduced Rework Costs: Poorly fitting or low-quality tools from external vendors can lead to significant rework, production delays, and material waste. An in-house team that works closely with production engineers can build tools correctly the first time.

- Lower Shipping and Logistics Fees: Transporting heavy, delicate molds and dies, especially from overseas, is expensive and carries the risk of damage. In-house tooling removes these logistical hurdles and associated costs.

- Optimized Maintenance: When molds are built and maintained by the same team that uses them, maintenance is more proactive and efficient, reducing long-term repair expenses and costly downtime.

How In-House Tooling Accelerates Timelines

In today's fast-paced markets, speed is a critical competitive advantage. In-house tooling capabilities allow companies to be more agile and responsive. When market trends shift, manufacturers must be ready to get new parts to market quickly, and a tooling process reliant on external communication is often too slow. Key time-saving benefits include:

- Faster Prototyping and Iteration: Design changes and adjustments can be made almost immediately without the lengthy back-and-forth communication required with external toolmakers.

- Shorter Lead Times: By removing reliance on a supplier's queue, transit delays, and potential errors, companies can significantly shorten the time from design finalization to production.

- Streamlined Communication: When engineers, toolmakers, and machinists work in the same facility, collaboration is seamless. This prevents crucial details from being lost in translation and allows for real-time problem-solving.

- Increased Production Uptime: With tools designed and maintained on-site, any necessary repairs or adjustments can be handled swiftly, minimizing production downtime that could otherwise halt operations for days or weeks.

Reduced Supply Chain Risk and Clearer Communication

Relying on external suppliers for critical components like dies and molds introduces significant risks into the supply chain. Outsourcing can lead to a lack of transparency and control, creating vulnerabilities that can disrupt production and impact profitability. A key benefit of an integrated in-house model is the drastic reduction of risks, including the risk of design or tooling errors, the risk of miscommunication, and the risk of delays. By consolidating these processes under a single company, the likelihood of these issues occurring—and costing valuable time and money—is greatly diminished.

Miscommunication is one of the most common and costly pitfalls of outsourcing. When the design team, toolmaker, and injection molder are separate entities, often in different time zones, important details can easily be lost in translation. This can lead to tools that don't meet specifications, resulting in expensive rework and project delays. An in-house model eliminates these communication barriers. Direct, face-to-face collaboration between engineers and toolmakers ensures that everyone is aligned on project requirements, leading to more accurate and effective tool production from the start.

Furthermore, an in-house approach fosters greater accountability. When a problem arises, there is no ambiguity about who is responsible for solving it. The integrated team has full ownership of the entire process, from design to final inspection. This clear line of responsibility enables faster and more effective problem-solving, as the team can work together to diagnose the issue and implement a solution without the finger-pointing or contractual disputes that can plague relationships with third-party suppliers. This streamlined workflow not only saves time but also builds a more resilient and reliable manufacturing operation.

Greater Production Flexibility and Agility

In a market defined by rapidly changing consumer demands and fierce competition, the ability to adapt quickly is paramount. In-house die and mold manufacturing provides the production flexibility and agility needed to stay ahead. Having direct control over tooling allows a company to pivot its manufacturing strategy in response to new opportunities or challenges without being constrained by the rigid schedules and contractual obligations of external vendors. This capability is a powerful competitive differentiator.

This agility is most evident during product development and modification. With an in-house toolroom, design iterations can be implemented rapidly. If a prototype reveals a design flaw or an opportunity for improvement, the tool can be adjusted and tested in a fraction of the time it would take to coordinate with an outside shop. This accelerates the entire product development cycle, enabling a faster time-to-market for new products. It also empowers companies to offer greater customization, as they can create or modify tools for specialized or short-run production without incurring prohibitive costs or long lead times from a third party.

Moreover, in-house tooling allows a manufacturer to control its own production schedule completely. This means the company can scale production up or down to meet fluctuating demand, run tests on new materials, or prioritize urgent orders without negotiating with a supplier. This autonomy removes dependencies on external factors that can cause bottlenecks, such as a vendor's internal workload or shipping delays. Ultimately, this level of control translates into a more responsive and resilient business that can seize market opportunities and deliver for its customers with greater speed and reliability.

Making the Strategic Choice for In-House Tooling

The decision to bring die and mold manufacturing in-house is a significant strategic investment, not just a capital expenditure. While outsourcing can offer lower upfront costs, the long-term advantages of an internal model—superior quality, robust IP protection, reduced costs, and enhanced speed—often create a more compelling business case. By taking control of this critical manufacturing stage, companies can build a more resilient, agile, and competitive operation. This approach transforms tooling from a simple procurement task into a core strategic asset that drives innovation and profitability.

Frequently Asked Questions

1. What are the main disadvantages of in-house mold manufacturing?

The primary disadvantages are the high initial investment in machinery, infrastructure, and skilled personnel. Companies also take on the full responsibility for equipment maintenance, repairs, and downtime, which can be costly. Furthermore, if production volumes are low or sporadic, it can be difficult to achieve a positive return on this significant capital investment.

2. When does it make more sense to outsource die and mold manufacturing?

Outsourcing is often a better choice for companies with sporadic or low-volume production needs, as it avoids a large upfront capital investment. It is also beneficial when a project requires highly specialized tooling or expertise that is not part of the company's core competency. For startups and small businesses with limited capital, outsourcing provides access to high-quality tooling without the financial burden of owning and maintaining the equipment.

3. How does in-house tooling affect product innovation?

In-house tooling can significantly boost innovation. It fosters closer collaboration between design, engineering, and manufacturing teams, allowing for rapid prototyping and faster product development cycles. This synergy makes it easier to experiment with new designs, materials, and processes, ultimately leading to more innovative products and a stronger competitive edge in the marketplace.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —