Why Aluminum Extrusion Dominates Car Chassis Design

TL;DR

Aluminum extrusion is a vital manufacturing process for creating strong yet lightweight car chassis components. This technology is central to the automotive trend of lightweighting, enabling improved fuel efficiency, extended electric vehicle (EV) range, and enhanced vehicle performance and safety through sophisticated, high-strength designs. Key applications include subframes, crash management systems, and battery enclosures.

The Strategic Imperative of Lightweighting in Automotive Design

In the automotive industry, a powerful trend known as "lightweighting" has become a primary engineering goal. This strategy involves systematically reducing a vehicle's overall weight to achieve significant performance and efficiency gains. The push for lighter vehicles is driven by several critical factors that are reshaping modern car design. Lighter cars require less energy to accelerate and maintain speed, directly translating to better fuel economy and lower emissions for internal combustion engine vehicles.

The transition to electric vehicles has further intensified the focus on weight reduction. For EVs, a lighter chassis and body structure directly correlates to a longer battery range—a key factor for consumer adoption. By shedding kilograms, manufacturers can either extend the distance an EV can travel on a single charge or use a smaller, less expensive battery pack to achieve the same range. As noted by industry experts at Gabrian, aluminum has become a material of choice in this context, often replacing heavier steel components. This shift is not just about efficiency; it also dramatically improves a vehicle's dynamics, including handling, braking, and acceleration, leading to a more responsive and enjoyable driving experience.

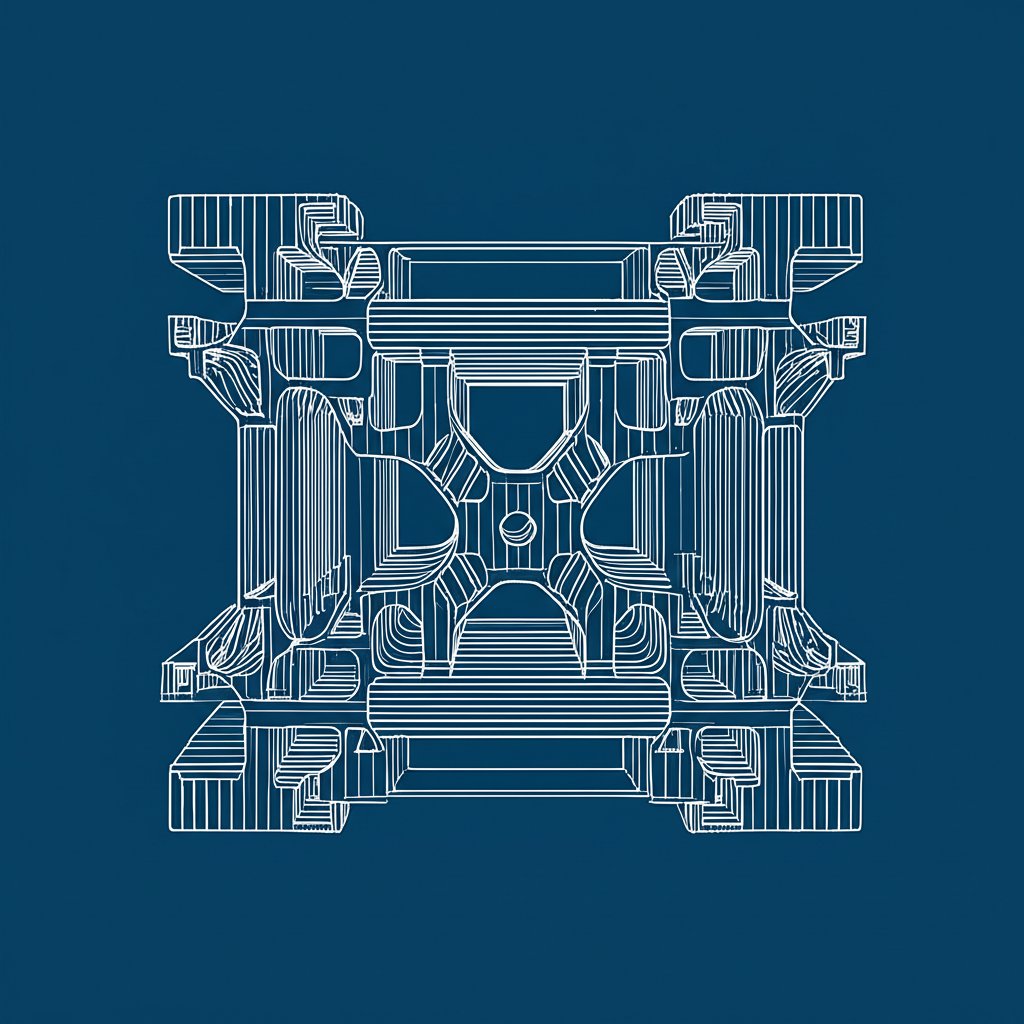

Aluminum extrusion has emerged as a cornerstone technology enabling this shift. The process allows for the creation of complex, hollow, and intricately shaped profiles that would be difficult or impossible to produce with traditional stamping or casting methods. This design flexibility allows engineers to place material precisely where it is needed for strength and remove it where it is not, optimizing the strength-to-weight ratio. As a result, aluminum extrusions are fundamental to building the next generation of efficient, high-performance, and sustainable vehicles.

Key Automotive Components Made with Aluminum Extrusions

The versatility of the aluminum extrusion process allows it to be used in a wide and growing array of automotive applications, from structural chassis parts to safety systems. The ability to create custom profiles with high strength and low weight makes it an ideal solution for many critical components. According to a comprehensive overview by Fonnov Aluminium, extrusions are found in nearly every system of a modern vehicle.

Key applications can be grouped into several categories:

- Chassis and Structural Components: This is where extrusions deliver some of their most significant benefits. Parts like subframes and engine cradles, which support the powertrain and suspension, rely on the torsional stiffness of hollow extruded profiles for stability and ride quality. Other critical applications include frame rails, strut tower braces, and cross members that form the vehicle's core structure.

- Crash Management Systems: Safety is paramount, and aluminum extrusions are engineered for superior performance in collisions. Front and rear bumper beams, anti-intrusion door beams, and other crash-absorbing structures are designed to deform in a controlled manner, dissipating impact energy to protect occupants. Constellium highlights its role as a key supplier of these components, which are engineered for superior safety and structural integrity.

- Electric Vehicle (EV) Specific Parts: The rise of EVs has opened new applications for aluminum extrusions. Battery enclosures are a prime example, where extrusions provide a strong, intrusion-resistant frame to protect the sensitive battery modules. The material's excellent thermal conductivity also helps with battery heat management.

- Body and Exterior Components: Extrusions are also used for parts like roof rails, sunroof frames, and exterior trim. Their corrosion resistance and ability to hold a high-quality surface finish make them suitable for both functional and aesthetic applications.

The use of 6xxx and 7xxx series aluminum alloys is common in these applications, as they provide the necessary combination of strength, formability, and durability required to meet the rigorous demands of the automotive industry.

Core Advantages of Aluminum Extrusions for Vehicle Chassis

Engineers and designers increasingly specify aluminum extrusions for car chassis components due to a compelling set of technical and commercial advantages over traditional materials like stamped steel. These benefits directly address the core industry goals of enhancing performance, safety, and efficiency.

The primary advantage is a superior strength-to-weight ratio. Aluminum is a low-density material, allowing for the design of components that are significantly lighter than their steel counterparts without compromising structural integrity. The Aluminum Extruders Council (AEC) notes that this can lead to weight reductions of up to 35% in components like subframes, which is crucial for meeting fuel efficiency and EV range targets. This lightweighting also contributes to improved vehicle dynamics, such as more responsive handling and shorter braking distances.

Another key benefit is unmatched design freedom. The extrusion process allows engineers to create complex, multi-void hollow profiles in a single piece. This enables the integration of multiple functions—such as mounting points, cooling channels, or wiring conduits—into one component. This part consolidation reduces complexity, simplifies assembly, and lowers the overall piece count, leading to faster and more efficient manufacturing. For custom projects, specialized partners can accelerate development. For instance, Shaoyi Metal Technology offers comprehensive services from rapid prototyping to full-scale production under the IATF 16949 quality system, helping to deliver highly customized parts tailored to precise specifications.

Finally, aluminum extrusions offer excellent durability and cost-effectiveness. Aluminum naturally forms a protective oxide layer, providing inherent corrosion resistance that extends the life of the vehicle, especially in harsh environments. From a manufacturing perspective, the extrusion process produces near-net-shape parts, which, as explained by Thunderbird Metals, minimizes the need for costly and time-consuming secondary machining operations and reduces raw material waste.

| Feature | Aluminum Extrusion | Stamped Steel |

|---|---|---|

| Weight | High strength-to-weight ratio; significant weight savings | Heavier; contributes to higher overall vehicle mass |

| Design Flexibility | High; allows complex, multi-functional, hollow profiles | Limited; requires multiple parts and welding for complex shapes |

| Tooling Cost | Lower; dies are relatively inexpensive and quick to produce | Very high; stamping dies are complex and costly |

| Corrosion Resistance | Excellent; naturally forms a protective oxide layer | Poor; requires coatings like galvanization to prevent rust |

| Assembly | Simpler; part integration reduces piece count and welding | More complex; often requires assembly of multiple stamped parts |

Frequently Asked Questions

1. Can you make a car frame out of aluminum?

Yes, absolutely. Many high-performance, luxury, and electric vehicles utilize aluminum for their primary frame structures, often referred to as a space frame or monocoque chassis. Using a combination of aluminum extrusions, castings, and sheets allows automakers to build a frame that is both incredibly strong and lightweight, providing significant benefits in performance, handling, and efficiency.

2. What are the disadvantages of aluminum for car bodies?

While aluminum offers many benefits, it has a few disadvantages compared to steel. The primary drawback is often the higher cost of repair. Aluminum requires specialized tools, equipment, and technician training to repair correctly after a collision, which can make bodywork more expensive. Additionally, the initial material and manufacturing costs can be higher than for conventional steel, making it more common in premium vehicles.

3. Why aren't all car frames made out of aluminum?

The main barrier to the universal adoption of aluminum for all car frames is cost. Steel remains a more economical material for mass-market vehicles, and the global automotive industry has a vast, long-established supply chain and manufacturing infrastructure built around it. While the performance benefits of aluminum are clear, manufacturers must balance those advantages against the cost targets for a particular vehicle segment. As manufacturing technologies evolve and efficiency improves, the use of aluminum continues to expand into more mainstream models.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —